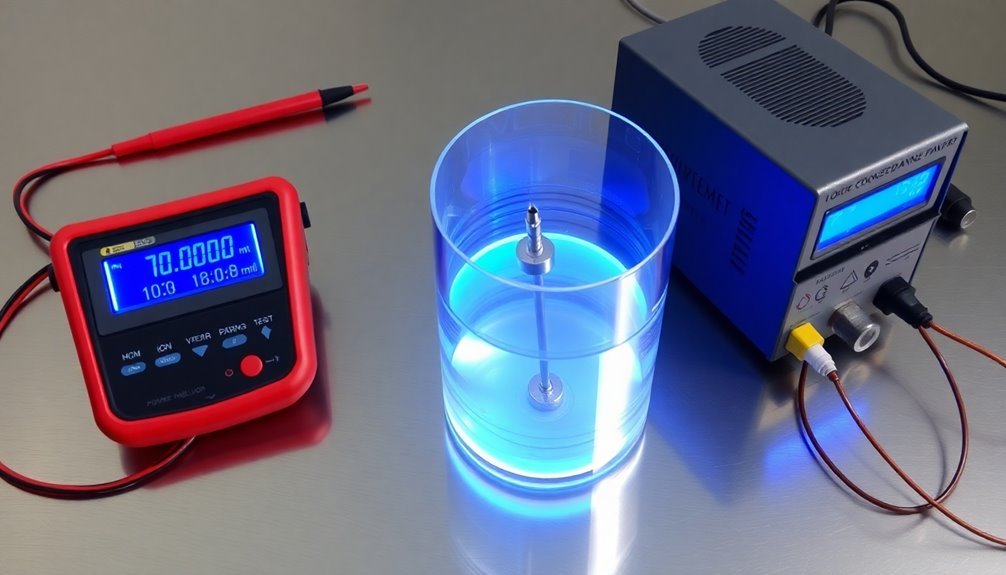

An ionizer test kit measures several key aspects of your ionization equipment's performance. You'll be able to check static voltage levels up to ±19.99 kV, analyze offset voltage to confirm balanced positive and negative ion output, and evaluate discharge times as voltage drops from ±1000V to lower target levels. The kit typically includes a charge plate monitor that detects deviations from electrical ground using a 20 picoFarad capacitance plate. Testing confirms your ionizers meet ANSI/ESD S20.20 requirements by maintaining offset voltage below ±35 volts. Understanding these measurements is essential for maintaining effective static control in sensitive environments.

Understanding Static Voltage Measurements

You can use different types of measurement tools depending on your needs.

Hand-held sensors work well for spot-checking items like PCBs, while inline sensors are better suited for continuous monitoring in production environments.

For precise measurements without charge loss, you might need to use the Faraday cage method, which employs a grounded outer electrode to measure the potential difference accurately.

Remember to maintain proper grounding of both yourself and the equipment to guarantee measurement accuracy.

LED indicators help verify that ionizing equipment is functioning correctly during testing procedures.

Ionization Balance Testing

Ionization balance testing is essential for measuring how well your ionizer maintains equilibrium between positive and negative ions.

When testing balance, your charge plate monitor measures voltage offset from zero, indicating whether the ionizer is producing equal amounts of both ion polarities.

Your measurements help guarantee the ionizer won't create unwanted static charges on sensitive components, as an imbalanced system can lead to voltage buildup rather than neutralization.

According to industry standards, the offset voltage limit must remain below ±35 volts to meet ANSI/ESD S20.20 requirements.

Static Charge Equilibrium

Static charge equilibrium testing zeroes in on how well an ionizer maintains the balance between positive and negative ions in the air. You'll need a Charged Plate Monitor (CPM) to measure how far the ionization deviates from electrical ground, which is expressed in volts.

The CPM uses a specialized 20 picoFarad capacitance plate to detect these variations. For air-assist ionizers, measurements must be taken at key test distances of 300mm, 600mm, and 900mm from the surface.

When you're testing an ionizer's balance, you'll place the CPM in the ionized air stream at a specific distance from the unit. The test involves charging the plate to a predetermined voltage and measuring how quickly the ionizer neutralizes that charge.

The ANSI/ESD STM3.1 standard defines the proper test conditions and procedures you'll need to follow.

To get accurate measurements, you'll want to use standardized equipment like Desco's Air Ionization Test Kit, which includes a digital static field meter and conductive plate. The CPM's 15 cm by 15 cm isolated conductive plate helps you measure both offset voltage and discharge time.

You can also use smaller monitoring plates to identify balance differences under specific ionizer points or in areas with non-laminar airflow.

Voltage Offset Measurement

Building on the equipment setup knowledge, voltage offset measurement provides specific data about an ionizer's balance performance.

When you're using an ionizer test kit with a Charge Plate Monitor (CPM), you'll measure how far the ionization deviates from zero volts, which indicates the ionizer's balance state. The standard CPM setup includes a 6" x 6" plate with 20 picoFarad capacitance that follows the V = Q/C relationship. Modern components requiring voltages as low as 1V make precise balance measurements critical.

You'll need to verify that your measurements comply with ANSI/ESD STM3.1 standards, which specify the proper testing methodology in controlled environments.

When you place the CPM in the ionized space, it'll display the offset voltage, letting you verify if the ionizer operates within acceptable limits, typically ±35 volts. If you detect values outside this range, your ionizer isn't maintaining proper balance.

Regular monitoring of voltage offset is essential because an unbalanced ionizer can potentially damage sensitive electronic components.

You should document these measurements during compliance verification checks. If you find balance issues, you'll need to adjust the ionizer or consult the manufacturer's guidelines for recalibration, following ESD Association's TR53 recommendations for troubleshooting.

Discharge Time Analysis

To accurately assess an ionizer's performance, measuring its discharge time serves as a vital benchmark in evaluating static control effectiveness. You'll need to measure how quickly the ionizer can neutralize a ±1000V charge down to lower voltage levels, typically ±100V, ±50V, or ±10V.

The measurement process requires you to charge a conductive plate to approximately ±1.10 kV using a charger, then time how long it takes for the voltage to decrease to ±0.10 kV. You'll use a static field meter to monitor the voltage levels and a stopwatch or static decay timer to track the discharge duration. Advanced monitoring systems can detect anomaly patterns in discharge times that may indicate equipment malfunction.

| Equipment | Purpose | Measurement Range |

|---|---|---|

| Static Field Meter | Voltage Monitoring | ±0-2000V |

| Charger | Initial Charge | ±1000V |

| Conductive Plate | Test Surface | N/A |

| Stopwatch/Timer | Time Measurement | 0.1-second increments |

| Static Decay Timer | Precision Timing | 0.1-second increments |

Regular discharge time measurements are essential because they'll help you identify when your ionizer isn't performing at its best. An ionizer operating out of balance can potentially damage sensitive electronic components, making these measurements vital for maintaining effective static control in your workspace.

Calibration Standards

You'll need to guarantee your ionizer calibration meets NIST traceable standards to maintain accurate measurements and proper ESD control.

Your verification procedures must follow ANSI/ESD S3.1-2006 test methods while keeping the offset voltage within ±35 volts as specified by ANSI/ESD S20.20-2014.

The test kit's ±5% measurement accuracy ensures precise calibration results. Regular calibration checks using certified test kits will help you comply with JESDD625-A recommendations for semi-annual testing and prevent your ionizers from operating out of balance.

NIST Traceability Requirements

Accurate measurements rely on NIST traceable calibration, which creates a documented chain linking your test results to recognized national standards. When you're using an ionizer test kit, you'll want to confirm its measurements are NIST traceable to guarantee reliability and accuracy in your testing procedures.

NIST traceability means your test kit's calibration can be tracked through an unbroken series of comparisons back to national or international measurement standards. You'll find this especially important when you're conducting quality control or compliance testing. Regular interval calibrations are typically performed every 1 to 12 months depending on usage requirements.

The calibration process involves comparing your instrument against reference standards that have been calibrated to NIST specifications.

You'll need to verify that your test kit's calibration certificate includes proper documentation of this traceability chain. The certificate should detail the calibration points used, measurement uncertainties, and references to the specific NIST standards.

Remember that calibration standards require regular recertification to maintain their traceability status. By following these NIST traceability requirements, you're confirming that your ionizer test kit's measurements are consistently reliable and can withstand scrutiny in quality audits or regulatory inspections.

Verification Procedure Standards

Following established verification procedure standards guarantees your ionizer testing meets industry requirements. You'll need to align your verification procedures with key standards like ANSI/ESD STM3.1 and ANSI/ESD SP3.3-2016, which outline essential testing protocols.

These standards dictate how you'll measure both offset voltage and discharge times during verification.

You must conduct tests semiannually according to JESDD625-A guidelines, while ANSI/ESD S20.20 requires you to maintain offset voltage within ±35 volts.

You'll use a Charged Plate Monitor (CPM) for precise measurements, and you should adjust your ionizer's potentiometers to achieve the specified voltage limits. When performing verification, you'll need to position your test equipment correctly under the ionizer and make necessary adjustments to meet these requirements.

ESD TR53 adds that you should clean and recalibrate ionizers when measurements fall outside acceptable ranges. You'll verify calibration through repeated testing and confirm alarm systems function properly.

For pulsed ionizers, you must account for average voltage measurements over varying pulse rates to maintain accuracy in your verification process.

ESD Control Compliance

Building upon verification procedures, proper calibration standards form the backbone of ESD control compliance. You'll need to guarantee your testing equipment and procedures align with key standards like ANSI/ESD S20.20 and ISO/IEC 17025. These standards establish the framework for reliable ionizer performance measurements and calibration practices. Since ionizers work by generating balanced ions to neutralize static charges, accurate calibration is essential for optimal performance.

| Standard | Purpose | Key Requirements |

|---|---|---|

| ANSI/ESD S20.20 | ESD Control Programs | Ionizer use and calibration guidelines |

| ANSI/NCSL Z540.1 | Calibration Labs | General testing equipment requirements |

| ISO/IEC 17025 | Lab Competence | Testing and calibration procedures |

| NASA-STD-8739.12 | Aerospace Metrology | Specific aerospace calibration needs |

| IEC 61340-5-1 | Component Protection | Electrostatic protection protocols |

When you're working with ionizer test kits, you'll need to verify they're calibrated according to these standards. Your test equipment must include properly calibrated charged plate analyzers (like SCS 770004 or 770005) and static sensors that meet the specified requirements. You'll also want to guarantee your calibration laboratory complies with either ANSI/NCSL Z540.1 or ISO/IEC 17025 standards for accurate measurements and reliable results.

Power and Operating Requirements

The power requirements for ionizer test kits vary substantially across different models and applications. You'll find that most systems operate on either 24VDC power supplies or 100-240VAC input with 24VDC output adapters.

The Air Ionizer Test Kit specifically runs on a 9-volt alkaline battery, which provides over 50 hours of operation at 21°C.

Current consumption ranges from 330mA to 700mA depending on the operating mode, with automatic and manual run options drawing different amounts. You'll need to verify your power adapter can handle 1A output current, while benchtop units may require 1.0-1.5A. Power consumption typically averages 9-10 watts for most ionization units.

For ideal operation, you must maintain specific environmental conditions. Keep your ionizer in an area with temperatures between 0 to 40°C and relative humidity between 35-65% without condensation.

Your unit can operate at altitudes up to 2000 meters. You'll need proper grounding for both the test kit and charger operation.

Most units come with CE, UL, and CSA certifications, while benchtop models specifically carry cULus and CE certifications for compliance and safety.

Key Performance Features

Key performance features of modern ionizer test kits center around three core measurement capabilities: surface voltage detection up to ±19.99 kV, offset voltage analysis, and charge decay assessment.

You'll find these kits can measure objects at a 1-inch distance using a static sensor, while the included aluminum conductive plate helps evaluate ionization equipment performance.

When you're testing ionizers, you'll benefit from the kit's impressive accuracy of ±5% of reading, ±2 counts, and 10 mV. The 3 ½ digit LED display updates three times per second, giving you near real-time measurements.

You can measure discharge times by applying a ±1000V charge to the conductive plate, which measures 2.95" x 1.18".

You'll appreciate practical features like the rotary zero knob and hold button that make readings easier to capture. The kit's grounded enclosure, when held by a grounded operator, guarantees accurate measurements.

For compliance purposes, these kits are NIST-traceable and meet ANSI/ESD SP3.3 standards for ionizer verification. The durable polypropylene enclosure with polyurethane foam protects your investment while maintaining measurement integrity in both normal and ionized environments.

Frequently Asked Questions

How Often Should an Ionizer Test Kit Be Recalibrated?

You'll need to recalibrate your ionizer test kit every six months according to JESDD625-A standards. If your ionizer requires adjustments, you might need to calibrate more frequently to maintain accuracy.

Can the Test Kit Measure Static Charges on Non-Conductive Materials?

Yes, you can measure static charges on non-conductive materials with the test kit. It'll detect surface charges up to ±19.99 kV at 1 inch distance, helping you verify ionizer effectiveness in neutralizing static buildup.

What Is the Typical Lifespan of an Ionizer Test Kit?

You'll typically need to replace your ionizer test kit after about one year from manufacture, though specific lifespans aren't well documented. It's best to check your manufacturer's guidelines for exact replacement schedules.

Does Humidity Affect the Accuracy of Ionizer Test Kit Measurements?

Yes, humidity considerably affects your ionizer test kit's accuracy. You'll notice that high humidity levels can alter ion mobility and distribution, leading to less reliable readings and longer discharge times during measurements.

Can Multiple Operators Use the Same Test Kit Calibration Settings?

You'll need unique calibration settings for each operator since handling techniques and environmental factors vary. It's best to recalibrate when switching operators to guarantee accurate measurements and consistent results.

In Summary

You'll find that ionizer test kits measure three critical aspects of your ionizer's performance: static voltage levels, ion balance (the ratio between positive and negative ions), and discharge time rates. By testing these parameters, you can verify your equipment meets industry standards and maintains proper ionization levels. Regular testing helps you guarantee workplace safety and protect sensitive electronic components from electrostatic discharge damage.

Leave a Reply