When selecting a surface resistance meter, you'll need to think about your specific testing requirements. For general maintenance and basic ESD testing, a travel meter ranging from 10^3 to 10^12 ohms will suffice. If you're conducting lab-grade qualification testing, opt for a meter with NIST certification and advanced features like automatic voltage switching. Verify that your choice complies with ANSI/ESD standards and includes appropriate electrodes for your testing needs. A quality meter should offer ±10% accuracy and operate reliably in your environment. Your testing environment and frequency will guide you toward the most cost-effective solution for your operations.

Understanding Surface Resistance Testing

Measuring surface resistance plays a vital role in protecting sensitive electronics and ensuring workplace safety. You'll need to understand the key differences between surface resistivity (measured in Ohm/square) and surface resistance (measured in Ohms) to make informed decisions about your testing equipment.

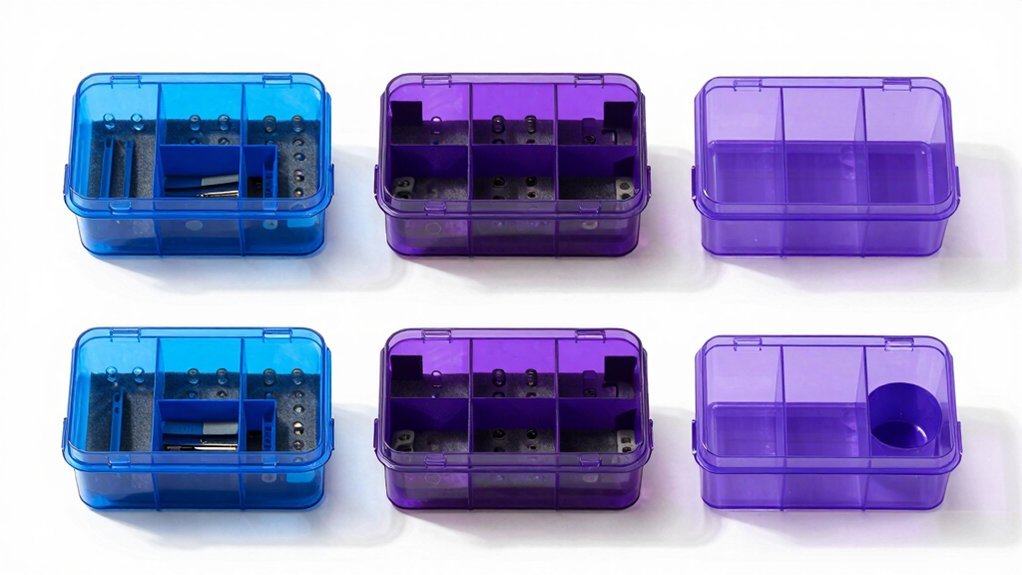

When you're testing surfaces, you'll encounter three primary measurement types: point-to-point (RTT), resistance-to-ground (RTG), and volume resistance. RTT measures resistance between two points on a surface, while RTG determines the resistance from a point to ground. Volume resistance measures through the material itself, which is particularly important for containers and non-grounded items. Hand-held meters are commonly used by field technicians for quick testing and verification.

You'll need to follow specific standards, particularly ANSI/ESD S4.1, which outlines procedures for RTT and RTG testing. These measurements help you classify materials as conductive, dissipative, or insulative.

Using a resistivity meter with a concentric ring probe, you can directly measure surface resistivity. To convert resistance to resistivity, you'll multiply the resistance by a geometry coefficient that's determined by your electrode configuration.

This understanding is essential for accurate testing and compliance verification in static-sensitive environments.

Essential Meter Features

For reliable surface resistance testing, you'll need to focus on three essential meter features: accuracy, display functionality, and power specifications.

When evaluating accuracy, you'll find most meters offer readings within half to one decade, with the 740 SRM providing ±10% accuracy and ±5% repeatability. The meter utilizes parallel bar sensing for enhanced measurement precision.

Display options differ substantially between models. The 740 SRM shows direct readings in Ohms and Ohms per Square, while the Surface Resistivity Meter and 990SRM use LED indicators for each decade. If you prefer visual clarity, LED displays can make it easier to quickly interpret measurements across multiple decades.

All three meters operate on standard 9V batteries, making power management straightforward. The 990SRM stands out with its impressive 40-hour continuous use battery life. If you're concerned about battery status monitoring, the Surface Resistivity Meter includes a low battery warning at 7.5V.

Consider your environmental conditions too. The 740 SRM specifically guarantees performance between 5-50°C and up to 90% relative humidity.

For compliance requirements, note that the 740 SRM carries CE certification, which may be vital for your testing environment.

Measurement Range Requirements

Reliable surface resistance testing consistently requires meters that cover a broad measurement range of 10^3 to 10^12 ohms. This range guarantees you'll be able to measure conductive, dissipative, and insulative materials accurately. Modern digital surface meters offer superior precision compared to analog alternatives.

While entry-level meters might only display basic readings like "Less Than 10^3" or "Greater Than 10^12," you'll find that advanced meters offer more detailed measurements within these ranges.

For the most precise ESD testing, you'll want to consider meters with expanded capabilities, such as those measuring from 1 ohm to 1.2 x 10^12 ohms. These broader ranges provide you with more accurate readings and better compliance with standards like ANSI/ESD S4.1. The PAS-853B exemplifies this extended capability, measuring from 0.01 Ω to 9.99 x 10^12 Ω.

When selecting your meter, you'll need to verify it matches your specific testing requirements. If you're conducting regular ESD audits or verification testing, choose a meter that complies with ESD TR53 and ANSI/ESD S20.20 standards.

Remember that measurement speed matters too – look for meters with built-in electrification periods that enhance testing efficiency while maintaining accuracy across the full measurement range.

Environmental Testing Considerations

Several critical environmental factors directly influence the accuracy of surface resistance measurements. When you're selecting a surface resistance meter, you'll need to take into account how temperature, humidity, surface cleanliness, and material characteristics affect your testing results.

The best meters operate within specific temperature ranges (50-95°F) and include features to monitor both temperature and relative humidity levels during testing.

Don't let poor environmental control compromise your test integrity – your measurements are only as reliable as your testing conditions.

Your facility's temperature and humidity fluctuations can impact readings substantially, so you'll want a meter that helps track these variables. The four-point probe method is recommended for avoiding contact resistance issues that can distort measurements.

Keep in mind that surface contamination can skew your results dramatically – clean surfaces are essential for accurate measurements.

Remember that different materials respond uniquely to environmental changes, making proper testing conditions vital for your specific application.

You'll want to make sure your meter can handle the environmental conditions in your facility while providing accurate measurements within the specified ranges. Think about choosing a meter with built-in temperature and humidity sensors to monitor these critical parameters during testing. This feature helps maintain compliance with standards like ANSI/ESD S4.1 and ensures consistent, reliable results.

Electrode Types and Applications

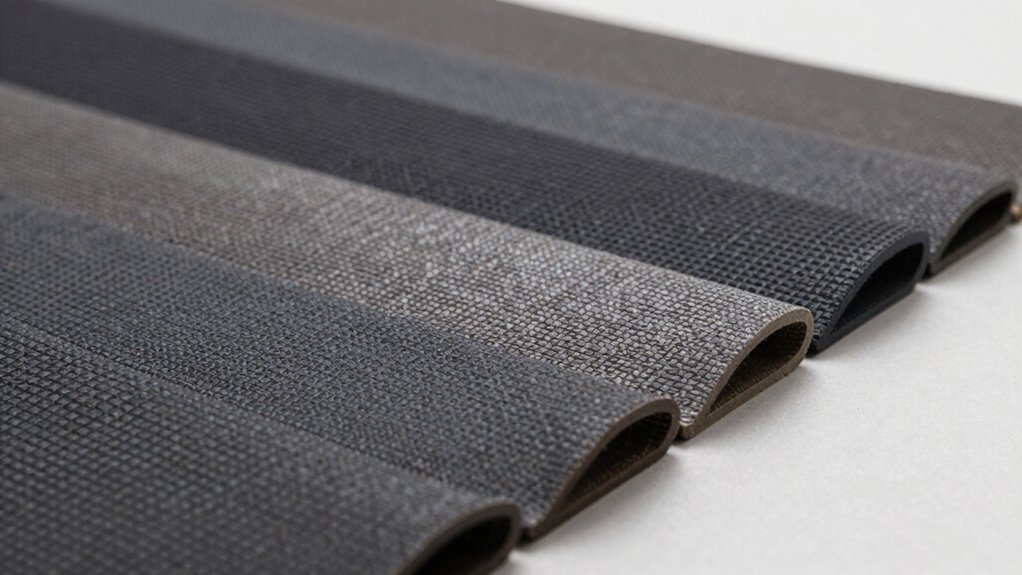

Understanding electrode types is essential when selecting a surface resistance meter, as each type serves distinct measurement purposes.

For compliance verification, you'll need external 5-pound electrodes. These versatile tools work for both resistance point-to-point and resistance-to-ground measurements, and you can position them precisely to guarantee accurate readings.

When measuring surface resistivity rather than resistance, you'll want to use concentric ring probes, which apply constant voltage and incorporate geometry coefficients for direct calculations.

If you're frequently on the move, consider handheld and travel electrodes. They're designed with portability in mind and often include mechanisms to simulate the required 5-pound pressure. These electrodes are especially useful for person/footwear/flooring system measurements when testing ESD protection in various facilities.

You'll find they're equipped with automatic test voltage selectors and built-in parallel electrodes for immediate surface measurements.

When choosing your electrode type, consider your specific measurement needs, compliance requirements, and whether you'll need to conduct tests in various locations or environments.

Parallel electrodes built into some meters offer quick measurements without external components, though they may not meet the standard 5-pound pressure requirement.

Lab Grade Vs Travel Meters

When choosing between lab grade and travel meters for surface resistance testing, you'll need to weigh accuracy against portability.

Modern meters come with automatic auto-ranging capabilities for both 10V and 100V test voltages. Lab grade meters offer superior accuracy and advanced features like automatic voltage switching, making them ideal for qualification testing and compliance verification. You'll find they meet specific industry standards like ANSI/ESD S4.1 and include extensive accessories for diverse testing needs.

Travel meters, while less feature-rich, provide a practical solution for quick verification testing. They're lightweight, easy to transport, and cost-effective for basic testing requirements. Though they may have limited test ranges and fewer accessories, they're perfect for routine checks and maintenance testing in less controlled environments.

Imagine the confidence you'll feel knowing your lab grade meter meets all compliance requirements for critical testing.

Think about the convenience of carrying a lightweight travel meter for quick on-site verifications.

Consider the peace of mind that comes with having accurate, reliable measurements for your ESD control program.

Picture the cost savings you'll achieve by matching the meter type to your specific testing needs.

Choose lab grade meters when accuracy and compliance are paramount, and opt for travel meters when portability and basic verification testing are your priorities.

Cost Investment Analysis

Making smart surface resistance meter investments requires careful analysis of both upfront and long-term costs. You'll find initial costs ranging from $300 for basic handheld units to over $1,900 for extensive kits, with brands like Desco, SCS, and Static Solutions offering various options.

If you're considering NIST certification, meters like the Desco 19784 and 19290 come with calibration certificates that add value to your investment. Many meters offer dual power options with both battery and AC line power capability.

Your ongoing costs will include regular calibration services, replacement parts, and potential battery expenses. You'll need to factor in periodic recertification and possible upgrades as standards evolve. However, investing in quality meters can reduce your long-term expenses through improved efficiency and reduced error rates.

When analyzing return on investment, consider how these meters protect your electronics and equipment from costly ESD damage. High-quality meters often provide better longevity and scalability, meeting future standards without requiring replacement.

You'll also benefit from streamlined testing processes that reduce labor costs. If you're purchasing in bulk, look for volume pricing discounts to optimize your investment. Remember that proper training might be necessary but will ultimately contribute to more accurate measurements and better operational efficiency.

Compliance and Certification Standards

Through extensive ESD standards, surface resistance meters must comply with multiple ANSI/ESD specifications for different workplace materials. You'll need to verify that your meter meets ANSI/ESD S4.1 for worksurfaces, S7.1 for floor materials, STM2.1 for garments, and STM12.1 for seating measurements. For thorough floor testing that includes human interaction, your meter should comply with ANSI/ESD STM97.1.

Your meter's certification requirements are equally vital. You must verify that it's calibrated to NIST traceable standards and comes with valid calibration certificates. The analog display should show measurements ranging from 1 x 10^3 to 1 x 10^13 ohms.

The measurement techniques require dry electrodes, five-pound electrode weights, and concentric ring probes for accurate surface resistivity readings. Your meter should feature automatic test range voltage selection for compliance verification.

Don't risk costly production failures by choosing an uncertified meter. Protect your reputation with fully compliant measurement tools. Save time and resources by getting it right the first time. Secure your facility's ESD safety with confidence.

To maintain compliance, you'll need to establish a verification plan that outlines technical requirements, measurement limits, and verification frequencies. Regular monitoring and checks verify that your ESD control program meets industry standards consistently.

Frequently Asked Questions

How Often Should a Surface Resistance Meter Be Calibrated?

You'll need to calibrate your surface resistance meter annually, but consider more frequent calibrations if you're handling critical ESD-sensitive items or working in environments with high usage and varying conditions.

Can Surface Resistance Meters Be Used Underwater or in Wet Conditions?

You shouldn't use surface resistance meters underwater or in wet conditions. They're designed for dry environments, and using them in wet conditions can damage the device and pose serious electrical safety hazards.

What Happens if You Test Materials With Incorrect Voltage Settings?

You'll get inaccurate readings if you use wrong voltage settings. Testing conductive materials at 100V instead of 10V can damage them, while testing dissipative materials at 10V instead of 100V yields unreliable results.

Do Wireless Connectivity Options Exist for Transferring Measurement Data to Computers?

You'll find that most surface resistance meters don't offer wireless connectivity. They typically use wired connections or manual data entry. However, some newer models are beginning to integrate basic wireless capabilities for data transfer.

How Long Do Electrode Probes Typically Last Before Needing Replacement?

You'll typically need to replace electrode probes within 1-2 years, depending on usage conditions. High temperatures, frequent CIP cycles, and improper storage can reduce lifespan, while proper maintenance helps maximize durability.

In Summary

When you're selecting a surface resistance meter, you'll want to match your specific needs with the right features and measurement capabilities. Consider your testing environment, required accuracy level, and budget constraints. Don't forget to verify that your chosen meter meets relevant industry standards and certifications. The right meter will balance precision, portability, and value while delivering reliable measurements for your application.

Leave a Reply