Static testing kits contain essential tools you'll need to measure and control electrostatic discharge (ESD) in sensitive work environments. Your basic kit should include a ground resistance tester with color-coded leads, auxiliary ground electrodes, and specialized cables with clamps. You'll also need measurement tools like ESD wrist strap monitors, surface resistivity meters, field meters, and charge plate monitors. Don't forget safety equipment featuring alarm systems and clear visual indicators. For maximum effectiveness, you'll want calibration tools and proper storage solutions. There's much more to discover about creating a thorough static testing setup.

Core Testing Kit Components

Static testing kits pack in several essential components that make up their core functionality. You'll find a ground resistance tester that offers both 2P and 3P measurement modes, allowing you to conduct thorough ground testing procedures. The kit's durable one-button operation makes testing straightforward and reliable even in challenging conditions.

The kit includes color-coded leads with specific lengths – 150-foot red and blue leads, plus a 30-foot green lead for proper testing configurations.

The core setup features T-shaped auxiliary ground electrodes measuring 14.5 inches, which you'll use alongside threaded copper-clad ground rods that extend 3 feet in length. Ground rod couplers enable you to connect these components effectively.

For proper bonding and grounding connections, you'll have access to specialized cables equipped with REB clamps and Mueller clips.

Your testing capabilities are enhanced by the tester's automatic frequency selection feature, which improves measurement accuracy. The equipment detects hazardous voltage up to 700 VAC/DC, while maintaining intrinsic safety ratings in accordance with IEC 61326-1 and IEC 61010-2-030 standards for 600V CAT IV operations.

The IP65 rating safeguards your core components against dust and water exposure during field testing.

Measurement and Monitoring Tools

Precision monitoring tools form the backbone of any thorough static testing kit. You'll need an ESD wrist strap monitor to verify proper grounding of personnel and work surfaces, along with constant monitors that provide real-time feedback on your ESD protection measures.

Surface resistivity meters are essential for testing ESD packaging and flooring materials, while field meters help you detect static charges in your work area. Daily testing of wrist straps and footwear with combo testers ensures compliance with safety protocols.

You'll want to include specific measurement tools like megohmeters for accurate surface resistance readings and charge plate monitors to evaluate your ionizers' effectiveness. Don't forget data loggers – they're vital for maintaining digital records of your test results for quality assurance purposes.

For extensive testing capabilities, you should also incorporate specialized tools like garment and glove testers to verify the effectiveness of your protective gear. Powder resistance testers and decay timers will help you assess specific materials and static discharge rates.

Remember to maintain all your equipment's accuracy through annual calibration services, preferably NIST certified. A complete measurement toolkit allows you to monitor, verify, and document your ESD control program's effectiveness with confidence.

Safety Features and Protection

Building upon your measurement toolkit, implementing robust safety features becomes a top priority for static testing operations.

You'll need a thorough alarm system that includes amber warning lights to signal active test units and audio alarms for evacuation procedures. Make certain you've installed clear visual indicators to monitor remotely operated valve status and posted warning signs specifying required safety equipment. Maintaining proper grammatical structure in safety documentation helps ensure clear communication of critical procedures.

Your testing area must incorporate multiple layers of physical protection. Install holddown fixtures and thrust stands to secure test units, and set up protective barriers to restrict unauthorized access.

You'll need extension handles that allow operation through these barriers, minimizing direct contact with test units. Remote control systems are essential for maintaining safe distances during operations.

For environmental safety, you'll want controls that prevent auto-ignition during temperature conditioning. Install monitoring systems for rainfall, leak, altitude, and vibration tests.

Your equipment must include properly isolated transducers and signal leads to prevent accidental ignition. When conducting impact-related tests like drop and shock testing, make certain you've implemented safeguards against repetitive impacts.

Monitor temperature limits carefully during road tests, as exceeding safe ranges requires reclassification as hazardous operations.

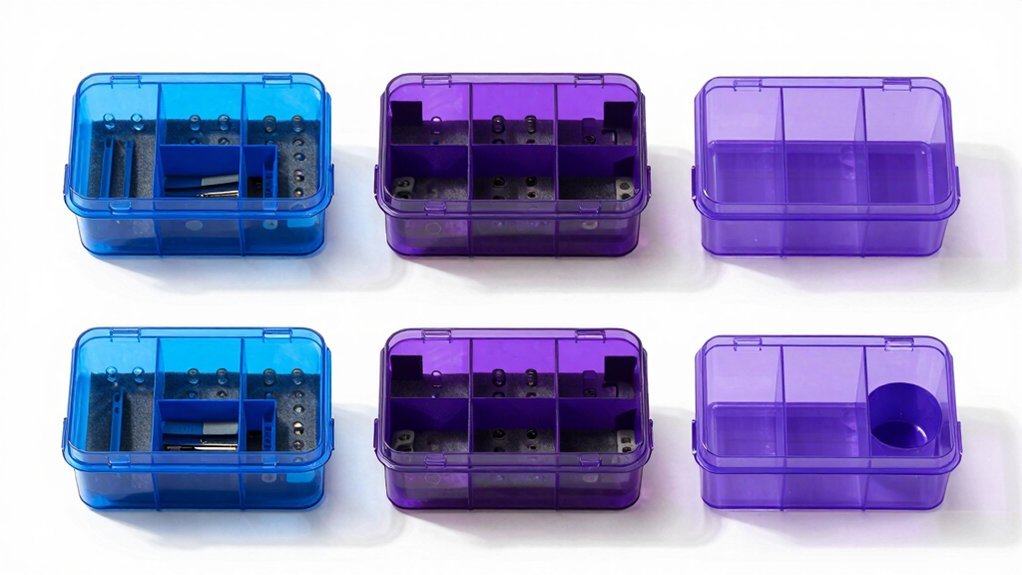

Portable Storage Solutions

Every testing facility needs reliable storage solutions that can adapt to changing project demands. You'll find extensive storage options through Portable Storage Solutions, serving northeast Texas and southeast Oklahoma with versatile containers that meet various testing equipment needs.

You can choose from customizable storage containers that protect your valuable testing kits and equipment. The containers undergo thorough inspections to ensure they remain leak-free and clean. Whether you're running a temporary testing site or need long-term storage for seasonal equipment, you'll have access to both rental and purchase options.

The containers can even be converted into on-site office spaces, providing a convenient workspace alongside your storage area.

When you're managing static testing operations, you'll appreciate the swift delivery and removal services that accommodate your project timeline. The containers offer robust security features to safeguard your sensitive testing equipment, and you can adjust your rental schedule as your project requirements change.

As a family-owned business, they'll work with you to create personalized storage solutions that match your specific testing facility needs. Whether you're part of a large retail chain, construction company, or smaller testing operation, you'll receive the same dedicated customer service and reliable support.

Calibration and Maintenance Equipment

You'll need specialized precision calibration tools to maintain the accuracy and reliability of your static testing equipment.

Your maintenance toolkit should include calibrated manometers, air data test sets, and RVSM-compliant devices for thorough system verification.

Regular equipment checks using these precision tools help you identify potential issues early and verify that your testing kits meet industry standards. User-programmed test profiles with 26 points allow for consistent and repeatable calibration procedures.

Precision Calibration Tools Required

Accurate testing of static systems regularly demands specialized precision calibration tools and equipment. You'll need various instruments to guarantee precise measurements and maintain compliance with industry standards.

These tools must be capable of performing pressure, vacuum, and resistance tests while providing reliable, traceable results. The ISO/IEC 17025:2017 accredited calibrations ensure the highest level of measurement accuracy.

- Pitot static test sets for measuring air pressure and velocity, such as the Barfield 1811HA163, which offers precise airspeed, altitude, and vertical speed readings.

- High-precision calibration test systems designed for electro-mechanical components, featuring pressure and vacuum testing capabilities.

- Static calibration kits specifically engineered for ADAS components, including camera and sensor testing equipment.

- Compression testing machines like the ALPHA 2-5000 S for accurate force sensor calibration.

You'll need to maintain these tools in controlled environments to guarantee accuracy, and they'll require regular calibration themselves. The frequency of calibration depends on factors like manufacturer recommendations, equipment age, and usage patterns.

Remember that your calibration equipment must meet national and international standards while providing consistent, reliable results for your testing procedures.

Regular Maintenance Check Equipment

Building upon the precision calibration tools discussed, maintaining static testing equipment requires its own set of specialized maintenance tools and calibration devices. Static pressure tips need frequent cleaning and inspection to ensure accurate readings. You'll need to track your calibration services regularly to guarantee your equipment maintains its accuracy and meets required standards.

Your maintenance toolkit should include calibration standards that serve as reference points for verifying equipment performance.

When you're performing maintenance checks, you'll want to keep detailed equipment records that document all calibration data, service dates, and maintenance activities. These records must include technician information and company details for accountability purposes.

You'll find that proper documentation helps you stay compliant with industry requirements while guaranteeing your static testing kits remain reliable.

Your maintenance check equipment should be able to verify the functionality of various components, including static pressure tips, high-temp silicone hoses, and gas pressure valves. For aviation-specific equipment, you'll need to confirm that your maintenance tools can handle the verification of pitot static test sets and digital LCD displays.

Don't forget to regularly check that your equipment can accurately measure pressure ranges from 0 to 20 PSI and verify appropriate airspeed and altitude readings.

Testing Accessories and Adapters

Testing accessories and adapters form the crucial connection points between air data test equipment and aircraft systems. You'll need interface hoses that are both lightweight and color-coded, making them easy to identify and connect. These transparent hoses allow you to quickly spot any contamination while preventing excessive load on the adapters. Air data test sets connect directly to these components for precise measurements and calibration.

When selecting adapters for your static testing kit, you'll want to guarantee they're designed with proper sealing materials and easy attachment mechanisms. Pitot static adapters come in both fixed and removable types, customized for specific aircraft models to guarantee accurate readings during testing and calibration.

Here's what you'll find in an extensive air data accessory kit:

- Color-coded interface hoses with transparent construction for contamination detection

- Customized pitot static adapters with leak-proof seals for various aircraft types

- Suction cup adapters for static port testing without screw fixing requirements

- Auxiliary vacuum supply equipment for enhanced testing capabilities

Your adapters must feature datum mounting capabilities for precise sensor positioning and replaceable seals for maintenance purposes. These components work together to support routine checks, calibration, and troubleshooting across various aircraft types, from civil to military applications.

Frequently Asked Questions

How Often Should Static Testing Kits Undergo Professional Recalibration?

You should have your static testing kit professionally recalibrated every 12 months, but if you're using it frequently or in harsh conditions, you'll want to schedule calibration checks every 6 months.

Can Multiple Technicians Share One Static Testing Kit Simultaneously?

No, you can't share one static testing kit simultaneously among multiple technicians. It'll compromise test accuracy, create safety risks, and reduce operational efficiency. You should provide each technician with their own dedicated kit.

What's the Average Lifespan of a Complete Static Testing Kit?

You'll find that static testing kits don't have a fixed lifespan. Instead, you should focus on regular calibration and maintenance checks. With proper care and periodic recalibration, your kit can remain reliable for many years.

Are Static Testing Kits Covered Under Aviation Insurance Policies?

No, you won't find static testing kits covered under typical aviation insurance policies. They're considered specialized equipment outside standard aviation coverage, so you'll need separate insurance specifically for these testing devices.

Can Static Testing Kits Be Used in Extreme Weather Conditions?

You can use static testing kits in extreme weather, but you'll need specialized equipment like cryostats and thermal chambers. They'll function between -55°C to +85°C, with some capable of reaching -253°C.

In Summary

You'll need to maintain your static testing kit by regularly calibrating instruments and replacing worn components. Keep your safety equipment, like grounding straps and insulating mats, in prime condition. Don't forget to organize your storage cases properly and check that all adapters and measurement tools are working correctly. Remember, a well-maintained testing kit guarantees accurate results and safe operation.

Leave a Reply