Quality electronics tweezers are worth your investment because they protect your sensitive components through advanced ESD-safe features and anti-static coatings. You'll benefit from precision-engineered tips, crafted through rigorous manufacturing processes that guarantee perfect alignment and durability. Superior materials like stainless steel and titanium offer excellent corrosion resistance and temperature tolerance, while ergonomic designs prevent hand fatigue during detailed work. While they may cost more upfront, quality tweezers save you money by lasting longer and preventing costly component damage. There's much more to discover about what sets professional-grade tweezers apart from basic tools.

Static Protection Features

Static-safe tweezers serve as essential guardians against electrostatic discharge (ESD) in electronics handling. When you're working with sensitive electronic components, you'll need tweezers made from anti-magnetic stainless steel alloys that prevent static buildup and meet strict Class 0 CDM compliance standards of less than 40V ESD threshold.

You'll find various types of ESD tweezers designed for specific applications. Wafer tweezers feature flat teeth for secure handling of silicon components, while ceramic tip options excel in high-temperature soldering tasks. If you're working with gallium arsenide or delicate glass parts, PEEK tip tweezers offer the protection you need. The tweezers' epoxy resin coating provides additional protection against corrosion and oxidation.

To maximize your static protection, you'll want to pair your tweezers with proper grounding equipment. This includes anti-static wrist straps, conductive clothes, and Earth bonding points.

The tweezers' conductive layers help dissipate static electricity effectively, but you must maintain proper grounding connections during use.

Quality ESD tweezers provide lasting value through their durable construction and precise engineering. When you invest in high-grade static-safe tweezers, you're not just buying a tool – you're securing protection for your sensitive electronic components and ensuring compliance with industry standards.

Precision Engineering and Craftsmanship

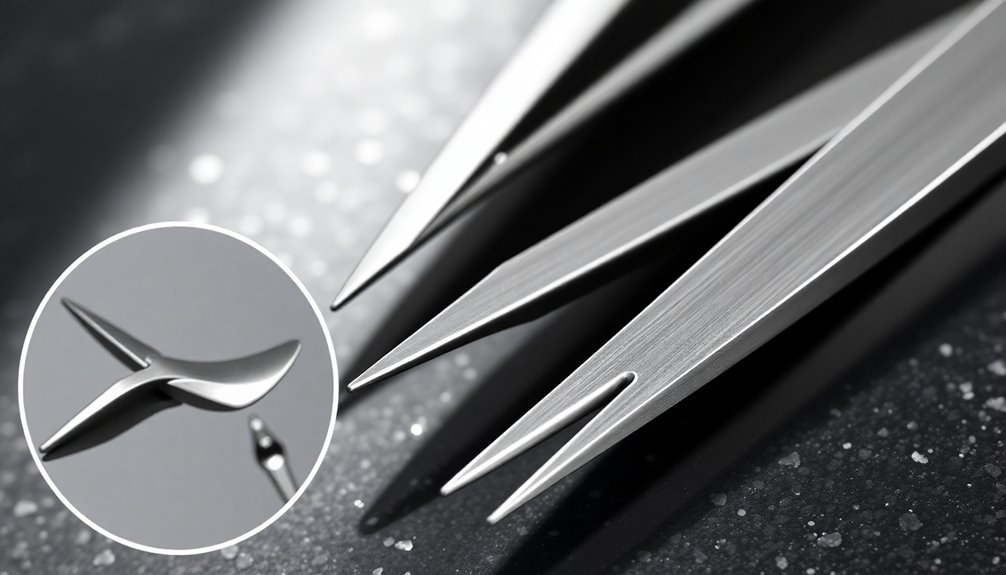

Beyond their static-protective qualities, quality electronics tweezers showcase remarkable engineering precision through a rigorous 25-step manufacturing process. You'll find meticulous handcrafting for perfect tip alignment, laser welding for enhanced durability, and thorough cleaning procedures including tumbling, electropolishing, and ultrasonic cleaning to maintain pristine surfaces.

The engineering excellence extends to ergonomic design features that'll make your work easier. These tweezers can handle temperatures of up to 800 degrees Celsius without losing their precision. You'll notice carefully rounded edges, non-reflective surfaces, and strategically placed grip hashing that provides excellent control even with gloves. Some models include ESD rubber or foam coatings to further enhance your comfort during extended use.

What you mightn't realize is that quality tweezers are designed at a specific 65-degree angle, offering you the ideal balance between visibility and handling precision. This careful engineering guarantees you'll have clear sight lines while maintaining proper control over delicate components.

You can trust these precision tools because they meet rigorous standards like ISO 9001 and ISO 13485. When you're working with sensitive electronics, these certifications guarantee that your tweezers will deliver consistent, reliable performance throughout their service life, making them a worthwhile investment for professional electronics work.

Material Selection Matters

When choosing electronics tweezers, you'll find that stainless steel and titanium each offer distinct advantages, with stainless steel providing excellent durability at a lower cost while titanium delivers superior non-magnetic properties and corrosion resistance.

Your choice between these materials should align with your specific needs, as stainless steel works well for general electronics work, while titanium excels in specialized applications requiring zero magnetic interference.

ESD-safe coatings on either material will protect your sensitive electronic components from static discharge while improving your grip and comfort during extended use. A high-quality finish process like electropolishing or sandblasting ensures optimal performance and longevity of the tweezers.

Stainless Steel vs. Titanium

Material selection plays a pivotal role in determining the performance and reliability of electronics tweezers. Your choice between stainless steel and titanium can markedly impact your work quality and efficiency. While stainless steel tweezers offer good corrosion resistance and are cost-effective for general applications, titanium tweezers provide superior performance in specialized environments. This evolution in materials follows the legacy of Industrial Revolution advances that transformed manufacturing capabilities.

When choosing between these materials, consider these critical factors:

- Environmental Requirements: Titanium excels in clean rooms and high-temperature settings (up to 800°C), while stainless steel may shed particles and has lower heat resistance.

- Component Sensitivity: Titanium's non-magnetic properties and zero charge retention make it ideal for handling delicate electronic components, whereas stainless steel poses potential risks in sensitive applications.

- Durability Needs: Titanium offers superior abrasion resistance and maintains its strength in extreme conditions, while stainless steel provides adequate durability for standard applications.

- Budget Constraints: Stainless steel tweezers are more economical for general use, but titanium's long-term benefits often justify its higher initial cost in professional settings.

If you're working with precision electronics or in clean room environments, titanium's benefits typically outweigh its cost premium. For general electronic work, stainless steel remains a practical choice.

ESD-Safe Coating Benefits

The manufacturing world's push for ESD protection has made ESD-safe coatings an essential feature in quality electronics tweezers. When you're handling sensitive electronic components, these specialized coatings provide a vital safeguard by dissipating static charges safely to ground, preventing potentially costly damage to your valuable parts.

ESD-safe coatings deliver measurable benefits through their resistance levels of 10^6 to 10^11 ohms, offering just enough conductivity to prevent static buildup without causing sudden discharges. The broad, flat tips provide exceptional stability when handling surface mount devices. You'll find these coatings particularly valuable in rubber and epoxy resin applications, where they not only protect your components but also enhance your grip and operating comfort.

The coatings' durability guarantees long-lasting protection against wear and environmental factors, making your investment worthwhile. You'll notice improved productivity as the coatings reduce static cling, making it easier to separate and handle small parts.

They'll also protect you from unexpected static shocks, which are especially common during winter months. Whether you're working in electronics manufacturing, semiconductor production, or any field requiring precise component handling, ESD-safe coatings provide the protection you need to maintain quality and prevent costly defects.

Longevity and Cost Benefits

Through careful consideration of quality electronics tweezers, you'll discover substantial long-term advantages in both durability and cost efficiency. When you invest in tweezers made from high-quality materials like series 300 stainless steel, you're getting tools that resist corrosion, maintain their precision, and deliver consistent performance over time. Choosing Vetus tweezers ensures exceptional value as they match Swiss performance at more reasonable prices.

The long-term value of quality tweezers becomes evident through these key benefits:

- You'll spend less on replacements since premium tweezers last considerably longer, offering superior resistance to wear and chemical exposure.

- You'll maintain consistent performance throughout the tool's lifespan, ensuring precise handling and reducing errors in your work.

- Your investment in anti-magnetic and ESD-safe properties protects both the tweezers and your sensitive electronic components.

- You'll experience improved ergonomics that reduce hand fatigue and prevent premature wear from improper handling.

Industry Compliance Standards

In accordance with stringent industry requirements, quality electronics tweezers must meet specific compliance standards that guarantee safety, reliability, and performance. When you're working with sensitive electronic components, you'll need tweezers that meet ISO 9001 and ISO 12485 certifications, confirming they've passed rigorous quality management standards.

These tools can endure extreme operating temperatures up to 800°C, making them suitable for various demanding electronics applications.

ESD safety is particularly vital for electronics manufacturing. You'll want tweezers with proper ESD coatings that provide resistance levels between 10^5-10^6 Ohm/sq to protect sensitive components from static discharge.

If you're handling static-sensitive devices like resistors, capacitors, or semiconductors, these protective features aren't optional – they're essential.

The material composition of your tweezers matters substantially for compliance. You'll find that stainless steel options offer non-magnetic properties and corrosion resistance, perfect for clean room environments.

For specialized applications, you might need antimagnetic alloys with chromium and nickel additions that resist acids and salts.

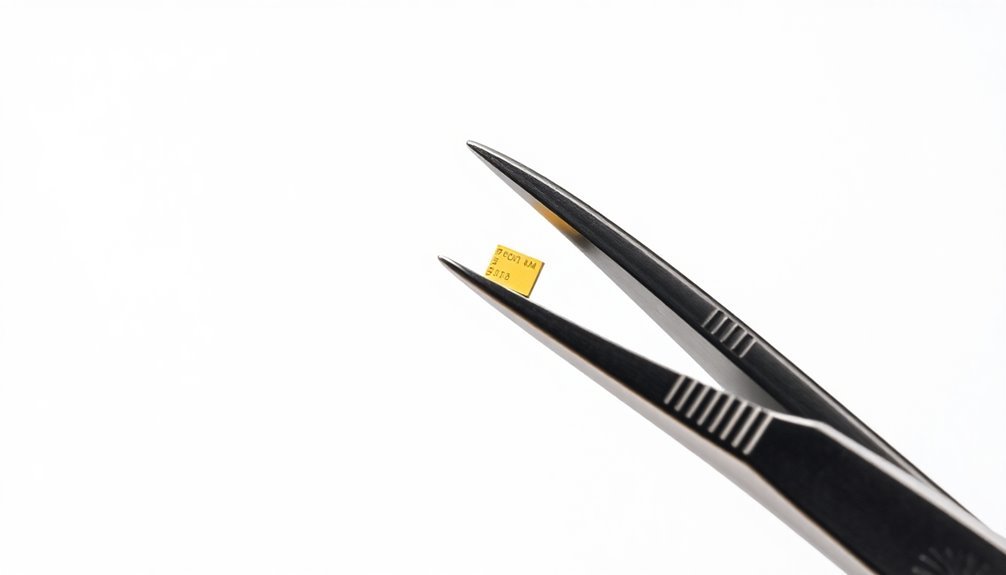

When working with SMD components, you'll require tweezers that meet specific electronics industry standards, including proper tip design and ESD protection to guarantee safe component handling and placement.

Performance in Electronics Assembly

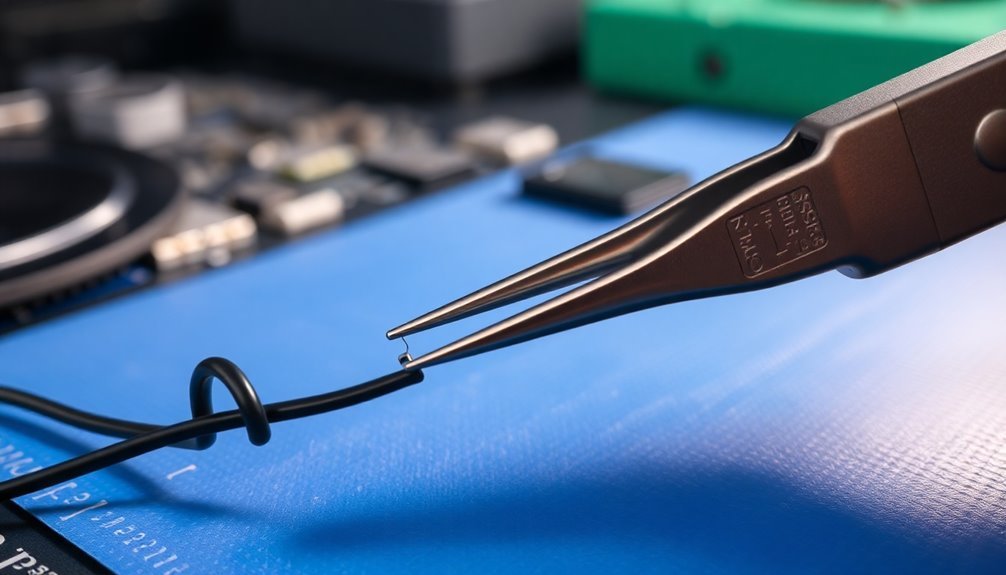

Selecting the right tweezers for electronics assembly can dramatically impact your work quality and efficiency. When you're handling delicate electronic components, you'll need tweezers that offer precise control, reliable protection against static discharge, and specialized features for specific tasks.

Look for tweezers with ESD-safe materials to protect sensitive components from static damage. You'll find that high-quality electronics tweezers come with specialized tips designed for specific tasks, such as SMD component placement or wire manipulation. The ability to swap between different tip types gives you versatility across various assembly tasks.

Here's what you should expect from quality electronics tweezers:

- Perfect tip alignment at 65 degrees for ideal component grip and placement

- Anti-magnetic properties to prevent interference with sensitive electronics

- Fine, symmetrical tips that allow precise manipulation of small parts

- Comfortable ergonomic design for reduced hand fatigue during long assembly sessions

When you're working with cutting tweezers, you'll appreciate their ability to precisely trim wires while maintaining control.

The right tweezers will help you handle fragile components with confidence and achieve consistent, professional results in your electronics assembly work.

Maintenance and Care Essentials

To keep your electronics tweezers in top condition, you'll need to follow daily cleaning procedures using warm water and detergent, followed by an isopropyl alcohol soak for proper sanitization.

You should store your tweezers with protective caps in a dry environment to prevent tip damage and maintain their precision.

When handling sensitive electronic components, it's essential to use ESD-safe tweezers and maintain proper grounding procedures to prevent static discharge damage.

Daily Cleaning Best Practices

Maintaining clean electronics tweezers requires a systematic daily approach that combines proper cleaning techniques with careful handling. You'll need to start with warm water, as extreme temperatures can cause bacteria to adhere to the surfaces.

Apply a mild detergent similar to dish soap to break down any oils or contaminants that may harbor harmful microorganisms.

For effective daily maintenance, follow these essential steps:

- Gently scrub all parts of your tweezers using a soft-bristled brush, paying special attention to the tips and inner surfaces where debris often accumulates.

- Rinse thoroughly with warm water to remove all traces of detergent, guaranteeing no residue remains.

- Allow your tweezers to air dry completely, or use a lint-free cloth to prevent water spots.

- Finish by wiping with rubbing alcohol using a clean cloth for quick sanitization.

You'll want to avoid using abrasive materials or exposing your tweezers to high heat, as these can damage the precision tips. When you're not using them, protect the tips with rubber caps.

This daily cleaning routine won't just maintain hygiene – it'll also extend your tweezers' lifespan and guarantee consistent performance in your electronics work.

Proper Storage Methods

Professional electronics tweezers' longevity depends heavily on proper storage methods. You'll want to invest in plastic or metal cases with individual compartments to prevent your tweezers from scratching or tangling with each other.

Choose storage containers with soft inserts and secure lids to protect against impact damage and accidental opening.

Organize your tweezers by categorizing them based on type, size, or application. You can use labeled containers, magnetic strips, or wall-mounted racks to maximize workspace efficiency while keeping your tools easily accessible.

Remember to store your tweezers in a controlled environment away from moisture and extreme temperatures.

To maintain your tweezers' quality during storage, always inspect and clean them before putting them away. Don't overcrowd your storage containers, as this can lead to unnecessary wear and damage.

If you're working in an electronics environment, guarantee your storage area is ESD-safe to protect both your tweezers and sensitive components. Keep storage areas clean and dry, maintaining low humidity levels to prevent oxidation.

Frequently Asked Questions

Can Tweezers With Magnetic Properties Damage Smartphone Components During Repairs?

Yes, your magnetic tweezers can damage smartphone components. They'll stick to magnets, disrupt electromagnetic fields, and interfere with sensitive electronics. You'll want to use anti-magnetic tweezers for safe, precise smartphone repairs.

How Often Should Professional Electronics Tweezers Be Recalibrated for Optimal Performance?

You'll need to inspect your tweezers regularly, but formal recalibration isn't typically required for mechanical models. Check for wear, damage, or performance issues, and follow your manufacturer's specific maintenance guidelines when provided.

Are Ceramic-Tipped Tweezers Better Than Metal Ones for LED Work?

You'll find ceramic-tipped tweezers superior for LED work due to their thermal insulation and non-conductivity. They're safer for sensitive components, though they're more expensive and brittle than metal options.

What Temperature Range Can High-Quality Electronics Tweezers Safely Operate In?

You'll find that high-quality electronics tweezers can safely operate between room temperature and 400°C. However, if you're using specialized ones with NM-SS or titanium tips, they'll handle temperatures up to 550°C.

Do Different Brands of Esd-Safe Tweezers Have Varying Static Discharge Ratings?

Yes, you'll find that ESD-safe tweezer brands have different static discharge ratings. It's important to check manufacturer specifications, as ratings can vary from 10^3 to 10^11 ohms depending on materials and construction methods.

In Summary

Quality electronics tweezers aren't just another tool – they're an investment in your work's precision and safety. You'll find the combination of ESD protection, superior materials, and expert craftsmanship makes a noticeable difference in your electronics projects. When you factor in their longevity and reliability, premium tweezers actually save you money while helping you achieve better results in your assembly work.

Leave a Reply