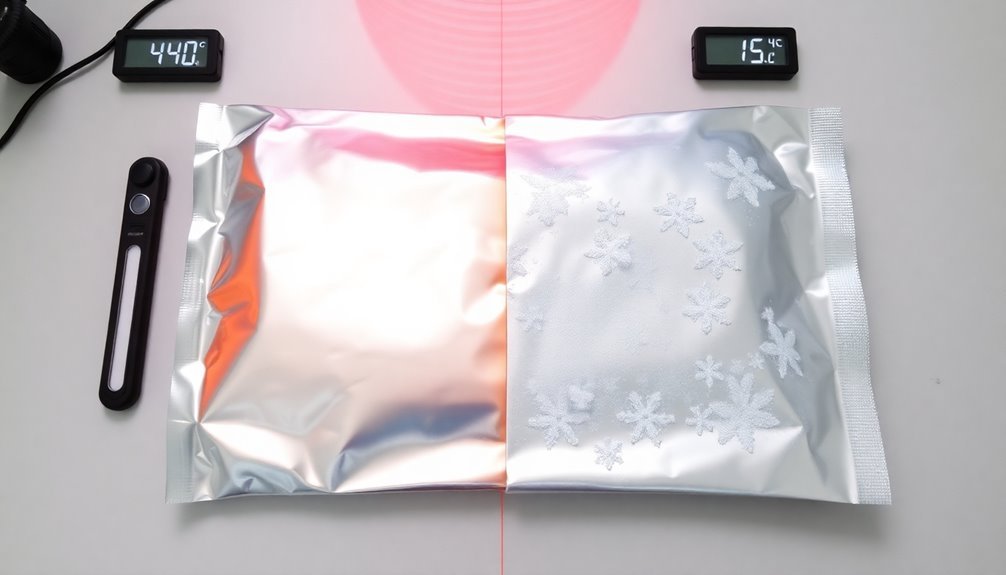

Static shielding bags can withstand temperatures between 300°F to 375°F (149°C to 190°C), but you'll want to store them at room temperature around 76°F (24°C) for maximum protection. The bags' multilayer construction, including polyethylene, aluminum, and polyester, creates a Faraday Cage effect that shields sensitive electronics from electrostatic discharge. You shouldn't expose them to direct sunlight, moisture, or excessive heat, as this can oxidize the aluminum layer and compromise their protective qualities. While heat sealing is safe within the specified range, proper temperature control guarantees your sensitive components stay fully protected. Understanding the complete temperature guidelines will help maximize your ESD protection strategy.

Understanding Temperature Range Specifications

The temperature range specifications for static shielding bags are critical for maintaining their protective properties. When you're working with these specialized bags, you'll need to understand that they're designed to operate within specific temperature boundaries.

While the minimum temperature isn't typically specified, you should store these bags at room temperature, ideally around 76°F (24°C), to prevent degradation of their protective qualities. The polyester and polyethylene construction of these bags contributes to their temperature resilience.

The maximum temperature tolerance ranges from 300°F (149°C) to 375°F (190°C) for standard static shielding bags. However, you shouldn't push these limits, as exceeding them can compromise the bag's ESD protection capabilities. The temperature stability of these bags directly affects their ability to shield sensitive electronic components from electrostatic discharge.

You'll find that these specifications align with important industry standards like ANSI/ESD S20.20 and ANSI/ESD S541, which establish testing protocols for ESD shielding materials. When you're managing static-sensitive components, maintaining proper temperature conditions isn't just about compliance—it's essential for preserving the integrity of the aluminum shielding layers and ensuring consistent protection throughout the bag's service life.

Material Composition and Heat Resistance

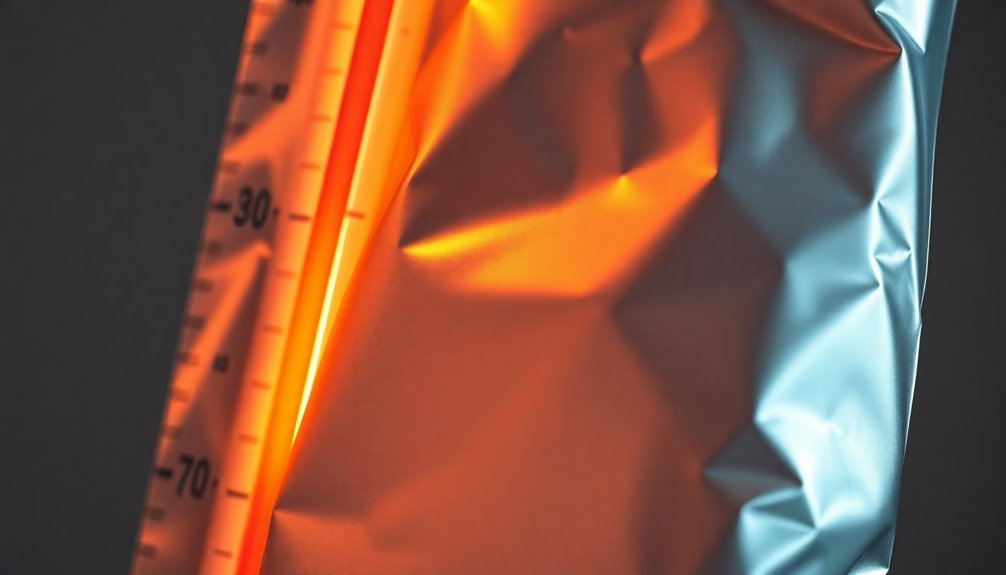

Understanding the temperature limits of static shielding bags requires knowledge of their sophisticated material construction. You'll find these bags are built with multiple layers, including vacuum-deposited aluminum sandwiched between polyethylene and polyester films. This multilayer structure creates a Faraday Cage effect that protects your sensitive electronic components from electrostatic discharge. The materials exhibit a 12 pound seam strength when tested according to industry standards. The bags' heat resistance stems from their durable construction, typically featuring a 3 mil thickness that withstands physical stress and moderate temperatures. While specific temperature limits aren't standardized, the bags' heat-sealable nature indicates they can handle sealing temperatures without degradation. The materials also provide moisture resistance and maintain their protective properties across varying conditions.

| Material Layer | Primary Function | Properties |

|---|---|---|

| Outer PE | Static Dissipation | Moisture Resistant |

| Middle Aluminum | ESD Shielding | Faraday Protection |

| Inner PET | Component Protection | Non-Corrosive |

These materials work together to create a bag that's not only heat-sealable but also maintains its structural integrity and protective capabilities. The combination of polyethylene, aluminum, and polyester guarantees durability while providing the necessary static shielding properties your sensitive components need.

Proper Storage Temperature Guidelines

Maintaining proper storage temperatures for static shielding bags plays a vital role in preserving their protective qualities. You'll want to keep these bags in a controlled environment with temperatures between 20°C to 24°C (68°F to 76°F). This consistent temperature range helps prevent damage to the bags' protective properties and extends their useful life. Exposure to temperatures above 90°C to 150°C will cause severe damage to the bags.

Don't store your static shielding bags near heat sources like radiators or in areas exposed to direct sunlight. These conditions can cause the aluminum shielding layer to oxidize and compromise the bags' effectiveness.

You'll need to guarantee your storage area remains well-ventilated and dry, as moisture can also impact the bags' protective capabilities.

To maintain ideal temperature control, you should regularly monitor your storage environment and make adjustments as needed. It's important to keep the bags in their original packaging when possible, as this provides an additional layer of protection against temperature fluctuations.

If you notice any temperature-related damage, such as warping or discoloration, you should remove those bags from circulation immediately. Remember to log purchase dates and conduct periodic inspections to guarantee your static shielding bags remain within acceptable temperature parameters.

Heat Sealing Best Practices

To properly heat seal your static shielding bags, you'll need to set your sealing equipment to the manufacturer's recommended temperature range, typically between 300-375°F (149-190°C).

You must operate your ESD-safe sealing equipment by first removing excess air from the bag, then applying consistent pressure across the seal area for the specified dwell time. The bags' metallized film construction ensures superior protection against electrostatic discharge during the sealing process.

After sealing, you should inspect the seal quality by checking for uniform width, proper fusion, and the absence of wrinkles or gaps that could compromise the bag's effectiveness.

Optimal Temperature Settings Guide

Successful heat sealing of static shielding bags depends on finding the right balance of temperature, pressure, and dwell time. When setting your heat sealer, you'll want to maintain temperatures between 90°C and 150°C to achieve the best sealing without risking material deformation or melting.

For the best sealing results, consider these critical factors:

- Start at 115°C as your baseline temperature, adjusting upward if needed for stronger seals

- Monitor your material for signs of shrinkage, which can occur at temperatures above 140°C

- Check seal quality regularly by testing for air leakage and visual defects

Your sealing equipment's actual pressure may differ from the input settings, so it's crucial to measure and verify pressure levels regularly. While pressure isn't as critical as temperature and dwell time, it still plays a crucial role in seal quality. Using electronic sensors or sensor paper can help you accurately measure the true pressure being applied to your materials.

You'll need to adjust these parameters based on your specific material combinations and thickness. Remember that constant heat sealing methods work best for thicker materials and static applications, but you might need different approaches for high-speed processes.

Keep your bags stored at around 24°C in a dry environment to maintain their anti-static properties and guarantee consistent sealing performance.

Safe Equipment Operation Steps

Safe operation of heat sealing equipment starts with proper preparation and attention to detail. Before you begin, inspect your equipment thoroughly and verify it's properly calibrated according to manufacturer specifications.

Clean the sealing area to prevent contamination, and select the appropriate static shielding bag for your application. Ensure your temperature settings align with ISO 13485 standards for consistent process control.

When handling the bags, you'll need to remove any existing static charge and handle them with care to protect the protective layers. If you're packaging items with sharp edges, add padding to prevent punctures. Make sure you're using a bag that's large enough for your product, and always use ESD-safe sealing equipment.

During the sealing process, implement impulse heat sealing for precise temperature control. Press out excess air before sealing, and maintain consistent temperature throughout the process. Check each seal for integrity immediately after completion.

Keep your equipment in top condition through regular maintenance and proper storage. Don't reuse static shielding bags, as this can compromise their protective qualities. Store your unused bags in a cool, dry place away from direct sunlight.

Validate your sealing process regularly to confirm consistent, reliable results every time you operate the equipment.

Quality Seal Inspection Criteria

Proper inspection of heat-sealed static shielding bags requires several key quality criteria. You'll need to examine each seal thoroughly for integrity and consistency while verifying the static dissipative layers remain undamaged during the sealing process. The 5-phase system layers provide superior durability during heat sealing operations.

When inspecting seals, focus on achieving tight closures without gaps or openings, and conduct air leakage tests to verify the vacuum seal's effectiveness.

To maintain the best seal performance, you'll want to:

- Use an ESD impulse bag sealer or specialized heat sealer designed specifically for static shielding bags

- Apply consistent pressure during the sealing process to prevent weak spots

- Remove excess air before sealing to avoid moisture buildup inside the bag

Your sealing equipment must be properly calibrated and maintained to verify consistent results. Monitor the sealing temperature carefully, as proper heat control is vital for creating reliable seals that protect sensitive components.

Regular inspections of sealed bags should become part of your quality control routine to verify that seals maintain their integrity over time and continue to provide effective static shielding and moisture barrier protection, even under varying environmental conditions.

Temperature Effects on ESD Protection

Three critical factors influence how temperature affects ESD protection performance. First, the breakdown voltage in ESD protection devices decreases substantially as temperature rises – you'll see up to a 27.32% reduction when temperatures climb from -75°C to 125°C in 28 nm FD-SOI MOSFETs.

Second, the holding voltage drops by roughly 8.49% across this same temperature range, which affects your device's protection capabilities.

You'll need to take into account specific temperature limits for your ESD protection materials. Most static shielding bags can only withstand temperatures between 90°C and 150°C before they begin to deform and lose their protective properties. For automotive applications, you'll want ESD protection devices that can handle temperatures from -55°C to 175°C, while standard devices typically operate between -55°C and 150°C.

Temperature also interacts with humidity to affect your ESD protection system's effectiveness. You should maintain relative humidity between 40% and 60% for ideal protection. When you can't maintain proper humidity levels, use ionized air to dissipate static charges.

Remember that operating outside recommended temperature ranges will compromise your device's reliability and protection capabilities.

Safety Limits and Thermal Stress

Static shielding bags routinely face temperature-related challenges that can compromise their protective capabilities. You'll need to maintain these bags within specific temperature ranges to guarantee they continue protecting your sensitive electronic components effectively. The recommended storage temperature is 76°F (24°C), while the maximum usage temperature shouldn't exceed 375°F (190°C).

To maintain the integrity of your static shielding bags, you'll want to focus on these critical factors:

- Monitor the bags for signs of thermal stress, such as discoloration or brittleness, which can indicate degradation of the metalized layer.

- Store bags away from direct sunlight, moisture, and heat sources to prevent premature deterioration.

- Avoid creasing or folding the bags, as this can break down the metalized shield's effectiveness.

The bags' three-mil thickness provides durability, but don't let this fool you into overlooking temperature limits. When you expose these bags to excessive heat, you risk compromising their Faraday Cage protection and static dissipative properties.

The polyethylene and polyester layers can degrade, while the aluminum layer may oxidize under high temperatures and humidity, reducing the bag's ability to protect against ESD.

Temperature-Related Performance Factors

Temperature variations substantially affect how static shielding bags perform their protective functions. When you're using these bags, you'll need to maintain temperatures between 300°F and 375°F for peak performance, though heat sealing can occur at temperatures as low as 250°F.

You'll notice several key performance factors change with temperature fluctuations. The static decay rate, which should be less than 2 seconds for high-quality bags, varies with both temperature and humidity levels.

Your bag's tensile strength must exceed 25 pounds at ideal temperatures, while the seam strength needs to meet MIL-PRF-81705 specifications.

Temperature also impacts the material's protective qualities. The aluminum shielding layer can oxidize if you expose it to high temperatures or UV light, potentially compromising its effectiveness.

You'll want to store your bags at around 76°F to maintain their protective properties. The multi-layer construction, including polyethylene, polyester, and aluminum layers, works together to maintain temperature stability, but you'll need to avoid extreme temperatures that could degrade these materials' performance.

When properly maintained, your bags will provide consistent Faraday Cage protection and prevent electrostatic charge buildup.

Standards for Temperature Control

Several industry standards govern the proper temperature control of static shielding bags, with ANSI/ESD S20.20 and ANSI/ESD S541 setting the primary requirements.

You'll need to maintain temperatures between 300°F and 375°F (149°C – 190°C) for peak performance while ensuring compliance with RoHS 2, REACH, and Conflict Minerals regulations.

When implementing temperature control standards, you must consider these critical factors:

- Surface resistivity requirements of 1 x 10^4 to <1 x 10^11 ohms, as specified by ANSI/ESD STM11.11

- ESD shielding performance limits of <10 nJ discharge energy according to ANSI/ESD STM11.31

- Storage temperature maintenance at 76°F (24°C) to preserve material integrity

Proper temperature control directly impacts the bag's performance characteristics, including its heat sealability and protective qualities.

The multi-layer construction of polyester, polyethylene, and metal requires strict adherence to these temperature standards to maintain its 4600 PSI tensile strength and 12-pound puncture resistance.

Remember that exceeding temperature limits can compromise the material's ability to provide Faraday Cage protection and maintain its dissipative properties on both inner and outer surfaces.

Frequently Asked Questions

Can Static Shielding Bags Be Reused After Exposure to Extreme Cold?

You can reuse static shielding bags after extreme cold exposure, but you'll need to inspect them carefully for physical damage. Check the material integrity and sealing to verify they'll still provide proper ESD protection.

How Do Altitude Changes Affect the Temperature Resistance of These Bags?

While altitude itself doesn't directly affect your bags' temperature resistance, you'll need to take into account changes in air pressure that could impact heat sealing performance. The bags maintain their standard temperature resistance across elevations.

Does Repeated Heat Sealing at Maximum Temperature Reduce the Bag's Lifespan?

Yes, you'll notice reduced effectiveness if you repeatedly seal at maximum temperature (400°F). It's best to use moderate heat settings around 325°F to maintain the bag's protective properties and structural integrity.

Are There Special Temperature Considerations When Shipping Across Different Climate Zones?

You'll need to maintain consistent temperatures (21-23°C) when shipping across climate zones. Use climate-controlled transportation to prevent damage, and monitor humidity levels to protect your static shielding bags' effectiveness during transit.

What Temperature Monitoring Methods Are Recommended During Extended Storage Periods?

You'll want to use digital data loggers with buffered probes taking readings every 30 minutes. For backup, install wireless temperature sensors that provide real-time alerts if conditions deviate from your 68°F target.

In Summary

You'll need to carefully monitor temperature conditions when using static shielding bags to maintain their protective properties. Don't exceed manufacturer-specified temperature limits during storage, handling, or heat sealing. Remember that extreme temperatures can compromise the bags' ESD protection capabilities. While these bags are durable, staying within recommended ranges guarantees they'll effectively shield your sensitive electronic components and maintain their structural integrity.

Leave a Reply