The most effective data center cabinet grounding methods you'll encounter today include the Master Ground Bus Bar (MGB) system, Direct Cabinet-to-Grid Connection, Isolated Ground Path Implementation, Mesh Ground Network Design, and Signal Reference Grid Integration. You'll want to implement an MGB system as your primary connection hub, while Direct Cabinet-to-Grid guarantees ANSI/TIA-942 compliance. Isolated Ground Paths maintain clean power delivery, and Mesh Networks provide redundant protection. Signal Reference Grids offer superior equipment protection through low-impedance planes. Understanding these grounding methods can make the difference between standard protection and exceptional system reliability.

Master Ground Bus Bar System

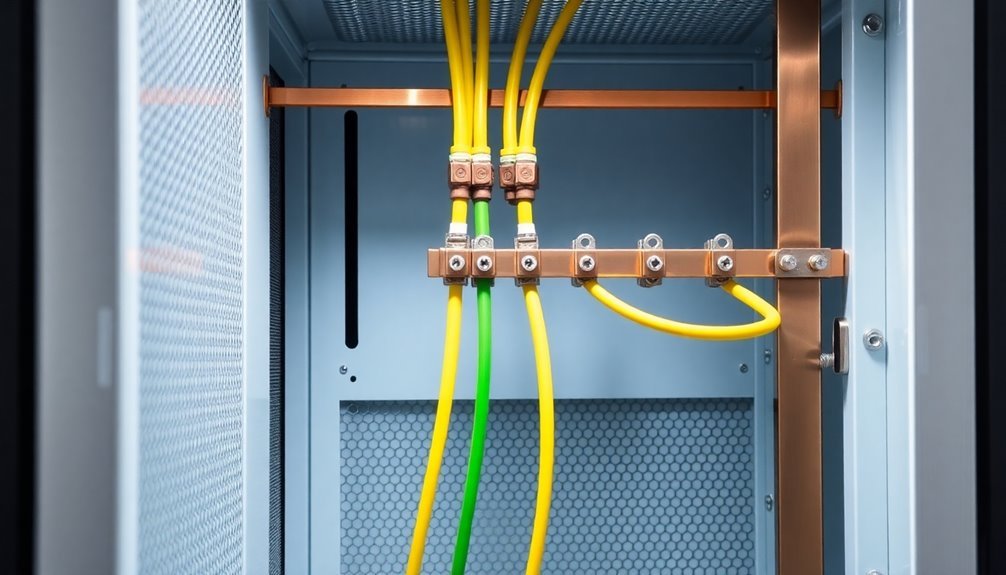

Three critical components form the foundation of a Master Ground Bus Bar (MGB) system in data centers. First, you'll find the central MGB serving as the primary connection point for all grounding elements.

Second, you'll need copper grounding bus bars mounted strategically throughout the facility.

Third, you'll require proper bonding conductors to link all metallic components to maintain uniform electrical potential.

When you implement an MGB system, you'll gain significant advantages for your data center's safety and performance. The system provides a low-resistance path to earth, effectively dissipating fault currents and protecting your valuable equipment from voltage fluctuations and electrical surges. The installation of a Signal Reference Grid helps minimize electromagnetic disturbances.

You'll also notice reduced electromagnetic interference, leading to enhanced system performance.

To maximize your MGB system's effectiveness, you'll need to conduct thorough site assessments and consider factors like soil resistivity and building structure. It's vital that you connect all rack grounding bus bars to the MGB and guarantee proper bonding between components.

You'll want to maintain UL-listed ground bars and regularly inspect your grounding system to guarantee its continued effectiveness. This thorough approach guarantees your data center maintains top electrical safety and performance standards.

Direct Cabinet-to-Grid Connection

Security drives the implementation of direct cabinet-to-grid connections in data centers, requiring strict adherence to ANSI/TIA-942 standards. Regular monitoring helps create a safe electrical barrier against harmful energy accumulation. You'll need to guarantee your system directs damaging currents away from equipment through a dedicated grounding setup, using permanent copper compression lugs and proper bonding between structural components.

Your implementation must include direct bonding of each rack to the grounding system, which needs to be separate from the building ground.

You'll want to verify compatibility with EIA-310 standards for enclosures and mounting rails, while maintaining proper access points for power and data pathways at both cabinet ends.

Don't overlook the importance of bonding all metal objects, including PDUs and CRACs, to prevent ungrounded equipment scenarios. You'll need to use grounding straps with listed ring or closed-loop terminals and guarantee your cabinets accommodate hot aisle/cold aisle configurations.

Regular maintenance checks are essential – inspect connections and cables for wear, and keep all components corrosion-free.

Remember to include cable organizers and environmental sensors in your setup, and don't forget to properly label cabinets and their contents for easy identification and management.

Isolated Ground Path Implementation

Implementing an isolated ground path effectively separates your data center's grounding system from the building's electrical system, substantially reducing interference and electrical noise.

You'll need to install a central ground bus and connect all equipment using special insulated conductors to maintain this isolation.

Start by establishing a low-impedance grounding electrode system, which can include a buried ground loop or chemically enhanced grounding electrodes. The system should achieve less than 5 ohms resistance to ground for optimal performance.

You'll want to connect your equipment frames, racks, and critical devices individually to the isolated grounding bus bar. Don't forget to use isolated ground receptacles for your power connections to maintain the separation from the building's ground.

To comply with NEC requirements, you must bond your isolated ground system to the building's ground system at a single point using a bonding jumper.

Install a current divider at this connection to maintain low noise while meeting safety standards.

You'll also need to implement proper cable management techniques and static discharge systems to prevent current leakage and static buildup.

Remember to schedule regular maintenance checks to verify your isolated ground system remains effective and compliant with all regulations.

Mesh Ground Network Design

Mesh ground networks deliver a robust foundation for data center grounding through their predictable capacity and interconnected design. You'll find that these networks enhance data transmission reliability while guaranteeing consistent performance under varying loads.

The architecture relies on interconnected switches that form a distributed network fabric, supporting high-speed packet switching between modules. The core layer switches provide essential connectivity between multiple aggregation modules.

When you're implementing a mesh ground network, you'll benefit from its inherent scalability and robustness. You won't need additional routers to expand the system, and you'll appreciate how nodes connect automatically with minimal management requirements.

The network's self-healing capabilities and redundancy features guarantee your data center maintains stability even during partial failures.

For protection, you'll need to follow established grounding standards like ANSI/TIA-942 and guarantee compliance with international specifications. You should use pre-grounded data cabinets to simplify setup and reduce potential risks.

Regular maintenance of bonding connections is vital, especially in high-power data centers where electrical hazards pose significant threats.

The leaf and spine switch configurations support efficient data flow for your cloud applications while maintaining the network's predictable capacity and performance.

Signal Reference Grid Integration

Integration of Signal Reference Grids (SRGs) provides your data center with a low-impedance equipotential plane that protects sensitive electronic equipment. You'll typically install these grids beneath raised floors, using flat braided copper cable for superior performance due to its excellent handling of high-frequency signals through the skin effect. FIPS PUB 94 introduced these foundational standards in 1983.

While connecting your SRG, you'll need to bond all metallic components to the grounding system, including racks, cabinets, ladder racks, and cable trays. You should guarantee your SRG integrates seamlessly with existing grounding systems to maintain a single, common equipotential plane that's visually verifiable for inspections.

However, you should know that modern IT equipment has evolved to be less susceptible to inter-system ground noise, making SRGs less critical than before. If you're managing a newer data center, you can achieve reliable operation without an SRG, especially in hard-floor environments.

You'll find that alternative grounding methods, such as equipment grounding or grounding bus bar systems, can effectively meet your needs while complying with industry standards like TIA-942 and NEBS Level 3. Remember to maintain low impedance to ground through proper electrode arrays or buried ground loops for superior performance.

Frequently Asked Questions

How Often Should Data Center Grounding Systems Be Inspected and Tested?

You'll need to conduct commissioning tests when installing, 9-month interval checks by staff, annual inspections in stable climates, 3-5 year third-party audits, and post-repair checks whenever you make system modifications.

What Are the Cost Differences Between Copper Versus Aluminum Grounding Materials?

You'll find aluminum grounding materials cost 75-80% less than copper initially. While copper's higher price brings better conductivity and durability, aluminum's stable pricing and lighter weight offer significant upfront savings in your installations.

Can Existing Data Centers Be Retrofitted With Modern Grounding Systems?

Yes, you can retrofit your existing data center with modern grounding systems, but you'll need to plan carefully for downtime, assess compatibility with current infrastructure, and guarantee compliance with safety regulations.

How Does Humidity Affect Data Center Grounding System Performance?

You'll find that humidity substantially impacts your grounding system. High humidity causes corrosion and shorts, while low humidity increases static electricity risks. Follow ASHRAE's guidelines (20-80% RH) to maintain ideal grounding performance.

What Grounding Considerations Are Needed for Modular or Containerized Data Centers?

You'll need external ground rods, isolated neutrals, frame grounds between racks, and a copper bus bar system. Don't forget to implement a ground halo and guarantee all connections meet local electrical codes.

In Summary

You've now learned the top 5 grounding methods used in modern data centers. Whether you're implementing a master ground bus bar system or utilizing signal reference grid integration, proper cabinet grounding remains critical for protecting your equipment and ensuring reliable operations. Choose the method that best fits your facility's needs, and don't forget to regularly test and maintain your grounding system for peak performance.

Leave a Reply