Smart foam storage solutions protect your electronic components while maximizing organization. You'll find custom anti-static foam trays that prevent ESD damage, temperature-controlled packaging systems for sensitive parts, and modular organizer kits that stack efficiently. ESD-safe component storage boxes feature precision-cut inserts for secure component placement, while protective transport cases shield devices during shipping. Conductive foam workstation layouts enhance workflow efficiency, and specialized electronic storage inserts offer perfect component fits. These innovative solutions combine practicality with essential ESD protection, ensuring your valuable components stay safe and organized. Discover how each solution can transform your electronic storage strategy.

Custom Anti-Static Foam Trays

Static electricity poses a significant threat to sensitive electronic components during storage and transportation. To combat this risk, you'll find custom anti-static foam trays offering thorough protection through various specialized materials like anti-static pink polyethylene and conductive polyethylene.

You can choose from several types of foam trays based on your specific needs. Anti-static trays provide basic protection for electronic parts, while conductive foam trays offer full shielding against static discharge. The foam's resistivity range 10^3-10^10 Ohms ensures reliable static control performance. If you're working in a production environment, static dissipative trays allow charges to disperse gradually, preventing sudden shocks that could damage components.

These trays aren't just protective – they're practical. You'll appreciate their reusability and stackable design, fitting standard boxes and bins while reducing long-term packaging costs.

The materials resist chemical corrosion and won't damage your electronic devices or packing materials. When you need specific dimensions or densities, manufacturers can customize trays to your exact requirements.

Whether you're packaging computer chips, storing sensitive equipment, or transporting electronic components, you'll find these trays provide excellent cushioning and shock absorption while meeting essential ESD protection standards.

ESD-Safe Component Storage Kits

When you're selecting ESD-safe component storage kits, you'll need to think about foam materials that meet strict static protection standards like ANSI ESD-S20.20 and EN 61340-5-1.

Your choice of conductive polystyrene foam guarantees reliable protection against electrostatic discharge while safely housing your sensitive electronic components. The spring-loaded hinges ensure easy access and secure closure of storage compartments.

The kit's compatibility with various component sizes allows you to store everything from tiny surface-mount devices to larger integrated circuits in properly sized compartments.

Foam Kit Material Selection

Anyone working with sensitive electronic components knows the critical importance of proper ESD-safe storage materials. When selecting foam materials for your component storage kits, you'll need to evaluate several proven options that offer reliable ESD protection.

Conductive polyurethane foam stands out as a top choice, providing excellent ESD protection while cushioning your delicate electronics. The soft foam material naturally conforms to protect components of various shapes and sizes.

If you're looking for consistent surface resistivity, anti-static polyethylene foam offers various thickness options to suit your specific needs.

For component storage and shipping requirements, EVA foam trays deliver reliable performance, while EPE foam combines electrostatic dissipative properties with superior shock absorption.

You'll want to guarantee your chosen foam material meets industry standards for electrostatic discharge protection, particularly if you're working in cleanroom environments or the semiconductor industry.

Evaluate the material's reusability factor, as this can lead to significant cost savings over time. Many foam options are recyclable, making them environmentally responsible choices for your storage needs.

Remember that proper material selection isn't just about protection – it's an investment that prevents costly component damage while extending the lifespan of your electronic parts.

Component Size Compatibility

ESD-safe storage kits' precise sizing guarantees maximum organization and space utilization in your facility. The SM0810 cabinet system accommodates four distinct box sizes, letting you customize your storage based on component dimensions.

| Size Category | Dimensions | Boxes per Cabinet |

|---|---|---|

| Small | 16x12x15mm | 144 boxes |

| Medium | 37x12x15mm | 72 boxes |

| Large | 40x37x15mm | 36 boxes |

| Extra Large | 68x57x15mm | 16 boxes |

You'll find these storage solutions particularly effective for engineering labs and component handling. The boxes feature volume-loaded conductive polystyrene construction with spring-loaded hinges, and you can choose between conductive black or clear metalized lids. They're designed to meet ANSI ESD-S20.20 and EN 61340-5-1 standards, with a surface resistivity of 10² to 10⁵ ohms/sq. cm.

The interlocking modular design enables you to stack and organize boxes efficiently within the six-drawer cabinet system. The 265 x 355 mm cabinet footprint provides a compact storage solution while maximizing component organization capacity. You'll appreciate the compatibility with SM0880 and SM0870 series SMD boxes, making it ideal for kitting and in-process handling. The boxes operate reliably in temperatures from -10°C to +70°C, and they're fully recyclable when they reach end-of-life.

Static Protection Standards

Proper ESD protection standards form the cornerstone of reliable component storage in modern electronics facilities. When you're selecting foam storage solutions, you'll need to guarantee they comply with key standards like ANSI/ESD S20.20, IEC 61340-5-1, and JEDEC JESD625B. These standards establish the requirements for protecting your sensitive electronic components from potentially damaging electrostatic discharge. The standard provides compliance verification plans to ensure storage solutions maintain their protective properties over time.

Your storage solutions must incorporate static dissipative materials that effectively shield components while preventing charge buildup. You'll want to verify that your foam storage kits meet the grounding and bonding requirements outlined in the standards, guaranteeing all conductive elements are properly connected to a common ground point.

When you're storing components in an Electrostatic Protected Area (EPA), your foam solutions should integrate seamlessly with other ESD control measures.

Don't forget to check that your storage solutions feature appropriate ESD warning labels and markings. This helps prevent mishandling and guarantees compliance with industry standards.

If you're working with military or aerospace components, you'll also need to confirm that your storage solutions meet additional requirements specified in standards like MIL-STD-1686.

Temperature-Controlled Foam Packaging Systems

Your temperature-controlled foam packaging needs both heat-resistant design features and thermal insulation layering to protect sensitive electronics effectively.

You'll find expanded polystyrene (EPS) and polyurethane (PU) foam working together in multi-layer configurations to create reliable thermal barriers against temperature fluctuations.

The system's design incorporates prompt engineering assessments to determine optimal cushioning requirements based on your specific storage conditions.

Heat-Resistant Design Features

Modern temperature-controlled foam packaging systems represent a critical advancement in storage solutions, combining sophisticated heat-resistant properties with practical design features. You'll find these systems particularly effective due to their temperature stability and customizable nature, guaranteeing your electronic components remain protected in varying conditions.

When you're selecting heat-resistant foam solutions, you'll need to evaluate both polyurethane and polyethylene options, as they offer superior insulation properties. These materials provide consistent temperature control while maintaining structural integrity over time. The incorporation of anti-static foam materials helps prevent potential damage from electrostatic discharge during handling and storage.

| Feature | Benefit |

|---|---|

| Low Thermal Conductivity | Maintains stable internal temperature |

| Variable Density | Allows customization for specific needs |

| Moisture Resistance | Prevents humidity-related damage |

| Flexible Design | Enables precise component fitting |

| Durable Construction | Guarantees long-term reliability |

You'll appreciate how these design features work together to create an efficient packaging system. The foam's ability to resist temperature fluctuations while providing customizable protection makes it ideal for electronic components. Whether you're shipping sensitive electronics or storing aerospace parts, you'll find that these heat-resistant features substantially reduce the risk of thermal damage while extending your products' lifespan.

Thermal Insulation Layering Systems

Building on these heat-resistant properties, advanced thermal insulation layering systems take foam packaging to the next level of temperature control.

You'll find that combining different insulation materials, like Vacuum Insulation Panels (VIPs) and Phase Change Materials (PCMs), creates a superior thermal barrier for your electronic components.

When you're designing temperature-controlled packaging, you'll want to think about Temprecision® Foam, which efficiently absorbs phase-change materials while maintaining its shape. This foam can be customized to fit your specific packaging requirements, offering the best payload volume and consistent thermal resistance. The inclusion of ultra-low conductivity materials, like those found in GORE thermal insulation, significantly enhances the foam's insulating capabilities.

You can enhance the system's performance by incorporating aerogel layers, which provide exceptional insulation due to their nanostructure.

For maximum effectiveness, you'll need to carefully layer your materials. The Layered Composite Insulation (LCI) technology offers higher R-values than traditional MLI and foam products alone.

You can tailor the thickness and material selection based on your temperature control needs. Whether you're protecting sensitive electronics during transit or storage, these advanced layering systems guarantee reliable temperature management through the combination of high-performance materials like VIPs, PCMs, and specialized foams.

Modular Foam Organizer Solutions

Designed for maximum efficiency and protection, modular foam organizer solutions transform cluttered storage spaces into well-ordered systems. You'll find these customizable solutions offer precise fitting for your electronic components while protecting them from impact, vibration, and static electricity.

When you implement modular foam organizers, you're investing in a time-saving system that lets you quickly locate and retrieve components. The adaptable design means you can organize items by type, size, or usage frequency, considerably reducing search time and preventing loss.

You'll appreciate how these solutions maximize your available space through efficient compartmentalization and stackable configurations.

You can choose from various applications, including custom foam trays, shadow boards, and drawer inserts. Whether you need wall-mounted organizers or stackable containers, you'll find options that fit your specific requirements.

When selecting your foam solution, you'll want to take into account material types like polyurethane or EVA based on your components' needs.

To get the most value, make certain your chosen system complies with industry standards and integrates seamlessly with your existing storage infrastructure. You'll find these modular solutions particularly cost-effective when factoring in the long-term benefits of component protection and improved workflow efficiency.

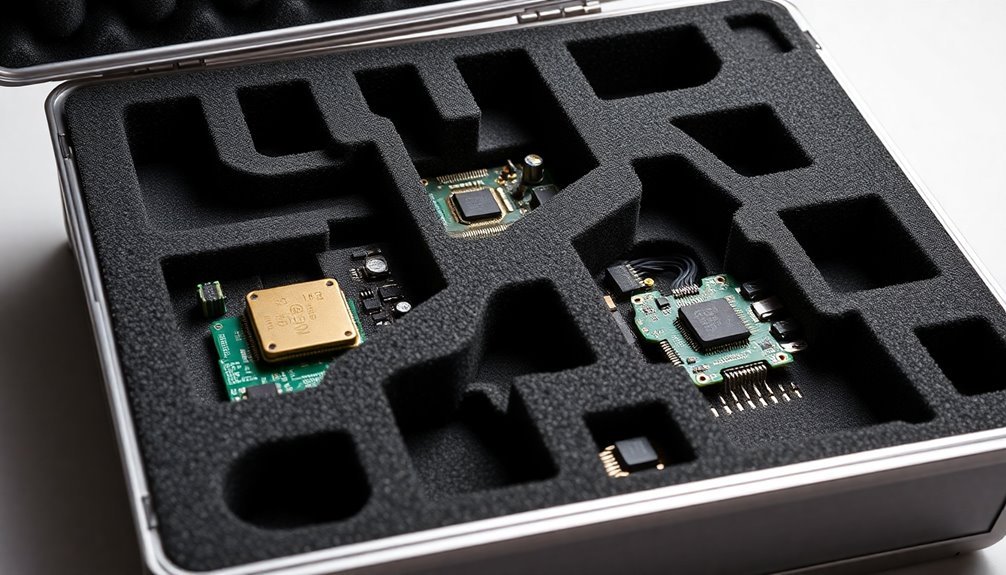

Protective Transport Foam Cases

When moving sensitive components between locations, protective transport foam cases provide an unmatched level of security and organization.

You'll find these cases feature customizable foam interiors that absorb shocks and vibrations, while anti-static materials protect against harmful electrostatic discharge that could damage your electronics.

You can choose from various foam materials to match your specific needs. Polyethylene foam offers excellent anti-static properties, while polyurethane and EVA foam deliver superior shock absorption.

The hard shell construction, typically made from durable plastics or aluminum, adds an extra layer of protection against impacts.

You'll find these protective solutions across multiple industries. Whether you're transporting medical equipment, broadcast gear, or industrial components, you can get custom-designed foam inserts tailored to your exact specifications.

The quick response manufacturing process lets you rapidly obtain prototypes and final products that perfectly fit your equipment.

For enhanced protection, you can opt for advanced features like climate control systems and specialized exterior finishes. Many manufacturers now offer environmentally responsible materials, ensuring your transport solution doesn't just protect your equipment but also considers environmental impact.

Precision-Cut Electronic Storage Inserts

Through advanced precision engineering, electronic storage inserts offer unparalleled protection for your sensitive components. These custom-designed foam solutions, made from high-density materials like EVA, polyurethane, and polyethylene, guarantee your electronics remain secure and protected from impact, vibration, and static electricity.

You'll find these precision-cut inserts particularly valuable for professional storage and transportation needs. They're manufactured using state-of-the-art cutting technology to create perfectly sized compartments that hold your components snugly in place.

The anti-static properties of specific foam materials add an extra layer of protection, preventing damage from electrical discharge.

- Store multiple components efficiently with custom-designed layouts that maximize your space usage while maintaining professional organization

- Protect your investment with high-density foam that absorbs shocks during transport and prevents movement-related damage

- Track your inventory more effectively with clearly defined compartments that make component identification quick and simple

Whether you're managing a warehouse, running a repair shop, or shipping sensitive electronics, these precision-cut inserts provide the perfect blend of protection and organization. They'll help reduce damage risks while maintaining your components in pristine condition.

Conductive Foam Workstation Layouts

Modern workstations demand robust protection against electrostatic discharge, and conductive foam layouts provide the perfect foundation for your ESD-safe workspace. When designing your workstation, you'll want to focus on materials that effectively dissipate charges while maintaining ideal organization for your tools and components.

You can customize your layout using conductive foam with surface resistivity ranging from 10^2 to 10^5 ohms/sq, ensuring thorough static protection across your workspace.

Consider incorporating shadow trays and foam boards that you can precisely cut to fit your specific tools and electronic components. These solutions don't just protect your equipment – they'll also improve your workflow efficiency and comply with ESD and 5S programs.

For your component storage needs, you'll find that custom-fit foam inserts provide excellent protection while keeping items organized and easily accessible.

The foam's X, Y, and Z-axis conductivity offers complete shielding for sensitive electronics, particularly in areas handling microprocessors.

When selecting materials, opt for conductive crosslink high-density polyethylene foams for blocking and bracing, or memory foam for more delicate components requiring additional shock protection.

Frequently Asked Questions

How Long Does Smart Foam Storage Typically Last Before Needing Replacement?

You'll need to replace your smart foam storage every 6-12 months under ideal conditions (40-80% humidity, 40-90°F). However, if you notice degradation, discoloration, or changes in texture, replace it immediately.

Can Smart Foam Solutions Be Cleaned Without Compromising Their Protective Properties?

You can safely clean smart foam using compressed air or mild detergents. Just avoid harsh chemicals and guarantee complete drying. Following manufacturer guidelines helps maintain protective properties while keeping surfaces debris-free.

What Certifications Should I Look for When Purchasing Esd-Safe Foam Storage?

You'll want foam that meets ANSI/ESD STM11.11 for surface resistance and ANSI/ESD S541 for packaging standards. Look for MIL-STD 3010 certification for durability, and ASTM F1249 for vapor transmission testing.

Are There Recycling Options Available for Used Electronic Component Foam?

Yes, you can recycle your used foam through Foam Cycle systems at local drop-off centers. They'll process EPS into new products, while specialized facilities can handle chemical recycling for more complex electronic-grade foams.

Can Smart Foam Storage Be Safely Used in Extreme Humidity Conditions?

You shouldn't rely solely on smart foam in extreme humidity conditions. It won't protect against moisture damage. You'll need to combine it with dry storage cabinets or desiccants for proper component protection.

In Summary

You'll find these foam storage solutions essential for protecting and organizing your electronic components. Whether you're working with sensitive ICs or bulky circuit boards, there's a foam solution that fits your needs. Invest in the right storage system to prevent ESD damage, maintain inventory control, and streamline your workspace. Your components deserve proper protection, and these solutions deliver professional-grade security and accessibility.

Leave a Reply