You'll need different conductive foam protection grades because each grade serves a specific purpose in safeguarding your electronic components. Low-density foam works best for lightweight transit packaging, while high-density foam excels at securing legged components with better compression resistance. Component grade foam protects larger items like circuit boards, and lead-insertion grade specifically handles mounted components. Your choice depends on factors like the item's weight, fragility, and static protection requirements. The right grade guarantees the best ESD protection, physical cushioning, and long-term performance – key factors that can make or break your component's safety.

Understanding Conductive Foam Basics

Four key aspects define conductive foam's fundamental nature: its specialized composition, electrical properties, versatile applications, and varying types. You'll find this material is primarily made from polyethylene infused with carbon or polyurethane foam plated with copper and nickel. These components work together to create permanent conductive performance that won't degrade over time. This protection acts as a Faraday cage effect, eliminating any need for additional static shielding bags.

When you're working with conductive foam, you can expect surface and volume resistivity measurements of less than 10^4 ohms, delivering reliable EMI shielding and effective static charge transfer to grounding sources. You won't need to worry about humidity affecting its performance, and you'll benefit from its superior dust-sealing capabilities.

You can choose between low-density and high-density variations to match your specific needs. If you're packaging for transit, you'll want the softer, more flexible low-density foam. For securing legged components, you'll find high-density, semi-rigid foam more suitable.

The material excels in protecting highly sensitive electronic products, offering both cushioning and static protection. You can use it repeatedly for multi-trip packaging, and it's easily customizable to fit your exact size requirements.

Types of Protection Grades

Conductive foam's protection grades fall into four distinct categories, each engineered for specific applications.

Low-density conductive foam serves as your go-to choice for general protection, offering both mechanical and electrical safeguards for static-sensitive devices. Its density of 1.7-1.9 lbs./ft³ makes it perfect for cushioning delicate components. It's soft, flexible, and meets essential standards like TS10218 and IEC-61340-5-1.

When you're working with components that have leads or pins, high-density conductive foam is your best option. It's semi-rigid and specifically designed to prevent potential differences between component pins. You'll find it particularly useful when inserting legged components directly into the foam.

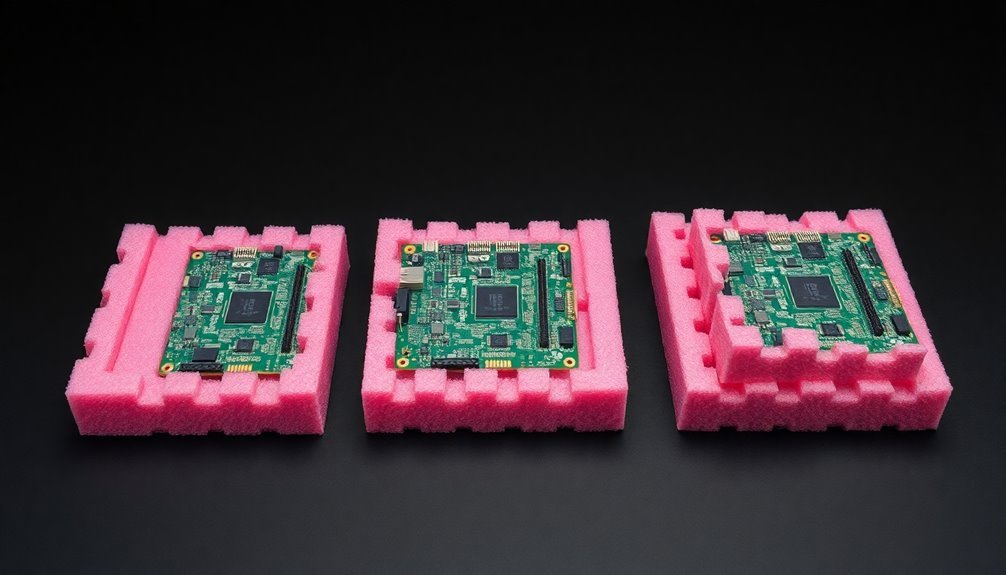

Component grade foam provides thorough protection for larger items like circuit boards and hard drives. You'll benefit from its Faraday cage effect when fully enclosing items, which can eliminate the need for additional static shielding bags.

For specialized lead insertion applications, you'll want to use lead-insertion grade foam. It's specifically engineered to mount components via their leads while maintaining superior ESD protection. This grade offers permanent conductive performance that won't be affected by atmospheric conditions, making it ideal for both in-plant handling and multi-trip packaging scenarios.

Density Impact on Performance

The density of protective foam plays a significant role in determining its performance characteristics. When you're selecting conductive foam for your electronic components, you'll find that higher density materials offer superior compression resistance and load-bearing capacity, which is essential for protecting heavier or fragile items. Support factors of 2.0 or higher indicate excellent weight-bearing capabilities for demanding applications.

These denser foams effectively absorb energy and disperse shock, reducing the risk of damage during transit or handling.

You'll need to take into account that higher density foams provide better thermal insulation and maintain their protective properties over time. However, it's important not to over-protect, as this can unnecessarily increase your shipping costs and weight.

If you're packaging lightweight or delicate components, lower density foams might be more suitable, offering softer cushioning while maintaining adequate protection.

For static-sensitive components, you'll find that density affects the foam's conductivity performance. Low-density conductive foams work well for general transit packaging, while high-density options are better suited for specific applications like inserting legged components.

The key is to match the foam's density to your specific application needs, considering factors like product weight, fragility, and static protection requirements.

Material Selection Criteria

Selecting appropriate conductive foam material requires careful evaluation of several key properties, including surface resistivity, volume resistivity, and structural integrity. You'll want to look for surface resistivity below 10^4 ohms/sq. and volume resistivity under 10^4 ohms/cms if you're seeking highly conductive protection. For extremely fragile electronics requiring 15-25 g's protection level, use precision foam cushioning.

When choosing your foam grade, consider your specific application needs. If you're handling components with legs or pins, you'll need high-density conductive foam for ideal protection without compromising structural integrity.

For multi-trip packaging or in-plant handling, low-density options will serve you better.

You'll also need to decide between conductive, anti-static, or static dissipative foam based on your protection requirements. Conductive foam offers direct charge transfer through its carbon-enhanced structure, while anti-static foam relies on atmospheric moisture for conductivity.

If you need permanent ESD protection that won't degrade under varying atmospheric conditions, opt for conductive foam.

Consider customization options like die-cutting, CNC routing, or water jet cutting to match your specific packaging needs.

The foam's ability to act as a Faraday cage when fully enclosing items provides additional protection for highly sensitive components.

Cost Versus Protection Benefits

Weighing cost against protection benefits requires careful analysis of your ESD protection needs and budget constraints. While conductive foam typically costs more due to its carbon content, it offers superior long-term value, especially for multi-trip packaging applications. Breaking down features helps evaluate the cost-benefit ratio more effectively.

Component sensitivity largely determines your required protection level, directly impacting your foam selection and costs. When you're handling highly sensitive electronics, you can't compromise on protection – you'll need conductive foam despite its higher cost, as it provides permanent ESD protection with rapid static charge transfer.

For less sensitive components, you might opt for more economical anti-static or static-dissipative foams, which still offer adequate protection within their specified resistance ranges.

Consider your specific application needs carefully. If you're dealing with high-humidity environments, conductive foam's performance remains stable, potentially saving you from costly component damage.

While customization adds to initial costs, it can prove cost-effective by providing ideal protection for your specific components. You'll also need to factor in durability – higher-grade conductive foams often last longer, spreading the cost over multiple uses and potentially reducing your long-term packaging expenses.

Frequently Asked Questions

Can Conductive Foam Be Recycled or Disposed of Safely?

You can safely dispose of conductive foam in landfills, but recycling options are limited. New methods using zirconium-based catalysts show promise for reprocessing the foam while maintaining its properties, though these aren't widely available yet.

How Often Should Conductive Foam Packaging Be Replaced for Optimal Protection?

You'll need to replace your conductive foam packaging annually, or sooner if it's frequently handled. Test the material's ESD properties after one year and inspect regularly for signs of wear or degradation.

Does Humidity Affect the Conductivity Performance of the Foam?

You don't need to worry about humidity affecting your foam's conductivity. While moisture can temporarily change the foam's mechanical properties like hardness, it won't impact its ability to protect against electrostatic discharge.

Can Conductive Foam Leave Residue on Components After Prolonged Contact?

Yes, your conductive foam can leave residue on components during prolonged contact. You'll notice this risk increases with pressure, humidity, and extended storage time. It's best to minimize direct long-term contact.

Is It Safe to Stack Multiple Layers of Conductive Foam?

Yes, you can safely stack conductive foam layers. It'll maintain its ESD protection and shock absorption properties. However, you should monitor pressure on lower layers to prevent potential structural compromise over time.

In Summary

You'll need to match your conductive foam protection grade to your specific ESD-sensitive components and handling requirements. Don't underestimate the importance of choosing the right density and material type – it's essential for both protection and cost-effectiveness. By understanding your needs and evaluating the protection benefits against your budget, you can select the best foam grade that'll safeguard your electronics while maintaining operational efficiency.

Leave a Reply