Electronic components most vulnerable to electrostatic discharge (ESD) include your integrated circuits, transistors, and microprocessors. You'll need to protect sensitive components like USB ports, LAN interfaces, and other I/O terminals that can be damaged by static electricity. High-speed data lines operating up to 5 Gbps are particularly at risk, along with memory chips and logic devices. Don't forget about semiconductor devices, which can suffer both immediate and hidden damage from ESD events. Using proper protection methods like TVS diodes, anti-static packaging, and grounding equipment will help safeguard these critical components. There's much more to explore about keeping your electronics safe from ESD damage.

Understanding ESD Basics

Many electronic devices can be instantly destroyed by a single electrostatic discharge (ESD) event. When you touch an electronic device or bring a charged object near it, you can unknowingly release static electricity that's built up in your body, sometimes reaching several thousand volts.

This discharge can enter through USB ports, buttons, or other external interfaces, potentially damaging or destroying sensitive integrated circuits inside. The most common cause of ESD damage comes from internal and external surges that exceed the permissible voltage ranges of components.

ESD is particularly devastating to electronic components because the discharge phenomenon occurs when static electricity jumps between conductive objects. Your body naturally generates static electricity through everyday movements, making you a potential source of ESD damage. That's why you need to understand that protection isn't optional – it's vital for preserving electronic equipment.

To combat ESD risks, you'll need various protection devices like TVS diodes, suppressors, varistors, and arresters. These components work by redirecting harmful voltage surges to ground before they can damage sensitive circuits.

When you're handling electronic components, you should always use proper protection tools, including antistatic mats, grounding plugs, and ESD wrist straps, to prevent accidental discharge events.

Semiconductor Device Protection

To protect semiconductor devices from gate oxide breakdown, you'll need to implement voltage clamping diodes and proper ESD protection circuits that limit voltage stress across the sensitive oxide layers.

Snubber circuits can be integrated to suppress harmful voltage transients and spikes that could damage the device.

You can further safeguard junction areas by using multi-faceted protection strategies, including current-limiting resistors and thermal sensors that monitor device temperature.

Cascode configured output drivers and proper grounding techniques work together to reduce hot carrier generation and protect both the gate oxide and junction regions from damage.

Gate Oxide Breakdown Prevention

Like a fragile glass shield, gate oxide layers in modern semiconductor devices require careful protection against electrical breakdown. Modern devices with gate oxides below 100 Å are particularly vulnerable, as their reduced thickness makes them susceptible to various breakdown mechanisms and increased leakage currents. Hard breakdown events create permanent conductive paths that can render devices inoperable.

To protect your devices from gate oxide breakdown, you'll need to implement specific protection schemes. Gated diodes are more effective than conventional junction diodes, as they provide reduced breakdown voltage and create preferred leakage paths to the substrate.

You'll find that N+/P gated diodes are particularly useful, as they can protect both NMOS and PMOS devices effectively.

You must also consider proper handling practices to prevent electrostatic discharge damage. Internal protection circuits are essential, as they'll absorb ESD energy and safeguard internal components.

When testing your devices, you'll need to carefully select screening voltages to avoid negative threshold voltage shifts. Keep in mind that both direct tunneling and Fowler-Nordheim tunneling can occur under high electric fields, leading to oxide wearout and eventual breakdown.

Regular standardized testing will help guarantee your devices maintain their reliability against ESD events.

Junction Protection Methods

Semiconductor junctions require robust protection methods to prevent damage from voltage surges and electrostatic discharge.

Metal-semiconductor junctions utilize Schottky barriers for rectification and ohmic contacts for non-rectification, with the barrier height determining their protective behavior. In high-speed applications, Schottky diodes are particularly effective due to their fast switching capabilities. Low voltage systems up to 1000V AC or 1200V DC require special consideration for proper protection.

When it comes to diode configurations, you can use avalanche breakdown diodes for surge protection in both directions, while unidirectional diodes work best for DC power supplies. TVS diodes offer secondary protection with quick response times and low clamping voltages that effectively safeguard your circuits.

For thorough protection, you'll want to evaluate ceramic gas discharge tubes for lightning protection and thyristor-based semiconductor discharge tubes for overvoltage scenarios.

Varistors are essential for protecting against ESD in power supply and control lines. In integrated circuits, you can implement cascode protection circuits that combine MOS devices and bipolar transistors to shunt stress currents.

These protection methods, along with local voltage clamps and CDM current resistors, work together to prevent gate oxide damage and protect your device's internal components.

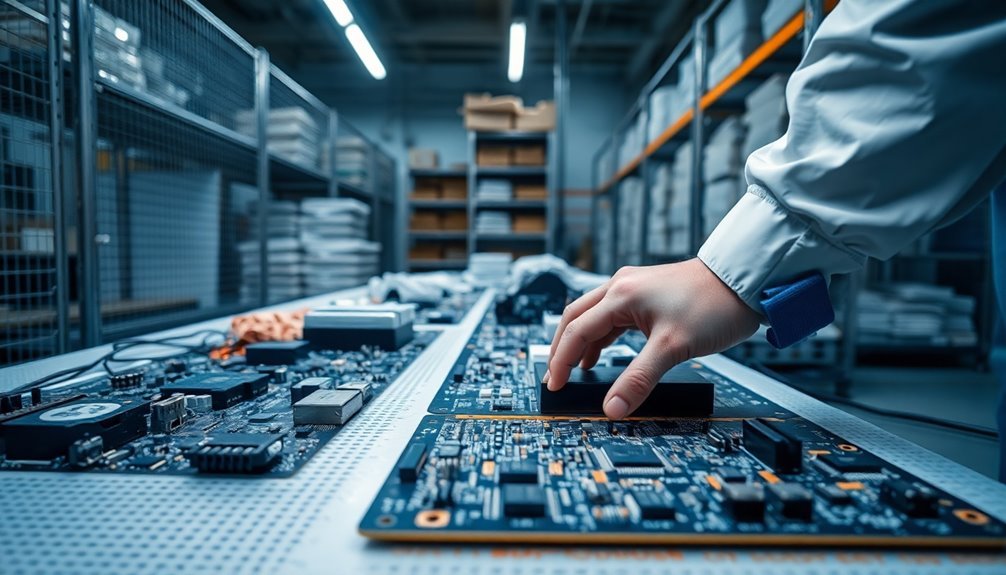

PCB Handling Guidelines

You'll need to keep your work area and hands meticulously clean when handling printed circuit boards to prevent contamination and damage.

Your workspace must include proper grounding equipment, including anti-static mats and wrist straps, to safely discharge any static electricity before touching sensitive components.

Using these essential protective measures, you're creating a safe environment that substantially reduces the risk of electrostatic discharge damage to your PCBs. This is especially critical since device-level ESD can be particularly harmful to semiconductor components.

Clean Hands, Clean Workspace

Maintaining a clean workspace is critical when handling printed circuit boards (PCBs) to prevent damage from electrostatic discharge (ESD) and contamination. You'll need to establish an ESD-controlled environment with static-dissipative surfaces and proper grounding equipment.

Keep your workspace free from carpets, rugs, paper, and fabrics that can generate static electricity. Maintaining the temperature between 15°C to 30°C helps ensure optimal storage conditions.

When you're handling PCBs, always use proper ESD protection and follow these essential guidelines:

- Wear ESD-safe gloves and replace them regularly to prevent static buildup – always handle boards by their edges to avoid touching sensitive components.

- Ground yourself using a wrist strap or mat before touching any PCBs, and maintain humidity levels between 20% and 80% non-condensing.

- Store PCBs in ESD-shielded bags or containers with desiccants and humidity indicator cards when they're not in use.

- Keep your tools ESD-safe and properly grounded, avoiding any contact with static-generating materials like plastic binders or cardboard.

You'll want to minimize the time PCBs are exposed to air and maintain a controlled environment. For storage, use ESD-free racks and include rigid protective backing for thin or irregularly shaped boards to prevent mechanical damage.

Proper Grounding Equipment Required

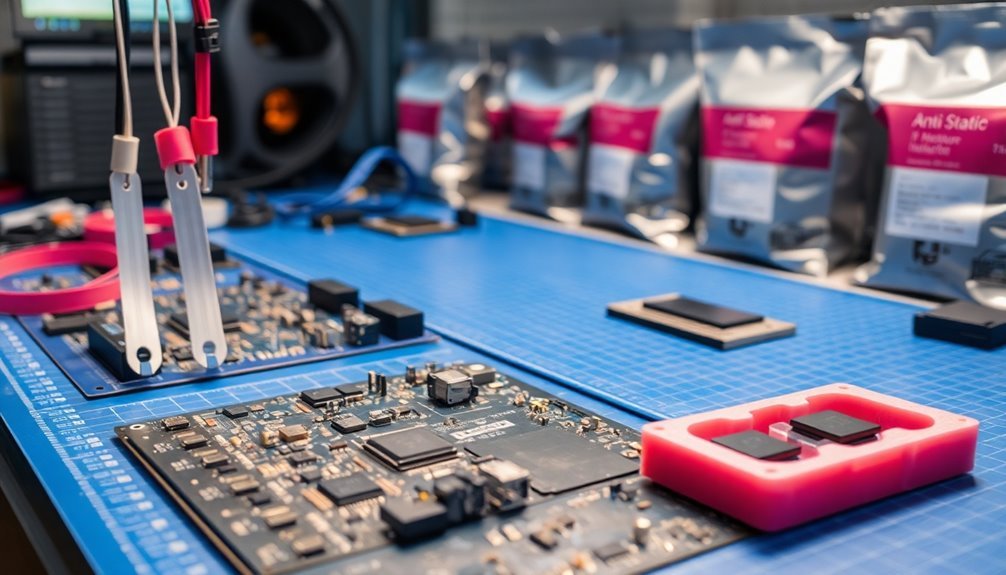

Three essential pieces of grounding equipment are required for safe PCB handling: a grounded workbench or table, static dissipative mats, and wrist straps. You'll need to guarantee each piece provides a low-resistance path to ground and maintains proper electrical conductivity.

Your workbench should include a grounding plate that creates a common point for connecting multiple components. Single-point grounding helps prevent unwanted ground loops from forming.

When you're setting up your workspace, you'll need both table and floor mats for complete static control. Don't forget that your relative humidity must stay between 20% and 80% non-condensing to prevent static buildup.

You'll also need to wear a properly connected wrist strap whenever you handle ESD-sensitive components.

For additional protection, you should incorporate ground planes in your PCB design to bypass ESD effectively. You'll want to maintain proper spacing between traces carrying different voltages and run ground tracks around the board's periphery when possible.

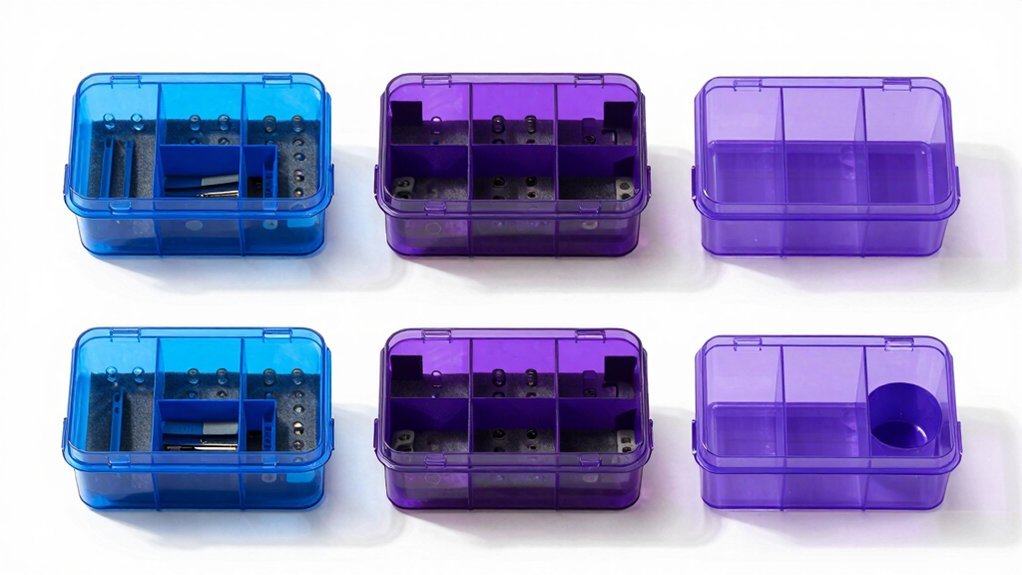

If you're transporting circuit boards, place them in static shielding bags or clamshells – but don't use bags that are torn or punctured. Remember, you shouldn't remove sensitive components from their protective packaging until you've properly grounded yourself and your equipment.

Critical Electronic Components

In accordance with modern electronics design, critical electronic components require robust ESD protection to prevent costly damage and system failures. Sensitive components like USB ports, LAN interfaces, and various I/O terminals are particularly vulnerable to static electricity damage, which can occur through routine handling or operation. Static discharge events can generate several thousand volts through human contact alone.

To effectively protect your electronic components, you'll need to implement multiple layers of protection:

- Install TVS diodes and varistors at critical connection points to suppress transient voltage spikes that could damage your system's ICs.

- Use proper grounding equipment, including wrist straps and ESD mats, whenever you're handling sensitive components.

- Set up designated electrostatic protected areas for component handling and maintenance work.

- Employ ESD-safe tools and equipment during installation and repair procedures.

The protection of these components isn't just about preventing immediate failure – it's about ensuring long-term reliability and protecting your investment.

You'll need to pay special attention to high-speed data lines up to 5 Gbps, where ESD protection components must be carefully selected to maintain signal integrity while providing adequate protection against static discharge events.

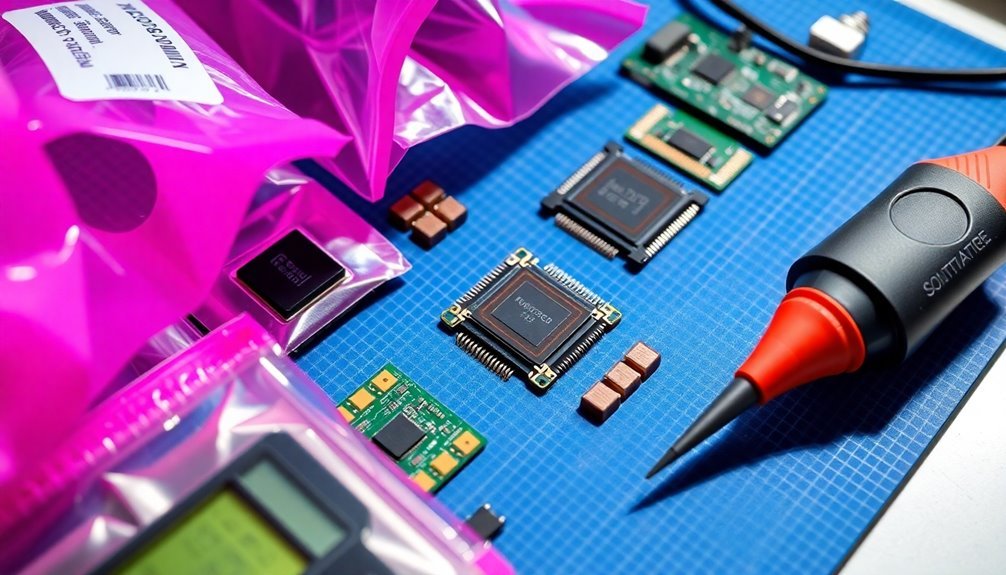

Static Control Packaging Methods

Static control packaging methods serve as your first line of defense against ESD damage during component transport and storage. You'll need to choose from several types of protective packaging, including conductive, dissipative, shielding, and anti-static materials, each designed for specific protection needs.

When you're implementing static control packaging, start by identifying your most ESD-sensitive components. You'll want to use conductive packaging to quickly channel static charges away from sensitive parts, while dissipative packaging will help you slow down charge movement in a controlled manner.

For maximum protection, you can opt for shielding materials that create a protective barrier against discharge.

You'll find various material options at your disposal, including specially treated polythene films, coated cardboard, and protective foams. If you're dealing with blister packaging or horizontal pouch filling, you'll need to pay special attention to static control, as these processes can generate significant charges.

Don't forget to establish proper grounding procedures and maintain designated ESD-protected areas in your facility. When you're handling components, make sure you're using appropriate anti-static materials and following documented ESD control procedures.

Grounding Equipment and Tools

Properly grounding your equipment and tools serves as a fundamental requirement for effective ESD protection. You'll need to guarantee all grounding points maintain a resistance of less than 10 Ohms to effectively channel static charges away from sensitive components.

When setting up your workspace, connect your grounding equipment through an Earth bonded plug inserted into a standard socket, and regularly monitor the connection to verify proper grounding.

To protect your electronic components effectively, you'll need these essential grounding tools:

- ESD wrist straps that maintain constant skin contact and connect to a grounded outlet, guaranteeing you're safely discharged while handling components.

- Anti-static mats made of conductive materials that provide a safe work surface and connect directly to your grounding system.

- Anti-static gloves that prevent static transfer from your hands to sensitive electronic parts during assembly or maintenance.

- Earth bonding points that connect all your equipment to a verified ground, creating a thorough protection system.

Remember not to use grounding straps when working with high-voltage equipment, as this can create a safety hazard. Instead, rely on properly insulated tools designed specifically for high-voltage work.

Environmental Control Measures

You'll need robust humidity management systems to maintain ideal moisture levels between 30-70% relative humidity in your ESD-protected areas.

Your facility should include ionization equipment to neutralize static charges in the air and on non-conductive materials.

Proper air control through filtered ventilation systems will help remove dust particles and maintain consistent atmospheric conditions throughout your workspace.

Humidity Management Systems

Managing humidity levels stands out as a critical component in protecting against electrostatic discharge (ESD) in sensitive environments. You'll find that maintaining proper humidity helps reduce static charge accumulation and prevents damage to sensitive electronic components.

Through effective humidity management systems, you're able to create a controlled environment that minimizes ESD risks while ensuring regulatory compliance.

To maintain ideal humidity levels, you'll need to implement these essential tools and practices:

- Install both humidifiers and dehumidifiers to regulate moisture levels, ensuring they're within manufacturer-specified ranges

- Set up humidity monitors throughout your facility for continuous tracking and quick response to any fluctuations

- Integrate air conditioning systems that can simultaneously control temperature and humidity levels

- Deploy air purification systems to remove dust and debris that contribute to ESD risks

You'll need to regularly maintain your humidity management equipment and keep detailed records of all readings and maintenance activities.

Don't forget to train your personnel on proper humidity management procedures and the importance of maintaining these systems. By implementing these measures, you're creating a safer environment for handling sensitive electronic components while meeting industry standards.

Ionization and Air Control

Environmental control measures like ionization and air control systems form a critical defense line against electrostatic discharge in sensitive workspaces. You'll need to implement ionizers to neutralize static charges by emitting balanced ions into the air. These devices come in various forms, including overhead, benchtop, and point-of-use ionizers, each designed for specific applications in your protected areas.

Your air filtration system plays an essential role in reducing dust particles that can contribute to static buildup. You must maintain clean air through regular filter replacement and proper air circulation. Some filters are specifically designed to reduce static charges, providing an additional layer of protection against ESD risks.

You'll also need to establish effective ventilation systems to help dissipate static charges and maintain a controlled environment. When combined with proper grounding and bonding measures, these systems create a thorough approach to ESD protection.

You should connect all conductive surfaces to a common ground and bond them together to eliminate potential differences. Remember to regularly maintain your ionizers through cleaning and calibration to guarantee they're working effectively in controlling static charges throughout your workspace.

Design Protection Strategies

When implementing electrical discharge protection, multiple design strategies work together to create a thorough defense system. You'll need to incorporate several layers of protection, starting with proper grounding methods and extending to extensive shielding solutions.

By using ESD-safe tools and maintaining a clean workspace, you're already establishing a foundation for effective protection.

To create a robust design protection strategy, you should implement these critical measures:

- Install proper grounding systems using wrist straps, conductive mats, and anti-static flooring that maintains a continuous path for static discharge

- Set up ionization equipment like blowers or bars in areas where isolated conductors can't be grounded directly

- Use appropriate shielding materials such as conductive enclosures and specialized packaging with air gaps to create effective Faraday cage protection

- Maintain humidity levels between 40-60% while using ESD-safe clothing and footwear

You'll want to guarantee your protection strategy includes both permanent solutions, like installed grounding systems, and temporary measures, such as topical antistats.

Remember that shielding bags and specialized packaging materials provide essential protection during component transportation and storage, completing your extensive protection system.

Testing and Verification Procedures

After establishing your design protection strategies, you'll need to verify their effectiveness through rigorous testing procedures. You'll primarily follow standards like IEC 61000-4-2, ISO 10605, and ANSI/ESD S20.20, which define specific test methods and requirements for different applications.

You'll need to set up your device under test (DUT) with proper grounding and connect it to an ESD simulator or ESD gun. During testing, you'll apply controlled ESD events using both contact and air discharge methods. While contact discharge is preferred, you'll use air discharge when direct contact isn't possible, typically at higher test levels up to 16 kV for commercial applications.

Monitor your DUT's performance throughout the testing process to detect any malfunctions or permanent damage. Remember that environmental factors like humidity and temperature can affect your test results, especially during air discharge testing.

You'll need to document all test results thoroughly to demonstrate compliance with relevant standards. If your device fails any tests, you'll need to identify the weakest points in your ESD protection scheme and implement necessary design improvements before retesting.

Storage and Transportation Requirements

The safekeeping of ESD-sensitive components requires thorough protection strategies for both storage and transport. You'll need to implement extensive measures using ESD-safe containers, protective packaging, and controlled environments to prevent static discharge damage.

When storing components, you must maintain dedicated ESD-protected areas with proper grounding systems and static control measures. Use low-charging, conductive materials for packaging, and guarantee your storage spaces have appropriate humidity levels between 30% and 70%.

Regular monitoring and maintenance of these areas are essential to prevent static charge accumulation.

For safe transportation, here are the critical requirements you'll need to follow:

- Package components in ESD-safe containers with static protective materials like anti-static bags and foam inserts

- Include desiccants to control moisture levels and prevent static charge build-up

- Guarantee all transportation vehicles and equipment are properly grounded

- Use clear ESD warning labels and handling instructions on all packages

You'll also need to maintain environmental controls during both storage and transport. This includes proper temperature regulation, air ionization systems, and regular cleanliness assessments to minimize static charge generation.

Train your personnel regularly in proper handling procedures to maintain ESD protection throughout the process.

Standards and Compliance Protocols

Implementing effective ESD protection requires strict adherence to established industry standards and compliance protocols. You'll need to guarantee your facility meets ANSI/ESD S20.20 certification requirements, which major OEMs like IBM and Lockheed Martin demand from their suppliers. This standard integrates seamlessly with other quality management systems like ISO 9001 and AS9100.

Your compliance plan must include thorough personnel standards, such as daily testing of wrist straps and proper use of static dissipative clothing in EPAs.

You'll need to establish clear protocols for workstation grounding, maintain humidity levels between 30% and 70%, and implement ionization systems where necessary. Your EPAs should have strict access controls and clear identification, with absolute prohibition of static-generating materials.

To maintain compliance, you must develop a verification plan that includes regular audits, inspections, and documentation of all ESD control measures. You'll need to keep records of training sessions and testing results as objective evidence.

Remember to regularly review and update your ESD control program to guarantee it remains effective and meets current standards. This continuous improvement process is vital for maintaining certification and protecting sensitive components.

Frequently Asked Questions

Can Antistatic Bags Be Reused Multiple Times for Storing Sensitive Components?

You can reuse antistatic bags multiple times, but you'll need to inspect them carefully for damage before each use. If you notice tears, holes, or excessive wrinkles, don't reuse them for sensitive components.

How Often Should ESD Protection Equipment Be Tested for Effectiveness?

You'll need to test wrist straps daily, worksurfaces quarterly, and ionizers quarterly. Don't forget to check continuous monitors semi-annually and adjust testing frequency based on your specific ESD program requirements.

Do Wireless Devices Require Different ESD Protection Than Wired Components?

Yes, you'll need different ESD protection for wireless devices versus wired ones. Your wireless components require protection against static discharge, while wired components need additional surge protection against lightning and power line transients.

What Temperature Conditions Affect the Performance of ESD Protection Materials?

You'll notice that high temperatures substantially reduce ESD protection performance, with breakdown voltages dropping up to 27% and holding voltages falling by 8.5% when temperatures rise from -75°C to 125°C.

Can Damaged ESD Protection Components Self-Repair Over Time?

No, your damaged ESD protection components won't self-repair over time. Once they're compromised, you'll need to replace them since they can't recover their protective capabilities and won't effectively guard against future ESD events.

In Summary

You'll need to protect sensitive electronic components like integrated circuits, MOSFETs, microprocessors, and memory chips from ESD damage. Don't forget to safeguard PCBs, display screens, and delicate sensors. Always use proper grounding, anti-static packaging, and handling procedures to prevent costly failures. Following industry standards and implementing protective measures in your design will guarantee your components survive from production to end-use.

Leave a Reply