You don't actually need wireless anti-static straps – they're more of a marketing gimmick than an effective ESD protection solution. While they promise convenience and mobility, wireless straps fail to meet critical ANSI/ESD safety standards and can't effectively drain static charges from your body. Testing shows they allow dangerous voltage buildups exceeding 1,000 volts, putting sensitive electronics at risk. Traditional wired straps remain the industry standard because they reliably reduce static charges to safe levels within 0.1 seconds. Understanding the real science behind ESD protection will help you make smarter choices for your electronics work.

Understanding Wireless Anti-Static Technology

The concept of wireless anti-static straps represents a significant shift from traditional tethered ESD protection methods. These devices are designed with stainless steel components and promise continuous ESD protection while offering greater freedom of movement compared to conventional wrist straps. Fast discharge times of 0.1 seconds make these straps appealing for rapid ESD protection needs.

You'll find that wireless anti-static straps claim to discharge static electricity within 0.1 seconds through their low-resistance design. The hand ring features a resistance of 10^3 ohms, while the wrist strap maintains an impedance factor of less than 50 ohms. This design is marketed as both durable and cleanroom-compatible. The strap's universal fit design ensures comfortable wear for various wrist sizes.

However, you should be aware that these wireless solutions don't meet vital ANSI/ESD S20.20 standards. Tests have shown that you can generate voltages exceeding -500 volts within 10 seconds while wearing these devices.

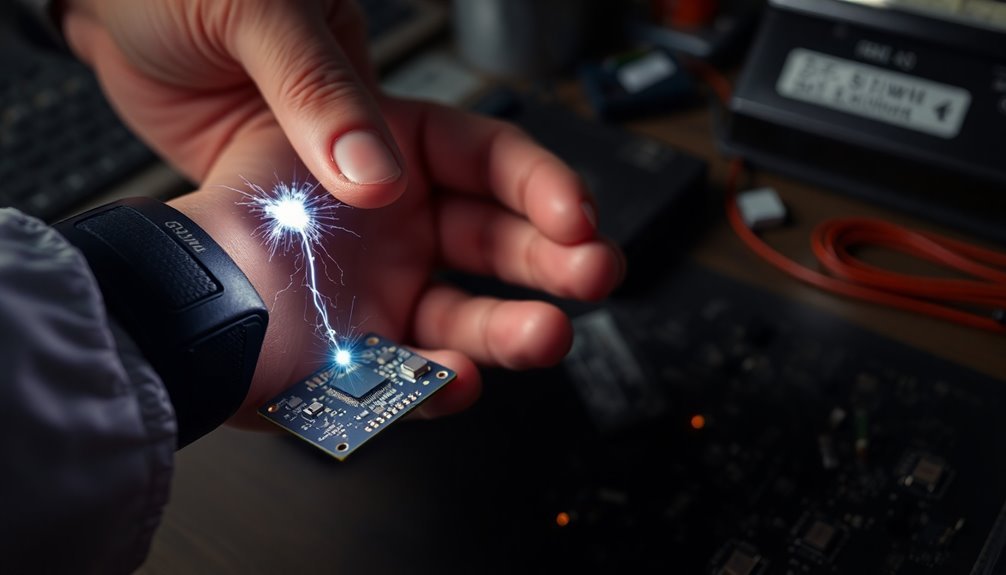

The fundamental issue lies in the physics of static electricity: you must be physically and electrically grounded to effectively drain charge from your body. Without this direct connection, the wireless straps can't prevent charge build-up or decay it at an acceptable rate for handling sensitive electronic components. This limitation makes them unsuitable for environments where strict ESD control is essential.

Traditional Vs Wireless Grounding Methods

While traditional grounding methods require a physical connection that limits mobility, wireless anti-static straps promise unrestrained movement without cords or cables. Walking tests revealed that operators using wireless straps generated voltage spikes over -100V.

Tests consistently show that wireless solutions fail to match the proven effectiveness of traditional grounding methods, with voltage build-ups often exceeding safe thresholds. Microscopic damage to components can occur from even minor static discharges that humans cannot feel.

You'll find that traditional grounding methods remain the only reliable option that meets ANSI/ESD S20.20 standards, maintaining operator resistance below 35 megohms for proper ESD protection.

Physical Connection Vs Wireless

Traditionally, anti-static protection methods have centered around two distinct approaches: physical connection straps and wireless solutions.

While physical connections use a cord and bonding plug to maintain continuous electrical grounding, wireless methods rely on built-in sensors and circuitry to detect and neutralize static charge.

You'll find that physical connections consistently meet ANSI/ESD S20.20 standards, maintaining body voltage below 100 volts and resistance under 35 megohms. They've proven reliable for over 50 years in electronics manufacturing, though they can limit your movement and require regular maintenance. The use of physical connections has prevented billions in damage to the electronics industry annually through effective static control. NASA testing demonstrates that even 25 volt discharges can cause undetectable damage to sensitive electronics.

On the other hand, wireless solutions might seem appealing with their enhanced mobility and comfort, but you shouldn't trust them for sensitive electronics handling.

They don't meet industry standards due to their lack of physical grounding, and you'll risk potential ESD events that could damage components. While they use advanced sensors and energy dissipation techniques, these wireless devices can't provide the consistent protection you need.

When you're working with sensitive electronic components, you'll want to stick with traditional physical connections despite their limitations – they're the only proven method that guarantees reliable ESD protection.

Performance Testing Results

Recent performance testing has revealed stark differences between traditional and wireless anti-static straps. When tested for charge dissipation, traditional wrist straps quickly reduce 1,000 volts to 5 volts in just 0.1 seconds, while wireless straps fail to achieve safe levels even after 5 minutes. Marketing claims mislead users about wireless strap effectiveness, despite clear empirical evidence showing their inadequacy.

You'll find that traditional wrist straps meet ANSI/ESD S20.20 standards with resistance levels below 3.5 x 10E7 ohms, providing a controlled path to ground. Daily testing showed that proper grounding enables consistent performance and reliability. In contrast, wireless straps don't comply with these standards and allow dangerous voltage buildups exceeding 1,000 volts within seconds.

The data shows you can't rely on wireless straps for ESD protection. They're unable to neutralize static electricity effectively and don't prevent charge accumulation on your body. When you're handling sensitive electronic components, this lack of protection puts your devices at significant risk.

If you're considering alternatives to traditional wrist straps, you'll want to look into ESD footwear and flooring systems instead of wireless options. These provide proven protection that meets industry standards, unlike wireless straps that consistently fail to deliver adequate ESD control.

Safety Standard Compliance

Through extensive industry testing and certification processes, traditional grounding methods consistently meet ANSI/ESD S20.20 safety standards, while wireless alternatives fail to comply with vital requirements.

If you're working with sensitive electronic components, you'll need to maintain proper physical bonding to your grounding system, as specified by industry standards.

You can't rely on wireless anti-static straps because they don't provide the direct electrical connection required for effective ESD control. Traditional methods, like corded wrist straps and grounding mats, guarantee resistance values between 10^5 and 10^8 ohms, meeting the standard's requirement of less than 35 megohms between operator and ground.

When you're handling mission-critical hardware, you'll need to follow NASA guidelines and industry regulations that specifically call for physical grounding methods. These requirements aren't arbitrary – they're based on extensive testing and real-world performance data.

While wireless alternatives might seem convenient, they don't prevent charge buildup or effectively drain accumulated static electricity. This makes them unsuitable for ESD-controlled areas where component protection is essential for safety and reliability.

Safety Concerns and Risks

While wireless anti-static straps may seem convenient, they pose significant safety risks due to their inability to properly ground operators or maintain neutral charges. You'll find that these devices fail to meet ANSI/ESD S20.20 standards and can't provide the continuous grounding connection necessary for proper ESD protection.

| Risk Factor | Consequence | Prevention |

|---|---|---|

| Ineffective Grounding | Component Damage | Use Wired Straps |

| Static Build-up | Device Failures | Maintain Ground Connection |

| High Voltage Generation | Safety Hazards | Regular Testing |

You're putting your equipment and safety at risk when using wireless straps, as static charges can still build up to dangerous levels. These charges don't just threaten your electronic components – they can ignite flammable materials and cause both immediate and latent failures in sensitive devices. Your best protection comes from using traditional wired anti-static straps connected to a verified ground point. When you're handling electronic components, you'll need continuous and reliable grounding, which wireless options simply can't provide. Instead, consider using proper wired wrist straps combined with other ESD control methods like anti-static mats and footwear to guarantee thorough protection against static discharge.

Industry Standards and Testing

Testing confirms that wireless anti-static straps fail to meet ANSI/ESD S20.20 standards, which require human body grounding of less than 100 volts.

You'll find that charge plate analyzer tests, conducted by NASA's IAWG-ESD, demonstrate these straps' inability to prevent charge buildup or drain accumulated static electricity effectively.

Industry experts, including ESDA and major manufacturers like Desco, don't endorse wireless wrist straps because they can't maintain the continuous grounding connection required by safety benchmarks.

Testing Methods and Requirements

Because electronic components are highly susceptible to static damage, industry standards have established rigorous testing protocols for anti-static equipment.

You'll need to guarantee your grounding systems meet ANSI/ESD S20.20 requirements, which specify that human body voltage must stay below 100 volts and resistance to ground can't exceed 35 megohms. Testing methods include using the Warmbier WT5000 for voltage measurements during walking or standing, and ESD test stations to evaluate wrist strap system resistance.

Regular verification of your ESD control equipment isn't optional – it's vital for maintaining an effective static control program.

You'll need to conduct periodic tests of wrist straps and other grounding devices to detect potential failures like broken wires or dirty cuffs.

Key testing requirements include:

- Measuring voltage buildup with various footwear and flooring combinations

- Testing resistance between operator and ground

- Verifying continuous connection to common point ground

- Monitoring for immediate disconnect alerts

- Conducting regular quality process audits

These testing protocols help guarantee your ESD control measures are working effectively and protecting sensitive electronic components from potentially devastating static damage.

Compliance With ANSI Standards

Nearly all electronic manufacturing facilities must comply with ANSI/ESD S20.20 standards, which establish strict requirements for ESD control programs. When you're working with ESD-sensitive components, you'll need to maintain proper grounding through physical connection to an equipotential bonding system.

| Requirement | Compliance Status |

|---|---|

| Physical Ground Connection | Wireless straps fail – no direct connection |

| Voltage Reduction (<100V) | Wireless straps fail – can't drain charge |

| Continuous Monitoring | Wireless straps can't be monitored |

| Industry Certification | Wireless straps lack certification |

You should know that wireless anti-static wrist straps don't meet these critical standards. They can't effectively drain static charge from your body since they lack physical connection to ground, potentially leaving you with hundreds or even thousands of volts of static charge. NASA and other major organizations have rejected wireless wrist straps for use in ESD-controlled areas due to their inability to meet performance requirements.

To maintain compliance, you'll need to use traditional corded wrist straps or other approved grounding methods like properly maintained footwear-flooring systems. These alternatives guarantee you're meeting ANSI/ESD standards and protecting sensitive electronic components from potential damage.

Performance Against Safety Benchmarks

Industry safety benchmarks reveal consistent failures in wireless anti-static strap performance through rigorous laboratory testing.

Tests conducted using the Warmbier WT5000 walking test instrument show that you'll generate voltages exceeding 1000 volts while wearing these devices, putting your sensitive electronics at serious risk.

NASA's engineering tests have further confirmed that wireless straps don't meet basic product qualification requirements for ESD protection.

When you're working with electronic components, you need reliable protection that meets ANSI/ESD S20.20 standards.

Unfortunately, wireless anti-static straps fail to deliver on these critical safety requirements:

- Voltage levels spike above 100 volts within seconds of use, far exceeding acceptable limits

- There's no controlled discharge path to ground, leaving static buildup unmanaged

- Walking tests consistently show operators aren't maintained at neutral charge levels

- Real-world scenarios demonstrate complete failure in static charge prevention

- Comparative testing against traditional strapped models shows markedly inferior performance

You'll find that these devices lack the fundamental ability to prevent charge build-up or effectively drain accumulated static.

Without a direct connection to a grounding circuit, they simply can't provide the protection your sensitive equipment requires in ESD-controlled environments.

Real-World Performance Results

Real-world testing of wireless anti-static straps reveals significant performance concerns that challenge their effectiveness in ESD protection. You'll find that these devices fail to meet essential industry standards, including ANSI/ESD S20.20, which requires less than 35 megohms resistance between operator and ground.

What's more concerning is that wireless straps can allow voltages to exceed -500V within seconds, putting your sensitive electronic equipment at risk.

While you'll appreciate the improved mobility and comfort these wireless straps offer, the benefits don't outweigh the technological limitations. You won't get the reliable grounding that traditional wired straps provide, as wireless technology hasn't proven effective in neutralizing static charges in real-world applications.

Even though they're designed with advanced detection mechanisms, they simply don't deliver the consistent protection you need.

You should know that compliance with international standards like IEC-61340-5-1 requires a physical connection to a grounding point, which wireless straps can't provide.

If you're working in electronics manufacturing or repair, you'll need to stick with traditional wired straps to guarantee proper ESD protection and maintain industry compliance.

Common Marketing Claims Examined

Marketing claims for wireless anti-static straps often clash up against scientific evidence and industry standards.

You'll find manufacturers touting these devices' freedom of movement and enhanced mobility, promising effective static discharge protection without the hassle of grounding cords. They'll highlight advanced mechanisms with built-in sensors and intelligent circuitry, claiming to keep you safely grounded.

The comfort and ergonomic benefits are heavily promoted, emphasizing the lightweight design and wire-free experience.

However, these marketing promises don't align with real-world performance testing or regulatory requirements. You're fundamentally paying for convenience that compromises protection.

- NASA testing confirms wireless straps fail to meet ESD control standards

- They don't maintain the required resistance to ground of less than 35 megohms

- Human body voltage exceeds the 100-volt limit specified by ANSI/ESD S20.20

- Built-in grounding mechanisms fail to prevent or dissipate static charge effectively

- Marketing focuses on comfort and mobility while downplaying protection inadequacies

When evaluating these products, you'll need to look beyond the appealing marketing claims and consider the scientific evidence that shows they're not suitable for protecting sensitive electronic components in ESD-controlled environments.

Cost-Benefit Analysis

When weighing the financial aspects of wireless anti-static straps, you'll find their higher initial costs don't justify their limited benefits. While these devices promise freedom from wired connections, you're paying a premium for technology that fails to meet essential industry standards and regulatory requirements.

You'll need to take into account both direct and indirect costs. The upfront investment is considerably higher than traditional wired straps, and you'll face ongoing expenses for battery replacements.

Though manufacturers tout the elimination of grounding equipment as a cost advantage, this supposed benefit is overshadowed by the straps' inability to maintain consistent voltage levels and proper grounding.

While you might appreciate the increased mobility and convenience these wireless straps offer, the trade-off in performance and reliability isn't worth the investment.

Traditional wired straps remain more cost-effective, providing superior ESD protection that meets industry standards. Your money is better spent on proven wired solutions that guarantee consistent grounding and compliance with regulations.

The apparent convenience of wireless technology can't compensate for its fundamental shortcomings in ESD protection and regulatory compliance.

Alternative Protection Solutions

A thorough approach to ESD protection extends beyond wireless and traditional wrist straps.

You'll find several effective alternatives that can either complement or replace wrist straps in your ESD-sensitive environment. Grounded flooring paired with specialized conductive footwear creates a continuous path to ground, though it requires significant initial investment.

For enhanced protection, you can incorporate conductive clothing and accessories made with special fibers that help dissipate static charges.

Personal grounding points mounted on workbenches provide direct grounding connections, while ESD-safe work environments offer extensive protection through anti-static furnishings and controlled humidity levels.

You'll need to maintain and regularly audit these solutions to verify their effectiveness.

- ESD flooring systems combined with conductive footwear provide continuous grounding while allowing freedom of movement

- Conductive clothing and accessories like finger cots offer additional layers of protection

- Strategically placed personal grounding points provide immediate access to ground connections

- Anti-static furnishings and humidity control systems help maintain an ESD-safe environment

- Regular testing and maintenance of these solutions guarantee consistent protection levels

These alternatives can work independently or synergistically with wrist straps, giving you flexibility in designing your ESD protection strategy.

Future of ESD Protection

Innovation in ESD protection continues to evolve, though wireless solutions have proven inadequate for meeting industry standards. If you're looking toward future developments in ESD protection, you'll find that most advancements are focusing on enhancing traditional wired solutions rather than pursuing wireless alternatives.

You can expect to see improvements in wired ESD straps that address comfort and mobility concerns while maintaining the critical direct ground connection that's essential for proper static discharge. Research is concentrating on developing more flexible, durable materials that'll make wired straps less cumbersome without compromising their ability to meet ANSI/ESD S20.20 standards.

While you might hope for a wireless breakthrough, the physics of ESD protection demands a physical ground connection. Future solutions will likely enhance this fundamental principle rather than try to work around it.

The emphasis will remain on maintaining resistance levels below 35 megohms between operator and ground, as required by industry standards. This means you'll continue to see innovations in traditional wired systems, with potential developments in advanced conductive materials and more ergonomic designs that make compliance easier while ensuring reliable static discharge protection.

Frequently Asked Questions

Can Wireless Anti-Static Straps Be Recharged or Do They Eventually Wear Out?

You shouldn't rely on wireless anti-static straps, as they're ineffective regardless of charging or wear. There's no reliable information about recharging them, and they fail to meet industry standards for static control.

How Often Should Wireless Anti-Static Straps Be Tested for Proper Functionality?

You shouldn't rely on wireless anti-static straps at all, as they don't meet industry standards. There's no recommended testing frequency because they're ineffective at preventing static buildup and can't provide reliable ESD protection.

Do Temperature and Humidity Levels Affect Wireless Anti-Static Strap Performance?

Yes, your wireless anti-static strap's performance is greatly affected by temperature and humidity. High temperatures reduce effectiveness due to conductivity issues, while extreme humidity levels can interfere with static electricity dissipation capabilities.

Are Wireless Anti-Static Straps Waterproof or Water-Resistant?

You shouldn't assume wireless anti-static straps are waterproof or water-resistant, as manufacturers don't specify these features. It's best to keep them away from moisture since water could compromise their already questionable ESD protection capabilities.

Can Multiple Wireless Anti-Static Straps Interfere With Each Other's Functionality?

You don't need to worry about interference between wireless anti-static straps since they're ineffective to begin with. They lack proper grounding capability, so multiple straps won't impact each other's already limited functionality.

In Summary

You'll find wireless anti-static straps aren't necessary for most electronics work. While they offer convenience, traditional wired straps remain more reliable and cost-effective. Don't fall for marketing hype about wireless solutions – they often can't match the consistent grounding of wired options. Stick to proven ESD protection methods unless you've got specific needs that justify the higher cost of wireless technology.

Leave a Reply