To repair your ESD wrist strap, first check for visible signs of wear like breaks in metal fibers or faulty anti-static yarn. Test the strap using a proper wrist strap tester to guarantee resistance falls between 800 kΩ to 9 MΩ. If you find issues, clean the band thoroughly and inspect the current limiting resistor. For metal bands, adjust links at a downward angle and secure over the backplate. With elastic bands, adjust by pulling the tail and trim excess after wearing. Remember to test electrical resistance after any adjustments. The following maintenance steps will help guarantee your ESD protection stays reliable and effective.

Identifying Common Wrist Strap Problems

A properly functioning ESD wrist strap is essential for protecting sensitive electronic components, but several issues can compromise its effectiveness.

You'll need to watch for signs of wear and tear, particularly in the wrist strap wire where repeated bending can break the metal fibers and disable its anti-static capabilities.

Check your wristband's inner layer for defective anti-static yarn, as this can prevent proper electrical conduction. Testing shows total system resistance should never exceed 1.0 x 10^6 ohms for proper grounding. If you're using a domestic anti-static product, be especially vigilant as these often have inferior quality and fail more easily. Poor quality materials are especially common in budget-friendly options.

You should also inspect the coiled cord for any damage or patching, as these repairs won't provide adequate ESD protection.

Don't assume your wrist strap is working just because it looks fine. Poor fitting or incorrect wear can prevent effective grounding, even if the strap appears undamaged.

Regular testing is vital – if you haven't been checking your wrist strap's functionality, you might be exposing sensitive components to dangerous ESD events.

Remember that material degradation occurs even in high-quality products, so monitoring your wrist strap's condition should be part of your routine maintenance procedures.

Testing Your Wrist Strap

Regular testing of your ESD wrist strap involves three essential components: a specialized tester, proper wear, and consistent daily checks.

You'll need either a portable wrist strap tester or a combo tester that can verify both wrist straps and heel grounders. To test your strap, wear it properly, insert the snap into the tester's jack, and touch the metal plate until you receive a pass/fail indication. Green LED lights will confirm proper functioning when resistance is between 800 kΩ to 9 MΩ.

Your wrist strap must maintain a resistance of less than 35 megohms to pass the test, but it shouldn't fall below 750K ohms. Safety standards require this resistance range to limit current flow to 250 microamps at 250 Volts rms AC.

If you're getting failures, check these common issues:

- High skin resistance or a soiled wristband can trigger a high-resistance failure

- A shorted resistor in the coil cord typically causes low-resistance failures

- Poor connections between the band and your wrist often lead to inconsistent readings

- Contact with grounded metal objects during testing can create false readings

Keep your testing equipment calibrated according to ANSI/ESD S20.20 standards for accurate results.

If your strap fails testing, clean the band, check for wear, and consider using ESD lotion to improve skin contact. Replace any damaged components immediately and always re-test before returning to work.

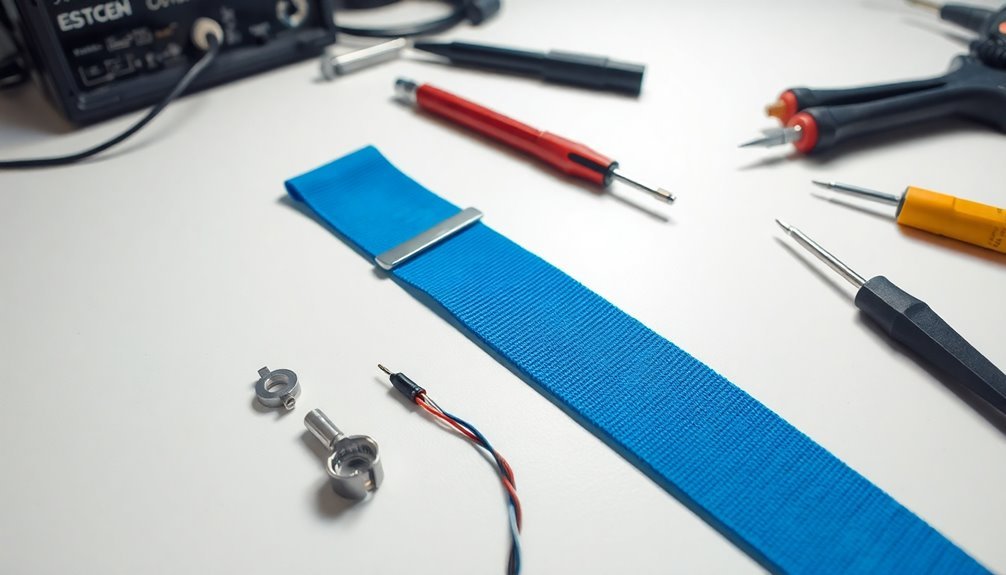

Replacing Faulty Components

Replacing faulty components in your ESD wrist strap requires identifying the specific failure point and choosing the correct replacement parts. If you've detected a high resistance fail (above 35 megohms), check your wristband for soil or wear. You'll need to either clean or replace it if it's damaged. The current limiting resistor is crucial for safety and must be properly maintained. A proper crimping tool should be used when making repairs to ensure conductivity.

For high skin resistance issues, apply electronics-approved lotion to improve conductivity.

When dealing with low resistance failures (below 750 kilohms), focus on the coil cord's 1 megohm resistor. If it's shorted, you'll need to replace the entire cord. Check for alternative grounding paths that might be causing the low reading and eliminate them.

For damaged wires, you can repair them using epoxy or heat shrink tubing, but make sure you're using approved materials.

After any component replacement, it's essential to test the entire system to verify proper electrical continuity from your wrist to ground. Don't use the wrist strap with voltages exceeding 250 VAC, and always maintain proper grounding connections.

If you're working with sensitive ESD items, consider installing a continuous monitoring system to catch failures immediately and prevent potential damage to components.

Adjusting Metal and Elastic Bands

Proper adjustment of metal and elastic wrist straps guarantees ideal ESD protection while maintaining comfort during extended wear.

For metal bands, insert the link end into the slotted cap opening at a downward angle, then adjust by sliding links in or out of the backplate. You'll need to lock the links by pulling down on the band until it's secure over the backplate's lip.

For elastic bands with clasps, place the band on your wrist and pull the tail to adjust the fit. It's smart to wear it for a day before trimming excess material.

If you're working with a non-clasp elastic band, simply pull the tail to tighten or hold both sides of the buckle and pull apart to loosen.

Key considerations for proper band adjustment:

- Test electrical resistance after each adjustment to verify proper grounding

- Don't clip straps to dissipative mat edges as this can exceed resistance limits

- Connect only to designated groundable points or equipotential bonding points

- Apply ESD lotion if needed to improve skin contact

Remember to perform regular testing regardless of band type to maintain ideal ESD protection throughout your work sessions.

Grounding System Maintenance

Beyond wrist strap adjustments, maintaining your ESD grounding system requires attention to multiple components for reliable protection.

You'll need to regularly inspect and test your grounding points, ensuring they're clearly marked and easily accessible. Connect your ground cord to a designated groundable point or equipotential bonding point, and make sure your ESD mat has a specific grounding connection rather than relying on edge contact.

Test your system daily or implement continuous monitoring to catch issues early. If you're getting high resistance readings, check for soiled wristbands, poor skin contact, or damaged coil cords.

Low resistance failures often point to problems with the vital 1 megohm resistor or unwanted ground paths. Don't hesitate to apply ESD lotion if you're experiencing skin resistance issues.

Remember that your equipment must connect to the green wire ground, and all ESD control materials should link to the equipment grounding conductor.

Never use your wrist strap with voltages above 250 VAC, and always verify that the 1 megohm resistor is functioning correctly.

Replace any coil cords showing signs of wear or damage immediately to maintain proper protection.

Frequently Asked Questions

Can I Wear My ESD Wrist Strap Over Long Sleeves?

You shouldn't wear your ESD wrist strap over long sleeves. It'll interfere with proper skin contact and increase resistance. For effective ESD protection, always wear the strap directly against your skin.

How Often Should I Apply ESD Lotion to Maintain Conductivity?

You don't need to apply ESD lotion on a set schedule – just use it when you notice decreased conductivity during testing. Focus on keeping your wrist strap clean and properly connected to ground instead.

What Happens if I Accidentally Get My Wrist Strap Wet?

If your wrist strap gets wet, let it air dry completely and test its electrical resistance before using it again. If you notice any damage or conductivity issues, you'll need to replace it immediately.

Is It Safe to Share ESD Wrist Straps Among Multiple Users?

You shouldn't share ESD wrist straps due to cross-contamination risks. If you must share, thoroughly clean the strap with mild detergent between users to prevent bacterial spread and maintain proper hygiene standards.

Can Extreme Temperatures Affect the Performance of My Wrist Strap?

Yes, extreme temperatures can greatly affect your wrist strap's performance. High heat can degrade materials and increase resistance, while cold temperatures can make components brittle and unstable. You'll need regular testing after temperature exposure.

In Summary

Taking proper care of your ESD wrist strap will extend its life and maintain its protective function. By regularly testing, replacing worn components, and adjusting the bands as needed, you'll guarantee reliable static discharge protection. Don't forget to inspect your grounding system periodically. If you can't repair your wrist strap successfully, it's better to invest in a new one than risk damaging sensitive electronics.

Leave a Reply