To test your floor mat's conductivity, you'll need to perform five essential tests. Start with resistance-to-ground testing using a 5-pound electrode and resistance meter. Next, conduct point-to-point measurements with two electrodes placed 36 inches apart to check surface conductivity. Use a surface voltage tester to measure static charge dissipation, which should be under 100 volts. Don't forget to visually inspect mats for damage and verify proper grounding connections. Finally, test under different environmental conditions, especially varying humidity levels, as this affects performance. These methods will help guarantee your facility maintains proper static control protection.

Resistance to Ground Testing

For effective resistance to ground testing of ESD floor mats, you'll need to follow the standardized method outlined in ANSI/ESD STM7.1. You'll require a 5-pound cylindrical electrode, a resistance measurement meter, and a proper grounding point to perform the test accurately.

Before testing, you must condition your floor mat sample for 72 hours in an environment with 12% ±3% relative humidity. Your sample should be at least 12" x 24" and include a seam to reflect real-world conditions.

Install the flooring as you'd in actual use, including any necessary adhesives. Regular testing and maintenance are crucial for maintaining EPA safety standards.

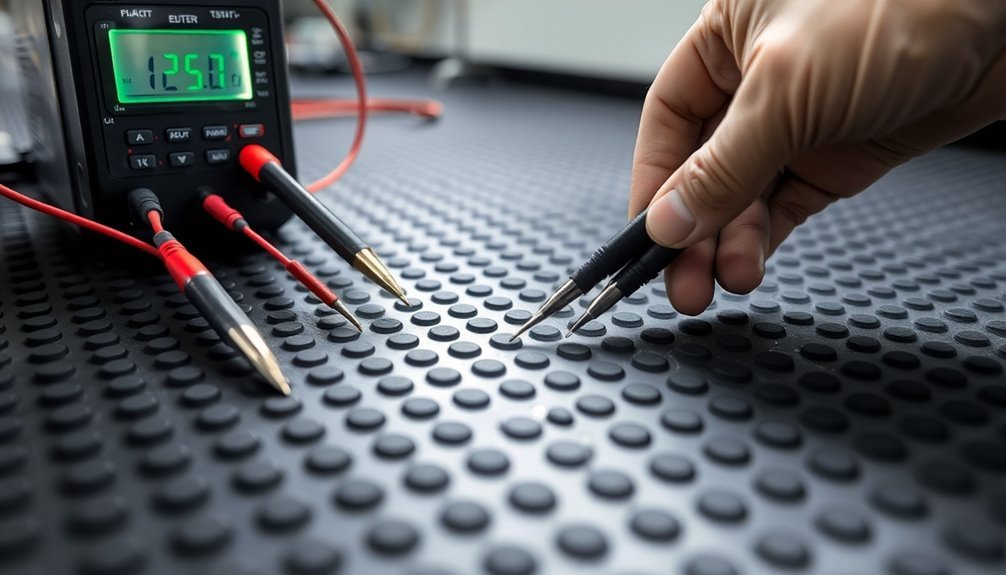

When conducting the test, connect one lead from your meter to the ground point and the other to the electrode placed on the mat. Keep the probe at least 2 inches from the ground point and 3 inches from any edges. You'll need to test multiple points for thorough coverage. You should perform six tests from each ground point to properly assess resistance variations.

The resistance to ground should measure less than or equal to 1 x 10^6 ohms for compliance.

Don't use standard multimeters, as they won't provide reliable results. Instead, use a dedicated resistance meter and document all readings for future reference.

If you're unsure about your equipment or expertise, seek third-party verification.

Point to Point Measurement

You must conduct your testing in an environment with 12% ± 3% relative humidity, as higher humidity levels can skew your results. Before testing, verify your floor mat samples are properly installed on an insulative support material and have been conditioned at low humidity for at least 72 hours. This setup helps ensure accurate readings similar to the standardized 5000 V Megger testing requirements.

When testing, you'll place the electrodes at various locations across the mat's surface, including across any seams, to verify consistent conductivity. Your measurements should indicate resistance values less than or equal to 1 x 10^6 ohms to meet standard requirements. Connect your meter's leads to the electrodes and take multiple readings from different spots.

Remember to maintain proper equipment calibration and follow ANSI/ESD STM 7.1 guidelines throughout the process. If you're testing different types of flooring materials, you'll need to take into account their specific conductivity properties and adjust your testing approach accordingly.

Surface Voltage Measurement

Surface voltage measurement represents a essential step in evaluating ESD floor performance, requiring specialized equipment to assess the floor's ability to dissipate static charges. You'll need to use a surface voltage tester and follow ANSI/ESD STM7.1 standards to guarantee accurate results.

When conducting the test, you'll want to place the probe directly on the floor's surface and record the voltage reading. Keep in mind that environmental factors like humidity and temperature can affect your measurements. The acceptable voltage reading should be less than 100 volts for ideal ESD protection. Testing should be performed at varying humidity levels to ensure consistent performance.

| Testing Component | Key Consideration |

|---|---|

| Equipment | Surface voltage tester with calibrated probe |

| Environment | Monitor humidity and temperature levels |

| Procedure | Direct contact between probe and floor surface |

| Standards | Comply with ANSI/ESD STM7.1 guidelines |

| Results | Maintain readings below 100 volts |

Regular testing is essential in electronics manufacturing, communications facilities, and end-user environments. For electronics manufacturing facilities, maintaining resistance levels of 1.0 x 10E9 ohms is crucial for optimal protection. You'll need to maintain consistent cleaning practices and watch for signs of wear that could compromise the floor's ESD properties. If you're unsure about your testing results, consider hiring a professional third-party service to verify your measurements and ascertain your facility meets all safety requirements.

Visual Inspection and Grounding

A thorough evaluation of floor mat conductivity begins with visual inspection and proper grounding assessment.

You'll need to examine the mat carefully for any signs of discoloration, uneven edges, or material imperfections that could affect its performance. Check that all components, including backing and adhesives, are securely attached and undamaged. These examinations should include anti-static properties verification commonly required by ISO certification. The experience and expertise of the testing technicians is vital for obtaining reliable conductivity results.

To test grounding, you'll follow ANSI/ESD STM7.1 standards, which require testing in a controlled environment with 12% relative humidity.

Using an ohm meter, you'll measure the mat's electrical resistance to determine its classification. If your readings show less than 1.0 x 10E6 ohms, you've got a conductive floor mat. Readings between 1.0 x 10E6 and 1.0 x 10E9 ohms indicate a static-dissipative mat.

Remember that different industries have specific resistance requirements. For instance, telecommunications and FAA facilities may demand different conductivity ranges.

You'll need to verify that your mat's performance meets your industry's standards. During testing, measure how quickly current passes across the surface, as this indicates how effectively the mat will ground static charges in real-world conditions.

Environmental Condition Testing

Environmental factors play an essential role in determining floor mat conductivity and performance. When you're testing floor mat conductivity, you'll need to take into account varying humidity levels, typically conducting tests at both 50% and 12% humidity.

Temperature changes can also affect your mat's electrical resistance, so you should perform tests in conditions that match the mat's intended environment.

To guarantee accurate results, you'll need to use calibrated equipment, including resistance meters and 5lb electrodes that comply with ANSI/ESD STM7.1 standards.

You'll perform several key tests: point-to-point resistance measures conductivity between two points on the mat, while resistance-to-ground testing evaluates the connection to your grounding point. Walking tests help you assess static generation in real-world conditions.

Remember that high humidity typically improves conductivity, while low humidity can increase resistance. You'll want to monitor these environmental conditions closely, as they can impact your test results and the mat's long-term performance.

Regular testing under various environmental conditions helps you identify potential issues before they affect your mat's static control capabilities. Document your findings according to relevant standards like IEC 61111 or IS 15652:2006 for thorough compliance.

Frequently Asked Questions

How Often Should Floor Mat Conductivity Testing Equipment Be Calibrated?

You'll need to calibrate your conductivity testing equipment every 12 months, or according to manufacturer guidelines. Don't forget initial calibration before first use and track usage for potential early recalibration needs.

Can Multiple Floor Mats Be Connected in Series for Testing?

While you can connect floor mats in series, you shouldn't test them this way. Test each mat individually to guarantee accurate resistance measurements and identify any compromised sections that series testing might mask.

What Causes Sudden Changes in Floor Mat Conductivity Readings?

You'll notice sudden changes in floor mat conductivity when there's a shift in humidity, contamination from spills, damaged mat surfaces, or unexpected temperature fluctuations. Environmental factors can drastically affect your readings.

Do Cleaning Chemicals Affect the Conductivity Properties of ESD Floor Mats?

Yes, cleaning chemicals greatly affect your ESD mat's conductivity. You'll find acidic cleaners can damage conductive layers, while alkaline ones leave harmful residue. It's best to use neutral, water-based cleaners for maintenance.

How Long Does a Typical Floor Mat Maintain Its ESD Protection Properties?

You'll typically get 2-5 years of reliable ESD protection from your floor mat, but it's highly dependent on usage, maintenance, and material quality. Regular cleaning and proper care can extend its effective lifespan.

In Summary

You've now learned five reliable methods to verify your floor mat's conductivity. By performing resistance to ground testing, point to point measurements, surface voltage checks, visual inspections, and environmental condition assessments, you'll guarantee your mat provides proper ESD protection. Don't skip regular testing – it's essential for workplace safety and equipment protection. Remember, a well-maintained conductive mat is your first line of defense against static discharge.

Leave a Reply