When you're planning ESD flooring installation, you'll want reliable calculators to guarantee ideal coverage and protection. The top 7 ESD coverage calculators include the Simple Square Footage Calculator for basic area measurements, the Grounding Point Distance Tool for precise point placement, and the Tile Layout Optimization System for efficient material use. You'll also benefit from the Material Cost Estimation Platform, Resistance Measurement Planning Calculator, Coverage Area Mapping Tool, and Installation Timeline Assessment Calculator. Each tool serves a specific purpose in your ESD flooring project, and understanding their unique features will help you achieve the best possible results.

Simple Square Footage Calculator

A simple square footage calculator lies at the heart of planning any ESD flooring project. When you're determining your ESD flooring needs, you'll want to start with basic measurements of your space. The fundamental formula is straightforward: multiply the length by the width in feet to get your square footage. This type of precision calculation helps prevent static electroshock damage to sensitive equipment.

If you're working with non-rectangular rooms, you'll need to break down the space into smaller rectangular sections and add their areas together. Before you begin, make sure all your measurements are converted to feet to avoid calculation errors. Regular testing and documentation is essential for ongoing compliance with ESD standards. You can use online calculators or perform manual calculations, but always double-check your measurements for accuracy.

To get the most precise results, consider factors specific to ESD flooring installation. You'll need to account for seam allowances and potential material waste during installation.

When you've calculated the basic square footage, you can multiply this number by the cost per square foot of your chosen ESD flooring material. Remember that different types of ESD flooring – whether vinyl, rubber, or epoxy – may require different calculation considerations for waste factors and installation requirements.

Grounding Point Distance Tool

You'll need to follow strict distance measurement standards when planning your grounding point layout, with one grounding point recommended for every 1,000 square feet of contiguous ESD flooring.

Your grounding points must be strategically placed and properly attached to approved structural elements like electrical outlets, conduit, or building steel.

Copper grounding straps should extend 24 inches from the connection point to ensure proper conductivity.

To guarantee peak ESD protection, you'll want to maintain consistent spacing between ground points while ensuring each room has at least one grounding strap, regardless of its size.

AC equipment ground is preferred for proper bonding to the ground bus at the main service panel.

Distance Measurement Best Practices

When implementing ESD flooring solutions, accurate distance measurement between grounding points stands as a critical factor for ideal static control.

You'll need to evaluate both physical layout and material conductivity to guarantee proper coverage across your facility. Path resistance and grounding point spacing directly impact your static dissipation effectiveness. Total ownership costs must be considered when selecting measurement tools and planning grounding point placement. Since ESD flooring contains conductive elements like carbon and graphite, precise measurements are essential for optimal performance.

- Use measurement tools like dew point calculators and resistance meters to determine best grounding point placement based on your floor's specific conductivity.

- Account for heavy equipment locations and traffic patterns when mapping out your measurement points, as these affect your overall ESD protection scheme.

- Reflect on local climate conditions and subterranean vapor issues that might influence your distance measurements between grounding points.

- Factor in material thickness and expansion joints when calculating distances to maintain continuous static control.

Remember to comply with standards like ASTM F 150 and IEC 61340-5-1 when measuring distances for your ESD flooring installation.

Your measurements should account for conductive coatings and primers that'll enhance your floor's ESD performance.

Grounding Point Layout Standards

Standards for grounding point layout rest upon precise measurements and strategic placement throughout your facility.

You'll need to guarantee copper bars don't exceed 25-meter spacing, while your grounding lead-in wires must stay under 30 meters in length. When you're planning your layout, connect each grounding point to either Electrical, Machine, or Building Ground.

Your grounding system requires ESD flooring material to measure less than 1.0 x 10^9 ohms to ground, with resistance between AC and auxiliary ground staying below 1 ohm. Testing must be conducted in controlled humidity conditions to ensure accurate resistance measurements. For raised access floors, maintain grounding resistance under 4 ohms. Braided copper wire should be used for signal grounds to prevent interference.

You'll want to create a grid using copper tape, typically ½" wide, though other widths are available. Install a minimum of two ground plates for areas up to 500 square feet, adding more for larger spaces.

You'll need to partition your grounding tape equally to create an efficient grid pattern. Don't forget to bond auxiliary grounding to AC equipment ground, and avoid using isolated ground receptacles.

When implementing your grounding system, use insulated wires with anti-corrosion treatment to guarantee long-term effectiveness and compliance with ANSI/ESD standards.

Tile Layout Optimization System

According to industry experts, a well-designed tile layout enhancement system serves as the cornerstone of efficient ESD flooring installation. You'll find that modern software solutions like MeasureSquare and Precision Tile Pro offer advanced calculation features that account for your specific ESD tile dimensions, grout requirements, and layout patterns.

- Strategic placement maximizes ESD protection while minimizing material waste

- 2D and 3D visualization tools help you plan precise grounding point locations

- Pattern selection tools accommodate various tile sizes and installation methods

- Built-in calculators factor in room dimensions and recommended waste percentages

When you're working with ESD flooring, you'll want to utilize these enhancement systems to guarantee proper coverage and cost-effectiveness. The software helps you determine ideal tile placement, starting points, and cutting patterns while considering your specific grounding requirements.

You can input room measurements, select desired patterns like herringbone or chevron, and receive detailed calculations for material needs. By leveraging these tools, you'll reduce waste, optimize your tile usage, and guarantee thorough ESD protection throughout your facility.

The system's professional planning capabilities help you achieve both technical compliance and aesthetic appeal while maintaining budget constraints.

Material Cost Estimation Platform

You'll find essential bulk price comparison tools that let you evaluate different ESD flooring materials side-by-side, factoring in variables like square footage, material type, and regional pricing variations.

Real-time cost analysis features help you track fluctuating material prices and calculate total project expenses, including installation and maintenance costs.

These digital platforms integrate with major supplier databases to guarantee you're getting accurate, current pricing while accounting for factors like subterranean vapor protection and warranty coverage.

Bulk Price Comparison Tools

Modern flooring's bulk price assessment requires reliable comparison tools that streamline the material cost estimation process. You'll find that today's digital platforms offer thorough solutions for comparing bulk pricing across multiple suppliers while factoring in shipping costs and additional fees.

These tools help you make informed decisions by analyzing both online and offline vendor options, guaranteeing you're getting the most competitive rates for your ESD flooring needs.

- Advanced quote comparison features that automatically calculate per-unit costs and potential bulk savings

- Real-time overstock monitoring systems that alert you to deals offering up to 50% off retail prices

- Integrated shipping cost calculators that help determine total landed costs for bulk purchases

- Warehouse availability trackers that guarantee suppliers can fulfill your bulk order requirements

When using bulk price comparison tools, you'll want to leverage features that analyze supplier reliability ratings and customer feedback.

These platforms often include built-in calculators for accurate material estimation, helping prevent costly over-purchasing. By utilizing specialized comparison tools like those offered by Tasoro Products, you can effectively evaluate bulk purchase opportunities while maintaining quality standards and meeting project timelines.

Real-Time Cost Analysis

Building on bulk pricing tools, real-time cost analysis platforms take material estimation to the next level with dynamic calculations and instant updates.

You'll find advanced software solutions like Cyncly's Measure Desktop and Kreo Software that leverage AI technology to automate takeoff tasks and minimize manual errors in your ESD flooring calculations.

These platforms integrate seamlessly with your existing project management software, enabling you to track costs, materials, and labor in real-time.

You can access detailed breakdowns of project expenses, including waste evaluations and installation costs, through cloud-based systems that support team collaboration.

Tools like Tarkett's LCCA provide thorough analysis of floor installation, maintenance costs, and life expectancy.

When selecting a real-time cost analysis tool, you'll want to assess its ability to handle complex flooring layouts and custom designs.

Look for features like automatic measurement capabilities from digital drawings and 3D visualization options for client presentations.

The right software will help you generate accurate estimates, reduce material waste, and create detailed proposals while saving valuable time on your ESD flooring projects.

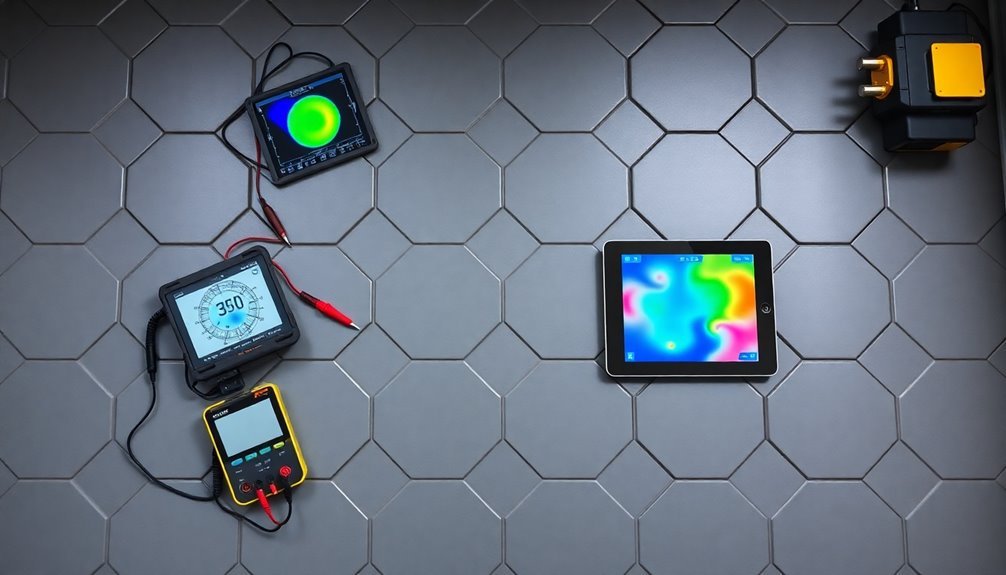

Resistance Measurement Planning Calculator

A facility's resistance measurement planning requires precise calculations to ascertain accurate ESD floor testing and compliance. You'll need a specialized calculator that accounts for various testing methods and environmental factors to guarantee your measurements meet industry standards like ANSI/ESD S20.20 and NFPA 77.

When selecting a resistance measurement planning calculator, you'll want to focus on these critical features:

- Real-time resistance value computation that factors in temperature and humidity variations

- Multi-method testing capabilities including point-to-point, point-to-earth, and walking voltage calculations

- Automated data interpretation that flags measurements outside acceptable ranges

- Built-in compliance checking against current ESD standards and regulations

Your calculator should help you determine ideal testing intervals and locations while considering your floor's material composition and installation specifics.

It's vital to input accurate conductivity data and material specifications to receive reliable calculations. You'll also want to guarantee your calculator can track resistance stability over time, helping you identify when measurements drift from baseline values.

This data-driven approach will strengthen your ESD floor maintenance strategy and help prevent costly compliance issues.

Coverage Area Mapping Tool

Precise facility mapping stands at the core of effective ESD flooring installation. You'll need reliable coverage area mapping tools to guarantee accurate material calculations and ideal installation planning. Leading manufacturers offer specialized calculators designed to streamline this process.

When you're using Fosroc's Tile Grout & Adhesive Calculator, you can quickly determine the exact quantities of materials needed for your project. This online tool simplifies your ordering process while confirming you've accounted for all necessary materials.

Sika's Flooring Systems takes mapping a step further by providing tailored ESD solutions with their MultiDur ES-56 ESD system. You'll receive detailed specifications that match your industry requirements and help maintain compliance with ESD standards.

For thorough planning, StaticWorx's approach emphasizes total cost calculations alongside area mapping. You'll want to evaluate their guidelines when measuring square footage, accounting for room shapes, and planning for obstructions.

Remember to:

- Measure all areas in square feet

- Include irregular spaces and obstacles

- Calculate additional material for waste

- Factor in system-specific coverage rates

- Document all measurements for reference

These tools help you avoid costly mistakes and guarantee precise material ordering for your ESD flooring project.

Installation Timeline Assessment Calculator

Determining accurate installation timelines for ESD flooring requires sophisticated calculation tools that account for multiple variables. A well-designed timeline assessment calculator helps you factor in preparation requirements, material properties, installation processes, and post-installation evaluation needs.

Your installation timeline calculator should consider these critical elements:

- Subfloor preparation time, including cleaning, drying, and necessary repairs before installation can begin

- Material-specific requirements, such as epoxy curing times or interlocking tile assembly rates

- Labor expertise needed and availability of specialized installation teams

- Testing and quality assurance procedures that must follow installation

You'll want to input specific details about your project's scope, including square footage, selected material type, and current subfloor conditions. The calculator will then analyze these factors against known installation rates and manufacturer specifications.

It'll also account for potential variables like material delivery schedules and specialized tool requirements. When using the calculator, you're able to adjust timelines based on whether you're working with quick-install options like interlocking tiles or more complex solutions like epoxy coatings that require extensive curing periods.

This helps create realistic project schedules and manage resource allocation effectively.

Frequently Asked Questions

Can ESD Flooring Performance Be Affected by Extreme Temperatures During Calculation Phases?

Yes, you'll need to account for temperature effects in your ESD flooring calculations, as extreme heat or cold can considerably alter conductivity and resistance values, impacting the overall performance of your flooring system.

How Often Should Calculator-Recommended Grounding Points Be Recalibrated After Installation?

You'll need to recalibrate grounding points based on your specific environment and usage patterns. Don't follow a fixed schedule – instead, conduct regular testing and adjust based on environmental conditions and wear patterns.

Do Regional Humidity Variations Impact the Accuracy of ESD Coverage Calculations?

Yes, you'll need to adjust your ESD coverage calculations based on humidity variations, as moisture levels affect conductivity. You should recalibrate your calculations seasonally to maintain accurate coverage assessment in different climate conditions.

What Safety Margins Should Be Added to Calculator Results for Mission-Critical Areas?

You'll want to add a 25-50% safety margin for mission-critical areas, considering humidity fluctuations and equipment sensitivity. It's best to err on the higher end when protecting essential operations.

How Do Substrate Irregularities Influence the Precision of ESD Calculator Measurements?

You'll find substrate irregularities greatly affect your ESD measurements by creating variable contact points and resistance paths. They'll alter conductivity readings by up to 20% and require additional testing points for accurate calculations.

In Summary

You've now got the essential tools to calculate and plan your ESD flooring installation effectively. These seven calculators will help you determine square footage, grounding points, tile layouts, costs, resistance requirements, coverage mapping, and timeline projections. Don't hesitate to use multiple calculators together for the most accurate results – they're designed to work in tandem for your complete ESD flooring solution.

Leave a Reply