Polyethylene (PE) foam, anti-static foam, and specialized corrugated foam offer better protection than bubble wrap for your shipping needs. PE foam provides superior shock absorption and durability, while anti-static foam prevents harmful discharge that could damage electronics. Corrugated foam's unique structure adds excellent cushioning for heavier items. You'll find these foam options more cost-effective in the long run due to their reusability and space efficiency, though they cost more upfront than bubble wrap. They're also more environmentally friendly, with some varieties being 100% recyclable. Discovering the specific advantages of each foam type can transform your packaging strategy.

Understanding Static Protection Properties

Static protection remains a crucial factor in safeguarding electronic components during shipping and handling. When you're packaging sensitive electronics, you'll need to understand how different materials handle electrostatic discharge (ESD).

Anti-static bubble wrap offers specific advantages over standard bubble wrap, featuring a special coating that dissipates static charges and prevents buildup. The material is especially vital in aerospace and defense applications where protecting sensitive technology is paramount.

You'll recognize anti-static bubble wrap by its distinctive pink color, which distinguishes it from regular varieties. While standard bubble wrap can generate harmful static electricity, the anti-static version includes additives specifically designed to protect delicate items like microchips and circuit boards.

This specialized material helps you comply with industry safety standards and reduces the risk of product failure.

However, you should consider that anti-static bubble wrap isn't permanent. Its protective properties can degrade over time, especially when exposed to heat and sunlight.

While it's more expensive than regular bubble wrap, the investment is worthwhile when you're shipping valuable electronic components. You might also want to explore alternative options like protective foam sheets, which can provide similar static protection benefits.

Remember that standard bubble wrap remains suitable for non-electronic items where static protection isn't necessary.

Comparing Cost and Performance

Cost considerations between protective foam and bubble wrap extend beyond their initial price tags. While you'll find bubble wrap more cost-effective for bulk purchases, foam's space efficiency can offset its higher upfront costs through reduced storage needs. The choice ultimately depends on your specific packaging requirements and volume. Custom foam inserts can increase overall packaging expenses significantly but provide superior product protection.

When evaluating performance versus cost, you'll need to take into account these critical factors:

- Heavy items benefit more from foam's superior cushioning, justifying its higher cost

- Lightweight shipments can rely on bubble wrap's adequate protection at a lower price point

- Temperature-sensitive products require foam's thermal properties, making it worth the investment

- Custom-shaped items might need foam's precise cutting capabilities despite the added expense

You'll save money using bubble wrap for general packaging needs, but foam's specialized protection capabilities make it the more economical choice for valuable or fragile items.

For maximum cost efficiency, think about combining both materials for high-value shipments where damage prevention outweighs packaging costs.

Remember that foam's durability often means longer-term protection, potentially reducing replacement frequency and overall expenses.

Electronic Equipment Safety Measures

Protection protocols for electronic equipment demand specific attention to static electricity and surface preservation. When you're packaging electronic items, you'll find that foam offers superior protection due to its non-abrasive properties and lower risk of static buildup. It's particularly effective for items with polished surfaces that could be damaged by rougher materials. Standard bubble wrap can produce harmful charges that may damage sensitive components.

You'll want to consider using pre-cut foam sheets for stacking components, as they provide excellent shock absorption while saving packaging time. For larger electronic items, foam corners and edge protectors are essential to prevent shifting during transit.

If you're dealing with temperature-sensitive electronics, foam's thermal insulation properties make it the clear choice.

While bubble wrap remains a cost-effective option for moderately fragile items, it's not your best choice for premium electronic equipment. You can maximize protection by combining materials strategically, but remember that anti-static foam is vital for components sensitive to static electricity.

When you need custom protection, opt for foam inserts designed specifically for your electronic products. They'll guarantee precise fitting and minimal movement during shipping while maintaining the reusability factor that makes foam a sustainable choice.

Material Durability and Lifespan

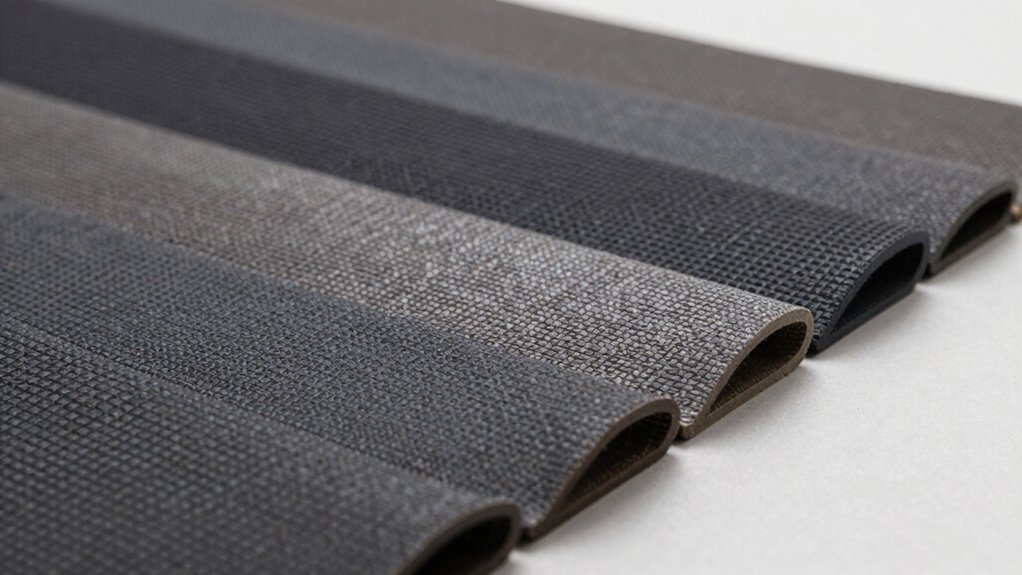

When comparing material strength, you'll find that polyethylene foam substantially outlasts bubble wrap in both durability and performance. Its denser structure and thicker material composition make it markedly more resistant to tears and punctures, while its superior shock absorption capabilities guarantee better protection during long-term use.

For heavy-duty applications and valuable items, PE foam's durability advantages become clear in these key areas:

- Higher density construction provides enhanced shock absorption and vibration protection

- Multiple thickness options allow for customized protection levels

- Superior puncture resistance guarantees lasting protection during shipping

- Better thermal insulation properties protect temperature-sensitive items

While bubble wrap offers flexibility and cost-effectiveness for lightweight items, you'll want to take into account PE foam for long-distance shipping and specialized applications. The foam's non-abrasive surface makes it particularly suitable for delicate items requiring scratch protection.

It's particularly effective for electronics, furniture, and polished surfaces where sustained protection is vital. The foam's ability to maintain its protective properties over time makes it ideal for storage and repeated use, despite its higher initial cost and weight.

When protecting high-value items or planning for long-term storage, PE foam's extended lifespan and reliable performance justify the investment.

Environmental Impact Assessment

The environmental toll of protective packaging demands careful examination when choosing between bubble wrap and foam alternatives.

While bubble wrap contributes to the 400 million tons of annual plastic waste, taking up to 1,000 years to decompose, foam packaging offers more sustainable options. With 91% of plastic waste ending up in ecosystems, bubble wrap poses a significant environmental threat. You'll find that bubble wrap's recycling rate remains dismally low at 9%, with much of it ending up in oceans and breaking down into harmful microplastics.

In contrast, many foam alternatives are 100% recyclable and provide multiple environmental benefits. You can reuse foam inserts several times, substantially extending their lifespan and reducing waste. They're also more space-efficient, leading to smaller package sizes and reduced carbon emissions during transport.

While bubble wrap is mainly air and wastes storage space, foam's compact nature minimizes transportation impacts.

You'll want to reflect on the fact that the growing e-commerce industry has increased bubble wrap demand, exacerbating environmental concerns. By choosing foam or other eco-friendly alternatives like Hexcel Wrap or corrugated cardboard, you're helping reduce landfill waste and environmental degradation.

These sustainable options also address fire safety concerns while providing effective protection without the centuries-long environmental impact of traditional bubble wrap.

Frequently Asked Questions

Can Protective Foam or Bubble Wrap Affect the Color of Wrapped Items?

You'll find protective foam won't affect item colors, but bubble wrap can leave lasting cell marks on polished surfaces. It's best to use foam first when wrapping delicate or polished items.

What Temperatures Can Each Material Withstand Before Losing Protective Properties?

You'll find bubble wrap maintains its protective properties up to 200°F while foam insulation stays effective between -40°F to 175°F. Both materials start losing their protective abilities when exposed beyond these temperature ranges.

Are There Specific Humidity Requirements for Storing These Packaging Materials?

You'll want to keep both protective foams and bubble wrap in environments with 35-65% relative humidity, ideally at 50%. Store them in well-ventilated spaces and use airtight containers to prevent moisture damage.

How Do Foam and Bubble Wrap Perform in High-Altitude Shipping Conditions?

You'll find foam performs better at high altitudes since it won't expand or burst like bubble wrap. Foam maintains its protective structure, while bubble wrap's air pockets can pop under reduced pressure conditions.

Can Either Material Trigger Allergic Reactions When Handling Frequently?

You're more likely to experience allergic reactions with protective foams, especially polyurethane types, causing skin and respiratory issues. However, bubble wrap rarely triggers allergies, making it a safer choice for frequent handling.

In Summary

You'll find that anti-static foam offers superior protection for electronics compared to bubble wrap, though at a higher cost. While bubble wrap remains economical for general shipping, protective foams deliver better long-term value through durability and reusability. For your sensitive electronic equipment, investing in specialized foam padding isn't just safer – it's more environmentally responsible due to its extended lifespan and recyclable properties.

Leave a Reply