Anti-static ionizers need extensive safety protection to shield you and your equipment from electrical hazards in sensitive manufacturing environments. Built-in features like emitter pin shutdown systems, voltage balance monitoring, and circuit protection mechanisms work together to prevent accidents and equipment damage. You'll find these ionizers equipped with self-diagnosis functions, surge protection, and continuous monitoring systems that maintain ideal performance while adhering to strict safety standards. Regular maintenance checks and proper environmental conditions guarantee these safety systems function effectively. Understanding these protection mechanisms can help you maximize your ionizer's safety potential.

Understanding Ionizer Safety Risks

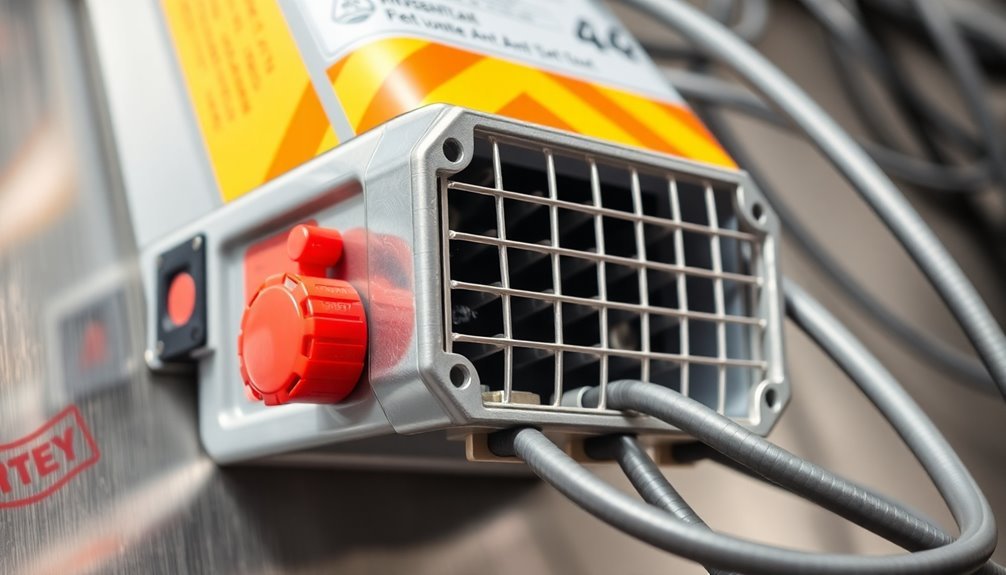

With the increasing use of ionizers in industrial settings, understanding their safety risks is crucial for proper operation. You'll need to be aware of several critical hazards that can compromise both safety and effectiveness. The devices shouldn't be operated in explosion-risk areas or EX zones, and you must avoid using them in environments with humidity levels above 80% or temperatures exceeding 40°C. It's especially important to maintain proper protocols in healthcare settings where static charge accumulation on workstations can create significant hazards. The installation of bench top ionisers in shared workspaces requires careful consideration of placement and airflow patterns.

You're at risk of electrical hazards if you don't follow proper safety protocols. The ionizer must always be connected to a grounded power cord, and you should never attempt repairs unless you're authorized service personnel. If you notice any operational issues, disconnect the device immediately from the power supply.

Don't use the ionizer outdoors or in vehicles, as this can be dangerous and void your warranty.

You must also consider environmental factors that affect safe operation. Don't touch the ion source, and verify there's no water or oil in the workspace. You'll need a proper air conditioning system to handle ozone production, and you should always let the device adjust to room temperature before use to prevent condensation issues.

Built-in Protection Mechanisms

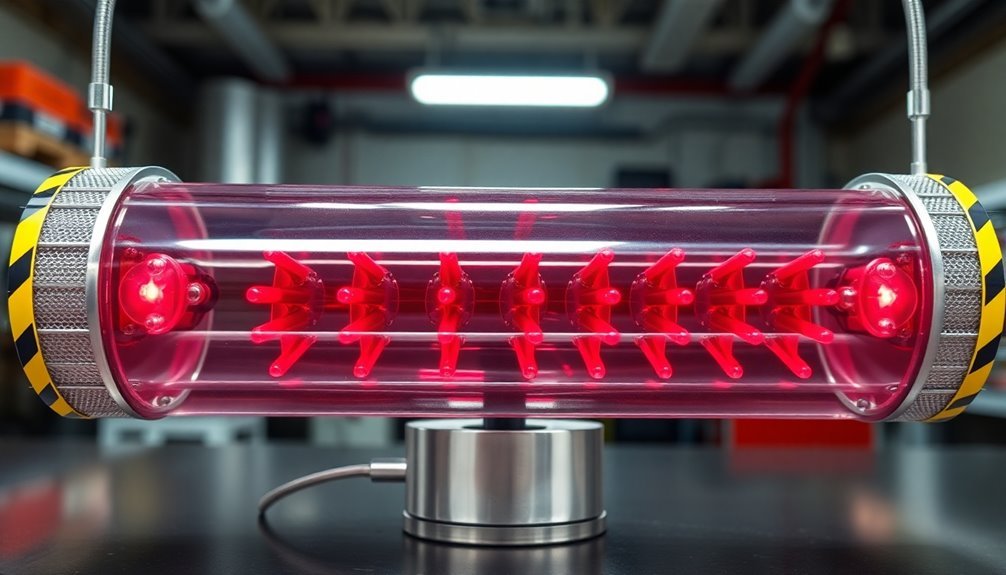

You'll find modern anti-static ionizers equipped with emitter pin shutdown systems that instantly deactivate if any unsafe conditions arise, protecting both users and sensitive equipment.

Voltage balance monitoring controls continuously track the ratio of positive to negative ions, ensuring ideal static neutralization performance. The advanced technology provides ultra-high-speed sensing capabilities for optimal charge control. The systems include self-diagnosis functions that actively monitor ion generation levels.

These sophisticated protection mechanisms work together to prevent potential hazards while maintaining precise ionization levels throughout operation.

Emitter Pin Shutdown Systems

Modern anti-static ionizers incorporate sophisticated emitter pin shutdown systems that serve as critical safety mechanisms. These systems automatically detect and respond to potential issues, protecting both your equipment and workplace safety. When emitter pins become clogged or damaged, the shutdown system immediately halts operation, preventing overheating and potential damage. Regular maintenance every 6 months helps ensure these safety systems function properly.

The systems are designed around the principle that corona discharge creates the necessary ions for static elimination. You'll find these systems equipped with advanced self-diagnosis capabilities that monitor performance continuously. Through LED indicators or alarm outputs, you're promptly alerted to any maintenance requirements or malfunctions before they become serious issues. The systems include robust thermal and overcurrent protection, ensuring your ionizers operate within safe parameters.

Whether you're using pulse AC or DC methods, you can rely on multiple protection layers working together. These include automatic airflow control and fault detection mechanisms that maintain peak performance while preventing dangerous conditions.

You'll notice that modern designs, such as the SJ-M and SJ-H Series, offer flexible installation options while maintaining strict safety standards. The systems effectively manage static elimination from distances exceeding one meter, making them versatile for various workplace setups.

With features like I.R.G. technology, you're getting energy-efficient operation without compromising on safety or performance.

Voltage Balance Monitoring Controls

Voltage balance monitoring controls serve as the heart of an ionizer's protection system, maintaining precise equilibrium between positive and negative ions.

You'll find these controls constantly working to prevent static buildup by monitoring and adjusting ion output levels in real-time, guaranteeing your sensitive electronics remain protected.

When you're operating the ionizer, these monitoring systems actively track voltage levels through I.R.G. technology and the pulse AC method.

The systems are particularly effective in explosion-proof environments, making them essential for industries working with flammable materials.

If they detect any imbalance, you'll receive immediate alerts through LED indicators and built-in alarms.

The system's self-diagnosis functions will notify you when maintenance is needed, while automatic shutdown features activate if dangerous voltage levels occur.

You won't need to worry about over-ionization damaging your components, as these controls keep static levels within safe limits at all times.

They're designed to operate efficiently without requiring airflow, and you'll notice improved production quality with fewer static-related disruptions.

The maintenance-free design means you'll experience less downtime, while still meeting international ESD safety standards.

Whether you're working with small electronics or large-scale manufacturing, these voltage balance controls guarantee your ionizer operates safely and effectively.

Electrical Hazard Prevention Features

Your ionizer's circuit protection mechanisms work alongside electrical isolation systems to create multiple layers of safety against power-related hazards.

Proper safety features are essential since voltage applied fields generate the ionization process around emitter points.

You'll find advanced surge protection components that instantly respond to voltage fluctuations, preventing damage to sensitive internal circuitry.

These safety features complement the ionizer's core function while ensuring your equipment remains protected from electrical faults and power surges during static elimination operations.

Circuit Protection Mechanisms

Circuit protection mechanisms serve as the first line of defense against electrical hazards in anti-static ionizers. When you're operating these devices, you'll find multiple safety features working together to prevent electrical accidents. These include fuses, circuit breakers, and ground fault circuit interrupters (GFCIs) that automatically shut down the system if they detect an electrical overload or short circuit.

You'll notice that modern ionizers comply with strict electrical safety standards, such as UL and CE certifications, guaranteeing they meet industry requirements for safe operation. The circuit protection system continuously monitors electrical flow, responding instantly to any abnormal conditions that could pose risks to you or your equipment.

To maintain these safety features, you'll need to conduct regular inspections and testing. Your ionizer's circuit protection mechanisms won't function properly without routine maintenance.

It's essential that you verify the functionality of all safety components, including fuses and circuit breakers, to make certain they'll respond effectively when needed. By keeping these protection mechanisms in peak condition, you're safeguarding both your workforce and valuable equipment from potential electrical hazards.

Electrical Isolation Systems

Modern ionizers' electrical isolation systems provide multiple layers of protection against shock hazards while operating your equipment.

These systems create a physical barrier between the power source and the ionizer's operating components, guaranteeing you're protected from potentially dangerous electrical currents. The high voltage necessary for ionization remains safely contained within the device, while external ground plates are carefully enclosed to prevent accidental contact.

You'll find these key safety features in modern ionizers:

- I.R.G. (Insert Ring Ground) technology that internally encapsulates the ground plate, eliminating exposure to electrical components

- Physical separation mechanisms that prevent current flow between the ionizer and connected devices

- Enclosed ground plate designs that minimize the risk of accidental electrical contact during operation

When you're working with anti-static ionizers, these isolation systems act as your primary defense against electrical accidents.

They're specifically engineered to maintain a safe operating environment while still delivering effective static elimination. The combination of physical barriers and specialized grounding technology guarantees you can safely operate your ionizer without worrying about electrical shock risks, even in demanding industrial applications.

Maintenance Safety Requirements

Several critical safety requirements must be followed when maintaining anti-static ionizers to guarantee peak performance and prevent hazards.

You'll need to monitor maintenance indicators closely, as modern ionizers come equipped with overhaul notification functions and discharge needle cleaning alerts that signal when service is due. These indicators help you maintain ideal performance and prevent potential safety risks. Regular air filters in purifier-ionizer combination units require frequent checks and replacement.

You should pay attention to accessibility features when performing maintenance tasks. One-touch cleaner systems and easy-to-clean designs make your daily maintenance routines more efficient and safer. The device's compact design features allow for convenient maintenance access in tight workspaces.

If you're working with explosion-proof ionizers, you must follow strict maintenance protocols to maintain their safety features, especially in environments with flammable materials.

When maintaining your ionizer, you'll need to confirm it continues meeting specific safety standards, including ozone emission limits.

You should regularly check the condition of discharge needles and probes, replacing them when indicated by the system's notifications.

For ionizers with automatic cleaning functions, you must verify that these systems are operating correctly to maintain the device's safety features and prevent potential hazards from static discharge or component damage.

Balanced Ion Generation Controls

Balanced ion generation's effectiveness depends on precise control systems that maintain equilibrium between positive and negative ions. You'll find these controls vital in protecting sensitive electronic components from both electrostatic discharge (ESD) and electrostatic attraction (ESA). Modern ionizers use sophisticated monitoring systems to guarantee consistent performance across various environmental conditions.

To maintain ideal protection, you'll need to understand these critical control elements:

- Ion balance monitoring that continuously adjusts output to maintain equal quantities of positive and negative ions

- Airflow distribution systems that guarantee ions reach all target areas effectively

- Environmental sensors that compensate for humidity changes affecting ion generation

When you're working with sensitive electronics, you can't rely on grounding alone. That's why balanced ion generation controls offer flexible solutions through multiple ionization methods, including AC, DC, and pulse AC systems.

You'll notice these controls are particularly effective in cleanroom environments where precise static elimination is vital. Whether you're using overhead ionizers or bar-type systems, proper control mechanisms guarantee you're getting consistent, reliable protection against static-related damage while maintaining compliance with ISO 20.20 ESD standards.

Emergency Shutdown Systems

Safety-critical emergency shutdown systems serve as your last line of defense against potential equipment damage and hazardous conditions in ionizer operations. When you're working with explosion-proof ionizers, these systems become essential safeguards that automatically detect and respond to potential malfunctions before they escalate into serious incidents.

You'll find these shutdown systems equipped with advanced sensors and automated logic that continuously monitor operating conditions. If they detect any abnormalities, they'll immediately initiate a controlled shutdown sequence, isolating electrical components and triggering integrated alarm systems to alert you and other personnel.

The systems are designed to respond within milliseconds, which is vital when preventing electrical surges or other hazardous situations. You can also manually activate the shutdown sequence if you notice any concerning signs. The system's clear status indicators help you monitor its operational state, while backup power supplies guarantee it'll function even during power failures.

To maintain this critical safety feature, you'll need to schedule regular maintenance checks and confirm compliance with relevant safety standards. Remember, your emergency shutdown system's reliability directly impacts your facility's overall safety protocol.

Personnel Protection Design Elements

Building upon robust emergency shutdown systems, personnel protection design elements provide multiple layers of defense against static-related hazards.

You'll find extensive safety features integrated into modern ionizers, including self-diagnosis functions and visual feedback systems that alert you to maintenance needs and static charge presence.

The key design elements emphasize operator protection through:

- Non-blower ionization technology that prevents dust and air pressure damage while protecting sensitive components and personnel.

- Ultra-robust construction with rubber protectors that withstand impacts and guarantee long-term durability in demanding environments.

- One-touch cleaning systems that minimize maintenance risks and reduce your exposure to static-related hazards.

You'll benefit from compact, installation-friendly designs that reduce workplace hazards while maintaining peak static elimination performance.

The combination of high-speed neutralization capabilities and balanced ion production ensures you're protected from both electrostatic discharge (ESD) and electrostatic attraction (ESA).

When you're working in clean rooms or controlled environments, these ionizers effectively eliminate particulate contamination while providing targeted protection through localized ionization, making them essential for maintaining both personnel and product safety.

Environmental Safety Considerations

Industrial environments demand extensive static control measures to protect against multiple hazards. In areas with explosive risks, static electricity can create dangerous sparks that might trigger fires or explosions, particularly in ATEX zones.

You'll need to take into account that high humidity, while helping reduce static charges, can introduce complications like oxidation and soldering issues.

When you're working in cleanrooms, you'll find that ionization becomes essential for eliminating both particulate contamination and ESD risks. Air filtration alone won't solve the problem of subvisible particles smaller than 25 microns.

You'll want to implement localized ionization solutions that can move with your workstations, offering flexibility as production layouts change.

Your ESD safety plan should incorporate different ionizer types based on specific needs. Whether you're using bar, blower, or spot type ionizers, you'll need to guarantee proper airflow and regular maintenance.

Don't forget that human interaction and improper workstation setup are common ESD hazard sources. You should maintain humidity levels between 40-60% and implement a thorough grounding program that includes regular inspections and training to create a truly static-safe environment.

Performance Monitoring Safeguards

Modern anti-static ionizers come equipped with sophisticated monitoring systems to maintain peak performance and safety. Both TRINC and KEYENCE models feature extensive LED indicators and diagnostic functions that alert you when maintenance is required, ensuring uninterrupted protection against static buildup.

You'll find multiple safeguards working together to maintain ideal performance:

- Automated Cleaning Systems – KEYENCE's SJ-F700 Series and TRINC's one-touch cleaner provide automated maintenance functions that protect discharge needles and probe tips, reducing the risk of performance degradation.

- Real-Time Diagnostics – KEYENCE's SJ-H Series continuously monitors ion generation levels through self-diagnosis functions, while TRINC systems track cumulative usage and needle cleanliness through LED notifications.

- Performance Verification – KEYENCE's visualization technology lets you confirm static elimination effectiveness through visible indicators and bar LEDs, ensuring you're always aware of the system's operational status.

These monitoring features work alongside advanced technologies like I.C.C. and I.R.G., delivering consistent static elimination across wide areas while maintaining efficiency.

You'll receive timely alerts for cleaning and overhaul needs, typically after 4 years of use, ensuring your ionizer's safety features remain fully functional.

Frequently Asked Questions

Can Ionizers Interfere With Nearby Electronic Test Equipment or Measurement Devices?

Yes, your ionizers can interfere with nearby electronics, especially AC and fan-based models. You'll notice potential disruptions in test equipment readings, so it's best to position ionizers carefully away from sensitive devices.

What Is the Typical Lifespan of Ionizer Emitter Points Before Replacement?

You'll find that ionizer emitter points don't have a fixed lifespan. They typically need replacement based on usage, environment, and maintenance. Most devices alert you when it's time for cleaning or replacement through built-in indicators.

Do Ionizers Produce Any Ozone as a Byproduct During Operation?

Yes, your ionizer can produce ozone as a byproduct during operation. You'll find that high-voltage electric fields split air molecules, which then recombine into ozone. Modern designs aim to minimize this production.

How Does Temperature Fluctuation Affect the Performance of Anti-Static Ionizers?

You'll notice your ionizer's performance drop when temperatures fluctuate outside 10-40°C. It'll affect ion balance, air conductivity, and static elimination efficiency while potentially damaging components if operated in extreme conditions.

Are There Different Voltage Requirements for Ionizers Used in Explosive Environments?

Yes, you'll need specialized low-voltage ionizers for explosive environments. They're designed to operate at reduced power levels to prevent sparks and ignition risks, meeting strict safety requirements for hazardous area protection.

In Summary

You'll find anti-static ionizers are built with safety protection because they manage potentially dangerous high voltages and ion emissions. These safeguards protect you, your equipment, and the environment from electrical hazards, ozone exposure, and uncontrolled discharges. When you're working with ionization technology, these built-in safety features guarantee reliable operation while preventing accidents and maintaining precise ion balance for peak performance.

Leave a Reply