You'll need several essential anti-static tools to protect your sensitive electronics from damage. Start with an anti-static wrist strap connected to a reliable ground point, which prevents static discharge while you work. Add an ESD-safe mat for your workspace, along with proper storage solutions like metallic-blend bags and HDPE containers. Don't forget humidity control – keeping levels between 30-60% helps prevent static buildup. Since walking across carpet can generate up to 35,000 volts, and components can be damaged by just 100 volts, proper protection is vital. There's much more to learn about keeping your electronics safe from invisible static threats.

Essential Anti-Static Equipment

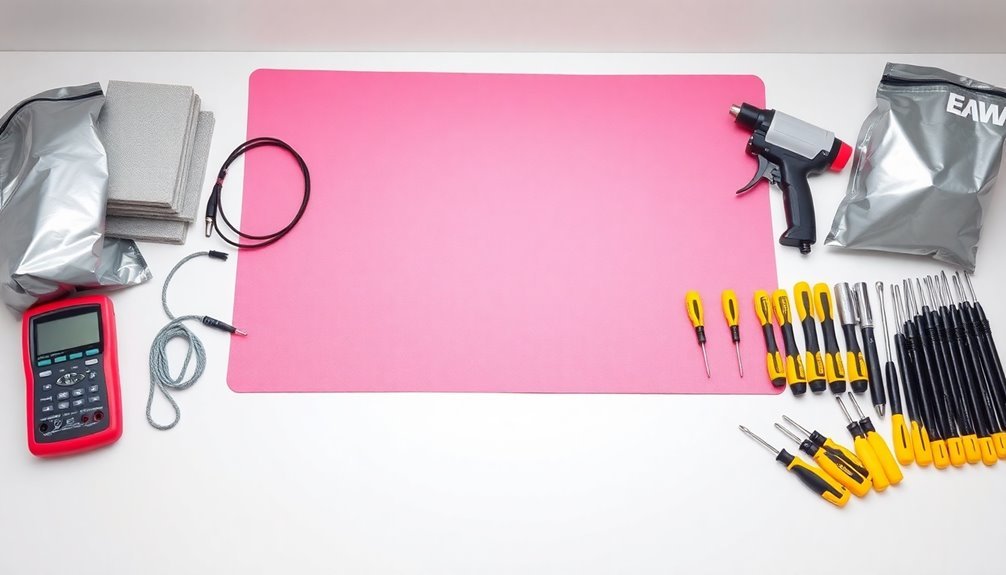

Anyone working with sensitive electronic components needs proper anti-static equipment to prevent costly damage. Your workspace should include an anti-static mat that dissipates static charges, creating a safe surface for handling electronics.

You'll also need an ESD-safe workbench specifically designed with materials that protect against static electricity. Maintaining proper temperature and humidity levels helps prevent static buildup in your workspace. Consider using metallic-blend bags when storing or transporting components to block electromagnetic interference.

Don't overlook the importance of personal grounding equipment. You should always wear a grounding wrist strap that connects you to a common ground point, preventing accidental static discharge to sensitive components.

For workspace maintenance, you'll need an ESD vacuum cleaner that's built with static-dissipative materials to safely clean your area without generating harmful static charges.

Your furniture choices matter too. Invest in ESD-safe chairs and benches made with static-dissipative materials. These pieces of equipment work together to create a thorough static-free environment.

Remember that each piece of anti-static equipment serves a specific purpose in protecting your electronics. When you're setting up your workspace, confirm all these elements are properly connected and grounded to maintain an effective static-control system.

Understanding Static Discharge Risks

The dangers of static electricity pose a constant threat to electronic components, with damage occurring at surprisingly low voltage levels. Your electronic components can suffer damage from static discharges as low as 100 volts, while simply walking across a carpeted floor can generate up to 35,000 volts.

Even if you can't see the damage immediately, static discharge can cause cumulative harm that leads to component failure over time.

You'll face increased static risks in low humidity environments and areas with synthetic materials. When you're working with integrated circuits, you need to be particularly careful, as they're highly susceptible to electrostatic discharge damage.

Your workplace environment plays an essential role – industrial settings and cleanrooms require specialized anti-static measures to protect sensitive equipment.

You should always follow proper safety procedures when handling electronic components. Using anti-static bags for storage and transportation is vital, and you'll need to ground yourself properly before touching any components.

Remember that static discharge isn't just a threat to your electronics – it can also create safety hazards, potentially causing electrical shocks or fires in certain situations.

Wrist Straps and Grounding Basics

When working with sensitive electronic components, proper grounding through an ESD wrist strap serves as your first line of defense against static damage. Most straps include a 1.8m cord length for optimal mobility.

These essential tools create a direct path for static electricity to flow safely from your body to the ground, preventing potential harm to delicate electronics. Modern wireless designs provide fast 0.1-second discharge capabilities while eliminating tether-related risks. You'll find various types available, from traditional tethered straps to wireless options that offer greater mobility.

For effective protection, you'll need to guarantee proper grounding connections. Your wrist strap must be connected to a reliable grounding source, such as a bonding plug or ESD table mat, to safely dissipate static charge.

Here's what you need to know about choosing and using wrist straps:

- Select a comfortable material that suits your needs – options include stainless steel, carbon-filled rubber, or anti-allergenic fabric.

- Ensure proper skin contact for effective discharge – the strap should fit snugly but not too tight.

- Check your grounding connection points regularly – they should be clean and secure.

- Consider your work environment – cleanroom settings may require specialized straps.

Choosing Work Surface Protection

Selecting proper work surface protection consistently ranks among the most critical decisions for electronics handling safety. You'll need surfaces with specific resistivity levels between 10^6 and 10^9 ohms to guarantee effective static dissipation while protecting your sensitive components.

Your primary options include ESD-safe mats, which come with built-in grounding capabilities and dissipative materials. You can also apply anti-static sprays like Staticide to existing surfaces or install specialized laminates made from carbon-filled plastics. The Staticide solution's effectiveness can last for several weeks to months on treated surfaces. Wearable Faraday cages created by antistatic garments provide additional protection when working with sensitive components.

For larger workspaces, consider adding ionizing bars to neutralize static charges across entire workbenches or factory floors.

Don't forget to verify your surface protection meets ANSI/ESD S20.20-2014 compliance standards. You'll want to pair your protected surfaces with complementary tools like ESD brushes for cleaning, anti-static trays for organizing components, and ESD test equipment to verify your setup's effectiveness.

Remember that proper grounding is essential – all your work surfaces must connect to a reliable ground point.

Anti-Static Mats and Their Uses

Modern electronics technicians consider anti-static mats their first line of defense against harmful electrostatic discharge. These essential tools are designed with specialized materials, including conductive carbon fibers and dissipative vinyl, to prevent static electricity buildup that could damage sensitive components. Regular resistance testing helps ensure these mats maintain their protective properties.

You'll find these mats in various configurations, from two-layer designs with dissipative surfaces to three-layer versions featuring conductive metal cores. Grounding every 5 feet ensures optimal protection against static buildup.

When you're working with electronics, you'll want to choose the right mat for your specific needs. They're particularly important in:

- Electronics repair stations where you're handling delicate circuit boards

- Data centers and server rooms that house critical equipment

- Manufacturing facilities producing sensitive electronic components

- Testing areas where precision and safety are paramount

You'll notice that anti-static mats come in different sizes and types to suit various applications. Whether you're setting up a workbench or protecting an entire floor, these mats create a safe pathway for static charges to dissipate.

They're not just about protecting your equipment – they also enhance workplace safety by reducing the risk of sparks and shocks that could harm both workers and sensitive electronics.

Storage Solutions for Components

You'll need three essential storage solutions to protect your sensitive electronic components from static discharge: ESD-safe containers made of specialized materials like HDPE and PP, humidity control systems that maintain levels above 15% relative humidity, and properly grounded shelving units.

Your ESD containers should match your specific needs, with blue anti-static options for cleanroom environments and black conductive containers for general storage.

When you're setting up your storage area, remember to integrate these solutions with your existing anti-static measures, including wrist straps and anti-static mats, to create a complete ESD-protected environment.

ESD-Safe Storage Containers

Effective ESD-safe storage solutions form the backbone of any electronics workspace where static-sensitive components need protection. You'll find various container types specifically designed to prevent electrostatic discharge damage, from conductive storage bins to specialized SMD component boxes.

These containers feature permanently conductive materials that maintain their protective properties over time, ensuring your sensitive electronics stay safe.

When choosing ESD-safe storage containers, you'll want to evaluate options that offer both protection and organization. The most effective solutions include interlocking designs, spring-loaded hinges, and stackable features that make accessing and organizing components easier.

Here are the essential types of ESD-safe storage you should evaluate:

- Conductive polypropylene bins for general component storage

- Six-drawer ESD cabinets for organized SMD storage

- Static dissipative boxes with protective membranes for shipping

- Stackable bins with reinforced walls and anti-slide tabs

You'll benefit from these containers' compliance with ANSI ESD-S20.20 standards while gaining practical advantages like damage prevention and efficient organization.

Whether you're working in an engineering lab or managing a data center, these storage solutions provide the protection your sensitive electronics need.

Humidity Control Systems

Beyond standard ESD-safe containers, humidity control systems serve as an essential layer of protection for moisture-sensitive electronic components.

These specialized storage cabinets let you maintain precise humidity levels between 20% and 60% RH, protecting your valuable electronics from moisture-related damage while preventing static electricity buildup.

You'll find these systems particularly valuable if you're working with moisture-sensitive devices like PCBs, integrated circuits, or LCD components.

They're designed to extend your components' floor life by up to 10 times when stored at ultra-low humidity levels below 5% RH.

The cabinets feature high-accuracy sensors and automatic desiccant regeneration, ensuring consistent performance without maintenance hassles.

What makes these systems especially practical is their quick recovery time – they'll return to your set humidity level within 30 minutes after a door opening.

You'll also benefit from their ESD-safe and anti-corrosion coatings, which provide additional protection for sensitive electronics.

For your manufacturing environment, maintaining ideal humidity levels (around 40% RH) creates a protective film on surfaces that helps dissipate electric charges, reducing the risk of ESD-related failures and ensuring consistent product quality.

Grounded Shelving Units

Grounded shelving units represent a critical foundation for any electronics workspace, combining static protection with efficient storage solutions.

These specialized storage systems use conductive materials and integrated ESD protection features to safeguard your sensitive electronic components from static damage. You'll find that modern grounded shelving offers modular designs that can adapt to your changing storage needs while maintaining strict static control standards.

When selecting grounded shelving for your workspace, you'll need to take into account several key features that guarantee ideal protection:

- Floor grounding capabilities through conductive casters and proper grounding cables

- ESD-safe materials like conductive powder-coated shelves or dissipative plastic components

- Adjustable wire shelves to accommodate various component sizes

- Easy-to-clean surfaces that maintain cleanroom compliance

Whether you're storing SMT reels, circuit boards, or other sensitive electronics, these shelving units help you meet industry standards while keeping your components organized.

You'll need to maintain them regularly by cleaning surfaces and checking grounding connections to guarantee continued ESD protection.

For mobile applications, make sure you're using conductive casters to maintain proper grounding as you move the units around your workspace.

Testing Your Anti-Static Tools

Regular testing of your anti-static tools guarantees their reliability and effectiveness in protecting sensitive electronic components. You'll need specific testing equipment to verify your anti-static setup meets safety standards and performs as intended.

| Testing Tool | What It Checks |

|---|---|

| Surface Resistance Meter | Conductivity levels of work surfaces and mats |

| ESD Wristband Tester | Functionality of wrist straps and footwear |

| Electro Field Meter | Static charge levels in your work area |

| Personal Grounding Tester | Proper grounding of your ESD equipment |

| Tera-Ohmmeter | Surface resistance for compliance verification |

Start your testing routine by checking your wrist strap daily using an ESD wristband tester. You'll want to verify your anti-static mat's conductivity weekly with a surface resistance meter. Monitor your workspace's static levels using an electro field meter, especially during dry seasons when static buildup is more common.

For thorough testing, use an ESD audit kit to evaluate your entire static control system. Don't forget to test your ESD-safe tools and equipment regularly to verify they're maintaining their static-dissipative properties. Replace any tools that show signs of wear or fail testing immediately.

Proper Handling of Circuit Boards

Three fundamental principles guide the proper handling of circuit boards: using ESD-safe tools, maintaining proper grounding, and following safe handling procedures.

To protect your sensitive electronics, you'll need to use specialized tools like ESD-safe tweezers, anti-static brushes, and static dissipative gloves. Always work on static dissipative mats and confirm you're wearing a properly connected grounding strap.

For ideal protection of your circuit boards, follow these essential handling practices:

- Hold circuit boards by their edges only, avoiding direct contact with components and traces.

- Store boards and components in conductive containers or anti-static bags when not in use.

- Keep your work surface clean and free of debris that could cause static buildup.

- Use ionizing tools or anti-static sprays to neutralize existing charges on boards.

Remember to regularly inspect your anti-static tools and equipment for wear or damage.

When moving circuit boards between workstations, maintain proper grounding procedures throughout the transfer. You'll also want to confirm your workspace has clearly marked grounding points and that all your tools, including screwdrivers and pliers, are ESD-safe to prevent accidental static discharge during maintenance or repairs.

Workplace Environmental Controls

You'll need robust humidity control systems in your electronics workplace to maintain ideal conditions between 30-60% relative humidity, which helps prevent static electricity buildup.

Air purification methods, including HEPA filtration and proper ventilation, work alongside humidity controls to remove particles that could contribute to static charges.

These environmental control systems should run continuously and be monitored regularly to guarantee your workspace stays within the recommended specifications for safe electronics handling.

Humidity Control Systems

Maintaining precise humidity control stands as a cornerstone of electronics manufacturing and handling.

You'll need sophisticated systems to protect your electronic components from both excessive moisture and dangerous dry conditions. Advanced humidity control systems help prevent corrosion, short circuits, and electrostatic discharge while ensuring your components' longevity and reliability.

Modern humidity control solutions incorporate real-time monitoring and data analytics to maintain ideal conditions.

You'll find that these systems can make dynamic adjustments across your production lines, helping you avoid costly component failures and latent defects that could lead to product recalls.

Key elements of an effective humidity control system include:

- Programmable relative humidity controllers that provide precise ON/OFF management of moisture levels

- Adiabatic humidification systems that offer environmentally friendly air cooling while stabilizing indoor climates

- Desiccant dehumidification units that remove excess moisture during high-humidity conditions

- Real-time monitoring sensors that trigger automatic adjustments to maintain ideal humidity levels

Air Purification Methods

Clean air's impact on electronics manufacturing can't be overstated, making advanced purification methods essential for your workplace environment.

You'll need a multi-layered approach to protect sensitive components from airborne contaminants.

Start with mechanical filtration using HEPA filters, which trap 99.97% of particles 0.3 microns or larger. While HEPA filters excel at removing dust and particulates, you'll want to pair them with chemical filtration systems that use activated carbon to tackle VOCs and chemical emissions that could damage your electronics.

For thorough protection, consider adding electrostatic precipitation and UV-C technology to your air purification strategy. Electrostatic systems use electrical charges to capture particles, while UV-C technology eliminates harmful microorganisms that could compromise your clean room environment.

You'll get the best results from an integrated system that combines these technologies. Modern smart purification systems can monitor air quality in real-time and adjust filtration levels automatically.

Make sure your setup includes both particle and chemical filtration capabilities, as electronics manufacturing often involves various contaminants that could affect product quality and worker safety.

Common Static Protection Mistakes

The most damaging static protection mistakes often stem from a fundamental misunderstanding of ESD threats. You might think you're protected because you can't see any sparks, but invisible ESD discharges can silently destroy your sensitive electronics.

Many people falsely believe that only expensive components need protection, when in reality, all electronic components require proper ESD safeguards during handling, storage, and transportation.

Your static protection strategy might be failing due to these common oversights:

- Relying solely on wrist straps without implementing a thorough ESD protection plan

- Using contaminated or poorly maintained ESD equipment, including ionizers and garments that have lost their protective properties

- Bringing non-ESD items like bubble wrap, plastic containers, or personal belongings into static-controlled areas

- Neglecting regular testing and monitoring of ESD protection equipment

You'll need to maintain strict control over your EPA (ESD Protected Area) by keeping out unauthorized materials and regularly checking your equipment's effectiveness.

Don't forget that proper training is essential – everyone who handles electronic components should understand basic ESD principles and proper use of protection equipment.

Emergency Static Prevention Methods

When you're dealing with electronic components and don't have professional anti-static equipment on hand, you can create quick DIY solutions like using aluminum foil as a temporary grounding surface or dampening your work area with a light mist of water.

You'll want to set up your workspace by clearing plastic materials, maintaining proper humidity levels, and touching a grounded metal object before handling sensitive electronics.

For emergency home grounding methods, you can connect yourself to a metal water pipe using a simple wire wrapped around your wrist, or work on a concrete floor which naturally helps dissipate static charge.

Quick DIY Static Solutions

During unexpected static emergencies, you can implement several quick DIY solutions to protect your sensitive electronics. When proper anti-static equipment isn't readily available, you'll need to rely on household items and quick fixes to prevent static discharge damage.

Creating a makeshift wrist strap using conductive materials and a metal clip can serve as a temporary grounding solution, while increasing room humidity through a humidifier or steam can help dissipate static charges.

Here's what you can do immediately to protect your electronics:

- Ground yourself by touching metal objects like door handles or faucets before handling sensitive components.

- Change out of static-prone clothing (like wool or synthetic materials) and opt for cotton garments.

- Create a temporary anti-static workspace using aluminum foil as a grounding mat.

- Use a light mist of water-based anti-static solution on your work surface and clothes.

Remember to identify temporary grounding points in your immediate environment.

If you're working with electronic components, store them in makeshift anti-static containers like aluminum foil wrapping until you can obtain proper ESD-safe storage solutions.

While these methods aren't permanent fixes, they'll help protect your electronics until you can implement proper anti-static measures.

Static-Free Workspace Setup

In accordance with proper ESD safety protocols, setting up an emergency static-free workspace requires immediate protective measures for your sensitive electronic components.

You'll need to establish a grounded foundation using an anti-static mat with a resistance range between 10^5 and 10^8 ohms, connecting it properly to a ground point for effective static dissipation.

Your tools must be ESD-safe, utilizing either conductive materials that allow electricity to flow freely or dissipative materials that resist electrical flow.

Don't forget to pair these with an anti-static wrist strap for complete protection.

You'll also need to wear appropriate anti-static clothing and accessories that meet ANSI/ESD S20.20-2014 standards, ensuring they're properly grounded to create an effective Faraday cage around your body.

For additional protection, you can employ static reduction devices like ionizing bars or anti-static guns.

These tools emit ions that neutralize static charges on various surfaces and objects.

When you're working with sensitive electronics, you'll want to use these devices to eliminate static cling and prevent dust attraction that could compromise your components' integrity.

Home Emergency Grounding Methods

Throughout emergency situations, you'll need reliable grounding methods to protect sensitive electronics from static damage. Understanding the available grounding options can help you make informed decisions when setting up protection for your devices.

- Rod grounding serves as your primary defense in residential settings, requiring an eight-foot copper or stainless steel rod driven into the ground to create a safe path for excess current away from your electronics.

- For larger spaces, you'll want to evaluate plate grounding, which uses a buried metal plate to handle higher electrical loads and provides thorough protection across extensive areas.

- The Ufer method offers a modern approach using concrete-encased electrodes, making it an excellent choice if you're building a new home or upgrading your current grounding system.

- You'll need to maintain any grounding system you choose by keeping the surrounding area clear and scheduling regular inspections.

Remember to work with licensed electricians for installation and maintenance of these systems. They'll guarantee proper implementation based on your specific soil conditions and electrical requirements, while following safety guidelines to protect both you and your valuable electronics from static-related damage.

Frequently Asked Questions

Can Anti-Static Tools Lose Their Effectiveness Over Time?

Yes, your anti-static tools can lose effectiveness through material degradation, improper cleaning, environmental exposure, and continuous static loads. You'll notice reduced performance through visible wear, increased component failures, and static discharge incidents.

How Often Should Anti-Static Sprays and Coatings Be Reapplied?

You'll need to reapply anti-static sprays and coatings every few weeks to months, depending on humidity levels and usage. Check with a surface resistance meter and follow your product's specific manufacturer guidelines for timing.

Do Temperature and Humidity Affect Anti-Static Tool Performance?

Yes, your anti-static tools' performance is greatly affected by temperature and humidity. High temperatures can degrade materials and reduce conductivity, while humidity levels impact static dissipation and ionization efficiency. Monitor both factors carefully.

Are Generic Anti-Static Tools as Effective as Brand-Name Ones?

While you'll find generic anti-static tools work for basic tasks, brand-name options offer more reliable protection with proven quality control, better materials, and documented testing. They're worth the investment for sensitive electronics work.

Can Anti-Static Equipment Interfere With Sensitive Electronic Measurements?

Yes, your anti-static equipment can interfere with electronic measurements through EMI, ion emission, and grounding issues. You'll need to properly position and shield devices while maintaining correct grounding to minimize these effects.

In Summary

You'll save yourself significant time and money by investing in basic anti-static equipment for your electronics work. Make sure you've got a quality wrist strap, anti-static mat, and proper grounding tools before handling sensitive components. Don't forget to maintain proper humidity levels and always check your equipment's effectiveness. With these precautions in place, you're well-protected against costly static discharge damage.

Leave a Reply