Circuit boards need protection from static electricity because even a tiny discharge can destroy sensitive electronic components instantly or cause hidden damage that reduces their lifespan. You'll find that everyday activities like walking on carpet or handling plastic materials can generate up to 35,000 volts of static charge – far more than enough to harm delicate circuits. Static damage costs the electronics industry billions annually, with up to 25% of electronic failures linked to ESD (electrostatic discharge). That's why proper ESD protection measures, from anti-static mats to humidity control, are essential for anyone working with circuit boards. Understanding these risks is just the beginning of protecting your valuable electronics.

Understanding Static Electricity Basics

Static electricity builds up in and around electronic devices through a simple process of charge imbalance. When you interact with objects in your environment, you're constantly creating opportunities for electrons to transfer between surfaces.

This transfer occurs through the triboelectric effect, where materials exchange electrons when they're rubbed together or separated. The voltage potential between objects can reach levels exceeding 40 kilovolts per centimeter.

You'll find that static electricity becomes more prevalent in dry conditions, as humidity typically helps dissipate charges. When you walk across a carpet or remove clothing, you're creating charge imbalances that can accumulate on your body.

These charges remain until they find a path to discharge, which often happens when you touch a conductive material.

In electronic environments, this process is particularly significant because static electricity can move in two ways: through attraction or repulsion. When you have an imbalance of positive charges on one surface and negative charges on another, they'll attract each other.

Conversely, similar charges repel. This fundamental behavior explains why static electricity poses such a risk to circuit boards – the charges will naturally seek to balance themselves, potentially flowing through sensitive electronic components and causing damage.

ESD Damage to Circuit Boards

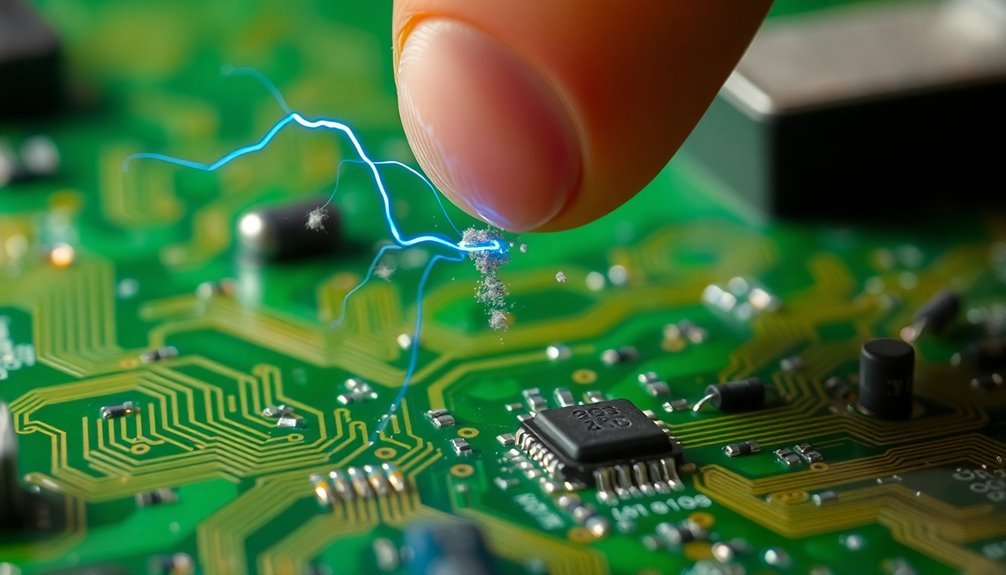

When you're working with circuit boards, electrostatic discharge can instantly destroy sensitive components through catastrophic failure.

Static electricity resembles miniature lightning bolts when discharging through PCB circuitry, following paths of least resistance.

You'll find that ESD doesn't always cause immediate destruction, as it can also create hidden damage that degrades component performance over time.

Your circuit board may continue functioning after ESD exposure, but its operational lifespan could be substantially reduced due to internal weakening of semiconductor junctions and materials.

Immediate Component Destruction

A sudden electrostatic discharge can instantly destroy sensitive electronic components on circuit boards, leading to catastrophic failures. When you're handling circuit boards, even a small static charge from your fingertip can release enough voltage to permanently damage critical components like transistors, capacitors, and integrated circuits.

| Component Type | Damage Mechanism | Result |

|---|---|---|

| Transistors | Gate oxide breakdown | Complete failure |

| Capacitors | Dielectric puncture | Loss of capacitance |

| ICs | Junction burnout | Immediate malfunction |

You'll find that immediate component destruction often occurs when ESD travels through the board's conductive pathways, creating a destructive chain reaction. The damage is particularly severe because today's electronic components operate at increasingly lower voltages, making them more susceptible to static discharge. Modern ESD protection components must be strategically placed near entry points to effectively guard against static damage. When ESD strikes, it can instantly melt internal connections, create short circuits, or burn through protective layers within components.

Unlike gradual wear and tear, immediate ESD damage is catastrophic and irreversible. You won't be able to repair these components once they're destroyed, requiring complete replacement of the affected parts or entire circuit boards. This type of damage directly impacts product reliability and can result in significant financial losses during manufacturing.

Long-Term Performance Degradation

Though circuit boards may seem to function normally after an ESD event, hidden damage can trigger a slow decline in their performance over time. This latent damage isn't immediately apparent but can steadily degrade your circuit's reliability and functionality through accumulated ESD exposure. You'll notice your devices becoming less reliable as partially conducting paths develop within components. The rapid current flow during discharge events can create microscopic holes in integrated circuits.

What makes latent damage particularly concerning is that you won't detect it during initial testing. Your circuit board might pass quality checks but harbor microscopic weaknesses that'll manifest weeks or months later.

Several factors can contribute to this hidden deterioration, including uncontrolled static from human touch, charged objects in proximity, and even the use of common materials like plastic and Styrofoam.

You can protect your circuits from these long-term effects by implementing proper ESD protection measures. Install ESD bench mats and wristbands in your workspace, and design your PCBs with built-in protection like ground planes and transient voltage suppressors.

It's also vital to keep your electrical equipment properly grounded and maintain strict ESD control protocols. These steps will substantially reduce the risk of performance degradation and extend your circuit board's operational life.

Common Sources of Static Discharge

You'll find that static electricity sources are all around you in everyday items like water bottles, packaging materials, and even your clothing, which can generate thousands of volts.

Your own body acts as a significant static source through normal activities like walking, handling materials, and general movement throughout the day.

When you're working with circuit boards, these common static sources pose a real threat since even a minor discharge from your fingertip can damage sensitive electronic components. The manufacturing industry loses up to $5 billion annually due to ESD-related damage and failures.

Everyday Items and ESD

Inside our everyday environment, static electricity lurks in surprising places and poses substantial risks to electronic components. You'll find static voltages reaching dangerous levels in common items you use daily – from packaging materials to furniture and flooring.

When you handle packaging materials, you're generating considerable static charges. Simply picking up a polybag from your workbench can create up to 20,000 volts, while using packing tape can produce 3,000 volts. The sudden flow of these charges between objects can create visible sparks during discharge.

Your everyday movements contribute notably to static buildup – walking across carpet can generate 35,000 volts, and even vinyl tile walking produces up to 12,000 volts.

You're also creating static charges through routine office activities. Sitting in a chair with urethane foam can generate 18,000 volts, and handling component bags produces between 100 and 800 volts. Even water bottles can create over 5,000 volts of static charge.

The risk persists when you're working with electronic devices, as they can accumulate charges through movement across surfaces or contact with their housings and metal leads. It's crucial to observe that these static discharges occur even in high humidity conditions, making proper protection essential for circuit board handling.

Human Body as Source

Beyond everyday objects, your own body serves as a major source of static electricity and potential harm to circuit boards. When you walk across a floor or move around, you're generating static electricity through a process called triboelectric charging. This occurs due to the contact and separation between your body and other materials, allowing you to accumulate significant electrical charges.

Your body can store enough static electricity to damage sensitive electronic components when you touch or even come near them. The relative humidity of your environment can significantly affect how much static charge builds up, with low humidity levels creating more dangerous conditions. This phenomenon is so well-documented that engineers use the Human Body Model (HBM) to simulate and test how electronic devices respond to electrostatic discharge from people.

The discharge happens rapidly when you touch an electronic component, as the voltage potential between your body and the device equalizes.

You're particularly dangerous to microchips, resistors, and capacitors, which can be permanently damaged by even a small discharge that you mightn't feel or see. That's why it's essential to use protective measures like anti-static wrist straps and grounding mats when handling circuit boards.

These tools help safely dissipate any static charge you've accumulated before it can harm sensitive components.

Protection Methods Against ESD

Effectively protecting circuit boards against electrostatic discharge (ESD) requires a thorough approach that combines facility controls, built-in circuit protection, and proper handling procedures.

You'll need to start with facility-level protection by establishing Electrostatic Protected Areas (EPAs). These zones should include conductive flooring materials, anti-static mats, and proper humidity control.

Your staff must wear protective clothing with conductive filaments to maintain proper grounding while handling sensitive components.

For circuit-level protection, you'll want to implement built-in safeguards. Place suppressors at ESD entry points and select appropriate transient circuit protection devices. It's vital to minimize impedance between protected IC pins and surge sources, guaranteeing ESD current flows through protection circuits rather than sensitive components.

When storing or transporting circuit boards, you must use anti-static bags that work on the Faraday Cage principle. Always guarantee your boards are properly packaged in ESD-protective containers, and verify that anyone handling them is properly grounded.

You can add extra protection by incorporating ESD protection devices like TVS diodes and varistors on critical components. Remember to keep vias close to inputs for efficient ESD current drainage to ground.

Environmental Factors Affecting Static

The environmental conditions surrounding your circuit boards play a critical role in static electricity generation and control. You'll find that humidity levels are particularly essential, as dry conditions substantially increase the risk of static build-up.

When relative humidity drops below 40%, you're more likely to experience static-related issues because there isn't enough moisture in the air to dissipate electrical charges.

You'll notice these effects are more pronounced during winter months when the air is naturally drier and colder. Your heating system can worsen this situation by further reducing indoor humidity levels.

In contrast, summer's higher humidity typically reduces static concerns, though air conditioning can create pockets of dry air that require attention.

To protect your circuit boards, you'll need to maintain proper environmental controls. Installing humidifiers can help you keep relative humidity between 40% and 60%, which substantially reduces static build-up.

You should also implement static control measures like ESD bench mats and wrist straps, especially in areas where you handle sensitive electronics.

Remember to regularly monitor your facility's temperature and humidity levels using appropriate measurement tools to guarantee your static protection measures remain effective.

Cost Impact of Static Damage

Understanding environmental controls is just one piece of the static protection puzzle – the financial stakes make it even more compelling. When you consider that static damage costs the electronics industry billions annually, with product losses ranging from 8-33%, you'll realize why protection is essential.

You're looking at damage costs that can range from mere cents for simple components to hundreds of dollars for complex devices.

If you're manufacturing or handling circuit boards, you should know that even a single static discharge can destroy them instantly or create latent defects that worsen over time. Major companies report that up to 25% of their electronic part failures stem from static damage.

You'll face not just the immediate replacement costs but also expenses for repair, rework, shipping, and labor.

The good news is that investing in static protection measures offers significant returns. Companies often see a 10:1 return on their ESD control investments.

Without proper protection, you're risking more than just immediate costs – you're potentially compromising your product reliability, customer satisfaction, and business reputation. For companies relying heavily on electronic equipment, a major static-related failure could even threaten their survival.

Best Practices for Static Control

Setting up proper static control measures can shield your circuit boards from devastating ESD damage. To protect your PCBs during design, you'll need to implement ground planes, minimize metallic connectors, and use transient voltage suppressors at input and output ports. Keep track lengths short to reduce parasitic inductance, and guarantee proper spacing between tracks, especially near high-voltage areas.

In your manufacturing environment, you must maintain strict static control protocols. Always use wrist straps connected to earth ground when handling PCBs, and install static control mats at workstations.

You'll also benefit from bi-polar ionization generators that neutralize static charges by producing both positive and negative ions.

When handling PCBs, grasp them by their edges and wear appropriate protective clothing. Store your boards in protective bags to prevent exposure to moisture and static buildup.

Keep your workstation clean and free of materials that could generate static electricity. Don't forget to regularly inspect and maintain your static control equipment to guarantee it's working effectively.

Frequently Asked Questions

Can ESD Damage Occur During Shipping Even With Protective Packaging?

Yes, your circuit boards can still face ESD damage during shipping if the protective packaging is damaged, improperly sealed, or doesn't meet required standards. You'll need intact, properly sealed ESD packaging for complete protection.

How Often Should ESD Protection Equipment and Materials Be Tested?

You'll need to test your ESD equipment at different frequencies: wrist straps daily, worksurfaces quarterly, ionizers quarterly, and continuous monitors semi-annually. Critical items and high-risk environments require more frequent testing.

Do Wireless Devices Require Different ESD Protection Than Wired Ones?

Yes, you'll need specialized ESD protection for wireless devices due to their exposed antennas, higher signal powers, and sensitive RF ICs. They're more vulnerable than wired devices and require two-stage protection approaches.

What's the Average Lifespan Reduction of Components Exposed to Minor ESD?

You'll find it's difficult to pinpoint exact lifespan reductions, but minor ESD exposure typically cuts component life by 20-50%. Even small static events can weaken internal structures, accelerating normal wear and degradation.

Can Circuit Boards Recover From Minor ESD Exposure Without Immediate Failure?

You can't guarantee recovery from minor ESD exposure. While your board may continue functioning initially, it's likely experiencing latent damage that'll reduce its lifespan and reliability over time without visible symptoms.

In Summary

You'll want to take static protection seriously when handling circuit boards, as even a small discharge can cause immediate or latent damage to sensitive components. By following proper ESD protection methods, maintaining controlled environments, and using anti-static equipment, you're safeguarding your valuable electronics from costly failures. Remember, prevention is far less expensive than replacing damaged circuit boards or troubleshooting mysterious performance issues.

Leave a Reply