You'll find three reliable storage shelf systems that effectively prevent static charge in sensitive environments. Anti-static storage racks use specialized materials like ABS resin and galvanized steel with electrostatic spray coating for thorough protection. Carbon steel ESD shelving provides excellent conductivity with its high carbon content and surface resistance of less than 1 x 10^6 ohms. Grounded tote container systems feature high-density polyethylene construction with copper wire grounding mechanisms for maximum safety. Each system meets strict industry standards and offers unique advantages to protect your valuable electronic components. Discover which solution best fits your specific storage needs.

Anti-Static Storage Racks

Static electricity poses a significant threat to sensitive electronic components, making anti-static storage racks essential for protecting valuable equipment. These specialized storage solutions are constructed using materials like ABS resin, galvanized steel, and electrostatically dissipative plastics, safeguarding reliable protection against electrostatic discharge. The robust steel frame construction ensures these storage systems can handle both lightweight components and heavy industrial equipment.

You'll find these racks feature electrostatic spray coating that creates a protective baking paint layer, enhancing durability while preventing rust formation. To effectively dissipate static charges, the racks incorporate ground wires and anti-static rubber components.

You can adjust the layer height and pitch to accommodate various storage needs, while the modular design allows for both horizontal and vertical expansion.

When you're setting up your anti-static storage system, you'll need to guarantee proper grounding connections and maintain regular cleaning schedules. The racks comply with international standards like EN 61340-5-1, guaranteeing reliable ESD protection.

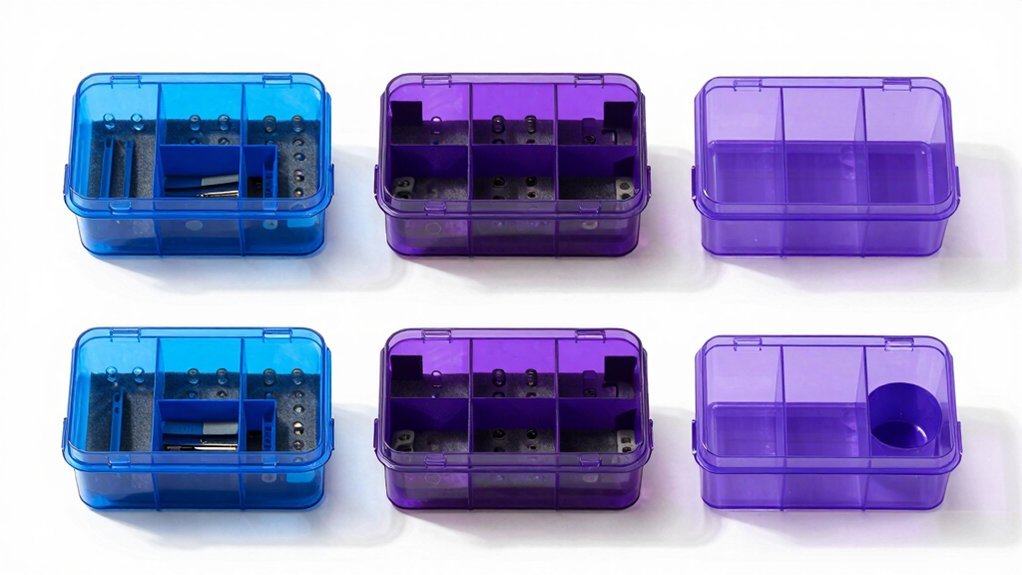

You can choose from various configurations, including stackable bins, cabinets with adjustable dividers, and specialized PCB racks with individual compartments. For maximum protection, you'll want to combine these storage solutions with other ESD safety measures, such as anti-static footwear and proper grounding protocols.

Carbon Steel ESD Shelving

Among the most robust anti-static storage solutions, carbon steel ESD shelving offers exceptional durability and reliable static discharge protection. You'll find these systems are constructed with steel containing 0.1% to 2.1% carbon content, which provides both strength and excellent conductivity. The surface resistance measures less than 1 x 10^6 ohms, making it ideal for dissipating static electricity safely.

When you're setting up carbon steel ESD shelving, you'll notice its tubular or channel frame design that maximizes structural integrity. The shelves come with either solid or perforated steel surfaces, protected by powder coat or epoxy finishes.

You'll need to guarantee proper installation on a level concrete floor and connect the built-in grounding points, such as copper strips or grounding clamps, to effectively discharge static.

You can customize these shelving systems with accessories like bins, totes, or drawers to meet your specific storage needs. To maintain peak performance, you'll want to clean the shelves regularly and inspect them for wear.

The system meets ANSI/ESD S20.20 standards, making it perfect for electronics manufacturing and other static-sensitive environments.

Grounded Tote Container Systems

In accordance with ESD safety standards, grounded tote container systems provide essential static protection through their specialized construction using high-density polyethylene and conductive materials.

These systems are compliant with MIL-B-81705-B regulations and incorporate robust grounding mechanisms like copper wires to effectively dissipate static electricity. The integration of safety interlocks ensures secure operation while preventing accidental discharge during material handling.

When you're handling sensitive electronic components, you'll appreciate how these containers prevent static damage through their anti-static or conductive materials, maintaining surface resistivity of 10^5 ohms/sq. or less.

You can customize these totes to fit your specific product dimensions, and they're suitable for clean rooms, warehouses, and production environments requiring stringent static protection.

You'll benefit from the system's cost-effective approach to protecting your components while meeting regulatory requirements. The containers feature quick disconnect valves and dust caps for efficient operations, and they're built with durability in mind to withstand regular use.

Whether you're storing regulated products or food items, these containers meet UN ratings and FDA compliance standards. They're particularly valuable in environments where static sparks could pose risks, offering you a reliable solution for safe storage and handling of sensitive materials.

Frequently Asked Questions

How Often Should ESD Storage Systems Be Tested for Proper Grounding Functionality?

You'll need to test your ESD storage systems quarterly to verify proper grounding functionality. Make sure the resistance to ground remains below 1.0E9 Ω to maintain effective static charge protection.

Can Humidity Levels Affect the Performance of ESD Storage Systems?

Yes, humidity levels substantially impact your ESD storage system's performance. You'll find that low humidity increases static buildup, while maintaining 40-60% relative humidity helps dissipate charges and improves ESD protection effectiveness.

What Is the Average Lifespan of an ESD Storage Shelf System?

You'll find that most ESD storage shelf systems last 12 months with basic protection, though some materials offer 3-year guarantees. With proper maintenance and protection from UV light, you can extend their functional lifespan substantially.

Are ESD Storage Systems Effective in Extreme Temperature Environments?

Yes, you'll find ESD storage systems are effective from -60° to 250°F, but you should maintain temperatures between 18-22°C for ideal performance. Extreme temperatures can affect conductivity and increase ESD risks.

How Do You Properly Clean ESD Shelving Without Compromising Its Anti-Static Properties?

You'll need to use ESD-specific cleaners with microfiber cloths, working top to bottom. Don't use regular cleaners or IPA wipes. Wipe with slightly damp cloths and let surfaces dry completely before use.

In Summary

You'll find these three storage solutions offer reliable protection against static discharge in your sensitive inventory areas. Whether you choose anti-static racks, carbon steel ESD shelving, or grounded tote systems, you're taking essential steps to safeguard your electronic components. By implementing any of these storage options, you'll minimize the risk of static damage while maintaining an organized, efficient workspace.

Leave a Reply