The top anti-static monitoring solutions for your workstation include the Desco 19341 Mini Monitor, Botron B9201, Static Solutions CM-1700 Guardian, and SCS 770732 724 Plus for thorough ESD protection. You'll also want to think about the Transforming Technologies CM310, which offers reliable single-wire monitoring capabilities. These systems provide essential features like real-time alerts, continuous wrist strap testing, and workstation surface monitoring to prevent costly ESD damage. When choosing your solution, you'll need to decide between single-wire monitors for basic protection or dual-wire systems for critical operations. Let's explore what makes each option uniquely suited for your specific needs.

Understanding Anti-Static Monitoring Systems

Standing at the forefront of electrostatic discharge protection, anti-static monitoring systems serve as crucial safeguards for sensitive electronic components and manufacturing processes.

These reliable systems can be installed in various configurations including on ESD mats or under workbenches to suit different workplace setups. Single wire monitors offer an economical solution for basic ESD protection, while dual wire systems provide enhanced safety through continuous resistance monitoring. If you're managing multiple workstations, you might want to think about advanced stationary monitors or module-based systems that can oversee several operators simultaneously.

These systems don't just protect your equipment; they'll save you time and money by eliminating the need for periodic testing and manual logging. You'll receive instant feedback on the status of your ESD protection measures, and the systems will alert you immediately if there's a protection failure.

When you're implementing an anti-static monitoring system, you'll need to think about factors like compatibility with your existing equipment, regular calibration requirements, and integration capabilities. Don't forget to factor in user training and maintenance needs.

The right system will provide thorough protection while fitting seamlessly into your current operations and safety protocols.

Key Features To Consider

Now that you're familiar with anti-static monitoring systems, selecting the right features will determine your success in ESD protection.

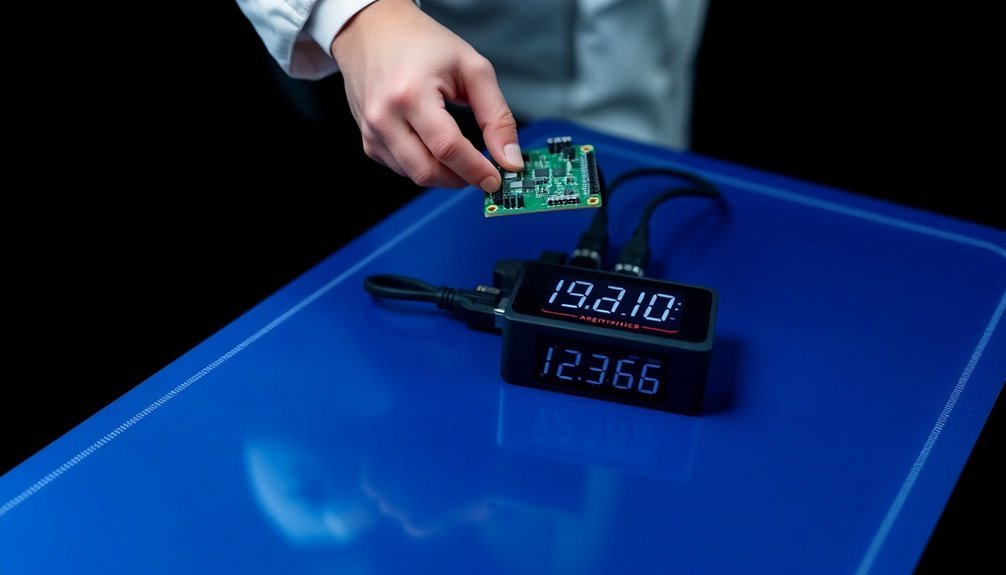

Focus on monitoring capabilities that include visual and audible alarms for immediate alerts, along with continuous assessment of static electricity levels. You'll want instant feedback on your wrist straps and work surfaces, plus reliable resistance monitoring using dual conductor technology. Operating on 120 VAC power supply, these systems ensure consistent performance throughout your workday.

Consider how well the solution integrates with your existing setup. Look for systems that support both single and dual wire configurations, and if you're managing multiple workstations, opt for multi-user options.

You'll need a system that's built tough for industrial environments while maintaining a compact footprint.

Don't overlook data management features. Your monitoring solution should track historical data and display real-time information to help you identify trends and maintain compliance. Choose a system with thorough logging capabilities that'll support your decision-making process.

Finally, prioritize user experience and safety features. You'll want an intuitive interface that promotes compliance while protecting your sensitive equipment. Make sure the system can be customized to match your specific monitoring requirements and operational workflow.

Top ESD Monitoring Solutions

While numerous ESD monitoring solutions exist in the market, several standout products offer exceptional value and reliability. You'll find the Desco 19341 Mini Monitor leading the premium segment at $154.69, offering thorough monitoring capabilities. For budget-conscious buyers, the Botron B9201 Continuous Monitor provides reliable protection at just $48.54, while the Static Solutions CM-1700 Guardian offers a balanced mix of features at $53.90.

| Brand | Model | Price |

|---|---|---|

| Desco | 19341 Mini Monitor | $154.69 |

| Botron | B9201 Continuous | $48.54 |

| SCS | 770732 724 Plus | $59.36 |

When selecting your ESD monitoring solution, you'll want to think about the installation requirements. You'll need a grounded 110-volt outlet and proper mounting location for ideal visibility. Most of these monitors come with NIST calibration certificates, ensuring accuracy in your ESD protection efforts. They'll provide instant feedback on wrist strap and worksurface status, eliminating the need for daily testing and logging. For high-reliability applications, continuous monitoring systems comply with stringent ESD TR-19 standards. You can find these products through various distributors like Correct Products, Ultrastat, and Gotopac, which offer extensive selections from multiple manufacturers.

Single-Wire Vs Dual-Wire Monitors

Two distinct technologies dominate the ESD monitoring landscape: single-wire and dual-wire monitors. Your choice between these systems will substantially impact your workstation's ESD protection effectiveness and overall costs.

Single-wire monitors use capacitance technology and offer a cost-effective solution for general applications. You'll benefit from lower life-cycle costs and simpler operation, but you should be aware of their limitations.

These monitors can be fooled by dry skin and don't guarantee a consistent electrical connection, making them less suitable for critical operations. The monitors rely on parasitic capacitance of the operator's body to ground for signal measurement.

If you're working with highly sensitive components, you'll want to contemplate dual-wire monitors. They employ resistance-based technology and provide true continuous monitoring through redundant grounding paths.

While they're more expensive than single-wire systems, you'll get superior accuracy and reliability that matches touch tester performance.

When making your decision, you'll need to weigh several factors: your work environment's sensitivity requirements, budget constraints, and comfort considerations.

Keep in mind that dual-wire systems may cause skin irritation due to constant DC voltage, while single-wire monitors don't present this issue.

Always verify that your choice complies with your industry's ESD control standards.

Installation Best Practices

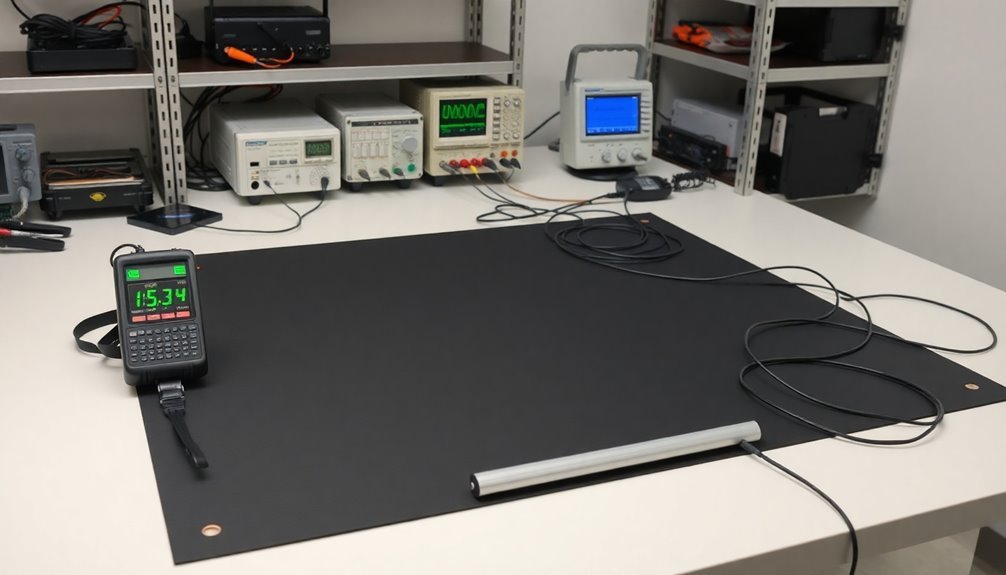

Proper installation of anti-static monitoring equipment starts with thorough preparation and attention to detail. You'll need to identify the green wire building ground point according to EOS/ESD Standard 6 and gather essential equipment, including a surface resistivity meter with resistance-to-ground capabilities.

Start by laying your table mat flat on the workbench, positioning the snaps toward the operator. You can use mild heat to remove any creases that might affect performance. Carefully ensure that the mat is free of debris before proceeding with the installation.

Connect the common point ground cord to the left or right snap of the table mat, and attach the floor mat ground cord to your floor mat.

Don't forget to properly mount the Workstation Monitor where you can easily see the indicator lamps.

When setting up operator grounding, snap your wrist band to the coil cord and verify it's worn directly on bare skin without gaps.

You'll need to configure your Workstation Monitor by selecting appropriate resistance limits (either 10 or 35 megohms) and setting the audible alarm using DIP switch SW2.

Test the entire system's continuity using your surface resistivity meter, and verify all connections from the ground point to each workstation component.

Cost-Benefit Analysis

When you're considering anti-static monitoring solutions, you'll need to account for initial costs including equipment, installation, and employee training, which typically range from $5,000 to $50,000 depending on facility size.

Your long-term savings will come from reduced product failures, fewer repairs, and enhanced manufacturing efficiency, with most facilities reporting significant cost reductions within the first year. Studies show that approximately 30% of electronic failures are attributed to ESD damage, making proper monitoring essential.

The ROI timeline shows exceptional returns, with many companies experiencing a 1,000% return on their investment through decreased warranty claims and improved product quality within 24-36 months of implementation.

Initial Investment Breakdown

Investment decisions for anti-static monitoring solutions require careful analysis of various cost components. When you're planning to implement an ESD monitoring system, you'll need to break down the initial costs into distinct categories.

Basic Equipment Costs

You'll need to budget for workstation monitors, wrist straps, and coil cords, with dual-wire systems typically commanding higher prices than single-wire alternatives. Pink anti-static materials provide Faraday Cage protection for sensitive electronic components at workstations.

Installation Requirements

Your initial investment should account for installation costs, which you can minimize by selecting compact designs that integrate easily with your existing workbench setup.

Supporting Components

Don't forget to factor in anti-static materials, grounding equipment, and any necessary additional components specific to your workspace.

Brand Selection Impact

Your choice between top brands like SCS, Desco, or Transforming Technologies will substantially influence your initial investment, as each offers different pricing tiers and feature sets.

When calculating your initial investment, you'll also need to take into account training costs and potential system integration expenses to guarantee a thorough budget assessment.

Training costs and system integration expenses are crucial components to consider. Training ensures that personnel understand how to use the equipment effectively, which can affect the overall efficiency and reliability of the ESD monitoring system. System integration expenses involve ensuring that the new monitoring system seamlessly integrates with existing infrastructure, which may require additional hardware or software adjustments.

Long-Term Savings Potential

Beyond the initial setup costs, anti-static monitoring solutions offer substantial financial advantages that can offset your upfront investment. You'll find that implementing these solutions leads to substantial reductions in hardware damage, component failures, and unexpected downtime. The implementation of proper ESD control measures significantly enhances product reliability and extends operational lifespans.

| Cost Area | Without ESD Protection | With ESD Protection |

|---|---|---|

| Equipment Lifespan | Shorter due to damage | Extended considerably |

| Maintenance Costs | Frequent repairs needed | Minimal repairs required |

| Production Downtime | Regular disruptions | Rare interruptions |

| Warranty Claims | Higher frequency | Markedly reduced |

| Component Replacement | Regular replacements | Minimal replacements

Return On Investment Timeline

Consistently, organizations implementing ESD control programs achieve remarkable returns on investment, with documented ROIs reaching up to 1,000%. You'll find that major companies like AT&T and Lucent Technologies have tracked their ESD damage costs, reporting substantial savings after implementing proper control measures. A typical payback ratio of 95:1 demonstrates the compelling financial benefits of these programs.

To understand your potential timeline for ROI, you'll need to track several key metrics before and after implementation:

- Initial capital costs divided by the equipment's useful life

- Annual operating and maintenance expenses

- Reduction in repair and return costs, which can drop by 50% as demonstrated by AT&T

- Decrease in scrap rates and improved throughput efficiency

You can expect to see measurable results within the first year of implementation. Even though electronic companies may still lose about 5% of revenue from all product failures, ESD control programs markedly reduce this impact.

With ESD damage potentially costing up to $10 million for major quality failures, your investment in anti-static monitoring solutions can deliver substantial returns relatively quickly.

Real-Time Monitoring Benefits

Real-time monitoring of anti-static equipment gives you instant alerts when protection fails, allowing you to address issues before they damage sensitive components.

You'll benefit from continuous tracking of wrist straps and work surfaces, ensuring your ESD protection remains effective throughout operations.

The immediate detection of faults substantially reduces downtime by eliminating the need for periodic testing and preventing unexpected equipment failures.

Immediate Protection Detection

Modern manufacturing facilities can't afford delays when it comes to ESD protection. With systems like the Dual Operator Workstation Continuous Monitor, you'll receive instant notifications through audible and visual alarms the moment an ESD protection failure occurs. This immediate detection capability guarantees you can address potential threats to sensitive electronics before they cause costly damage.

The RangerBOSS Dual Wire Constant Monitor provides thorough protection through independent monitoring of both operators and work surfaces. You'll benefit from its ultra-low voltage technology and precise threshold detection, guaranteeing reliable ground monitoring around the clock.

Here's what you can expect from immediate protection detection:

- Real-time alerts that trigger the moment your wrist strap or cord fails, allowing you to take immediate corrective action

- Continuous 24/7 surveillance that monitors multiple workstations simultaneously through network-ready devices

- Independent tracking of operator and work surface conditions, minimizing the risk of overlooked issues

- Instant notification through both visual and audible alarms when resistance or voltage thresholds are exceeded

These features work together to provide you with a robust defense against ESD-related incidents, maintaining your facility's productivity and protecting valuable electronic components.

Continuous Performance Tracking

Your manufacturing facility's success hinges on maintaining reliable ESD protection through continuous performance tracking. By implementing real-time monitoring solutions, you'll gain immediate insights into your anti-static systems' performance and guarantee consistent protection of sensitive electronic components.

Real-time tracking enables you to detect and address potential ESD issues before they escalate into costly problems. You'll benefit from detailed analytics that show performance trends, helping you make data-driven decisions about your ESD protection measures.

The system's immediate feedback allows you to quickly adjust your anti-static controls and maintain ideal protection levels.

Through continuous monitoring, you can streamline your facility's ESD management processes and align them with your overall quality objectives. You'll be able to track performance across multiple workstations simultaneously, guaranteeing consistent protection throughout your manufacturing floor.

The unified platform brings all your ESD monitoring data into one accessible location, making it easier to manage and analyze protection levels.

This proactive approach to ESD monitoring helps you maintain high production standards while identifying areas for improvement. You'll create a more responsive and efficient ESD protection system that supports your facility's long-term reliability goals.

Reduced Operational Downtime

Efficiency in manufacturing operations dramatically improves with continuous ESD monitoring systems that minimize production interruptions. You'll notice immediate benefits through real-time alerts that detect potential issues before they become critical failures, allowing your team to take swift corrective actions.

By implementing advanced dual-wire resistance monitors, you're guaranteeing fail-safe protection while maintaining continuous operations.

Your facility can achieve significant downtime reduction through:

- Instant notification systems that alert you when ESD levels exceed safe thresholds, enabling immediate intervention

- Elimination of manual periodic testing requirements, which traditionally interrupt production schedules

- Seamless integration with existing ESD control systems for thorough monitoring without operational pauses

- Automated data logging that supports quality assurance without disrupting workflow

You'll find that professional suppliers like Correct Products can help you select and implement the right monitoring solution for your specific needs. With systems from trusted brands like SCS, Desco, and Transforming Technologies, you're investing in reliable equipment that protects both your operations and workforce.

The dual-wire technology guarantees continuous protection even if one conductor fails, maintaining your production flow without compromising safety standards.

Industry Standards and Compliance

In today's electronics manufacturing environment, strict adherence to industry standards and compliance requirements guarantees reliable ESD protection across workstations and facilities. You'll need to follow ANSI/ESD S20.20, the primary multi-industry standard administered by the EOS/ESD Association through ISO9000 Certification Bodies.

| Standard/Requirement | Specification |

|---|---|

| Wrist Strap Systems | < 3.5 x 10^7 ohms |

| Worksurface Resistance | 1.0 x 10^6 to 1.0 x 10^9 ohms |

| Footwear/Flooring | < 1.0 x 10^9 ohms |

| Common Point Ground | Must use ANSI/ESD S8.1 symbol |

To maintain compliance, you'll need to implement continuous monitoring systems that provide immediate feedback on your ESD control measures. Your monitoring setup should verify that all workstation elements meet the resistance specifications outlined in ESD TR53. This includes checking wrist straps, worksurfaces, and grounding connections. You'll also need to conduct regular audits to confirm your facility maintains proper ESD protection levels. Remember to document all verification results and maintain records of compliance testing, as they're essential for certification requirements and quality assurance programs.

Maintenance Requirements

Through proper maintenance of anti-static monitoring systems, you'll guarantee consistent ESD protection and regulatory compliance.

You'll need to perform annual calibrations on continuous monitors using specialized units like the Desco EMIT 50512 or SCS 770065 Verification Tester. While these devices are typically maintenance-free with no user-adjustable settings, you must still conduct regular inspections of ground connections and confirm proper functionality.

Your maintenance routine should include these essential tasks:

- Check all ground wires and connections daily to confirm they're secure and properly connected to separate electrical grounds

- Test your continuous monitors every 6-12 months using approved verification testers

- Inspect worksurface condition regularly, including resistance checks and resistance-to-ground measurements

- Verify fail-safe mechanisms by confirming alarms trigger when wrist strap or worksurface connections fail

Don't forget to disconnect the mat monitor cord before using a high voltage megohmmeter for worksurface resistance testing.

You'll minimize downtime by using on-site verification testers and following a systematic maintenance schedule. Remember that proper maintenance becomes even more critical when you're handling sensitive electronic components.

Common Troubleshooting Tips

Problems with anti-static monitoring systems can disrupt your production flow and compromise ESD protection. When you encounter issues, start by checking all physical connections, ensuring your wrist straps and cables are securely attached to the monitor and operators.

Don't overlook the importance of verifying ground integrity and inspecting wrist straps for wear that could cause resistance problems.

You'll need to recognize different alarm conditions to troubleshoot effectively. A red LED with an alarm typically indicates high resistance or worksurface mat issues, while a flashing yellow LED signals low resistance. When you see blinking red LEDs, check for high body voltage or disconnected operator remotes.

If you're experiencing false alarms, verify your resistance settings are appropriate for your environment and inspect all cables for damage or corrosion. You can use a resistance substitution box to test the monitor's functionality. For persistent issues, don't hesitate to reset the monitor according to the user guide specifications.

Remember to maintain your system regularly by keeping your workspace clean, using only ESD-safe materials, and performing periodic monitor tests. These preventative measures will help minimize troubleshooting needs in the future.

Future of ESD Monitoring

You'll see significant changes in ESD monitoring through wireless systems that enable remote tracking of critical parameters like grounding integrity and environmental conditions.

Smart integration solutions will connect your ESD flooring, workstation monitors, and facility controls into a unified IoT network for thorough static management.

These advancements will give you real-time data access and automated alerts through mobile devices, making ESD compliance management more efficient and responsive than ever before.

Wireless Monitoring Advancements

Wireless technology has revolutionized ESD monitoring by enabling real-time tracking of static charge levels, grounding integrity, and environmental conditions. This advancement allows these advanced systems to integrate seamlessly with IoT technology and smart building management systems, offering significant cost savings compared to traditional wired solutions.

The implementation of wireless monitoring brings several key advantages to your workstation setup:

- You can track critical parameters remotely through smart sensors that provide instant alerts for static charge fluctuations.

- You'll benefit from predictive maintenance capabilities that identify potential issues before they become serious problems.

- You're able to leverage data logging features for enhanced analysis and operational efficiency.

- You can integrate various components like smart ESD flooring and workstation monitors into a unified system.

With wireless communication protocols like WirelessHART, you're getting secure and efficient data transmission in industrial environments. The system's ability to monitor environmental conditions, including temperature and humidity, guarantees optimal ESD control.

As nanotechnology and IoT continue to advance, you'll see even more sophisticated monitoring solutions that offer superior protection while maintaining efficiency and reliability in your operations.

Smart Integration Solutions

Smart integration solutions in ESD monitoring are ushering in a new era of intelligent manufacturing oversight. You'll find automated testing systems like SmartLog Pro 2 that validate personnel grounding equipment while maintaining thorough compliance records. These solutions integrate seamlessly with access control systems, ensuring only properly grounded operators can enter sensitive areas.

| Feature | Benefit | Implementation |

|---|---|---|

| Real-Time Monitoring | Immediate fault detection | CM300 continuous monitors |

| Automated Testing | Reduced manual oversight | SmartLog Pro 2 stations |

| Data Management | Enhanced compliance tracking | SmartLog Pro Manager |

| Access Control | Improved safety protocols | Electronic door integration |

The future of smart integration extends beyond basic monitoring. You're looking at systems that'll incorporate augmented reality for operator guidance, automated vision inspection for quality control, and data-driven insights for manufacturing optimization. These solutions don't just meet current ANSI ESD S20.20 and IEC 61340-5-1 standards; they're preparing you for Industry 5.0's human-technology collaboration model. With centralized management through web-based applications, you can oversee multiple departments, manage employee certifications, and generate automated compliance reports, substantially reducing your auditing costs while enhancing operational efficiency.

Frequently Asked Questions

Can ESD Monitors Be Used in High-Humidity Environments?

Yes, you can use ESD monitors in high-humidity environments. While humidity helps reduce static, you'll still need monitoring to guarantee proper grounding. Just verify that your monitors are rated for your facility's humidity levels.

How Often Should Calibration Be Performed on Anti-Static Monitoring Devices?

You'll need to calibrate your ESD monitoring devices annually, but check them monthly in high-usage areas. If you're working in extreme conditions or notice performance issues, you should calibrate more frequently.

Are Wireless ESD Monitoring Solutions Available in the Market?

Yes, you'll find wireless ESD monitoring solutions like the StatIQ Band available today. They'll measure your body voltage without wires, provide mobility, and offer real-time monitoring through Bluetooth-connected mobile apps.

Do Anti-Static Monitors Interfere With Other Electronic Equipment Nearby?

No, you won't experience interference from anti-static monitors. They're designed to comply with EMI/EMC standards and use proper grounding techniques, ensuring they work safely alongside other electronic equipment in your workspace.

Can Multiple Brands of Wrist Straps Work With Any Monitor?

You'll find that single-wire monitors work with most standard wrist straps, but dual-wire monitors require specific dual-wire straps from compatible brands. It's best to check manufacturer specifications before mixing brands.

In Summary

You'll find that investing in the right ESD monitoring solution protects your workstation equipment and guarantees workplace safety. Don't overlook regular maintenance and compliance checks to keep your system running efficiently. Whether you choose single-wire or dual-wire monitors, following installation best practices and staying updated with industry standards will help you maintain a static-free environment for years to come.

Leave a Reply