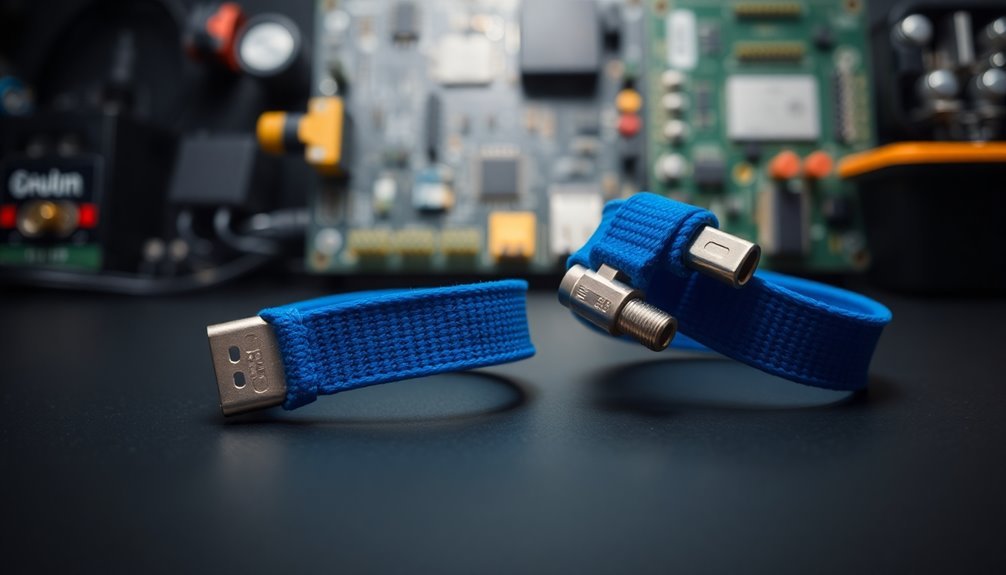

Anti-static wristbands need different connectors to match your specific workplace requirements and safety standards. You'll find options like single-conductor banana plugs for basic protection, dual-conductor systems for critical electronics work, and alligator clips for flexible grounding points. Each connector type serves a unique purpose – some offer quick-release features, while others provide redundant safety through multiple conductors. Your workspace setup, industry requirements, and the level of ESD protection needed will determine which connector works best. Understanding the distinct advantages of each connector type will help you make the right choice for your static-safe environment.

The Purpose of Multiple Connectors

Multiple connectors on anti-static wristbands serve an essential role in protecting sensitive electronic components through diverse grounding options. You'll find these connectors can be attached to various grounding points, including electrical outlets and metal surfaces, ensuring you have flexibility in your workspace setup while maintaining safety standards. The 4mm stud snap on the wristband provides a secure connection to the coil cord.

When you're setting up your ESD-safe workspace, you need to evaluate how to achieve the lowest possible resistance to ground. You don't want to rely solely on alligator clips connected to anti-static mats, as this can increase your system resistance beyond the recommended 35-megohm limit set by ANSI/ESD 20.20 guidelines. Instead, you'll want to use direct connections to proven conductive pathways. Regular inspection and maintenance of connectors ensures consistent protection against static discharge.

The variety of connectors also lets you customize your workspace based on your specific needs. Whether you're left or right-handed, you can position grounding points conveniently on your workbench. You might prefer connecting to your computer case's non-painted metal surfaces or power supply.

Common Connector Types

Understanding the right connector type is vital when setting up your ESD protection system. You'll encounter four main connector types, each serving specific needs and compatible with different monitoring systems.

Single-conductor connectors, featuring a standard banana plug, are the most common and cost-effective option. They're perfect for basic impedance monitoring and ESD testing. Technicians can find these starting at under $2 for disposable options. Stretchy cable designs offer improved mobility while working.

Dual-conductor connectors offer enhanced protection through redundancy, using a stereo plug that works with resistance-style monitors.

For shared workstations, common ground point connectors with 10mm male studs allow two technicians to work simultaneously.

When mobility is important, alligator clip connectors provide versatile grounding options.

- Single-conductor systems are your best bet for basic ESD protection needs

- Dual-conductor setups offer peace of mind with backup protection

- Common ground points work great for team environments

- Alligator clips give you flexibility for mobile work

Each connector type has unique compatibility requirements with monitoring systems and grounding points.

You'll need to match your connector choice to your specific work environment, equipment, and safety protocols to guarantee effective static discharge protection.

Snap Connectors in Action

Your snap connector's quick-release design lets you rapidly detach from grounding points while maintaining secure connections during normal use.

The 1 Meg Ohm resistor inside ensures safe discharge of static electricity during connection and disconnection.

You'll find these connectors reliably perform thousands of attach-detach cycles throughout daily operations, making them ideal for constant workplace use. The stainless steel crocodile clip provides a strong and movable grounding connection.

The standardized 4mm and 10mm sizes guarantee you're using industry-approved attachments that work seamlessly with most ESD protection equipment.

Secure Quick-Release Design

Modern snap connectors form the backbone of anti-static wristband safety systems, combining secure attachment with instant-release capability. These components protect against billions in annual losses due to ESD damage in the electronics industry. American manufacturing ensures the highest quality standards in these critical safety components. You'll find these connectors specifically designed to protect both you and sensitive electronic components while guaranteeing you can disconnect quickly if needed.

When you're working with ESD-sensitive equipment, you'll appreciate how these quick-release mechanisms let you detach instantly without compromising your safety or the integrity of your work.

The design incorporates multiple safety features you'll need for effective static control, including proper insulation and standardized 10mm press studs. You can easily connect and disconnect these components while maintaining consistent grounding throughout your work session.

- You'll notice the snap connectors click firmly into place, giving you clear tactile feedback

- The coil cords stretch and retract smoothly, keeping your movement unrestricted

- Your connection points remain secure until you deliberately disconnect them

- You can quickly adapt the system to different grounding points using various clips

Regular inspection of your connectors guarantees they maintain their quick-release functionality while preserving their secure connection capabilities.

Daily Connection Reliability

Reliable snap connectors prove essential for daily ESD protection, especially when you're connecting and disconnecting multiple times throughout your workday. These connectors guarantee you'll maintain consistent grounding while working with sensitive electronic components, featuring integrated 1 Meg Ohm resistors that help control static discharge events.

You'll find that snap connectors work seamlessly with various workstation setups, offering compatibility with different ESD mats and grounding systems. Whether you're using banana plugs or alligator clips, you can easily secure your grounding connection to electrical outlets or metal railings.

The coil cords that come with these connectors provide flexibility in movement while maintaining reliable contact.

To keep your ESD protection effective, you'll need to regularly inspect your wrist strap and connector components for signs of wear. Testing your connections daily guarantees continuous protection against static discharge.

When you're sharing a workspace, common ground points support multiple users while maintaining individual protection. By choosing the right connector type for your specific needs, you'll create a versatile and reliable ESD protection system that adapts to your changing work requirements.

Standardized Industry Attachment

Industry-standard snap connectors form the backbone of effective ESD protection systems, utilizing 10mm press studs that connect wristbands to various grounding points.

You'll find these connectors made from conductive materials like stainless steel or copper, woven directly into the wristband fabric for peak performance.

When you're working with ESD-sensitive equipment, you'll need different attachment options to suit various scenarios. The standard connections include banana plugs for ESD mats, alligator clips for mobile applications, and ring terminals for electrical outlet connections.

Each connector features built-in 1MΩ resistors to guarantee safe static dissipation while maintaining your protection.

- Socket snaps provide quick-release capability for emergency situations

- Swivel plugs with 6-leaf design guarantee secure banana jack connections

- Coil cords stretch from 1.5m to 1.8m for comfortable movement

- Alligator clips offer versatility for temporary grounding needs

The standardized 10mm size guarantees you'll always have compatibility across different manufacturers and equipment types.

Whether you're using basic grounding points or sophisticated ESD workstations, these connectors maintain consistent performance while meeting industry safety requirements for static discharge protection.

Alligator Clips and Their Uses

Along with their spring-loaded mechanism and serrated jaws, alligator clips serve as essential connectors in anti-static wristband applications. When you're working with sensitive electronic components, you'll want to select insulated clips rated for your specific voltage requirements to guarantee safety and proper grounding.

You'll find that alligator clips in ESD (Electrostatic Discharge) applications come in various types, each serving distinct purposes in static control. For electronics work, you'll typically use mini or standard insulated clips to maintain a secure connection between your wrist strap and grounding point.

| Clip Type | Best for ESD | Key Features |

|---|---|---|

| Insulated | Yes | Protective coating, safe handling |

| Mini | Yes | Precision work, small components |

| Heavy-Duty | No | Too robust for delicate electronics |

| Non-Insulated | No | Lacks safety features |

| Wire-Attached | Yes | Ready-made connections |

When choosing alligator clips for your anti-static wristband, you'll need to evaluate the clip's conductivity and connection stability. The right clip will maintain consistent grounding while protecting both you and your sensitive electronic components from static discharge.

Eyelet Connector Applications

You'll find eyelet connectors offer reliable mounting options through their secure terminal design, making them ideal for permanent industrial installations.

When you're setting up a static-safe workstation, these connectors provide straightforward bolt-through solutions that guarantee consistent grounding.

The ring-shaped terminals create a solid connection point that won't loosen over time, unlike temporary fastening methods.

Secure Terminal Mounting Options

Secure mounting options for anti-static wristband terminals require careful consideration to guarantee reliable grounding connections. You'll need to choose the appropriate terminal type based on your specific application, whether it's a snap connector, banana plug, or ring terminal.

When installing these connectors, you must prioritize safety by deactivating circuits and following proper installation guidelines.

For permanent installations, you'll want to focus on ring terminals that attach securely to electrical outlets or designated grounding points. If you're working in field service or need temporary solutions, consider using alligator clips or portable wristband options that can quickly connect to metal surfaces.

- Snap connectors provide versatility with both 4mm and 10mm options, making them compatible with most standard workstation setups.

- Banana plugs offer a reliable connection for common ground points and can be easily integrated into existing systems.

- Ring terminals guarantee stable, permanent grounding solutions when properly installed in electrical outlets.

- Alligator clips give you flexibility for temporary grounding needs in various field situations.

Remember to verify compatibility between your wristband connectors and grounding points, particularly when working with specific stud sizes or snap configurations.

You'll also need to maintain direct skin contact and proper connection to the grounding source for effective static control.

Industrial Permanent Installation Methods

Industrial-grade eyelet connectors form the backbone of permanent anti-static wristband installations in manufacturing environments. You'll find these metal rings specifically designed to screw into electrical outlets, creating a reliable path to transfer static from your wristband to the building's ground line.

When you're installing these connectors, they'll provide grounding within the 35 megohm limit that ANSI/ESD 20.20 standards require. You'll need to pay attention to safety features when working with permanent installations. The built-in resistor prevents shock hazards while guaranteeing effective static discharge.

If you're setting up common ground points, you should use ring terminals that loop around ground screws, but don't forget to deactivate the circuit during installation. These points typically come with 10mm male studs that connect to ESD mats equipped with female snaps.

For maximum effectiveness, you must verify your installation complies with IEC-61340-5-1 and ANSI/ESD S20.20 standards. You'll want to confirm that your workers are properly electrically bonded to ground through the system.

The stable connection these permanent installations provide will greatly reduce the risk of static buildup on your body during sensitive electronic operations.

Quick Bolt-Through Solutions

For quick workstation setup, eyelet connectors provide a straightforward method of grounding anti-static wristbands through standard electrical outlets. You'll need to secure the eyelet to the outlet screw, creating a direct path to ground for your ESD protection equipment. This method complies with ANSI/ESD 20.20 standards and is commonly found in professional ESD workstation kits.

Before you install an eyelet connector, it's crucial to understand your outlet's wiring and take proper safety precautions. You should always deactivate the circuit before installation and verify both the outlet screw and eyelet are firmly tightened for maximum safety and performance.

- You'll find eyelet connectors are most effective when used exclusively with wrist straps.

- You shouldn't use this method with anti-static mats due to increased system resistance.

- You can identify proper installation by checking for secure connections at both ends.

- You'll need to maintain clear access to the grounding point for regular safety checks.

While eyelet connectors offer convenience for quick setups, they're just one of several grounding options available. Alternative methods include free-standing grounds, common point grounds, and banana plug connections, depending on your specific workplace requirements.

Choosing the Right Connection Method

Selecting an appropriate connection method for your anti-static wristband guarantees reliable static discharge and equipment protection.

You'll need to evaluate several factors when choosing between single-conductor and dual-conductor systems. Single-conductor wristbands use banana plugs and work well with impedance-type ESD monitors, while dual-conductor versions utilize stereo plugs and pair effectively with resistance-style monitors.

Your working environment will determine the best connector type. If you're frequently moving between workstations, you'll benefit from removable coiled cords with alligator clips, which let you attach to various grounding points.

For fixed workstations, you might prefer a 10mm stud connection to an anti-static mat or a direct connection to a common point ground.

The cord length matters too. You can choose between 6-foot and 12-foot coiled cords based on your mobility needs.

Remember that all cords include a built-in 1 Meg Ohm resistor for safety.

When connecting to ground, you've got options: use a grounding socket for dual connections, connect to electrical outlets with eyelet terminals, or attach to common point grounds that accommodate both wrist straps and ESD mats.

Safety Features of Different Connectors

When you're selecting an anti-static wristband connector, you'll find essential safety features like the built-in 1 Meg Ohm resistor that protects you by controlling the rate of static discharge.

You'll get better protection from dual-conductor systems, which maintain grounding even if one conductor fails, compared to single-conductor options that could leave you unprotected if damaged.

The secure connection standards, including 4mm snap sockets and standardized banana plugs, guarantee you maintain consistent grounding while preventing accidental disconnections during your work.

Built-in Current Protection

Built-in current protection stands as a critical safety feature in anti-static wristband connectors. The heart of this protection lies in the 1 Meg Ohm resistor that's integrated into the coil cords. This resistor effectively controls the flow of static electricity, preventing sudden discharges that could damage sensitive electronic components or cause injury.

When you're working with electronic equipment, you'll find that the encapsulated resistors and insulative materials work together to create a safe path for static electricity to dissipate. The protection system allows you to handle sensitive electronics without worry, as it guarantees a controlled release of static charges through proper grounding points.

The current protection features you'll commonly encounter include:

- Built-in resistors that slow down electrostatic discharge rates

- Insulated connectors that prevent direct electrical contact

- Grounding mechanisms that provide safe paths for static dissipation

- Safety-certified components that meet industry standards

You'll notice that different connector types, from banana plugs to alligator clips, all incorporate these protective elements. This standardized approach to current protection helps maintain safety while offering flexibility in how you connect your anti-static wristband to various grounding points.

Secure Connection Standards

Through careful engineering, anti-static wristband connectors adhere to strict safety standards that protect both users and sensitive electronic components. You'll find these connectors equipped with encapsulated 1 Meg Ohm resistors that prevent sudden electrostatic discharges, while their static dissipative materials guarantee safe electricity flow.

When you're working with anti-static equipment, you'll need to understand the different connection standards and their safety features:

| Connector Type | Safety Feature |

|---|---|

| Banana Plug | Direct grounding capability with insulated housing |

| Alligator Clip | Flexible attachment with protective coating |

| Snap Connector | Secure 10mm press stud compatibility |

| 4mm Socket Snap | Standard wrist strap connection with lock mechanism |

| Ring Terminal | Secure ground screw attachment with isolation |

You'll notice that each connector's design prioritizes secure attachment while maintaining isolation from unwanted current flow. The standardized dimensions (4mm and 10mm) aren't arbitrary – they're specifically chosen to guarantee compatibility across different systems and maintain safety protocols. When you're selecting a connector, you'll want to verify it matches your grounding system's requirements and includes proper isolation features to protect against electrical hazards.

Industry-Specific Connector Requirements

Different industries demand specific connector types for their anti-static wristband applications, with requirements varying based on safety protocols and operational needs.

You'll find that single-conductor wristbands with banana plug terminations are widely used in general manufacturing, while dual-conductor systems with stereo plug connections are vital in high-sensitivity electronics production.

When you're working in environments where reliability is essential, you'll want to take into account dual-conductor systems that offer a backup grounding path. These systems integrate seamlessly with resistance-style monitors, guaranteeing continuous protection even if one conductor fails.

For mobile applications, you'll need flexible options like alligator clips that allow quick connections to various grounding points.

- Electronic assembly facilities typically require stereo plug connectors for compatibility with sophisticated monitoring systems

- Medical device manufacturing often demands dual-conductor systems for enhanced safety and reliability

- General manufacturing can utilize standard banana plug connectors for basic static protection

- Research laboratories need versatile connector options, including both snap connectors and 10mm male studs

The key is matching your connector type to your industry's specific monitoring systems, safety requirements, and operational procedures to guarantee effective static control.

Connection Points and Grounding Options

Selecting the right connection points and grounding options directly impacts your ESD protection system's effectiveness. You'll find that electrical outlets provide the most reliable grounding source, offering a direct path to earth.

When setting up your workstation, you can use common point grounds to connect both your ESD mat and wrist strap simultaneously.

Your wrist strap's coil cord comes equipped with a 1 Meg Ohm resistor that's essential for controlling the rate of static discharge. You'll encounter various connector options: banana plugs that fit into grounding jacks, alligator clips for metal surfaces, and ring terminals for ground screws. These cords typically come in 6' or 12' lengths to suit your workspace needs.

You can choose between single-conductor straps, which work with impedance-type monitors, or dual-conductor straps for enhanced protection with resistance-style monitors.

The connection points feature 4mm socket snaps, 10mm studs, or swivel plugs to guarantee secure attachment. Remember, your wrist strap must maintain consistent contact with both your skin and the grounding point to effectively dissipate static electricity and protect sensitive electronics.

Maintenance of Wristband Connectors

Proper maintenance of wristband connectors forms the foundation of reliable ESD protection. You'll need to regularly clean your connectors with a soft cloth to prevent dirt buildup that can compromise electrical conductivity.

When cleaning, avoid harsh chemicals or abrasive materials that might damage the connector's surface. For metal connectors, you can use a soft brush to remove loose particles.

Regular inspection and testing are essential for maintaining your wristband connectors' effectiveness. Check for signs of wear, damage, or corrosion, and test the resistance using an ESD tester to verify proper grounding.

Don't wait to replace defective connectors, as they can compromise your ESD protection.

Here's what you need to focus on for proper connector maintenance:

- Store your wristbands and connectors in a cool, dry place to preserve their antistatic properties

- Keep coil cords unwound to prevent insulation damage and kinking

- Use protective caps when connectors aren't in use

- Replace connectors showing signs of wear, even if they're still functioning

Remember that while maintenance can extend connector life, they'll eventually need replacement. Follow manufacturer guidelines for replacement intervals to guarantee continued protection against ESD damage.

Cost Considerations for Connector Types

When evaluating ESD wristband connectors, understanding cost variations between types can help you make budget-conscious decisions without compromising protection. Single-conductor straps with standard banana plugs offer the most cost-effective solution and work well with impedance-type monitors, while dual-conductor options with stereo plugs cost more but provide additional reliability through redundancy.

You'll find the coil cord component greatly influences your total cost, with variables like length and quantity affecting pricing. If you're planning bulk purchases, you can expect notable discounts when buying 10 or more units compared to individual purchases.

| Component Type | Cost Level | Key Benefit | Best For |

|---|---|---|---|

| Single Conductor | Lower | Cost-effective | Basic ESD protection |

| Dual Conductor | Higher | Redundant protection | Critical applications |

| 6' Coil Cord | Medium | Standard coverage | Regular workstations |

| 12' Coil Cord | Higher | Extended reach | Large work areas |

When considering grounding solutions, you can optimize costs by purchasing bundled systems that include wrist straps and ground wires together. Remember that while alligator clips and specific connectors add to your initial investment, they're essential for proper grounding and shouldn't be overlooked for cost savings.

Frequently Asked Questions

Can Anti-Static Wristbands Protect Against High-Voltage Electrical Shocks?

No, you shouldn't rely on anti-static wristbands for high-voltage protection. They're only designed to dissipate static electricity through a 1 megohm safety resistor and won't protect you from dangerous electrical shocks.

How Often Should Connector Resistance Be Tested in Humid Environments?

You'll need to test your connector resistance daily in humid environments. Don't skip testing, as moisture can affect performance. Use an impedance tester to verify proper grounding and safety compliance.

Do Magnetic Fields Affect the Performance of Anti-Static Wristband Connectors?

You don't need to worry about magnetic fields affecting your anti-static wristband connectors. Their performance relies on electrical conduction and grounding principles, and magnetic fields have negligible impact on these functions.

Can Multiple Wristbands Share the Same Grounding Point Safely?

Yes, you can safely connect multiple wristbands to a shared grounding point as long as you're using proper resistors and maintaining total system resistance below 35 megohms per ANSI/ESD standards.

Are Wireless Anti-Static Wristbands as Effective as Traditional Wired Versions?

No, you shouldn't rely on wireless anti-static wristbands. They're ineffective and don't meet professional ESD standards. Only traditional wired wristbands provide the necessary direct path to ground for proper static protection.

In Summary

When you're working with anti-static wristbands, you'll need different connectors to match various grounding points and workplace requirements. You've learned that snap connectors, alligator clips, and eyelet connectors each serve specific purposes in ESD protection. Remember that choosing the right connector isn't just about convenience—it's about maintaining proper grounding and ensuring your safety while working with sensitive electronic components.

Leave a Reply