Anti-static wrist straps integrate a critical 1 megohm resistor to protect you while working with sensitive electronics. This specific resistance value creates the perfect balance – it's high enough to limit potentially dangerous electrical currents from harming you, yet low enough to effectively dissipate static electricity from your body to ground. You'll encounter static charges up to 20,000 volts from everyday actions like walking or removing clothing, which can instantly destroy electronic components. The 1 megohm protection meets strict ANSI/ESD standards and acts as your safety shield against both static and electrical hazards. Understanding these protective features can mean the difference between safe operations and costly mistakes.

Understanding Static Electricity Hazards

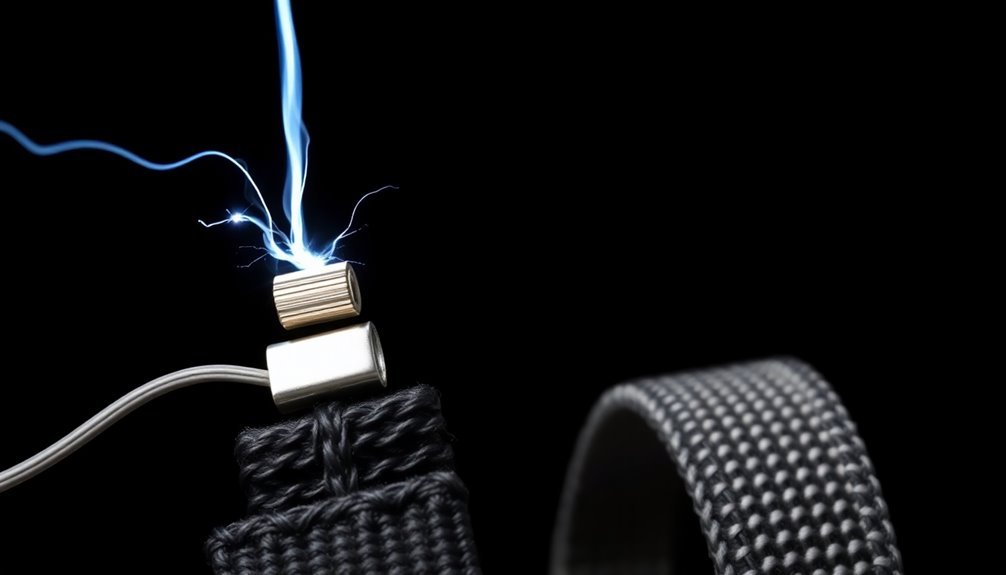

Why do electronics professionals take static electricity so seriously? The answer lies in the invisible but destructive nature of static electricity, which can instantly destroy sensitive electronic components.

When you work with electronics, you're dealing with a risk that's heightened by everyday actions like walking across a room or removing your jacket. The standard 1 Megohm resistor in wrist straps provides essential protection against sudden discharge. The conductive polyester material used in these straps ensures reliable static dissipation while remaining comfortable to wear.

You'll find that static electricity forms through simple friction between different materials, creating an imbalance of electrons. Your body becomes a static generator through normal movement and interaction with clothing, making you a potential threat to electronic components.

What's more concerning is that dry environments greatly increase this risk, while humidity can help reduce it.

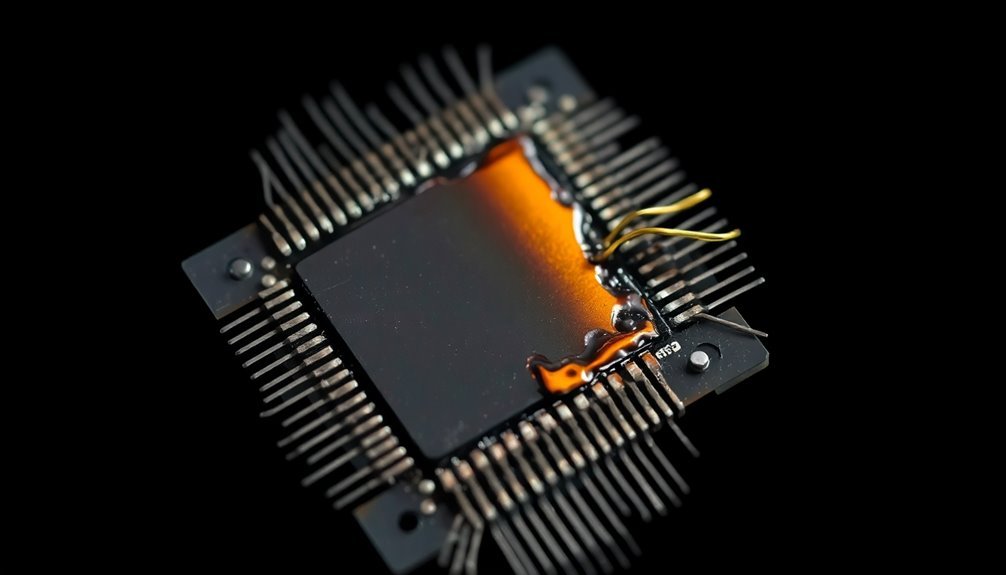

You need to understand that electronic devices are particularly vulnerable to static discharge damage, which often occurs without any visible signs.

That's why compliance with ESD (Electrostatic Discharge) standards isn't optional – it's essential for protecting sensitive equipment.

You'll find these standards strictly enforced in electronics manufacturing and repair facilities, where even a minor static discharge can result in costly damage.

Regular risk assessments and proper grounding procedures have become fundamental practices in managing these invisible but considerable hazards.

Essential Safety Components

What makes an anti-static wrist strap truly safe for electronics work? The core safety feature lies in the 1 megohm resistor, which limits current flow to protect you from electrical shock while still effectively conducting static electricity away from your body.

You'll find that proper anti-static wrist straps combine high conductivity materials with robust safety mechanisms to create a reliable grounding solution. Multiple color options are available to help identify different work areas or user assignments. The included 6 ft coil cord provides ample length for comfortable movement while working.

These essential components work together to guarantee both your safety and the protection of sensitive electronic components:

- A conductive band made from polyester or elastic nylon with metal fibers that maintains 360-degree contact with your skin

- A durable coil cord with built-in safety resistor that connects to ground

- Secure fastening mechanisms like adjustable buckles that guarantee constant contact

- Alligator clips or banana plugs that create reliable connections to grounding points

- Compliance with industry standards such as ANSI/ESD S20.20-2014

The effectiveness of your wrist strap depends on these components working together.

When properly designed, they'll provide consistent static discharge protection while preventing electrical hazards through current limitation.

You'll get maximum protection for both yourself and your sensitive electronic components when all these safety features are present and functioning correctly.

The Power of Megohm Resistance

The 1 megohm resistor serves as a vital safeguard in anti-static wrist straps, carefully balancing safety with static discharge effectiveness.

You'll find this specific resistance value isn't arbitrary – it's designed to limit current flow while still allowing harmful static charges to dissipate safely to ground. When you're working with sensitive electronic components, this resistance helps protect you from accidental exposure to electrical sources.

You'll notice the 1 megohm protection complies with essential industry standards like ANSI/ESD S20.20-2014 and EIA-625, making it important for quality control in electronics manufacturing. With a user satisfaction rating of 4.7, this protection standard clearly meets the needs of electronics repair professionals.

It's especially important when you're handling semiconductors and other ESD-sensitive devices, as it prevents damaging static buildup that could compromise component reliability.

The resistor works in conjunction with other technical features of the wrist strap, including conductive materials and proper grounding mechanisms.

You'll typically find it integrated into a 6-foot coil cord made with durable materials like PVC or polyurethane.

This combination provides you with 360-degree conductive contact while ensuring your safety through controlled static dissipation, making it an indispensable tool in ESD-protected areas.

Protecting Electronic Components

Consistently protecting sensitive electronic components from electrostatic discharge requires proper use of anti-static wrist straps in controlled environments. When you're handling delicate electronics like semiconductors, circuit boards, or hard drives, you'll need a reliable grounding solution that meets industry standards such as EIA-625 and ANSI/ESD S20.20-2014. Recent market growth shows rising ESD compliance requirements across industries are driving increased adoption of protective equipment.

To effectively protect your electronic components, you'll want to guarantee your anti-static wrist strap provides complete coverage with its 360-degree conductive contact around your wrist. The strap's elastic polyester conductive fiber and adjustable buckle will help you maintain consistent skin contact while working on sensitive devices.

- Guarantees protection for microelectronics and semiconductors through proper grounding

- Meets quality assurance standards with specific resistance values of <=10e6 ohms

- Provides continuous static reduction through secure 4mm snaps and alligator clips

- Features retractable coil cords in various lengths for flexible workspace movement

- Maintains safety compliance in ESD-controlled environments like laboratories and engineering facilities

Your anti-static wrist strap's design incorporates breathable materials and adjustable features, allowing you to work comfortably while maintaining consistent protection for your sensitive electronic components throughout your entire work session.

Industry Standards and Compliance

Your anti-static wrist strap must meet strict safety certification requirements, including a resistance range of 0.8 to 1.2 megohms and current limitation to 250 microamps at 250V rms AC.

Global standard specifications, set by ANSI/ESD, require proper marking of non-standard resistances with red features and mandate individual product testing for 20/20 conformance. A current limiting resistor must be positioned at the cuff end. Elastic wristbands are commonly used due to their comfort and adjustability.

You'll need to follow rigorous testing protocols that check both high resistance (above 35 megohms) and low resistance (below 750K ohms) to guarantee your wrist strap maintains proper grounding protection.

Safety Certification Requirements

Meeting rigorous safety standards, anti-static wrist straps must comply with multiple industry certifications to confirm proper ESD protection and user safety.

You'll need to verify your wrist straps meet essential standards like EIA-625, MIL-STD-1686, and ANSI/ESD S20.20-2014 for proper grounding and ESD protection.

The most critical safety requirement is the inclusion of a 1 megohm resistor in the grounding path, which protects you from accidental electrical shock while handling electronic components.

This resistance level effectively limits current flow and slows discharges, creating a safer working environment in ESD-controlled areas.

Key certification requirements you should check include:

- Compliance with MIL-HDBK-263 military standards for construction and materials

- Documented traceability for quality control measures

- Regular testing and inspection protocols

- Adherence to ANSI/ESD S1.1-1998 safety guidelines

- Proper maintenance and wear documentation

You're responsible for regularly checking your wrist strap's condition and confirming it maintains its protective features.

Remember to conduct routine inspections for wear and tear, and immediately report any malfunctions.

Always follow proper training guidelines for correct usage and maintenance to maintain the effectiveness of your ESD protection equipment.

Global Standard Specifications

International standards govern the specifications of anti-static wrist straps, with ANSI/ESD S1.1 setting the primary requirements for resistance limits between 0.8 and 1.2 megohms.

You'll find that the standard specifically calls for a current-limiting resistor of 1 megohm at the cuff end of the cord, with an acceptance testing tolerance of ±20%.

When you're working with ESD-sensitive equipment, you'll need to make sure your wrist strap complies with ANSI/ESD S20.20, which has been adopted globally across semiconductor and hard disk drive industries.

The 1 megohm resistance value isn't arbitrary – it's carefully calculated to limit current flow to less than 0.5 mA at maximum voltage exposure.

If you're using non-standard resistance values, you must clearly mark them on the wrist strap with a prominent red feature.

Your wrist strap's construction should include elastic nylon and metal conductive fibers, providing 360-degree contact around your wrist.

The surface and volume resistances shouldn't exceed 10^6 ohms, and you'll need to maintain direct, unobstructed grounding connections.

These specifications make certain both your safety and proper ESD protection across all industrial applications.

Testing Protocol Guidelines

Regular testing of anti-static wrist straps forms the backbone of an effective ESD protection program.

You'll need to confirm your wrist straps meet industry standards like ANSI/ESD S20.20, which requires resistance levels below 35 megohms. Using an ESD Test Station, you can check for both high and low resistance failures that might compromise safety or effectiveness.

When testing your wrist strap, you're specifically looking for these vital indicators:

- High fail (above 35 megohms) suggests ineffective voltage removal

- Low fail (below 750K ohms) indicates a potential safety hazard

- Damaged coil cords or shorted resistors require immediate replacement

- Soiled or poorly fitted wrist bands won't provide proper protection

- Alternate paths to ground can create false low fail readings

Your testing protocol must verify the 1 megohm resistor's functionality, as it's essential for limiting current to safe levels of 250 microamps at 250 Volts rms AC.

If your wrist strap fails testing, you'll need to replace it immediately to maintain compliance with standards like EIA-625 and MIL-STD-1686.

Proper Grounding Techniques

A robust grounding system forms the foundation of effective anti-static protection. When you're setting up your anti-static wrist strap, you'll need to guarantee a direct, unobstructed path to your grounding point that complies with ANSI/ESD standards. The connection must remain stable and secure throughout your work to maintain continuous protection.

You'll find that proper grounding relies heavily on key components, particularly the 1 megohm resistor that's vital for your safety. This resistor protects you from potential electrical shock while still allowing static discharge to flow safely.

Your wrist strap's conductive materials and coil cord specifications must match industry standards, with typical cord lengths of 6 or 12 feet.

To maintain effective grounding, you'll need to regularly inspect your system's components. Check that your snap connections are secure and that the adjustable strap fits snugly against your wrist.

Don't forget to take into account environmental factors like humidity and temperature, as they can affect your grounding system's performance. When you implement these proper grounding techniques, you're not just following protocol – you're protecting both yourself and sensitive electronic components from static damage.

Common Workplace Applications

You'll find anti-static wrist straps widely used across manufacturing assembly lines where workers handle sensitive electronic components and circuit boards.

In research laboratories, you're required to wear these straps when working with delicate scientific instruments and microelectronic samples to prevent static discharge damage.

Your responsibilities in data center operations include wearing anti-static wrist straps while maintaining or replacing server components to protect against electrostatic discharge that could harm expensive equipment.

Manufacturing Assembly Lines

Manufacturing assembly lines represent one of the most critical environments where anti-static wrist straps prove indispensable.

You'll find these devices essential in protecting sensitive electronic components during production processes, particularly in industries like semiconductor manufacturing and circuit board assembly.

When you're working on an assembly line, you're constantly handling components that could be damaged by even the smallest static discharge.

To guarantee maximum protection in manufacturing settings, you'll need to follow specific protocols and standards like ANSI/ESD S20.20-2014.

The wrist strap's 1 megohm resistor and grounding wire work together to safely dissipate static electricity from your body while you handle sensitive components.

Here's what you can expect when using anti-static wrist straps in manufacturing:

- Increased production efficiency through reduced component failures

- Compliance with industry-specific ESD protection standards

- Protection of microelectronic components during assembly

- Enhanced quality control in precision engineering tasks

- Cost reduction by preventing static-related damage

Research Laboratory Safety

While research laboratories handle diverse experiments and materials, maintaining proper static control is vital for both safety and accuracy. When you're working in biomedical research, you'll need anti-static wrist straps to prevent contamination of samples and protect sensitive analytical equipment from static discharge damage.

These devices are particularly important in labs where you're handling electronic components or conducting experiments that could be compromised by static electricity.

You'll find that static control becomes especially significant in pharmaceutical research labs, where even minor static charges can affect the integrity of your samples or compromise sterile conditions.

When you're packaging or handling sensitive materials, static electricity can't only damage your products but also create safety hazards, particularly in environments where flammable solvents are present.

To maintain safety standards in your lab, you must guarantee your anti-static wrist straps meet ANSI/ESD S20.20 requirements and incorporate the essential 1 megohm resistor.

You'll need to test your equipment regularly, keep it clean, and verify proper grounding connections.

Data Center Operations

Static control plays an essential role in modern data centers, where billions of dollars worth of sensitive electronic equipment requires constant protection.

With over 10,978 data centers worldwide and the market projected to reach $344.06 billion in 2024, protecting these important facilities from electrostatic discharge (ESD) is more important than ever.

You'll find this especially significant in major hubs like Northern Virginia, where vacancy rates are as low as 0.9%, indicating dense concentrations of valuable hardware.

When you're working in data center operations, you'll need to take into account these fundamental static control measures:

- Implement mandatory anti-static wrist straps for all personnel accessing server rooms or handling equipment

- Maintain proper grounding systems throughout the facility, especially in areas with high power consumption (data centers used 7.4 Gigawatts in 2023)

- Install ESD-safe flooring and workspace materials in equipment handling areas

- Use anti-static packaging and containers for component storage and transport

- Confirm climate control systems maintain ideal humidity levels, as extremely dry conditions increase static risks

These precautions are particularly significant in cooling zones, which account for 40% of a data center's energy consumption and require frequent maintenance access to sensitive equipment.

Safety Testing and Verification

Testing and verifying anti-static wrist straps is essential for maintaining workplace safety and protecting sensitive electronic components. You'll need to confirm your wrist strap meets key standards like EIA-625, MIL-STD-1686, and MIL-HDBK-263, while complying with ANSI/ESD requirements for effective grounding.

To verify proper functionality, check that your wrist strap provides 360-degree conductive contact and maintains surface resistivity of <=10e6 ohms. It's critical to confirm the presence of a 1 MegOhm resistor, which protects both you and the equipment by controlling discharge rates.

You should also regularly inspect the grounding wire for damage and verify it's properly connected to a marked grounding point.

Keep detailed records of all testing and verification procedures. You'll want to maintain documentation of compliance with industry standards and track regular maintenance checks.

Make certain your wrist strap's conductivity meets the specified 1 x 10^3 ohms/sq requirement and verify that grounding points are clearly marked and accessible.

Don't forget to regularly inspect alligator clips or banana plugs for secure attachment, as these connections are essential for maintaining proper grounding integrity.

Best Practices for Users

Success with anti-static wrist straps depends on proper selection and daily usage habits. When you're working with sensitive electronic components, you'll need to guarantee your strap maintains full contact with your skin while being connected to a proper ground point.

Choose a strap made from breathable materials like nylon with conductive fibers or polyester with conductive thread to stay comfortable during long work sessions.

For ideal protection of both you and your equipment, follow these essential practices:

- Adjust your strap to fit snugly but not too tight, assuring 360-degree conductivity with your skin

- Check the cord's integrity daily, looking for signs of wear or damage

- Connect only to designated grounding points that you've verified are properly earthed

- Replace your strap immediately if you notice any damage to the fabric, cord, or clasp

- Test your strap's conductivity regularly using appropriate testing equipment

Remember that your strap must meet industry standards like ANSI/ESD S20.20-2014 for reliable protection. The built-in 1 megohm resistor is vital for your safety, so never modify or bypass this component.

Keep your work area clean and maintain a clear path between your strap and the grounding point to guarantee consistent protection.

Frequently Asked Questions

Can Anti-Static Wrist Straps Be Washed or Cleaned Without Damaging Their Conductivity?

You can clean your anti-static wrist strap using mild detergent and minimal water. Don't use harsh chemicals or excessive moisture. Let it air dry naturally to maintain conductivity and avoid heat damage.

How Often Should Anti-Static Wrist Straps Be Replaced for Optimal Protection?

You'll need to replace your anti-static wrist strap every 6-12 months with regular use, or sooner if you notice visible damage, loss of elasticity, or failed resistance tests during routine inspections.

Do Anti-Static Wrist Straps Work Effectively in High-Humidity Environments?

Yes, your anti-static wrist straps will work effectively in high humidity. The built-in 1 megohm resistor maintains safety and performance, while the conductive materials continue to properly dissipate static charges regardless of moisture levels.

Can Multiple People Share the Same Anti-Static Wrist Strap Safely?

You shouldn't share anti-static wrist straps. It's unsafe due to cross-contamination risks, compromised effectiveness from wear and tear, potential health hazards, and violation of safety standards. Always use your own personal strap.

Will Anti-Static Wrist Straps Function Properly Through Clothing or Long Sleeves?

No, you shouldn't wear anti-static wrist straps over clothing or sleeves. They need direct skin contact to function properly. Roll up your sleeves or adjust your clothing to guarantee the strap touches your skin directly.

In Summary

You'll find that 1 megohm protection in anti-static wrist straps isn't just a safety feature – it's essential for both you and your sensitive electronic components. By limiting current flow while still allowing static discharge, you're protecting yourself from electrical hazards and your devices from damage. Make sure you're using properly tested straps that meet industry standards, and always verify your connection before handling electronics.

Leave a Reply