ESD wrist straps protect your sensitive electronic components from static electricity damage that can occur with discharges as low as 25 volts. When you work with electronics, your body can build up static charges, especially in low-humidity environments. These charges can instantly destroy circuits, leading to costly component failures and production delays that cost the electronics industry billions annually. Your wrist strap works by safely connecting you to a ground point through a 1 megohm resistor, preventing sudden discharges. Understanding proper grounding methods and equipment setup will help you maximize your protection and avoid expensive damage.

Understanding Static Electricity Basics

The materials you work with can greatly impact static electricity formation. Common insulators like plastics, wool, and carpets are particularly prone to creating static charges. Sudden discharge occurs when these charged materials come into contact with conductive surfaces. When you handle electronic components, these charge imbalances can pose serious risks. Lower humidity levels increase the likelihood of static charge buildup. Understanding that static electricity results from electron movement between materials helps you recognize why protective measures, like ESD wrist straps, are essential for preventing damage to sensitive electronic equipment.

ESD Risks in Electronics Manufacturing

ESD damage can cost your organization dearly through both immediate component failures and hidden expenses from troubleshooting latent defects that emerge over time.

Your electronic components can fail catastrophically from static discharges as low as 25 volts, which you won't even feel but can destroy circuits worth up to $1 million.

To prevent these costly failures, you must implement proper grounding methods like tested ESD wrist straps and continuous monitoring systems that verify your personnel maintain the correct electrical potential. The wrist straps effectively work by releasing static electricity through direct skin contact and a grounded connection. Annual costs from ESD-related damage in the electronics industry amount to billions of dollars.

Hidden Costs of ESD

Hidden costs of electrostatic discharge (ESD) add up quickly in electronics manufacturing, often catching businesses off guard. When you're dealing with sensitive electronic components, even a minor ESD incident can trigger a chain of expensive consequences that extend far beyond the immediate damage.

The financial impact of ESD-related issues manifests in several ways that you mightn't immediately recognize. ESD training programs for employees are crucial for maintaining a safe manufacturing environment. Quality wrist straps with 1MΩ resistors are essential for preventing large current impacts that could damage components.

- Production delays and decreased efficiency when you have to halt operations to replace damaged components

- Additional labor costs for troubleshooting and repairing ESD-damaged equipment

- Potential loss of customer trust if defective products reach the market

You'll find that investing in proper ESD protection, particularly high-quality wrist straps, is considerably more cost-effective than dealing with the aftermath of ESD damage.

Without adequate protection, you're not just risking component failure – you're also facing potential non-compliance penalties and safety violations. The cost of implementing ESD safety measures is minimal compared to the expenses you'll incur from damaged inventory, production downtime, and compromised product reliability.

Component Failure Prevention Methods

Preventing component failure in electronics manufacturing starts with understanding the primary culprit: your own body's static electricity. You'll need to implement reliable grounding mechanisms to protect sensitive electronic components from potential damage. ESD wrist straps provide a continuous, safe path for static discharge while incorporating essential safety features like current-limiting resistors. Aerospace and hospital environments frequently utilize these protective measures due to their proven effectiveness. Stainless steel bands offer exceptional durability for continuous daily use.

| Prevention Method | Key Benefit |

|---|---|

| Daily Testing | Maintains ideal strap function (<100V) |

| Physical Inspection | Identifies wear and tear early |

| Equipment Verification | Confirms proper resistance levels |

| Proper Grounding | Guarantees safe static dissipation |

| Regular Replacement | Maintains consistent protection |

When you're handling electronic components, you'll find that high-quality ESD protection gear offers significant long-term benefits. By wearing a properly maintained ESD wrist strap, you're creating a safer work environment while protecting valuable components from invisible yet destructive static charges. You should test your strap daily and inspect it regularly for signs of wear. Remember that proper grounding is essential – always connect your strap to an approved grounding point, and verify that the connection maintains the correct resistance levels through periodic testing with specialized equipment.

Discharge Impact on Circuits

While proper ESD protection methods help safeguard electronics, understanding the specific risks of static discharge reveals why such measures matter. When you work with electronic components, even a minimal static charge of 25 volts can inflict severe damage without you feeling the discharge. Your body acts like a capacitor, storing static electricity that can transfer to sensitive circuits through direct contact or proximity.

The impact of ESD on your electronic components can manifest in several critical ways:

- Immediate destructive damage that causes complete component failure

- Parametric damage that reduces performance or functionality

- Latent defects that don't show immediate symptoms but lead to premature failure

You'll find these risks particularly concerning in aerospace and high-precision electronics, where component failure isn't just costly—it's potentially catastrophic.

Static discharge can compromise circuit integrity through various mechanisms, from gate oxide breakdown to junction damage.

What's more troubling is that you won't always notice the damage immediately, as latent defects can surface days or weeks after the incident.

That's why maintaining proper ESD protection through tested, compliant wrist straps isn't just a precaution—it's essential for ensuring long-term electronic reliability.

Anatomy of ESD Wrist Straps

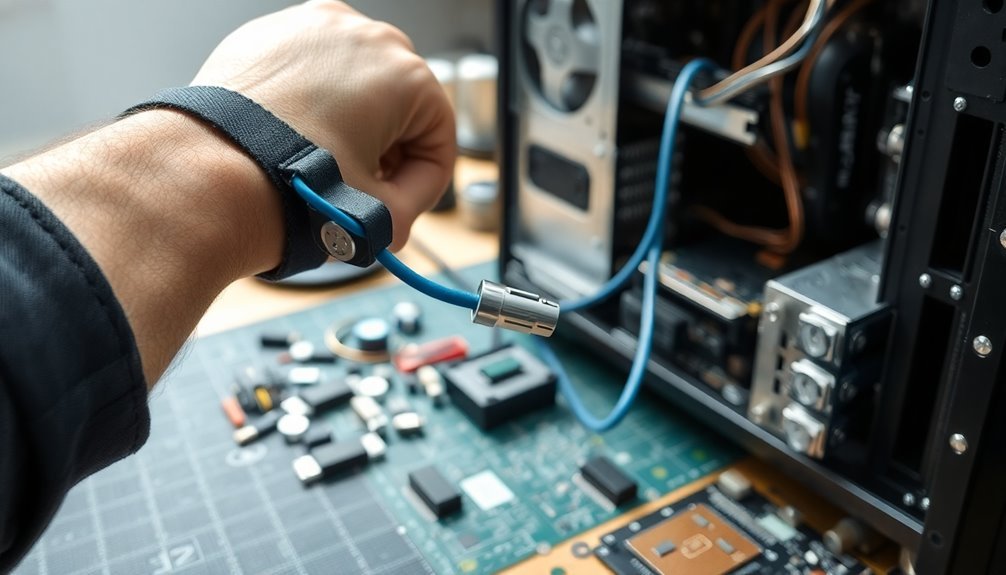

Understanding the anatomy of an ESD wrist strap reveals its surprisingly sophisticated design. You'll find that each component serves a vital purpose in protecting sensitive electronics. The strap itself consists of conductive materials like metal threads or carbon fibers, while the conductive band maintains direct contact with your skin to guarantee effective static transfer.

At the heart of the strap's safety features, you'll find a 1 megohm resistor that limits current flow to keep you protected. The coiled cord connects your wrist strap to a grounding point, typically an ESD mat or designated grounding location. You can adjust the band to fit your wrist comfortably, making sure of constant skin contact for peak performance.

There are several types of ESD wrist straps you can choose from. The most common is the elastic wristband with a Velcro closure, offering both comfort and cost-effectiveness.

Metal wristbands provide better durability and easier cleaning but come at a higher price. For temporary work, you might opt for disposable versions, while wireless types offer greater mobility. Some designs incorporate mixed materials, combining metal rings with rubber conductive wire for enhanced performance.

Proper Grounding Connection Methods

You'll need to guarantee your wrist strap is connected to a proper ground point, such as an equipment grounding conductor or common point ground block, rather than incorrectly attaching it to the edge of an ESD mat.

When setting up your workstation, connect the wrist strap's banana plug or metallic crimp directly to the designated grounding point, and test the connection using a wrist strap tester to verify proper resistance levels.

Avoid common mistakes like daisy-chaining multiple ESD devices or using unreliable alligator clips for grounding connections, as these practices can compromise your ESD protection.

Equipment Setup and Testing

To guarantee reliable ESD protection, proper equipment setup and testing procedures must be followed systematically.

You'll need essential components including grounding systems, ESD wrist straps, antistatic footwear, and a conductive workstation. When setting up your equipment, confirm all components connect to designated grounding points, maintaining the same electrical potential throughout your workspace.

Your daily testing routine should verify that wrist straps maintain less than 100V on your body. Don't skip these checks, as electronic components can be damaged by discharges as low as 25 volts. Remember to log all test results for compliance and tracking purposes.

Key requirements for your ESD protection setup include:

- A common ground point connecting all conductive surfaces

- Properly functioning wrist straps meeting ANSI/ESD S20.20 standards

- Regular verification and maintenance of all grounding components

Your wrist strap must have a direct connection to the grounding point via a conductive wire – wireless options won't provide adequate protection.

If you're using a conductive floor system, confirm it integrates properly with your overall grounding setup. This thorough approach helps prevent both immediate damage and latent defects in sensitive electronics.

Common Grounding Connection Mistakes

While establishing proper ESD protection systems is essential, many technicians make common mistakes when connecting their grounding equipment. You'll need to verify all grounding points before use and confirm they're clearly marked and protected from dust and moisture. Using untested or damaged grounding points can leave your sensitive electronics vulnerable to ESD damage.

Your grounding wires must be high-quality and maintained regularly. Don't use damaged or frayed wires, as they'll compromise your ESD protection. Keep the wires short and direct to minimize resistance, and select materials with proper conductivity for reliable performance.

You must test and maintain your ESD wrist straps daily. Check for physical damage and confirm they're maintaining less than 100 V on your body. Replace any non-conductive parts promptly, as neglected maintenance renders the straps ineffective.

When implementing grounding techniques, connect all conductive surfaces to a common ground point. You'll need to verify continuous grounding before handling any electronic components.

Remember that proper grounding equalizes electrical potential across all components, while incorrect methods can lead to dangerous static buildup and component damage.

Maintaining Your ESD Protection Equipment

Proper maintenance of your ESD wrist strap isn't just about extending its lifespan—it's crucial for maintaining consistent static protection. You'll need to perform daily inspections to check for physical damage, including frayed wires, loose buckles, and compromised grounding points.

Using a wrist strap tester regularly helps verify that your equipment maintains proper electrical integrity.

Your maintenance routine should include these critical components:

- Conducting resistance tests to guarantee the strap maintains less than 100V on your body

- Documenting all test results for compliance and tracking purposes

- Replacing any straps that show reduced conductivity or physical damage

Don't wait for equipment failure before taking action. Replace your ESD wrist strap immediately if you notice any signs of wear, reduced conductivity, or malfunctioning components.

Following manufacturer guidelines for replacement guarantees you're using appropriate, high-quality parts that meet safety standards.

You should also stay current with proper maintenance procedures through regular training. Understanding the correct usage, testing protocols, and inspection requirements will help you maintain effective static protection and prevent costly damage to sensitive electronic components.

Common Workplace Safety Standards

Building on your maintenance knowledge, understanding workplace safety standards helps create a thorough ESD protection strategy.

You'll need to confirm your workspace meets key requirements for effective static control, including properly designated ESD protected areas where sensitive electronic components are handled.

Your facility must maintain grounding systems that keep all components at the same electrical potential, reducing the risk of damaging static discharge. The standard requires that your body voltage remains below 100V when working with sensitive electronics.

You'll also need to integrate your ESD wrist straps with other grounding equipment to create a complete static control system.

To comply with workplace safety standards, you must address static electricity generated from human movement and friction throughout your facility. This means implementing proper grounding protocols and confirming all personnel consistently use their ESD protection equipment.

Your workplace integrity depends on following these standards precisely, as they're designed to protect both workers and sensitive electronic components.

Whether you're in electronics manufacturing, aerospace, or telecommunications, you'll need to adhere to industry-specific regulatory requirements while maintaining these fundamental ESD protection standards.

Choosing the Right Wrist Strap

Selecting the right ESD wrist strap involves more than just picking any conductive band from a catalog. You'll need to take into account your specific industry requirements, the type of work you're performing, and the level of protection needed for your sensitive electronic components.

When choosing your wrist strap, focus on these critical factors:

- Material composition: Look for anti-allergenic materials if you have sensitive skin, and make certain the band uses high-quality conductive materials like anti-static yarns or stainless steel.

- Grounding mechanism: Opt for wired straps over wireless options, as they provide more reliable static discharge protection.

- Compliance standards: Verify that your choice meets ANSI/ESD S20.20 requirements for your industry.

You'll want to prioritize comfort for extended wear while making sure of proper functionality. The strap should include a current-limiting resistor for safety and maintain continuous contact with your skin.

Don't forget to take into consideration the length of the grounding cord based on your workspace layout. If you're working in highly sensitive environments like aerospace or medical equipment manufacturing, you'll need to select straps with enhanced protection features and verified testing capabilities.

Cost Benefits of ESD Protection

Four compelling cost benefits make ESD wrist straps an essential investment for electronics handling. By preventing static damage, you'll protect critical components worth up to $1 million while avoiding latent failures that can surface over time. This direct damage prevention translates into significant savings on repair and replacement costs.

You'll also notice increased operational efficiency when using ESD wrist straps. They guarantee you're properly grounded, allowing continuous work without interruption. This streamlined process reduces downtime and minimizes the need for troubleshooting damaged components, keeping your projects on schedule.

The long-term value of ESD protection can't be overstated. You're not just protecting immediate investments; you're extending component life and guaranteeing device reliability. By complying with ANSI/ESD S20.20 standards, you're implementing a cost-effective solution that safeguards your electronic investments for years to come.

Perhaps most importantly, you'll avoid hidden costs that often go unnoticed. ESD protection prevents secondary expenses related to repairs, additional training, and schedule delays.

It's an integral part of quality control that helps maintain both productivity and profitability in electronics manufacturing and handling operations.

Frequently Asked Questions

Can ESD Wrist Straps Be Worn Over Long Sleeves or Clothing?

No, you can't wear ESD wrist straps over clothing or long sleeves. You'll need direct skin contact for proper static dissipation. Clothing interferes with conductivity, making the strap ineffective at grounding static charges.

Do ESD Wrist Straps Need to Be Removed During Bathroom Breaks?

Yes, you should remove your ESD wrist strap during bathroom breaks. It's both a hygiene necessity and a practical requirement. Just remember to properly reconnect and test it when you return to work.

How Often Should the Coiled Cord of an ESD Strap Be Replaced?

You'll need to test your ESD coiled cord daily if used regularly. Replace it immediately if it fails testing. While some facilities follow six-month replacement schedules, continuous monitoring can help determine exact replacement timing.

Are Wireless ESD Wrist Straps as Effective as Wired Versions?

No, wireless ESD wrist straps aren't effective at all. You shouldn't use them as they fail to properly ground you and can't prevent static build-up. Stick with traditional wired straps for reliable ESD protection.

Can Multiple People Share the Same ESD Wrist Strap During Shifts?

You shouldn't share ESD wrist straps between workers. It's unsafe due to hygiene concerns, can compromise the strap's integrity, and violates safety protocols. Each person needs their own properly fitted and tested strap.

In Summary

You can't afford to skip ESD wrist straps when working with sensitive electronics. They're your first line of defense against costly static damage that can destroy components in microseconds. By following proper grounding procedures and maintaining your ESD protection equipment, you'll save thousands in potential repairs and replacements. Make wearing your wrist strap a non-negotiable part of your electronics handling routine.

Leave a Reply