You'll need ESD-safe tweezers for PCB assembly because they protect sensitive electronic components from static electricity damage. These specialized tools prevent static discharge through their conductive materials and proper grounding features, which helps you avoid both immediate and latent component failures. High-quality ESD tweezers, made with materials like antimagnetic stainless steel or ceramics, offer resistance ratings between 102 and 106 Ohms/sq for ideal static dissipation. When you're handling expensive circuit components, this protection isn't just about safety—it's about saving money on repairs and replacements. Understanding the full scope of ESD protection can transform your assembly process.

Understanding Static Electricity Risks

Every electronic component faces potential damage from electrostatic discharge (ESD), making it essential to understand the risks when handling PCBs and sensitive components.

You'll find that static electricity can accumulate in various ways, even without direct contact between the PCB and charged objects. If you're working in low-humidity environments or around synthetic materials like plastic and Styrofoam, you're at increased risk of static buildup. Modern integrated circuits with their small lithography features are especially vulnerable to ESD damage.

When you're handling electronic components, you need to be aware that ESD damage can occur in two ways. First, there's immediate destruction, which you'll notice early in the manufacturing process.

Second, and more insidiously, there's latent damage that won't cause immediate failure but will degrade your component's performance over time. Even weak ESD events can pose significant risks to your electronics.

The danger intensifies in certain conditions. If you're working in an area with rapidly moving air or using materials that generate static, you're creating an environment where ESD damage is more likely to occur. Using anti-static gloves while handling components adds an essential layer of protection against ESD damage.

The risk is particularly high when you're dealing with sensitive components, as ESD can cause high heat dissipation within these parts, leading to their destruction.

Essential ESD Protection Features

Selecting the right ESD protection features for your tweezers is crucial for safe electronics handling. You'll need to take into account material properties that match your specific application needs.

For high-precision tasks involving chemicals, antimagnetic stainless steel tweezers offer excellent corrosion resistance and ESD protection. If you're working with high temperatures, ceramic tip tweezers can withstand up to 1000°C while maintaining their ESD-safe properties. Static discharge currents from human movement on vinyl floors can reach up to 35,000 volts, making proper ESD protection essential. The fiber tip conductive tweezers provide additional safety with replaceable CarboFib tips.

You'll find that properly designed ESD tweezers come with ergonomic comfort grips to reduce finger fatigue during extended use. Look for polished tip edges that won't scratch delicate components and replaceable tips that let you adapt to different tasks.

When handling sensitive electronics, you'll want tweezers with resistance ratings between 10^2 and 10^6 Ohms/sq for ideal static discharge protection.

Don't forget to pair your ESD tweezers with compatible safety accessories. You should always use anti-static wrist straps and maintain proper grounding connections.

For cleanroom applications, choose tweezers with non-magnetic properties to prevent contamination and guarantee consistent performance during microelectronics assembly and PCB repair tasks.

Material Science Behind ESD Tweezers

The advanced material science behind ESD-safe tweezers combines ceramic compositions and conductive polymer technologies to protect your sensitive electronic components.

You'll find ceramic tip options offering exceptional heat resistance up to 1000°C, while specialized conductive polymers maintain consistent static dissipation properties with resistivity ratings of 105-106 Ohm/sq. PVDF, Carbofib, and PEEK materials provide superior chemical resistance for reliable performance in various industrial applications.

These materials work together to create tools that won't just prevent static discharge but also provide the durability and precision you need for demanding electronics assembly tasks. The incorporation of 30% carbon fiber reinforcement delivers excellent wear resistance while maintaining the essential ESD-safe properties.

Ceramic Composition Benefits

Modern ceramic compositions used in ESD-safe tweezers deliver three critical benefits that make them superior to traditional metal alternatives.

You'll find that these ceramics offer exceptional material properties, effective ESD protection, and versatile application capabilities that guarantee safe handling of sensitive components.

The material properties stand out immediately – you're getting high strength and toughness combined with non-magnetic characteristics and superior chemical resistance. Regular ESD safety training helps technicians maximize these material advantages during PCB assembly.

These tweezers won't corrode when exposed to acids or alkaline solutions, and they'll maintain their integrity even in high-temperature environments.

When it comes to ESD protection, you can rely on the surface resistivity of 10^8-9Ω to effectively dissipate static charges. Multiple tip designs are available to accommodate different component handling requirements.

Since they're made from semiconductive zirconia, you won't have to worry about electrostatic breakdown or metallic contamination during component handling.

They're fully compatible with ESD-safe workstations and meet HBM requirements.

The ergonomic design and precision tips allow you to handle everything from delicate SMT components to sensitive biological samples.

You'll appreciate the excellent operability and comfortable feel during extended use, while the ESD-safe coating provides an extra layer of protection against static electricity.

Conductive Polymer Technologies

According to extensive material science research, conductive and semiconductive materials like stainless steel and ceramics form the cornerstone of ESD-safe tweezer technology, rather than traditional conductive polymers.

You'll find that these materials are specifically chosen for their superior ability to dissipate static charges while maintaining structural integrity during precision handling tasks.

When you're working with ESD-safe tweezers, you're benefiting from carefully engineered materials with surface resistivity levels optimized for static control. For instance, zirconia ceramic components typically feature a resistivity of 10^8-9Ω, providing an ideal balance between conductivity and protection.

The materials create controlled pathways that safely ground static electricity, preventing potentially damaging sparks or current spikes.

You'll notice that manufacturers focus on incorporating high-quality stainless steel and ceramic materials, often enhanced with anti-static coatings, to guarantee reliable static dissipation.

These materials don't just protect against ESD – they're also designed to limit peak current flow during handling operations.

Workplace Safety Compliance Standards

To meet global certification standards, you'll need ESD-safe tweezers that comply with OSHA's strict requirements for handling sensitive electronic components.

Your workplace must maintain thorough ESD control systems, including properly grounded workstations, static-dissipative materials, and regular testing protocols to guarantee safety compliance.

You're required to implement and document proper ESD safety training for all personnel handling electronic components, while following internationally recognized standards for ESD protection and control.

OSHA ESD Safety Requirements

While OSHA doesn't maintain specific ESD safety standards, workplaces must follow industry benchmarks like ANSI/ESD S20.20 to protect sensitive electronic components.

You'll need to implement a thorough ESD control program that includes regular training, proper equipment grounding, and the use of ESD-safe materials throughout your facility.

Your workspace must feature conductive surfaces with resistance to ground between 1 x 10^6 and 1 x 10^9 ohms, and all equipment should connect to a common ground point.

You'll need to guarantee your staff wears appropriate ESD-safe clothing and footwear that provides a reliable path to ground.

When handling PCBs, you must use ESD-safe tools, including properly rated tweezers.

You're required to provide ESD awareness training to all employees who handle sensitive components. This training should cover ESD principles, safe handling practices, and proper use of control equipment.

You'll need to maintain detailed records of training sessions, conduct regular audits, and perform routine inspections to verify compliance.

Remember to continuously monitor and evaluate your ESD control program's effectiveness to protect both your components and your workplace's safety standards.

Global Certification Standards

Successful ESD-safe tweezer implementation requires adherence to multiple global certification standards. When you're selecting ESD-safe tweezers for your PCB assembly operations, you'll need to verify they comply with internationally recognized standards like ISO 9001 and ISO 13485, which guarantee quality management and reliability in manufacturing processes.

To maintain compliance with global standards, your ESD-safe tweezers must meet specific requirements:

- Surface resistivity specifications outlined in ANSI/ESD.S20.20 to effectively dissipate static charges

- Material composition standards following DOD-HDBK-263 for defense-grade applications

- RoHS compliance to verify environmental safety and hazardous substance restrictions

- ESD-safe symbol certification indicating proper static discharge protection

You'll find that these certifications aren't just bureaucratic requirements – they're essential safeguards for your PCB assembly process. The tools must be made from certified conductive or dissipative materials that can safely channel static electricity away from sensitive components.

When you implement ESD control programs in your facility, you're not only protecting your components but also verifying workplace safety compliance. These standards help prevent component failures and maintain consistent quality across your assembly operations.

Cost Benefits for PCB Production

Smart investments in ESD-safe tweezers deliver substantial cost benefits across PCB production operations. You'll notice immediate savings through reduced component damage, as these specialized tools minimize the risk of static electricity compromising sensitive electronic parts. By preventing ESD-related failures, you're avoiding costly repairs and replacements while maintaining higher production yields.

The long-term financial advantages become clear when you consider the durability of ESD-safe tweezers. Made from high-quality materials like stainless steel and ceramic, they require minimal maintenance and resist corrosion, reducing your replacement costs over time. You're investing in tools that consistently perform while demanding fewer replacements.

Your production efficiency will improve greatly, leading to reduced labor costs. The precise tips and ergonomic design enable faster, more accurate component placement, streamlining your assembly processes. You'll spend less time handling components and more time completing assemblies.

Additionally, by meeting industry standards and regulations for static control, you're protecting your business from compliance-related expenses. The initial investment in ESD-safe tweezers pays off through enhanced productivity, reduced waste, and sustained quality control throughout your PCB production operations.

Common Applications in Electronics

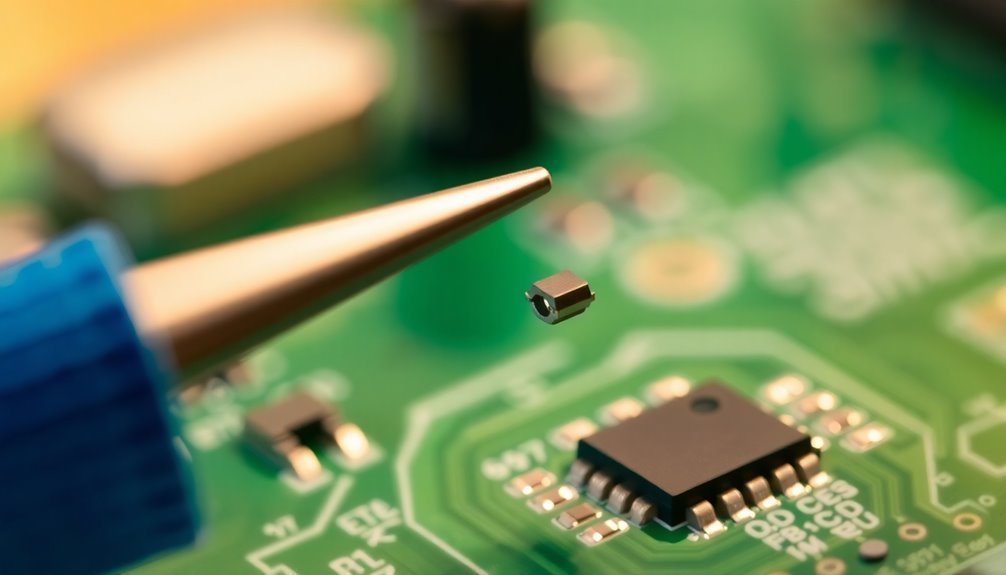

When setting up your PCB workstation, you'll need ESD-safe tweezers as a fundamental tool for handling sensitive electronic components.

You'll use these specialized tweezers to precisely place and position surface-mount devices, resistors, capacitors, and integrated circuits on circuit boards.

During component testing and inspection, your ESD-safe tweezers become invaluable for safely manipulating and examining individual parts without risking static damage.

PCB Workstation Setup Essentials

A properly equipped PCB workstation forms the backbone of any electronics lab, combining essential tools, safety equipment, and organized storage solutions.

You'll need to position your temperature-controlled soldering station, desoldering tools, and power supplies within arm's reach while maintaining a clean, well-ventilated workspace. A high-back office chair on wheels will help you maintain comfort during extended PCB assembly sessions.

To protect sensitive components and guarantee safety, you'll want to implement these critical elements:

- Install an anti-static mat and wear a wrist strap to prevent ESD damage

- Place heat-resistant silicone mats beneath your soldering area

- Keep a fire extinguisher nearby and use surge protectors for equipment

- Organize components in labeled storage containers for quick access

Your workbench should include a thorough selection of components, from resistors and capacitors to transistors and voltage regulators.

Don't forget to stock essential testing equipment like digital multimeters and variable power supplies with current limiting features.

Position your helping hands or articulated arm tools strategically to support PCB work while keeping cleaning materials like isopropyl alcohol within reach for maintaining workspace cleanliness.

Component Testing and Inspection

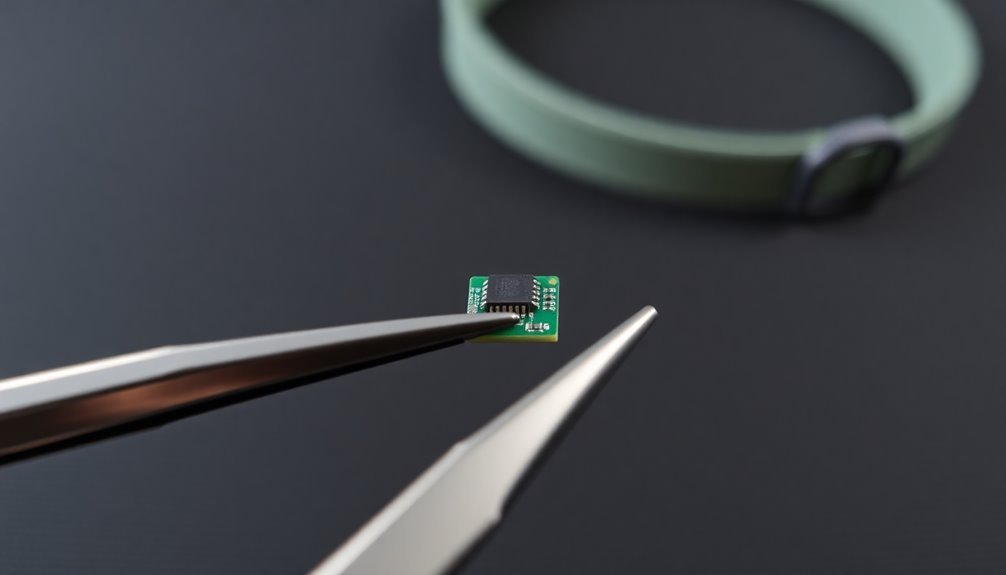

The precise testing and inspection of electronic components demands specialized tools that protect against electrostatic discharge (ESD) damage. When you're examining PCB components, ESD-safe tweezers become essential for preventing costly failures and guaranteeing reliable test results.

You'll find these tweezers particularly valuable during quality control processes, where you need to handle and test surface-mount devices (SMDs) and other sensitive components. Their precision tips allow you to securely grasp and manipulate tiny parts while their static-dissipative properties protect against invisible ESD damage that could compromise your test results.

During inspection routines, you can confidently use ESD-safe tweezers to check component placement, solder joint quality, and perform necessary adjustments. The non-magnetic properties guarantee you won't interfere with the electrical characteristics of the components you're testing.

Whether you're conducting visual inspections or using testing equipment, these tweezers provide the control and protection needed for accurate assessments.

If you're working with sensitive test equipment or performing detailed inspections under microscopes, you'll appreciate how the ergonomic design of ESD-safe tweezers reduces hand fatigue during extended inspection sessions. Their chemical resistance also means they'll maintain their protective properties even with frequent use.

Proper Handling Techniques

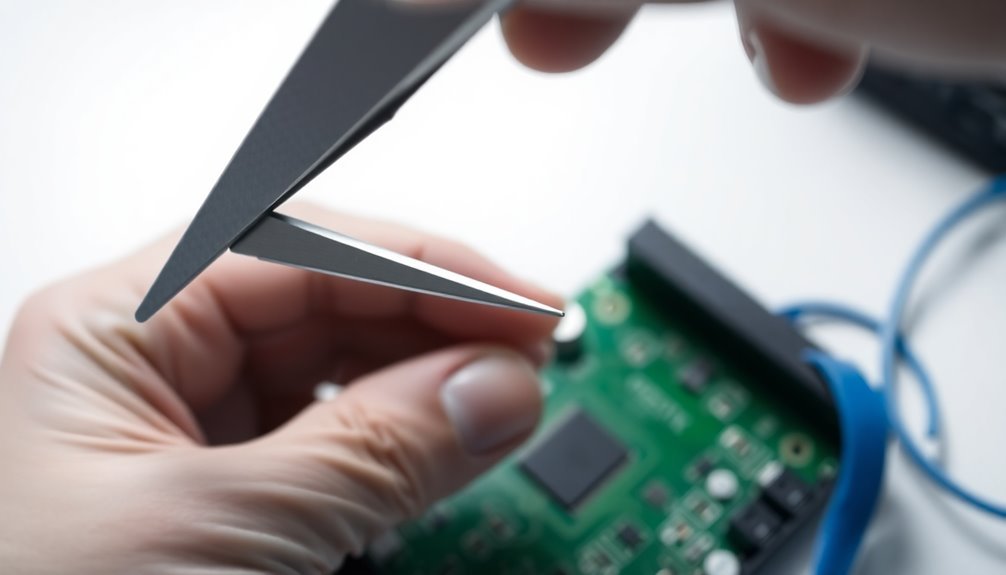

Proper handling of ESD-safe tweezers requires strict adherence to established safety protocols. Before you begin working with sensitive electronic components, you'll need to guarantee you're properly grounded through a wrist strap or heel strap system.

You should also wear appropriate ESD-protective clothing, such as a lab coat, to provide an additional barrier against static discharge.

When using ESD-safe tweezers, follow these essential handling techniques:

- Always hold the tweezers by their non-conductive handle to prevent static transfer from your body

- Maintain consistent contact with your grounding system while manipulating components

- Keep your work area clean and use static-dissipative surfaces

- Store tweezers in designated ESD-safe containers when not in use

You'll want to work in an environment with controlled humidity levels, as this helps dissipate static charges naturally.

Remember to minimize direct hand contact with electronic components, instead relying on your ESD-safe tweezers for manipulation. If you're transporting components between workstations, use appropriate ESD-protective packaging and maintain your grounding connection throughout the process.

Regular training and awareness of these procedures will help guarantee consistent ESD protection.

Maintenance and Testing Guidelines

Maintaining your ESD-safe tweezers requires a systematic approach to secure consistent performance and longevity. You'll need to implement regular cleaning procedures, conduct periodic testing, and follow proper storage practices to preserve their ESD-protective properties.

| Maintenance Task | Frequency |

|---|---|

| Clean with anti-static wipes | Daily after use |

| Visual inspection for damage | Weekly |

| Static dissipation testing | Monthly |

| Full calibration check | Quarterly |

Store your tweezers in designated holders and keep them in a dry environment to prevent corrosion. You'll want to avoid harsh chemicals or abrasive cleaners that could compromise the ESD properties. Instead, use soft cloths and anti-static wipes for regular cleaning.

Don't forget to document all maintenance activities and test results. You should maintain detailed records of repairs, replacements, and calibration checks for traceability. If you notice any damage or wear, especially to the tips, replace the affected parts immediately through authorized repair services. Remember to train all users on proper maintenance procedures and guarantee they understand your facility's ESD policies. Regular audits will help you verify compliance with ESD standards and identify areas for improvement.

Industry Best Practices

Industry leaders across the electronics manufacturing sector rely on extensive ESD control programs to protect sensitive components.

To maintain the highest standards of quality and reliability, you'll find that successful manufacturers implement thorough ESD-safe practices, particularly when it comes to handling tools like tweezers.

When working with ESD-sensitive components, you'll need to follow these industry-proven practices:

- Always use certified ESD-safe tweezers made from anti-magnetic stainless steel alloys and equipped with proper conductive coatings

- Confirm your workspace is a properly designated EPA with appropriate grounding equipment, including wrist straps and ESD-safe work surfaces

- Transport components exclusively in static shielding bags and conductive containers while maintaining controlled environmental conditions

- Participate in regular ESD awareness training and compliance verification programs

You'll notice that top manufacturers consistently pair their ESD-safe tweezers with thorough control measures, including proper grounding systems and static charge reduction techniques.

Alternative ESD Control Methods

Several effective alternatives to ESD-safe tweezers exist for handling sensitive electronic components. You'll find vacuum pick-ups particularly useful, as they eliminate direct contact while maintaining precise control. For larger components, ESD-safe clamps and fixtures provide secure handling during assembly processes.

| Tool Type | Primary Use | Key Benefit |

|---|---|---|

| Vacuum Pick-ups | Small component handling | No direct contact needed |

| Static Dissipative Brushes | Surface cleaning | Safe debris removal |

| ESD-safe Clamps | Component securing | Stable mounting |

| Automated Assembly Tools | Mass production | Minimal human contact |

When implementing these alternatives, you'll need proper ESD-safe storage and transport solutions. Use static shielding bags and conductive containers to protect components during movement and storage. Maintain controlled humidity levels in your storage areas and implement a first-in, first-out inventory system to minimize static exposure.

Remember to regularly inspect your ESD control equipment and maintain proper documentation of checks and maintenance. You can further enhance protection by using ionizers to neutralize static charges in the air and ensuring all workstations are properly grounded with ESD-safe surfaces and mats.

Frequently Asked Questions

Can Esd-Safe Tweezers Be Sanitized Without Compromising Their Static Dissipative Properties?

Yes, you can safely sanitize ESD-safe tweezers using dry lint-free cloths, deionized water, or moderate alcohol solutions. Just avoid harsh chemicals and guarantee complete drying to maintain their static dissipative properties.

How Often Should Esd-Safe Tweezers Be Replaced in High-Volume Production Environments?

You'll need to replace your ESD-safe tweezers every 6-12 months in high-volume production, but inspect them monthly. If you notice visible wear, coating damage, or failed static tests, replace them immediately.

Do Temperature Fluctuations Affect the Performance of Ceramic Esd-Safe Tweezers?

No, you won't notice performance changes in ceramic ESD-safe tweezers due to temperature shifts. Their stable material properties maintain consistent static dissipative characteristics and structural integrity across a wide temperature range.

Are Color-Coded Esd-Safe Tweezers Available for Different Component Handling Tasks?

Yes, you'll find color-coded ESD-safe tweezers in various shades to help you quickly identify different tip styles and applications. Common colors include blue, black, and green for distinct handling tasks.

Can Esd-Safe Tweezers Be Used With Liquid Flux Without Degrading?

Yes, you can safely use ESD-safe tweezers with liquid flux. Their ceramic or PEEK tips and stainless steel bodies are highly resistant to chemical degradation, ensuring they won't deteriorate when exposed to flux.

In Summary

You've learned why ESD-safe tweezers are essential tools in PCB assembly. They protect sensitive components from static damage, comply with industry standards, and save money by preventing component failures. Remember to regularly test your ESD equipment, maintain proper handling techniques, and integrate these tools into your broader ESD control strategy. Your choice of ESD-safe tweezers directly impacts your PCB assembly quality and reliability.

Leave a Reply