You'll need to select your static control audit form based on industry standards ANSI/ESD S20.20 and IEC 61340-5-1. Your best option is to use an extensive ESD audit form that combines program management, compliance verification, and quality process checking elements. Make sure your chosen form includes sections for training documentation, equipment verification, grounding system evaluation, and corrective action planning. You should tailor the checklist to your facility's specific needs while maintaining alignment with standard requirements. The right audit form will help you systematically evaluate and improve your ESD control measures.

Understanding ESD Audit Standards

A well-structured ESD audit relies on several key industry standards that guide organizations in protecting sensitive electronic components. You'll need to understand two primary standards: ANSI/ESD S20.20 and IEC 61340-5-1. These standards work together to provide extensive guidance for your ESD control program, covering everything from manufacturing to packaging operations.

Both standards align with ISO 9001:2015's quality management framework, guaranteeing your ESD control program integrates seamlessly with existing quality systems. Regular archived test records must be maintained and reviewed during audits to track discrepancies effectively.

When you're developing your audit form, you'll want to reference the ESD Association's guidelines and incorporate elements from MIL-HDBK-263's detailed checklist to ensure thorough coverage of all critical areas.

Your audit form should address the six core ESD control principles, with special attention to grounding requirements and EPA specifications. You'll need sections that verify proper use and maintenance of ESD control materials, along with spaces to document compliance issues and corrective actions.

Remember that these standards aren't just guidelines – they're essential tools that help you maintain consistent ESD protection across your facility and meet industry requirements.

Types of Audit Forms Available

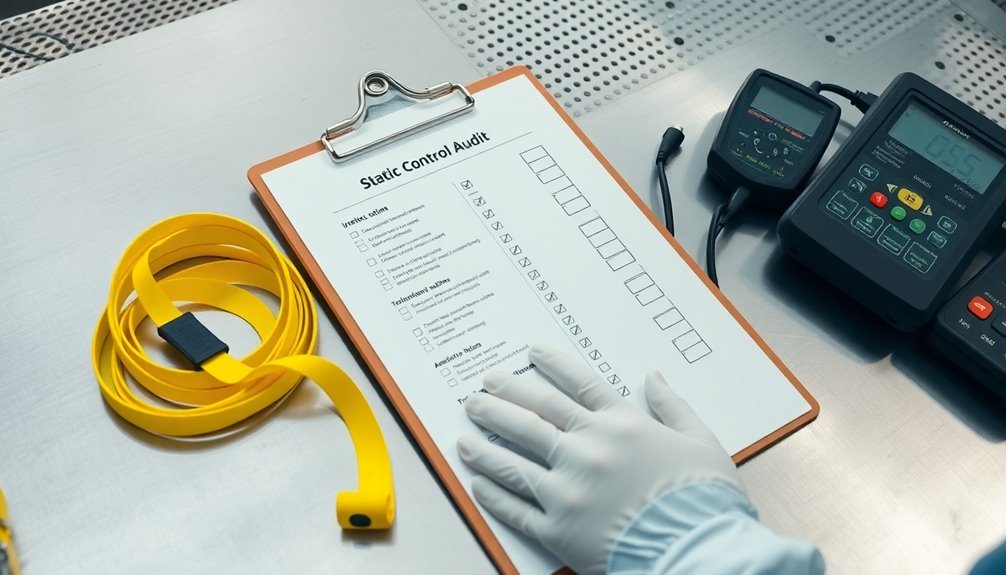

Building on established ESD standards, organizations can choose from several distinct types of audit forms to evaluate their static control programs effectively.

You'll find four main categories that serve different assessment purposes.

Program Management Audits help you evaluate your overall implementation strategy and commitment level. These forms typically don't require site visits and use surveys to assess factors like ESD training programs and implementation plans. Timely reporting of audit findings is essential for implementing necessary corrective actions.

Quality Process Checking Audits focus on your adherence to specific processes, using statistical analysis and detailed checklists to verify compliance in ESD-sensitive areas.

For regular monitoring, you'll want to use ESD Control Program Compliance Verification Audits. These forms help you verify that your procedures are being followed and equipment functions properly through monthly checks and sampling techniques.

If you're looking for the most exhaustive assessment, Extensive ESD Audit Forms combine elements from all three previous types. They're often based on standardized checklists like those in MIL-HDBK-263 and can be customized to match your organization's specific needs and control program requirements.

Essential Checklist Components

Your static control audit checklist must include thorough training records that verify all personnel have completed required ESD safety courses and refresher sessions.

A comprehensive approach involving safety performance indicators helps assess the ongoing effectiveness of the training program.

You'll need to document regular equipment testing results, including resistance measurements for wrist straps, footwear, and workstation surfaces according to industry standards.

The grounding system assessment portion should track daily verification logs of all connected equipment, ensuring proper impedance levels and continuous monitoring of ground connections.

Training Documentation Requirements

Thorough training documentation forms the cornerstone of an effective static control program.

When you're developing your static control audit form, you'll need to include extensive sections that track all training materials and records. Your documentation should capture both initial and recurring training sessions, along with all supporting educational resources that you've used to build employee competency. Adjusting content for cultural differences and regions helps ensure consistent understanding across various facilities.

Your audit form should verify these essential training documentation requirements:

- Training delivery methods and materials, including ESD Association bulletins, computer-based modules, DVDs, and technical papers you've used to educate staff.

- Records of standards implementation from recognized bodies like ESD Association, IEC, and JEDEC, ensuring your training aligns with industry requirements.

- Technical data sheets for all ESD control materials and equipment used in your facility, confirming proper training on specific tools and protection measures.

You'll want to maintain detailed records of who's been trained, when training occurred, and what specific materials were covered.

This documentation isn't just about compliance – it's your proof that employees understand proper ESD procedures and can effectively protect sensitive components.

Keep your training records organized and easily accessible for both internal reviews and external audits.

Equipment Verification Standards

While proper training documentation sets the foundation, effective equipment verification standards form the backbone of your static control audit process.

You'll need to guarantee your test equipment meets both ANSI/ESD S20.20 and IEC 61340-5-1 requirements, including essential tools like an electrostatic field meter, high-range resistance meter, and ground AC outlet tester. Converting to digital documentation systems can streamline the verification process significantly.

Your verification standards should specify clear measurement limits and testing frequencies. You'll want to conduct regular checks, typically monthly, using documented test methods that align with industry standards.

If you're using non-standard testing approaches, make sure they correlate with referenced benchmarks.

When verifying equipment, focus on key ESD control items such as worksurfaces, personnel grounding devices, and ionizers.

You'll need to test both the condition and functionality of these components. Don't forget to verify that operators are properly using their prescribed grounding devices and that continuous monitors for wrist straps and static mat connections are functioning correctly.

Remember to maintain detailed records of all verification results, including historical data to track performance trends and demonstrate compliance with technical requirements.

This documentation will help you identify potential issues before they become problems.

Grounding System Assessment

In accordance with thorough ESD control standards, an effective grounding system assessment begins with evaluating your ESD common point ground and auxiliary grounds.

You'll need to verify that all grounding conductors maintain equipotential balance and meet the specifications outlined in ANSI/ESD S6.1 and ESD TR20.20 standards.

Your audit form should include extensive testing protocols for measuring resistance values across your grounding system components. Document RTG measurements for worksurfaces, RTT readings for point-to-point resistance, and ground snap resistance checks using a multimeter to verify they're less than 1 ohm. Installing continuous monitoring systems provides real-time verification of wrist strap functionality and personnel grounding.

- Test and record all grounding connections daily, including wrist straps, floor mats, and common point grounds.

- Measure and document resistance values quarterly for worksurfaces, flooring systems, and auxiliary grounds.

- Verify electrical outlet integrity using an AC outlet analyzer and record findings.

Include sections for corrective actions when measurements fall outside acceptable ranges.

Track these measurements over time to identify trends and potential system degradation.

You'll want to maintain detailed logs of all testing activities, verifying your documentation supports compliance requirements and enables proactive maintenance of your ESD control program.

Program Management Assessment Guidelines

Successful program management assessment depends on a systematic approach to evaluating ESD control measures. You'll need to guarantee your ESD control program is thoroughly documented and approved by management, with clear objectives, scope, and responsibilities outlined at all operating levels. Your assessment documentation must require parallel phrasing to ensure consistent reporting across all evaluation categories.

When conducting your program assessment, you'll want to use a checklist that's specifically tailored to your ESD control requirements and based on ANSI/ESD S20.20 and IEC 61340-5-1 standards. You should verify that all ESD control products are regularly tested and functioning as intended, while also checking that proper training protocols are in place.

Your assessment should include a review of training documentation and records. Make sure your staff is trained in ESD prevention, handling procedures, and proper use of control products. If you discover any deficiencies during audits, implement retraining immediately.

Don't forget to maintain detailed records of your audit findings and corrective actions. You'll need to prepare and distribute prompt reports that include specific recommendations.

Track trends in your findings to establish effective corrective measures, especially if you're maintaining ISO 9000 or ANSI/ESD S20.20 certification.

Facility Equipment Requirements

Conducting thorough facility equipment audits requires specific measurement tools and testing devices to verify your ESD control program's effectiveness.

You'll need essential instruments like electrostatic field meters, wide-range resistance meters, and ground circuit testers to properly assess your facility's static control measures.

Your audit should focus on evaluating ESD protective equipment and workspaces, including dissipative flooring, grounded workstations, and protective gear.

Don't forget to check that all grounding terminals are clearly marked and that your ESD protected areas are properly defined and labeled.

- Test your dissipative floors regularly with appropriate measurement equipment, ensuring they're maintained with suitable cleaning products that won't compromise their static control properties.

- Verify all workstations have functional grounding points and dissipative surfaces using resistance meters and ground testers.

- Check protective equipment like wrist straps and footwear with specialized testers, documenting results with data acquisition systems.

Remember to utilize charge plate monitors and ESD event detectors to assess your overall static control performance. Following approved inspection checklists helps ensure systematic and thorough evaluations of all equipment components.

These instruments help you identify potential problems before they lead to component damage or production issues.

Personnel Training Documentation

Throughout your ESD control program, proper documentation of personnel training stands as a critical cornerstone for maintaining compliance and effectiveness.

You'll need to maintain thorough records that demonstrate your training content covers essential elements like static electricity physics, specific procedures, and each employee's role in the ESD Control Program Plan.

Your audit form should track various training methods implemented, including live instruction, video presentations, and interactive programs. Document how you're reinforcing the training through supplementary materials like bulletin boards and newsletters.

Include certification records showing that employees have been tested and verified for their understanding of the material. Make sure your documentation captures both initial training and retraining dates, along with pre and post-training assessment results.

You should record participant feedback and performance metrics that demonstrate the training's effectiveness. Include data showing how the training impacts yield and productivity improvements.

Your documentation must also reflect any corrective actions taken based on audit findings and subsequent training modifications. By maintaining detailed training records, you'll create a clear trail of compliance while identifying areas that need additional focus or improvement.

Grounding System Evaluation Points

In your grounding system audit, several vital evaluation points demand thorough inspection to confirm proper ESD protection.

You'll need to assess key areas including manufacturing floors, workbenches, and shipping centers, where static control is essential for protecting sensitive electronic components.

Your evaluation should focus on the grounding system's core components, verifying they meet ANSI/ESD S20.20 standards. Check that your common point ground maintains proper electrical potential across all connected elements, and verify that grounding conductors provide effective paths for static dissipation.

- Test resistance to ground measurements, confirming they're below 1.0 x 10^9 ohms as specified by ANSI/ESD STM97.1

- Monitor body voltage accumulation, confirming it doesn't exceed 100 volts in any work area

- Verify continuous monitoring systems are functional and properly calibrated

Don't forget to document soil resistivity measurements and maintain detailed records of your inspection findings.

If you identify any deficiencies, you'll need to implement immediate corrective actions following ESD Association guidelines.

Regular maintenance checks and updates to your grounding system evaluation protocols will help confirm continuous compliance with industry standards.

Quality Control Measures

Three essential quality control measures form the foundation of your ESD audit process.

First, you'll need to establish a thorough testing schedule that includes daily checks of personal grounding equipment, weekly inspections of workstations, and monthly static surveys of your EPA.

Second, you must use appropriate instrumentation for each measurement task, including electrostatic field meters, resistance meters, and ground testers that meet relevant standards' specifications.

Third, you'll need to maintain detailed documentation and checklists tailored to your facility's ESD control program. While standards like ANSI/ESD S20.20 and MIL-HDBK-263 K provide extensive guidelines, you should customize your audit forms to reflect your specific requirements.

Don't forget to confirm your checklists cover all areas where ESD-sensitive devices are handled.

To maintain consistency in your quality control process, you'll want to verify that all testing equipment is properly calibrated and that your staff is well-trained in audit procedures.

Remember to schedule semi-annual checks of ionizer balance and charge decay, and quarterly assessments of flooring RTG and ground continuity.

When you identify discrepancies, implement corrective actions promptly to maintain the integrity of your ESD control program.

Common Areas of Concern

Several critical areas stand out among ESD audit concerns, from high-traffic zones down to individual workstations.

You'll need to pay close attention to your work area's integrity, particularly the condition of static dissipative floors and properly grounded workbenches.

Don't overlook operator compliance – it's crucial to verify that your team members are following established ESD procedures and using appropriate protective equipment.

When conducting your audit, focus on these commonly problematic areas:

- Static monitoring systems that aren't regularly calibrated or maintained, leading to unreliable protection against electrostatic discharge.

- Improper handling of static-sensitive components due to inadequate training or rushed workflows, especially during high-production periods.

- Inconsistent documentation of compliance verification and test procedures, which can create gaps in your ESD control program's effectiveness.

Your audit form should specifically address equipment grounding points, ionizer functionality, and the condition of ESD-safe materials.

Watch for signs of wear on static control surfaces and verify that all EPA signage remains clearly visible.

Remember to include trash handling procedures and document storage in your inspection, as these often-overlooked areas can compromise your static control measures.

Storage and Handling Protocols

Proper storage and handling protocols form the backbone of any effective ESD control program.

You'll need to guarantee that all ESD-sensitive items are stored in appropriate containers, whether they're static dissipative, static shielding, or conductive. Each container must be clearly labeled to identify its static-sensitive contents.

When handling ESD components, you're required to maintain proper grounding at all times.

Don't allow unprotected ESD items to come into direct contact with conductive surfaces or equipment housings. For transporting items within your facility, you'll need to use static-safe containers or board carriers. If you're moving components off-site, closed static shielding containers are mandatory.

Your packaging practices must meet strict requirements.

Always verify that your packaging materials are ESD safe using a field meter, and whenever possible, use the original manufacturer's packaging.

Remember that antistatic packaging alone isn't sufficient for off-site transport.

You'll need to implement regular inspections of your storage areas and maintain detailed records of all handling procedures for at least 90 days.

Regular training sessions for your personnel will help guarantee consistent compliance with these protocols.

Measurement and Testing Methods

Through rigorous testing methods, you'll need to verify the effectiveness of your ESD control measures using both electrical resistance tests and walking body voltage assessments. Your resistance measurements should follow ANSI/ESD STM 7.1 procedures, ensuring floors in electronics manufacturing measure below 1.0 x 10E9 ohms and communications facilities fall between 1.0 x 10E6 and 1.0 x 10E9 ohms.

When testing ESD worksurfaces, you'll need to conduct three essential measurements:

- RTG (Resistance to Ground) – Use a 5 lb electrode with 10V testing, increasing to 100V if resistance exceeds 1.0 x 10E6 ohms.

- RTGP (Resistance to Groundable Point) – Connect to the grounding snap using 100V for higher resistance expectations.

- RTT (Resistance Point-to-Point) – Place two 5 lb electrodes 10" apart, applying 100V for measurements above 1.0 x 10E6 ohms.

Don't rely solely on resistance testing; incorporate walking body voltage tests for real-world performance evaluation. These tests provide a more thorough assessment of your ESD floor's effectiveness.

Consider engaging an independent consultant for a complete static control audit, which will examine your entire ESD control program's design, installation, and maintenance protocols.

Corrective Action Planning

Effective corrective action planning forms the backbone of your static control audit process. You'll need to establish SMART goals for each corrective action you identify during your static control audits – making them specific, measurable, achievable, relevant, and time-bound to guarantee successful implementation.

Start by clearly identifying static control problems through your audit findings. Use root cause analysis tools like the 5 Why method to uncover the underlying causes of static control issues. Once you've pinpointed the root causes, create a detailed action plan that outlines specific steps, responsibilities, and deadlines for implementing solutions.

Your corrective action plan should include employee training on new static control procedures, process updates to prevent future static-related incidents, and regular safety audits to monitor effectiveness. Document all corrective actions using digital templates and maintain detailed records of outcomes.

Don't forget to involve key stakeholders in both planning and execution phases.

Remember to verify and follow up on your corrective actions regularly. You should conduct periodic reviews to confirm your static control measures remain effective and make adjustments when necessary. Use audit findings to continuously improve your static control processes and procedures.

Frequently Asked Questions

How Often Should We Update Our Static Control Audit Forms?

You should update your static control audit forms annually and whenever significant changes occur in your ESD program. Additionally, review forms quarterly to verify they align with current standards and practices.

Can We Customize Audit Forms for Different Departments Within the Facility?

Yes, you can customize audit forms for each department using webform templates, field customization options, and layout controls. You'll efficiently track department-specific needs while maintaining consistent data collection across the facility.

What Software Platforms Are Recommended for Digital Static Control Auditing?

You'll find SmartLPA, Intact Platform, and SafetyCulture ideal for digital static control auditing. They offer customizable forms, mobile support, and automated workflows to effectively manage your facility's static control requirements.

Should Contractors Complete the Same Audit Forms as Permanent Employees?

You'll need to assess your contractor's role and system impact first. If they interact extensively with sensitive areas like permanent employees do, use the same forms. Otherwise, create tailored forms for their specific duties.

Are There Different Audit Form Requirements for Cleanroom Versus Non-Cleanroom Environments?

Yes, you'll need different audit forms. Cleanroom audits focus on environmental monitoring, HVAC systems, and microbial control, while non-cleanroom audits primarily address ESD control measures and protective equipment compliance.

In Summary

You'll want to select an audit form that aligns with your facility's specific ESD control needs and industry standards like ANSI/ESD S20.20. Consider using forms that cover all essential elements: personnel grounding, workstation requirements, packaging protocols, and testing procedures. Don't forget to include verification methods and corrective action sections. Regular updates to your audit form guarantee you're maintaining effective static control measures.

Leave a Reply