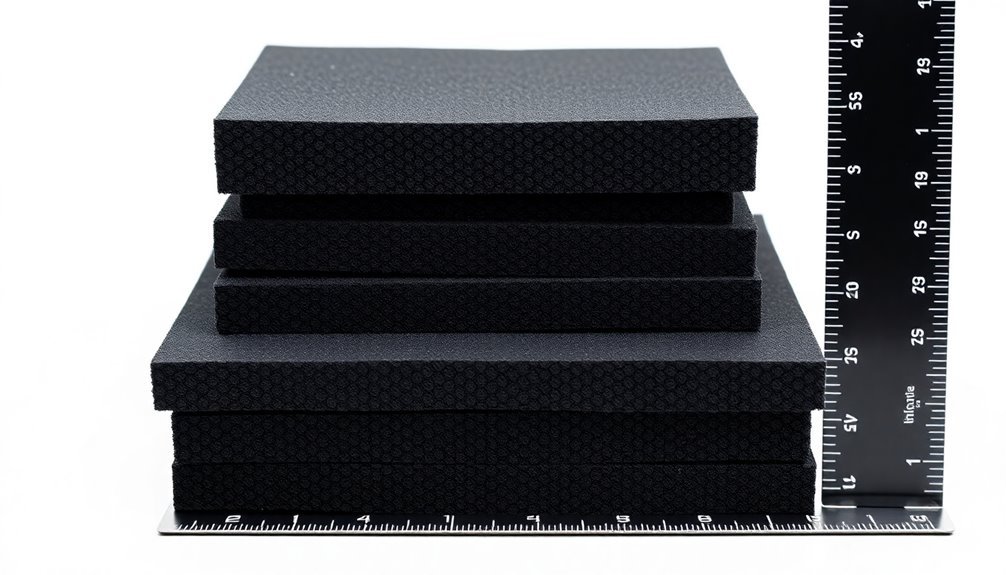

Black conductive foam comes in several standard thicknesses to protect your electronic components. You'll find 1/8-inch foam ideal for basic circuit board protection, while 1/4-inch offers enhanced cushioning for shipping. For components with pins or leads, choose 1/2-inch foam with its superior pin protection capabilities. The 3/4-inch and 1-inch options provide heavy-duty protection for larger items, while 2-inch thickness suits bulk storage needs. Custom layered combinations let you mix densities for specialized protection. Each thickness option features surface resistivity between 10³ and 10⁵ ohms/sq, ensuring reliable ESD protection. The right choice depends on your specific component requirements and storage conditions.

Standard 1/8-Inch Foam Applications

One of the most widely used protective materials in electronics packaging, standard 1/8-inch conductive foam offers essential protection for static-sensitive components.

You'll find this versatile material available in several forms, including conductive polyethylene, conductive polyurethane, and cross-linked polyethylene foam, each engineered to meet specific protection requirements. The strong closed cells provide exceptional durability and resilience for long-term use.

When you're selecting foam density, you can choose between low density (1.7-1.9 lbs/ft³) and high density (2.8-3.1 lbs/ft³) options. The material's surface resistivity ranges from 10² to 10⁵ ohms/sq, making it ideal for ESD-safe applications.

You'll appreciate its impressive tensile strength of 20 psi/min and 150% elongation capability, ensuring durability in demanding environments.

The foam's physical properties make it exceptionally reliable for industrial and manufacturing packaging. You can count on its non-corrosive and low-sloughing characteristics, while its high shock absorption protects valuable components.

The material remains stable at temperatures up to 250°F and resists chemicals, water, mold, and mildew. Whether you need sheets, pads, or custom shapes, this foam complies with ANSI/ESD S451 standards and offers excellent fabrication flexibility using standard techniques.

Quarter-Inch Protection Solutions

Electronics manufacturing's quarter-inch conductive foam solutions deliver enhanced protection for more demanding applications where standard 1/8-inch thickness isn't sufficient. At 6mm thick, this foam provides superior cushioning while maintaining essential anti-static properties with surface resistivity of 10^3 to 10^6 ohms per square meter and rapid charge decay times under 0.05 seconds.

You'll find quarter-inch conductive foam particularly valuable in these critical applications:

- Storage of larger, heavier electronic components requiring extra cushioning

- Shipping protection for sensitive circuit boards and assemblies

- Cleanroom environments where static control is paramount

- Manufacturing operations involving frequent component handling

When you're working with quarter-inch foam, you'll benefit from its robust technical specifications. The foam's density of 2-4 pounds per cubic foot guarantees reliable pin insertion and retention capabilities, making it ideal for storing integrated circuits and other pin-based components. The material's high-quality conductivity ensures consistent protection across all applications.

The foam also features tensile strength exceeding 0.5 MPa and tear strength greater than 1.2 N/mm. You can source this foam from various suppliers, and it's available in customizable sizes to match your specific requirements while maintaining compliance with industry ESD standards, ROHS, and REACH certifications.

Half-Inch Component Storage

Your half-inch storage solution offers ideal density for securing circuit boards and components while maintaining proper support across larger surface areas.

You'll find that this thickness provides superior pin protection for ICs and other sensitive electronic parts, preventing bend or breakage during storage and transport.

The half-inch depth works particularly well in drawer organizers and anti-static cases where you need to store multiple layers of components while ensuring each layer remains properly cushioned and protected from damage. Using clear plastic containers allows for easy visibility of stored components without having to remove the protective foam.

Density for Circuit Support

Professional circuit protection demands specific foam density requirements for half-inch component storage. You'll find two primary density options: high-density at 1.99 lbs/ft3 for static-sensitive components with legs, and low-density ranging from 40kg/m3 to 200kg/m3 for transit packaging.

The high-density foam's semi-rigid structure guarantees excellent pin retention without creating particles, while low-density options offer superior cushioning flexibility. The material's chemical stability properties ensure components remain protected during extended storage periods.

When you're working with these conductive foams, you'll notice they're manufactured with carbon-infused polymer and feature a closed-cell polyethylene structure. This composition delivers permanent ESD protection with surface and volume resistance of 10e3-10e5 ohms/sq, regardless of humidity levels.

Here's what makes conductive foam essential for circuit support:

- Acts as a Faraday cage to protect sensitive components

- Provides quick static charge transfer to grounding sources

- Maintains consistent ESD performance in varying conditions

- Features non-dusting properties for clean room compatibility

You can easily customize these foams through die-cutting or waterjet cutting for specific applications, making them ideal for ESD shelf liners, tote lining, and shipping box protection. The material's durability supports both multi-trip packaging and daily handling needs.

Pin Protection Capabilities

Reliable pin protection requires precise foam thickness selection for half-inch component storage. You'll find that conductive foam's 0.5 to 100mm thickness range offers versatile options for securing pins of various lengths.

When you're storing components with delicate pins, you'll want to choose a thickness that's at least 1.5 times the pin length to guarantee complete insertion and protection. The foam's waterproof properties ensure protection even in humid storage conditions.

The foam's rigid, closed-cell structure provides excellent pin support while preventing bent or damaged leads. You can customize the protection level by die-cutting or kiss-cutting the foam to match your specific component dimensions.

For components with longer pins, you'll benefit from layering multiple foam pieces to achieve the desired thickness, guaranteeing the pins don't protrude through the bottom.

Remember that while the foam offers excellent protection, you shouldn't place ESD-sensitive devices in direct contact with it. Instead, you can create pre-cut slots or pockets within the foam that maintain a small clearance around sensitive areas.

The foam's conductivity (≤ 10^6 Ω/cms) helps dissipate static charges effectively, while its density range of 40-125kg/m3 provides the right balance of firmness and cushioning for pin security.

Common Storage Applications

Building on proper pin protection methods, effective storage solutions play a key role in maintaining component integrity. You'll find various storage options specifically designed for electronic components, with plastic cases and drawer systems being among the most popular choices.

The AideTek BOXALL96 and Eightwood mini cases offer anti-static protection while providing organized compartments for different-sized components. Using transparent containers allows quick visual identification of stored parts.

For thorough storage solutions, consider these essential options:

- StackOn multi-drawer cabinets for larger component collections

- Plastic cases with removable compartments for flexibility

- ESD-protected fishing tackle boxes for cost-effective organization

- Conductive foam inserts for additional protection

You'll want to incorporate proper ESD protection in your storage system, regardless of the container type you choose. Dense black conductive foam can be cut to fit various storage solutions, providing both anti-static properties and shock absorption.

When you're setting up your storage system, don't forget to label your compartments and drawers clearly. You can expand your storage capacity by connecting modular cases or adding cabinet units as your component collection grows.

Three-Quarter Inch Heavy Duty

You'll find three-quarter inch conductive foam provides maximum protection for sensitive electronic components, with its substantial 19mm thickness creating secure cushioning against impacts and vibrations.

The foam's non-sloughing properties keep your components free from contamination while protecting them.

This heavy-duty thickness lets you stack multiple circuit boards with ample spacing between layers, preventing contact damage while maintaining static discharge protection.

When you're shipping valuable electronic assemblies, the foam's robust density of 1.99 lbs/ft3 guarantees your components remain secure and static-free throughout transportation.

Extreme Protection For Components

Durability meets precision in three-quarter inch heavy-duty conductive foam, delivering maximum protection for your most sensitive electronic components. With a density of 1.99 lbs/ft3 and high-density closed-cell polyethylene construction, this 3/4" thickness offers exceptional safeguarding for industrial and automotive applications where maximum protection is essential. The foam's amine-free composition ensures it won't react with or damage delicate circuit boards.

You'll benefit from the material's impressive electrical properties, featuring surface and volume resistance ratings of 10e3-10e5 ohms/sq, ensuring consistent static discharge protection. The foam's rapid charge decay time of less than 0.05 seconds means you won't have to worry about static buildup damaging your valuable components.

For extreme protection requirements, this thickness provides:

- Superior cushioning for heavy electronic components during shipping and handling

- Enhanced pin retention capabilities for lead insertion applications

- Robust protection in ESD-sensitive manufacturing environments

- Ideal thickness for lining industrial workstation surfaces

The foam's chemical and corrosion resistance, combined with its low FOD characteristics, makes it ideal for long-term use in demanding environments. You can easily customize it through die cutting or waterjet processes while maintaining its protective properties, ensuring a perfect fit for your specific applications.

Ideal For Circuit Stacking

Stacking circuit boards demands precise spacing and protection, and three-quarter inch heavy-duty conductive foam delivers both. You'll find this thickness particularly effective for creating stable layers between boards while maintaining proper electrical dissipation through its volume resistance of 10e3-10e5 ohms/sq.

The high-density composition of 1.99 lbs/ft3 guarantees your stacked circuits remain securely positioned without compression issues.

When you're working with multiple circuit boards, you'll appreciate how this foam's closed-cell, chemically crosslinked polyethylene structure provides consistent spacing. The three-quarter inch thickness is ideal for preventing component interference between layers while maintaining effective static discharge.

You can easily verify the foam's conductivity using a standard multimeter, confirming your sensitive electronics remain protected throughout the stacking process.

The foam's superior pin-insertion and retention characteristics make it perfect for temporary or permanent stacking arrangements. You won't need to worry about static buildup, as the conductive properties actively dissipate charges that could damage your components.

For manufacturing environments where you're handling multiple boards, this thickness provides the durability and protection required for daily use while meeting RoHS and REACH certification standards.

Static-Free Transportation Solutions

Designed for maximum protection during transit, three-quarter inch heavy-duty conductive foam provides essential safeguarding for your sensitive electronic components. Made from high-density polyethylene foam with a density of 1.99 lbs/ft^3, this material offers both physical stability and reliable static protection through its closed-cell construction.

You'll find this foam particularly effective for transporting electronics, as it features volume and surface resistance ratings between 10^3 and 10^5 ohms/square.

The amine-free composition prevents damage to delicate components, while its permanent ESD characteristics guarantee long-term protection against static discharge.

Key benefits you'll get from using this heavy-duty foam include:

- Superior pin insertion and retention capabilities for secure component handling

- Easy customization through die-cutting or waterjet cutting for precise fits

- Excellent shock absorption and abrasion protection during shipping

- Effective static field barrier and dissipation properties

Whether you're shipping semiconductor devices, circuit boards, or LCD screens, you can customize this versatile material to your specific needs. It's particularly useful when integrated into handling trays, conductive totes, or ESD shipping boxes, offering extensive protection for your valuable electronic components.

One-Inch Maximum Security Storage

Every one-inch security storage system offers extensive protection through multiple safeguarding features. You'll find UL-classified fire protection that guards your valuables for up to one hour at temperatures reaching 1700°F, along with ETL-verified water resistance protecting contents in 8 inches of water for 24 hours.

When storing sensitive electronics, you'll need to utilize the safe's 1.23 cu.ft. capacity efficiently. The digital locking system lets you program a 1-8 digit code, while pry-resistant hinge bars and live-locking bolts provide additional security against forced entry.

| Security Feature | Protection Level |

|---|---|

| Fire Protection | 1700°F for 1 hour |

| Water Resistance | 8" for 24 hours |

| Lock Type | Digital 1-8 digits |

| Construction | Solid steel |

| Storage Space | 1.23 cu.ft. |

For electronics storage, you'll want to take advantage of the interior organization features, including the key rack, door tray, and adjustable locking drawer. The integrated micro-USB ports provide backup power access, while the LED lighting helps you locate items easily. Remember to use conductive foam and anti-static bags for sensitive electronic components to prevent static damage.

Two-Inch Bulk Component Protection

While one-inch storage solutions work well for basic electronics protection, two-inch conductive foam offers enhanced safeguarding for bulk component storage.

When you're storing large quantities of sensitive ICs and electronic components, you'll need the superior protection that two-inch conductive foam provides. The increased thickness offers better cushioning and static protection through carbon black precompounding, guaranteeing your components remain safe from both physical damage and electrical discharge.

You'll find that quality two-inch conductive foam solutions like ETHAFOAM come in various densities, ranging from 2 to 6 pounds per cubic foot, allowing you to match the foam to your specific protection needs. When selecting your foam, verify it's genuinely conductive by testing with a multimeter – surface dissipation isn't enough.

Key benefits of two-inch conductive foam include:

- Superior protection for bulk storage applications

- Non-sloughing surfaces with process skins on all sides

- Consistent anti-static properties throughout the material

- Easy customization through professional fabrication services

Remember to verify the foam's conductivity before use, as non-conductive antistatic alternatives won't provide adequate protection for sensitive electronic components.

Custom Layered Foam Combinations

Custom layered foam combinations take electronic protection to the next level by combining different densities and materials for peak performance. You'll find these specialized solutions enhance both EMI shielding and ESD protection while providing superior shock absorption for your sensitive components.

When you're selecting layered foam combinations, you can choose from various materials including conductive polyethylene, polyurethane, and cross-link polyethylene foams. Each layer can be tailored with specific densities ranging from 1.2# to 4#, and surface resistivities between 10e2 and 10e5 ohms/sq to match your exact requirements.

You'll benefit from exhaustive protection as these layered structures offer X, Y, and Z-axis conductivity while improving thermal conductivity and dust sealing.

The combinations can be die-cut to your specifications and equipped with conductive adhesive backing for easy installation. Whether you're protecting bulk components or individual devices, you can customize the thickness and density of each layer to achieve thorough protection.

These versatile solutions work particularly well when you need to address multiple protection requirements simultaneously, such as combining soft, open-cell layers for cushioning with rigid, closed-cell layers for structural support.

Frequently Asked Questions

Can Black Conductive Foam Be Safely Reused for Different Electronic Components?

You can safely reuse black conductive foam for different electronic components as it maintains permanent ESD properties. However, you'll want to inspect it for damage and verify it's clean before each reuse.

How Long Does Conductive Foam Maintain Its Protective Properties During Storage?

You'll find that conductive foam maintains its protective properties indefinitely when properly stored, as it's permanently carbon-loaded. You can reuse it multiple times without losing its ESD protection capabilities.

Does Temperature Affect the Conductivity Performance of Black Conductive Foam?

No, temperature won't affect your foam's conductivity performance. It maintains stable conductivity from room temperature up to 90-110℃, and you won't see any degradation in its protective properties across this range.

What Cleaning Methods Are Safe for Maintaining Black Conductive Foam?

You'll want to use gentle isopropyl alcohol cleaning with a soft brush or lint-free tissue. Don't soak the foam, and avoid ultrasonic cleaners. Remember to let it dry completely after cleaning in a controlled environment.

Can Black Conductive Foam Be Recycled Through Standard Recycling Programs?

You can't recycle black conductive foam through standard recycling programs. You'll need to find specialized facilities that handle anti-static materials, as the additives require specific processing methods for proper recycling.

In Summary

You'll find these seven thickness options provide thorough protection for all your electronic components. From thin 1/8-inch foam for basic PCB storage to robust 2-inch layers for heavy equipment, you've got reliable static protection at every level. Whether you're storing microchips or shipping sensitive devices, these standardized thicknesses let you customize your storage solutions while maintaining consistent ESD safety standards.

Leave a Reply