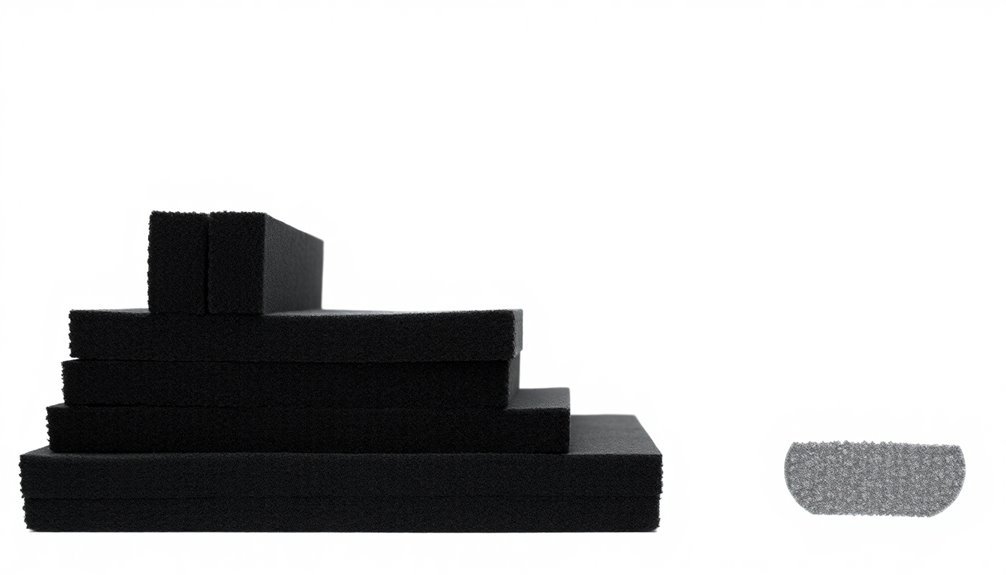

Black conductive foam comes in seven key thicknesses to protect your electronics. You'll find ultra-thin 1/48-inch options for minimal space requirements, quarter-inch standard thickness for everyday protection, and half-inch foam ideal for component storage. For heavy-duty safeguarding, consider one-inch four-layer foam, while two-inch maximum cushioning offers superior impact defense. Custom mid-range options between 1/16" to 1/4" provide flexibility for specific needs, and three-inch industrial grade protection delivers ultimate security for server equipment. Understanding each thickness's unique properties will help you choose the perfect protection for your valuable electronics.

Ultra-Thin 1/48-Inch Protection

Selecting ultra-thin 1/48-inch conductive foam provides essential protection for sensitive electronic components while maintaining minimal space requirements. At just 0.021 inches thick, this specialized material combines low-density microcellular urethane foam with a metalized coating to deliver superior EMI shielding and ESD protection. The die-cut processing capabilities allow for precise customization without compromising the foam's conductive properties.

You'll find this foam particularly effective for electrical contacts in PCBs and portable devices, offering 50 dB of attenuation between 300 MHz and 10 GHz. With a surface resistivity as low as 0.12 Ω/SQ, you're getting reliable conductivity in a remarkably thin package.

The material's ability to compress over 50% guarantees consistent contact without straining your hardware.

When you're working with LCD gaskets or sensitive manufacturing environments, you'll appreciate the foam's dual functionality as both an EMI shield and dust seal. It's made from PORON material, which outperforms standard polyethylene and urethane alternatives in respect of resilience and durability.

You can customize it with adhesive backing for your specific needs, making it ideal for compact designs where space is at a premium. The foam's energy-absorbing properties also help protect your components from shock and vibration damage.

Quarter-Inch Standard Thickness

The quarter-inch standard thickness serves as the workhorse of electronics protection, offering robust ESD defense for a wide range of components and assemblies. At 6.35mm thick, this black conductive polyethylene foam provides the perfect balance between protection and practicality.

You'll find it's particularly effective for shunting IC leads and securing ESD-sensitive assemblies in manufacturing environments. Offered at $1.350 per unit for small quantity orders, this foam provides exceptional value for its protective capabilities.

The foam's impressive specifications include a density of 2.5 lb and volume resistance ranging from 10e3-10e6 or 10e6-10e9, ensuring reliable static dissipation. You can easily cut and shape it to meet your specific requirements while maintaining its permanent anti-static properties.

Key features that make this thickness ideal for your electronics protection needs include:

- Superior conductivity combined with shock resistance for thorough component safety

- RoHS and REACH compliance, meeting strict industry standards for quality and safety

- Climate-resistant properties that maintain effectiveness in various environmental conditions

When you're working in cleanrooms, laboratories, or electronics manufacturing facilities, this quarter-inch thickness delivers consistent performance. It's become the industry standard because it effectively blocks static buildup while providing adequate cushioning for sensitive equipment.

Half-Inch Component Storage

Storage experts favor half-inch conductive foam for its superior component protection and versatility in electronics storage applications. You'll find this thickness particularly effective for storing various electronic components, from ICs to resistors, while providing essential electrostatic discharge (ESD) protection.

The conductive material actively dissipates static charges, keeping your sensitive components safe from potential damage. Clear view containers work especially well with this foam thickness, allowing you to quickly identify stored components.

When you're organizing your electronic components, you'll appreciate how the half-inch foam can be easily customized to fit your storage needs. You can cut it to size for drawers or storage cases, creating an efficient organizational system.

While you're setting up your storage solution, remember to properly label and categorize your components for quick access.

You'll need to verify that you're using genuinely conductive foam, not just antistatic material, as the difference is vital for proper component protection. The half-inch thickness works well for both professional and hobby workshops, offering ample protection while maintaining accessibility.

If you're storing particularly sensitive components, you'll find this thickness provides an extra measure of security compared to thinner alternatives, making it an ideal choice for your electronics storage needs.

One-Inch Heavy-Duty Safeguarding

Professional engineers choose one-inch conductive foam when maximum protection is essential for valuable or highly sensitive electronic components. The substantial thickness offers enhanced cushioning against physical impact while maintaining critical static dissipation properties. The four layer design provides unmatched structural stability for protection.

You'll find this heavy-duty foam particularly valuable in manufacturing environments, cleanrooms, and shipping applications where components need maximum safeguarding.

When you're working with one-inch conductive foam, you'll benefit from these key advantages:

- Measurable resistance of around 3KΩ guarantees reliable static protection for your sensitive electronics

- High-density construction (typically 2.5 lbs) provides superior durability for repeated use

- RoHS and REACH compliance certifies adherence to international safety standards

You can easily customize one-inch foam to fit your specific needs by cutting it to size, making it ideal for protecting circuit boards, integrated circuits, and other delicate components. The foam's conductivity, unlike basic antistatic materials, actively dissipates static electricity to maintain the operational integrity of your devices.

When you're handling expensive or irreplaceable electronic components, this thickness provides the thorough protection you need for both storage and transportation.

Two-Inch Maximum Cushioning

Three primary materials define two-inch maximum cushioning solutions: low-density conductive polyurethane, ETHAFOAM, and Anti Static PE foam. You'll find these materials particularly effective for protecting sensitive electronic components, with thicknesses ranging up to 2 inches for polyurethane and up to 100mm for Anti Static PE foam. Similar to how Web.com acquired Register.com to expand its services, these materials have evolved to meet growing industry demands.

When you're selecting cushioning materials, you'll notice each option offers distinct advantages. Low-density conductive polyurethane provides dual static defense and non-corrosive properties, while ETHAFOAM delivers superior protection against impact, vibration, and static with densities between 1.8 to 2.2 pcf.

The Anti Static PE foam features excellent electrical conductivity with surface resistance of 10^3-10^5 Ω/sq.

You can customize all three materials to meet your specific packaging needs. For electronics manufacturing and storage, you'll want to take into account that conductive foam offers better protection than standard anti-static foam for sensitive components.

These materials are especially suited for military applications, communications equipment, and integrated circuit packaging. They're also environmentally conscious choices, with the Anti Static PE foam being eco-friendly and non-toxic, while the polyurethane foam is CFC-free and low-shedding.

Custom Mid-Range Foam Options

Mid-range foam solutions offer exceptional versatility through customizable thicknesses ranging from 1/16″ to 1/4″ and densities between 1.2# to 4#. You'll find these options available in various materials, including polyethylene, polyurethane, and crosslink polyethylene foams, each engineered for specific protection requirements.

These materials provide permanent ESD characteristics, ensuring long-term protection for your sensitive electronics during packaging, shipping, and storage. The foam's surface resistance range of 10^3 to 10^6 Ohm ensures reliable static dissipation.

- Polyethylene foam delivers lightweight, closed-cell protection that's shatterproof and ideal for general electronics packaging.

- Polyurethane foam provides soft, open-cell cushioning perfect for delicate components and precise fitment.

- Crosslink polyethylene foam offers high-density protection, making it suitable for blocking and bracing applications.

When you're selecting custom mid-range foam options, you'll benefit from their high durability and resistance to shock, vibration, and chemicals. These foams can be die-cut or molded to fit your specific needs while maintaining compliance with industry ESD standards.

They're particularly cost-effective for long-term protection, as they reduce damage costs and can be fabricated into specific shapes and sizes for your unique applications. Whether you're working in electronics manufacturing, cleanrooms, or laboratories, you'll find these materials adaptable to your requirements.

Three-Inch Industrial Grade Protection

The three-inch industrial grade conductive foam provides you with maximum vibration absorption, making it ideal for protecting heavy server equipment during transport and handling.

You'll find that this thickness creates a best possible buffer zone that dampens strong impacts and prevents damage to sensitive electronic components.

The substantial depth of the foam lets you safely house complete server units while maintaining consistent static protection throughout the entire volume of the protective enclosure. Its surface resistance range of 10^3-10^5 Ω ensures reliable conductivity for sensitive electronics.

Maximum Vibration Absorption Benefits

Performance demands of industrial-grade protection meet their match in three-inch conductive foam's maximum vibration absorption capabilities. You'll find this high-density polyethylene foam, reaching up to 200 kg/m3, delivers superior shock absorption and vibration dampening across multiple industrial applications. The rapid electrical conductivity of this material makes it ideal for creating Faraday cage effects around sensitive components.

From aerospace components to sensitive electronics, the three-inch thickness guarantees your equipment receives maximum protection against mechanical stress and impact.

The closed-cell structure of this chemically cross-linked foam provides you with:

- Enhanced durability and tear resistance for long-term reliability

- Superior chemical and grease resistance for industrial environments

- Excellent protection against electromagnetic interference when using conductive variants

When you're working with high-end electronics or industrial machinery, you'll appreciate the foam's versatility and customization options. The material's anti-static properties protect sensitive components from static electricity, while its mildew-resistant nature guarantees lasting performance in various environments.

You can easily fabricate the foam into specific shapes and sizes, making it adaptable to your unique protection requirements. Whether you're shipping delicate aerospace components or safeguarding automotive equipment, three-inch conductive foam delivers consistent, reliable vibration absorption that meets demanding industrial standards.

Volume Protection For Servers

Building on the proven vibration absorption capabilities, three-inch industrial-grade conductive foam offers extensive volume protection for server environments. You'll find this robust solution particularly effective when you need to safeguard multiple server components simultaneously while maintaining consistent ESD protection throughout the entire space.

When you're protecting high-volume server installations, you can layer multiple sheets of high-density conductive polyethylene foam to achieve the desired three-inch thickness. You'll want to combine various thicknesses – 0.25, 0.5, and 1-inch sheets – to create customized protection that meets your specific requirements.

The black conductive foam's permanent ESD properties guarantee long-term protection, while its closed-cell structure provides superior durability.

You can easily customize the foam to fit your server room's unique specifications, whether you're working in cleanrooms or standard data centers. The material's low outgassing properties make it ideal for sensitive environments, and you'll appreciate how easily it can be cut and shaped to accommodate complex server configurations.

Remember to store your foam solutions in a dry, cool environment and regularly inspect them for peak performance in your volume protection strategy.

Frequently Asked Questions

How Long Does Black Conductive Foam Maintain Its Anti-Static Properties?

You'll find black conductive foam maintains its anti-static properties for several years when properly stored, as its carbon-filled composition guarantees stable conductivity. It won't degrade substantially even with regular handling and reuse.

Can Black Conductive Foam Be Safely Reused for Different Electronic Components?

You can reuse black conductive foam for different electronics, but you'll need to inspect it carefully each time. Watch for physical damage and test its conductivity regularly to verify it's still providing adequate static protection.

What Temperature Range Can Black Conductive Foam Withstand Before Losing Effectiveness?

You'll find black conductive foam maintains its effectiveness between -10°C and 85°C. If you operate outside this range, you're risking compromised performance. Don't expose it to temperatures beyond these limits.

Does Humidity Affect the Conductivity of Black Conductive Foam Materials?

No, humidity won't affect your black conductive foam's conductivity. The carbon additives in the material guarantee consistent conductive properties regardless of moisture levels, making it reliable for your electronics protection needs.

How Should Black Conductive Foam Be Disposed of After Its Useful Life?

You should dispose of black conductive foam through high-temperature incineration at authorized facilities. Don't send it to landfills. If it's contaminated with hazardous materials, you'll need specialized disposal through accredited waste companies.

In Summary

You'll find these seven black conductive foam thicknesses provide thorough protection for all your electronics storage and shipping needs. Whether you're working with delicate components requiring ultra-thin 1/48-inch foam or need heavy-duty protection with three-inch industrial grade material, there's a perfect thickness for your application. Pick the right foam thickness to guarantee your sensitive electronic components stay safe from static discharge and physical damage.

Leave a Reply