To verify your cleanroom's charge monitoring precision, you'll need to focus on three key methods. First, guarantee your sensors undergo proper calibration following ISO 21501-4 standards with annual scheduling and 5-point testing procedures. Second, implement real-time data validation using automated checks and pattern matching algorithms to confirm measurement accuracy within established limits. Third, deploy reliable static charge detection methods through ionization devices and ESD monitoring equipment while maintaining ideal environmental conditions. Following these verification techniques will help you maintain the highest standards of cleanroom monitoring and regulatory compliance.

Sensor Calibration Standards

Precision in cleanroom monitoring begins with proper sensor calibration standards.

You'll need to guarantee your calibration practices align with regulatory requirements, particularly ISO 21501-4 for particle counters and other essential monitoring devices. Environmental monitoring systems must maintain data integrity compliance with EudraLex Annex 11. It's vital to schedule calibrations at least yearly, preferably during plant shutdowns to minimize disruption to your operations.

When calibrating pressure gauges like Magnehelic devices, you'll want to implement a thorough 5-point rising and falling test.

Your particle counters should feature self-diagnostic capabilities to track flow status, laser health, and upcoming calibration dates. Don't forget to maintain detailed calibration records for traceability and compliance with the "Orange Guide" requirements.

You must use certified personnel or UKAS Calibration companies to perform your calibrations.

Your sensor outputs need to accurately correspond with measured conditions to prevent BMS errors. Tools like Rotronic's RMS can help you manage calibration schedules and generate necessary reports.

Remember that proper calibration isn't just about maintaining ISO 14644-1 compliance; it's essential for guaranteeing your cleanroom's efficient operation and product integrity.

Real-Time Data Validation

Real-time data validation forms the backbone of effective cleanroom monitoring. You'll need to implement automated checks and pattern matching algorithms to guarantee your data consistently meets required standards. By setting up range validation protocols, you can verify that numerical values for critical parameters stay within acceptable limits.

Your validation system should incorporate cross-field validation to compare related measurements, such as temperature and humidity readings, confirming they maintain logical relationships. NIST traceable calibrations ensure your monitoring equipment maintains the highest accuracy standards.

You'll want to establish continuous monitoring systems that use networked sensors to track particle counts, differential pressure, and air velocity in real-time.

To maximize efficiency, you should utilize a central monitoring system with data visualization capabilities. This allows you to view real-time metrics through detailed dashboards and respond quickly to any deviations.

You'll find that automated alerts are essential for immediate notification when parameters fall outside acceptable ranges.

The benefits of implementing real-time validation are significant. You'll experience improved response times to contamination events, reduced delays in problem detection, and enhanced regulatory compliance.

Most importantly, you'll optimize your cleanroom's performance while reducing the burden on your personnel through automated documentation and monitoring processes.

Static Charge Detection Methods

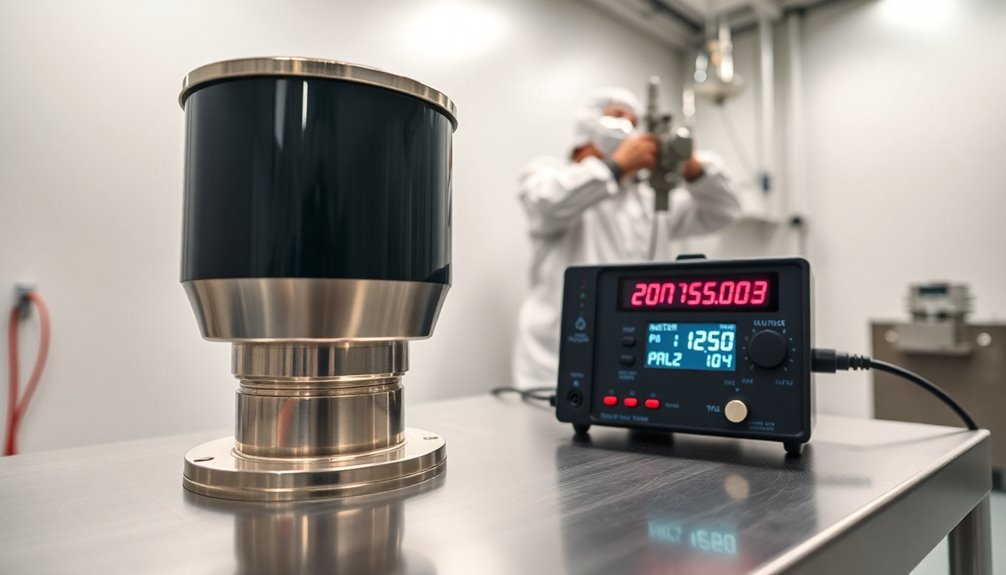

While real-time data validation helps maintain cleanroom standards, effective static charge monitoring requires specialized detection equipment and methods. You'll need to implement a thorough system that includes ionization devices and ESD monitoring equipment to detect and measure static charges accurately.

You can enhance your detection capabilities by installing environmental monitoring systems that track temperature, humidity, and pressure levels. Since low relative humidity can increase static charge generation, you'll want to maintain ideal environmental conditions. The monitoring of injection moulding processes requires particular attention due to unique static challenges.

Don't forget to reflect on how your HEPA filters and air flow patterns might contribute to static charge buildup.

To guarantee precise detection, you'll need to implement proper grounding techniques. Use wrist straps, ESD footwear, and grounded furniture with conductive tabs. Your equipment should include dissipative materials and grounded electrical conductors to prevent charge accumulation.

You can further improve your detection methods by incorporating deionization systems in critical areas. These systems release oppositely charged ions to neutralize static charges.

Think about installing ionization equipment in air showers and cleanbench hoods where static charges commonly accumulate. This thorough approach will help you maintain accurate charge monitoring throughout your cleanroom.

Frequently Asked Questions

How Often Should Cleanroom Monitoring Systems Undergo Complete Software Updates?

You should update your cleanroom monitoring software regularly, with automated systems like Sonicu performing updates automatically. For manual systems, schedule thorough updates every 6-12 months to maintain compliance and accuracy.

What Backup Power Systems Are Recommended for Continuous Cleanroom Monitoring?

You'll need a UPS system, backup generators, and battery-powered sensors with automatic switchover capabilities. Don't forget to include redundant data transmission options and regular maintenance to guarantee uninterrupted cleanroom monitoring.

Can Monitoring Systems Detect Cross-Contamination Between Adjacent Cleanroom Zones?

Yes, you'll detect cross-contamination between zones using differential pressure sensors, particle counters, and monitoring systems. They'll alert you when airflow patterns change or when particles move between adjacent cleanroom areas unexpectedly.

How Do Seasonal Changes Affect Cleanroom Monitoring System Accuracy?

You'll find that seasonal changes don't considerably impact your monitoring system's accuracy. However, you should make certain proper temperature and humidity control year-round, as these factors directly affect your sensors' long-term stability and performance.

What Role Does Artificial Intelligence Play in Predictive Cleanroom Monitoring?

You'll find AI continuously analyzes sensor data to predict contamination risks, detect anomalies, and automate responses. It's revolutionizing cleanroom monitoring by offering real-time insights and proactive maintenance recommendations.

In Summary

You'll find these three verification methods essential for maintaining accurate cleanroom charge monitoring. By following proper sensor calibration standards, implementing real-time data validation protocols, and using reliable static charge detection methods, you're ensuring the precision of your monitoring systems. Don't skip these critical steps – they're your key safeguards against costly contamination events and product quality issues in your cleanroom operations.

Leave a Reply