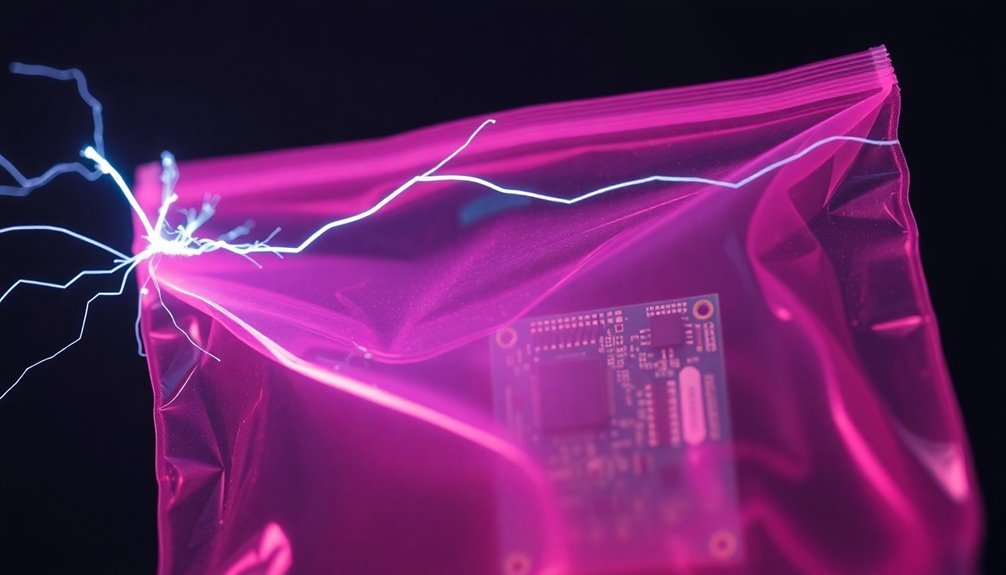

Clear static-reducing bags are essential for shipping your electronics because they protect sensitive components from damaging electrostatic discharge while allowing you to inspect items without opening the packaging. These specialized bags use antistatic additives in their LDPE polyethylene construction to safely dissipate static charges that could otherwise destroy your equipment. You'll benefit from reduced replacement costs, as static damage accounts for up to 33% of electrical product losses. The bags' multi-layer design, including metallic aluminum, creates a protective Faraday cage effect. Understanding the full scope of these bags' protective features will maximize your shipping success.

Protection Against Electrostatic Discharge

Throughout the shipping process, electronic components face significant risks from electrostatic discharge (ESD). When you're handling sensitive electronics, three main types of electrostatic threats can damage your components: triboelectric charge generation, direct discharge, and electrostatic fields.

You'll need protection against triboelectric charges that occur when materials rub against each other during transit. Clear static-reducing bags prevent this charge buildup, ensuring your electronics stay safe from friction-generated static electricity. Human contact with electronic components can generate thousands of volts of static electricity.

They also shield against direct discharge, which can instantly destroy electronic components. The bags create a Faraday cage around your items, safely dissipating any static charges before they can cause harm.

These specialized bags also protect your electronics from electrostatic fields in the surrounding environment. With their high surface resistivity, they're designed to block external static electric fields that could otherwise induce harmful charges in your components.

Material Construction and Design

The material construction of clear static-reducing bags combines specialized layers and design features to protect sensitive electronics. These bags are made from LDPE polyethylene with antistatic additives, offering reliable static dissipation properties while maintaining transparency for easy content identification. Their construction meets EIA-541 standards for static control packaging.

The bags come in various thicknesses, from 2 Mil for standard protection to 6 Mil for super heavy-duty applications.

When you're looking at static shielding options, you'll notice some bags feature multiple layers, including metallic aluminum that creates a Faraday cage effect. This design blocks external electrostatic discharge while protecting your components.

The bags are available with practical features like zip-lock closures or heat-sealable ends, letting you choose the best option for your specific needs.

The materials used aren't just about protection – they're also designed for environmental resistance. You'll get moisture protection and cleanliness preservation, essential for maintaining component integrity.

These bags meet military-grade MIL-B-81705 standards, ensuring you're using industry-compliant packaging that's often made from 100% virgin and recyclable materials for superior quality protection.

Cost Benefits for Businesses

Beyond the technical aspects of static-reducing bags, businesses can realize significant cost savings across multiple operational areas. When you consider that up to 33% of electrical product loss stems from static damage, implementing these protective bags can dramatically reduce your replacement and repair expenses.

You'll notice immediate benefits in operational efficiency as your team spends less time processing returns and handling damaged goods. The streamlined workflow leads to faster shipping times and reduced storage costs, ultimately improving your supply chain performance.

Labor costs decrease as fewer products require repairs or replacements. Since static discharges of 30 volts can damage sensitive electronics, proper anti-static packaging is essential for preventing losses.

Using static-reducing bags also strengthens your customer relationships. When products arrive undamaged, you'll see fewer returns, reduced customer service calls, and lower complaint-handling costs. Satisfied customers are more likely to leave positive reviews and recommend your business, enhancing your brand reputation.

The long-term financial impact is substantial. You'll build a competitive advantage as a reliable supplier, leading to increased customer loyalty and business growth. The cumulative effect of reduced waste, fewer damaged shipments, and improved operational efficiency directly contributes to your bottom line, making static-reducing bags a smart investment for your business.

Safe Storage and Handling

Proper storage and handling of electronics demands meticulous attention to static protection measures. You'll need to implement multiple layers of protection, starting with high-quality static-reducing bags that create a Faraday Cage effect. When storing your electronic components, always use cushioning materials inside the bags to protect against physical shocks and vibrations. Maintaining relative humidity between 40% and 80% helps prevent both static electricity and moisture damage.

| Protection Type | Purpose | Implementation |

|---|---|---|

| Static Control | Prevents ESD damage | Use amine-free bags |

| Moisture Protection | Prevents corrosion | Include desiccants |

| Physical Safety | Prevents impact damage | Add cushioning |

For ideal protection during storage and handling, you'll want to choose bags with appropriate thickness levels – typically 2-6 Mil depending on your needs. When handling sensitive components, use reclosable bags that meet Mil-B-81705 standards to maintain consistent protection levels. Don't forget to monitor environmental conditions, especially in areas with high humidity. You can incorporate humidity indicator cards to track moisture exposure and add vapor barriers when necessary. If you're shipping electronics to locations with extreme temperatures, you'll need to include additional insulation to maintain stable conditions throughout transit.

Industry Applications and Standards

Industry-wide adoption of clear static-reducing bags follows stringent standards and specifications across multiple sectors. You'll find these bags extensively used in electronics manufacturing, where they protect sensitive components during production and shipping. Incorporating ESD control solutions helps minimize costly repairs and replacements.

Companies must comply with standards like MIL-PRF-81075, particularly when handling military-grade electronics.

When you're selecting static-reducing bags, you'll need to think about whether your application requires anti-static or static shielding properties. Anti-static bags prevent static buildup and are suitable for less sensitive components, while static shielding bags offer superior protection through their Faraday Cage effect, making them essential for items like GPUs and SMD components.

Your choice should also account for the specific materials used in these bags. Static shielding options incorporate conductive materials like carbon or aluminum, combined with polyester and polyethylene laminates.

You'll need to match the bag's protection level to your product's sensitivity and environmental conditions. If you're working in an environment with high static potential, you'll want to opt for bags with metalized layers for maximum protection.

Frequently Asked Questions

Can Static-Reducing Bags Be Reused After Their Initial Use?

You can reuse static-reducing bags if they meet strict criteria for integrity, cleanliness, and static protection. However, it's not recommended as their effectiveness degrades over time and risks damaging your sensitive electronic components.

How Long Do Static-Reducing Bags Maintain Their Protective Properties?

Your static-reducing bags will maintain their protective properties indefinitely if they're stored properly and undamaged. However, you'll want to inspect them before each use and replace them if you notice any wear.

Are Clear Static-Reducing Bags Recyclable?

Yes, you can recycle clear static-reducing bags since they're made from PET or LDPE materials. Check with your local recycling facility, as they'll need to handle these specialized plastics with their static-dissipative additives.

Do Static-Reducing Bags Protect Against Moisture and Water Damage?

Yes, you'll find that static-reducing bags protect against moisture and water damage. They're made with water-impermeable materials and sometimes include desiccants to absorb moisture, keeping your electronics safe and dry during storage.

What Temperature Range Can Static-Reducing Bags Safely Withstand During Shipping?

Your static-reducing bags can safely withstand temperatures between 300°F – 375°F (149°C – 190°C) during shipping. However, you'll want to store them at 21-23°C to maintain their protective properties and prevent damage.

In Summary

Using clear static-reducing bags for shipping electronics isn't just a smart choice – it's essential for protecting your valuable components. You'll prevent costly damage from electrostatic discharge while maintaining visual inspection capability. By following industry standards and choosing these specialized bags, you're ensuring safe handling, storage, and transport of sensitive electronic items. It's a small investment that can save you significant money in the long run.

Leave a Reply