Don't let common anti-static wrist strap mistakes put your electronics at risk. You'll need to wear the strap snugly against bare skin, not over clothing, and guarantee it's properly grounded to an approved point – not just any metal surface. Test your strap daily before each shift using appropriate ESD testing equipment, and inspect it regularly for wear, cuts, or damage. You'll want to maintain consistent skin contact throughout your work period and verify the resistance stays between 750K ohms and 35 megohms. Understanding proper grounding techniques and maintenance protocols will help you protect your sensitive components even further.

Common Wrist Strap Usage Mistakes

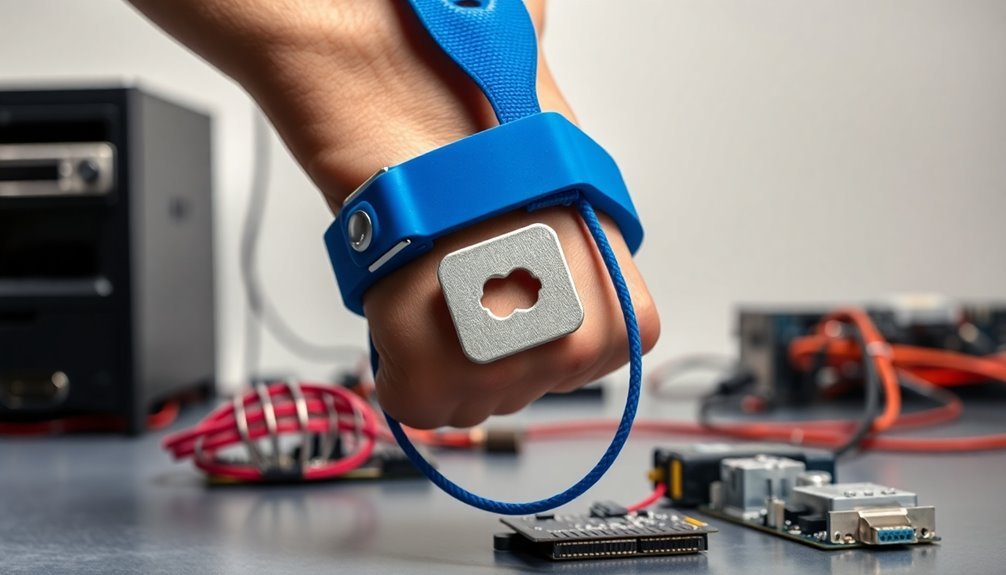

Static electricity poses a significant threat to electronic components, and proper wrist strap usage is your first line of defense. You'll compromise this protection if you don't wear your strap correctly or fail to wear it at all. Always secure the strap snugly against your skin before entering the ESD Protected Area (EPA), as loose or damaged straps won't provide adequate grounding. Using ripped or patched straps is unacceptable as they compromise essential ESD protection.

Pay attention to your skin's condition, as dry or soiled skin can increase resistance and reduce the strap's effectiveness. Consider using anti-static hand lotion to improve the connection between your skin and the strap.

Watch for common errors like incorrect sizing, which can lead to poor skin contact, or failing to ground your strap properly. Remember to connect your strap before entering the EPA, not after, to prevent static buildup.

If you're using a continuous monitor, don't ignore its warnings – they're telling you something's wrong with your grounding connection.

Quality Testing and Maintenance

Reliable testing equipment forms the backbone of any effective ESD protection program. You'll need properly calibrated ESD meters, wrist strap testers, and five-pound electrodes to guarantee your anti-static equipment meets safety standards. Approximately thirty percent of failures in electronic components can be traced back to electrostatic discharge damage.

Don't skip regular testing – it's vital to verify that your wrist straps maintain resistance levels below 35 megohms but above 750K ohms.

Industry standards require all wrist strap grounding to electrical outlets using properly secured cable eyelets.

To maintain your ESD protection system effectively, follow these essential practices:

- Test your wrist straps at the start of each shift using certified testing stations

- Clean your ESD equipment regularly to prevent contamination that could affect performance

- Document all test results to track patterns and identify potential issues early

Remember that compliance with standards like ANSI/ESD S20.20 and IEC 61340-5-1 isn't optional. Use combo testers for convenient checking of both wrist straps and footwear, and guarantee your testing instruments are calibrated to national standards.

When you notice signs of wear or damage during your regular inspections, don't hesitate to replace the equipment. Failed or worn-out wrist straps can't protect your sensitive electronics, and the cost of replacement is minimal compared to potential damage from static discharge.

Safety Risks and Solutions

A thorough testing program helps identify safety hazards, but you'll need to understand specific risks to protect both personnel and equipment.

Static electricity can cause unexpected shocks and injuries, particularly when you're working with live equipment. Don't treat anti-static wristbands as personal protective equipment – they're designed primarily to safeguard sensitive electronics, not people. The increasing sensitivity of circuits has made proper ESD protection more critical than ever. ESD damage can cost the electronics industry billions of dollars annually.

You'll need to guarantee proper skin contact by keeping straps clean and snug. Don't use wireless or cordless options, as they won't effectively prevent static buildup. If you're sensitive to certain materials in anti-static wristbands, inform your supervisor to explore alternative solutions.

Always connect your strap to an approved grounding point and avoid touching non-grounded surfaces.

When working in ESD Protected Areas, you must comply with industry standards like ANSI/ESD S20.20. Specialized training becomes essential if you're handling live equipment.

Remember that improper use can lead to significant risks and costly damage to electronic components. You'll need to regularly inspect your wristband and maintain proper wearing techniques to guarantee both your safety and the protection of sensitive equipment.

Proper Grounding Techniques

Through proper grounding techniques, you'll protect sensitive electronics from damaging static discharge. Start by connecting your anti-static equipment directly to a properly grounded electrical outlet, which provides a reliable path to earth through the building's wiring system. Proper ESD procedures should be followed to prevent unexpected static discharge damage.

When setting up your workspace, make certain you're using an anti-static mat with proper grounding snaps connected to a grounding cable with a 1 meg ohm resistor. Surface resistance testing helps ensure your mat meets required ESD standards.

For effective grounding, you'll need these essential components working together:

- An anti-static mat covering your work surface, connected to ground via a cable with an eyelet terminal

- A wrist strap properly attached to a grounding point on your mat or directly to ground

- A continuous monitoring system to verify your ground connection remains active

Don't make the mistake of connecting your wrist strap to an ungrounded computer case or using it without a proper ground connection.

Remember that non-conductive surfaces like wood or plastic won't provide protection. Always verify your grounding cable includes a safety resistor to control discharge rates, and regularly test your equipment to make sure it's functioning correctly.

Alternative Grounding Methods

When electrical outlets aren't readily available, several effective alternatives can safely ground your anti-static equipment. You'll find that metal tables on conductive floors, door frames, and properly grounded PC cases can serve as reliable grounding points. Just verify you're using appropriate grounding cables equipped with a 1 megohm resistor to maintain a safe static dissipative rate.

If you're setting up a permanent workstation, consider installing dedicated grounding pads near your equipment. These provide convenient access points and help maintain consistent protection against ESD. You can also utilize conductive flooring or grounded floor mats to enhance your overall static protection system.

When using alternative grounding methods, you'll need to exercise proper caution. Don't connect your wrist strap directly to an anti-static mat using alligator clips, as this increases total system resistance and compromises protection. Instead, use a common point ground to connect both your mat and wrist strap.

Remember to regularly test your grounding equipment to verify it's functioning correctly. If you're using exposed electrical connections, always cover them with electrical tape to prevent accidental contact.

Essential Daily Best Practices

You'll need to test your anti-static strap before starting each work shift to guarantee it's functioning correctly.

Make sure you establish proper skin contact by wearing the strap snugly against your wrist, with the conductive material making direct contact with your skin.

Check your strap daily for visible signs of wear, damage to the snap connector, or deterioration of the conductive material, replacing it immediately if you spot any issues.

Test Before Each Shift

Before starting your shift, testing your anti-static wrist strap is a critical daily practice that guarantees reliable ESD protection. Using a combo tester, you'll need to verify both your wristband and ground cord connections while ensuring proper skin contact.

Don't skip this step, as wrist straps can fail in various ways, potentially compromising your sensitive electronic components.

For ideal testing procedures, make sure you:

- Connect your strap to a verified grounding point and use an ESD meter kit for accurate resistance measurements

- Record your test results to maintain compliance with ANSI/ESD S20.20 and EN 61340-5-1 standards

- Check that you're not exceeding 250 VAC when working with powered equipment

When handling highly sensitive ESDS items, you'll want to implement continuous monitoring instead of relying solely on daily tests.

Always use testing equipment specifically designed for ESD verification, as standard multimeters won't provide accurate readings. If you receive a bad or open reading during testing, check each component individually to identify the failure point.

Secure Proper Skin Contact

Achieving proper skin contact with your anti-static wrist strap is essential for maintaining reliable ESD protection. You'll need to verify the conductive material makes direct contact with your skin, as any interruption can compromise its effectiveness.

Don't place the strap over clothing or sleeves, as this defeats the purpose of the grounding mechanism.

Adjust your wristband for a snug but comfortable fit. If you're using an elastic band, open the clasp and adjust the material until you achieve proper contact. For metal bands, carefully position the links in the backplate and secure them firmly.

If you have particularly dry skin, consider using ESD lotion to improve conductivity.

Watch out for common mistakes that can reduce your protection. Don't let your strap become loose or worn out, as this can cause intermittent contact. Clean the conductive material regularly and inspect the snap connector to maintain peak conductivity.

If you notice your wristband becoming stretched or damaged, replace it immediately. Remember to test your strap's effectiveness before each use and maintain consistent contact throughout your work shift.

Inspect for Visible Damage

Regular inspection of your anti-static wrist strap sets up an important defense against ESD damage. You'll need to check your strap daily for any signs of wear, cuts, or chemical damage that could compromise its effectiveness.

Don't forget to examine the ground cord and connection points for corrosion or loose attachments that might interrupt proper grounding.

Make these significant inspections part of your daily routine:

- Examine the strap's material and ground cord for cuts, breaks, or chemical exposure

- Check all connection points for secure attachment and signs of oxidation

- Verify that the grounding point remains properly earthed and the noise suppressor is functional

When conducting your inspection, you'll want to pay special attention to the continuity and resistance of your strap system. Use appropriate test equipment or continuous monitoring systems, particularly in high-sensitivity environments.

If you're working in these areas, it's vital to document all maintenance and testing activities for compliance purposes. Remember, only trained personnel should perform detailed testing and maintenance procedures.

Frequently Asked Questions

Can Anti-Static Straps Be Shared Between Multiple Operators During Different Shifts?

You shouldn't share anti-static straps between operators. It's unsafe and unreliable due to hygiene concerns, varying skin conductivity, and increased wear and tear. Always use your own personal strap for best protection.

How Does Humidity Affect the Performance of Anti-Static Wrist Straps?

Your anti-static wrist strap's performance improves with higher humidity, as moisture helps static charges dissipate. However, don't rely solely on humidity – you'll still need proper grounding and regular strap testing.

Are Wireless Anti-Static Wrist Straps as Effective as Traditional Wired Versions?

No, wireless anti-static wrist straps aren't as effective as wired ones. You can't rely on them because they fail to meet safety standards, don't provide proper grounding, and can't effectively dissipate static charges.

What Happens if an Anti-Static Strap Is Used With Non-Esd Compliant Clothing?

While you're wearing an anti-static strap, your non-ESD clothing can still generate and hold static charges. The strap only grounds your body, not your clothes, leaving components vulnerable to static damage from your garments.

Can Anti-Static Wrist Straps Cause Skin Irritation Over Prolonged Use?

Yes, you can experience skin irritation from prolonged anti-static wrist strap use. It's often caused by metal allergies, material sensitivity, sweat buildup, or prolonged contact, but you'll find hypoallergenic alternatives available.

In Summary

You'll protect your sensitive electronics by avoiding these common anti-static strap mistakes and following proper maintenance protocols. Remember to test your wrist strap daily, maintain solid contact with your skin, and guarantee proper grounding connections. Don't skip safety checks or ignore warning signs of wear. When in doubt, replace your strap – it's much cheaper than replacing damaged components.

Leave a Reply