Conductive floor mats are essential because they protect you, your workers, and sensitive equipment from dangerous static electricity buildup. In industrial settings, static discharge can ignite flammable materials, damage electronics worth billions annually, and increase slip-and-fall risks. You'll find these mats create a safe path for static charges through proper grounding, while their anti-fatigue properties boost worker comfort and productivity by up to 22%. They're particularly vital in electronics manufacturing, healthcare facilities, and chemical laboratories where static control is paramount. Understanding how these mats protect your workplace can help you make informed safety decisions.

Understanding Static Electricity Risks

In industrial settings, static electricity poses significant risks that you can't afford to ignore. When you're working with machinery, materials, or electronic equipment, the buildup of static charges can lead to dangerous situations that threaten both personnel safety and valuable assets.

You'll find that static electricity commonly develops during routine industrial processes like liquid handling, spraying, and material transport through conveyors. Dry conditions significantly increase the risk of static buildup and discharge. The risk increases when you're dealing with two dissimilar materials in contact, especially in environments where materials frequently separate and reconnect. Static charge generation becomes more intense as the separation speed between materials increases.

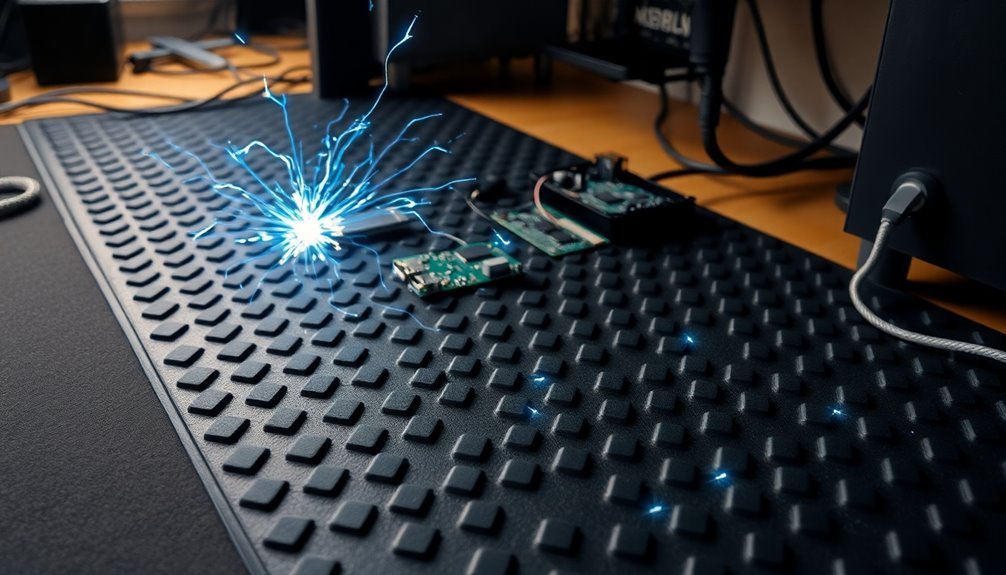

Beyond the immediate fire risks, you need to take into account how static electricity can damage sensitive electronic equipment through electrostatic discharge. It's not just about equipment damage – you're also looking at potential product contamination when static charges attract dust and particles in manufacturing environments.

Without proper prevention measures, you're facing potential hazards including sparks that can ignite flammable substances, causing fires or explosions.

Even your personnel's health is at stake, as repeated exposure to static shocks can cause physical discomfort and stress. Understanding these risks is vital because they can occur in almost any workplace setting, particularly in manufacturing and processing environments.

Key Benefits For Workplace Safety

Now that you understand the risks of static electricity, you'll find that without proper safety measures, annual losses of $40 billion impact electronics industries worldwide. You'll want to explore how conductive floor mats provide multiple layers of workplace protection. These mats actively prevent accidents by offering enhanced traction in high-traffic areas while safely dissipating static electricity that could cause injuries or equipment damage.

You'll find that conductive floor mats serve as essential safety tools by reducing slip-and-fall risks, particularly in wet conditions. With annual business costs exceeding $2.35 billion due to slip incidents, these safety investments are crucial. They work seamlessly with other ESD protection equipment, like grounding straps and specialized footwear, to keep your workers safe from static-related accidents.

The mats' anti-fatigue properties also help reduce worker fatigue through proper cushioning and support. Your sensitive electronic equipment benefits greatly from these mats, as they prevent static discharge that could lead to malfunctions, data loss, or complete system failure.

Protection Against Equipment Damage

Static electricity's destructive potential makes conductive floor mats vital for protecting your valuable equipment. When you use these mats with proper grounding equipment like heel grounders or grounding cords, you'll create a safe path for static charges to dissipate before they can harm sensitive electronics.

You'll find these mats particularly important in electronics manufacturing, testing, and repair facilities where static discharge can instantly destroy expensive components. The mats' insulated materials effectively prevent static buildup during processing and handling. The mats feature surface resistivity levels between 1×10^6 and 1×10^9 ohm to control static discharge rates. They work by drawing static electricity away from you and your equipment, preventing the buildup that could lead to costly damage or system failures.

This protection translates directly into cost savings by reducing equipment repairs and minimizing downtime.

In environments with flammable materials, you'll need these mats to prevent static-related fires. They're especially important where explosive dusts, gases, or chemicals are present, as static discharge could trigger dangerous ignitions.

Fire Prevention Through Static Control

Building on the importance of protecting equipment, conductive floor mats play an even more vital role in preventing fires caused by static electricity. You'll find these mats are specifically designed to prevent static electricity accumulation, which can act as an ignition source in high-risk environments where flammable materials are present. The Nitricell® sponge base helps workers remain comfortable during long shifts while maintaining critical static dissipation properties.

When you install conductive floor mats, they work continuously to dissipate static electricity through proper grounding. The mats require regular inspections to maintain their effectiveness in static control and fire prevention. They'll prevent dangerous static build-up on both workers and equipment, greatly reducing the risk of static-related fires. If you're working in areas with flammable chemicals or open flames, these mats become particularly important for your safety.

You can trust that quality conductive mats meet strict industry standards, including ESD-S7.1 compliance, ensuring effective static control. They're manufactured using fire-resistant materials and feature specific resistance properties that make them reliable for long-term fire prevention.

When you properly ground these mats, they'll create a thorough safety system that protects your workplace from static-related fire hazards. The mats' effectiveness in dissipating static electricity makes them an indispensable component of your facility's fire prevention strategy.

Types Of Conductive Floor Mats

Several distinct types of conductive floor mats are available to meet your specific workplace needs. You'll find options made from static dissipative natural rubber, 100% nitrile fire-resistant compounds, and durable vinyl materials. Each type offers unique benefits, with two-layer rubber mats providing superior heat and chemical resistance compared to three-layer vinyl alternatives.

When selecting a conductive floor mat, you'll notice various design features that enhance safety and functionality. Most mats include anti-slip surfaces and beveled edges to prevent tripping, while some incorporate air pockets for improved comfort during long standing periods. You can choose between textured surfaces for reduced glare or smooth microcellular vinyl tops for easy cleaning.

These mats serve multiple applications across different environments. You'll commonly find them in electronics manufacturing facilities, cleanrooms, server rooms, and individual workstations. They're essential for protecting sensitive equipment from static discharge while ensuring worker safety.

Whether you're equipping an industrial facility or setting up a single workstation, you'll benefit from the mat's dual purpose of static control and ergonomic support. Many models are made from recycled materials, offering both environmental consciousness and durability while meeting ESD safety standards.

Installation And Grounding Requirements

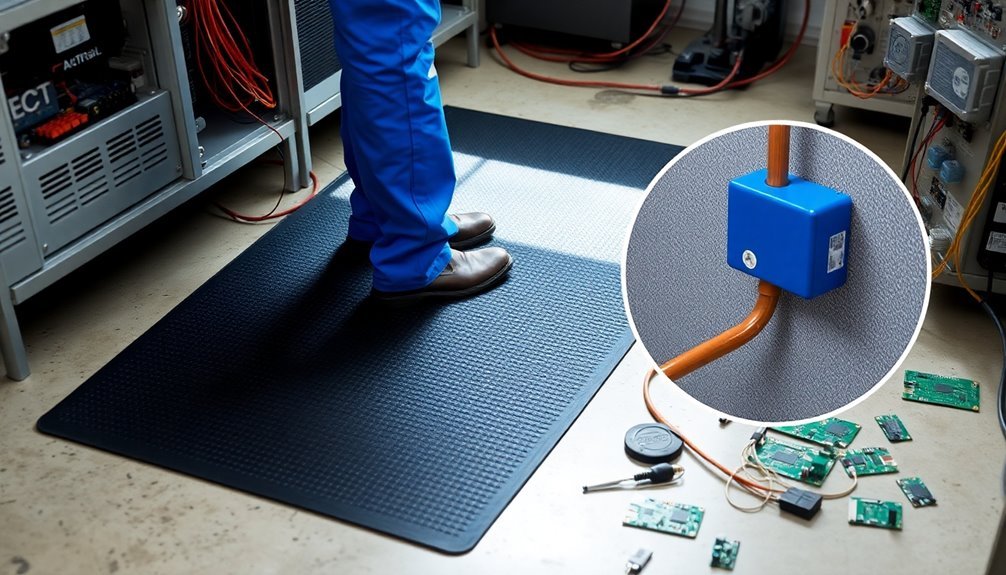

When installing conductive floor mats, you'll need to follow specific grounding requirements to guarantee ideal static protection. You'll want to verify proper placement at workstations or areas where static electricity poses significant risks. Connect your mats to the earth using grounding wires, and always pair them with other ESD safety equipment like wristbands and antistatic footwear for complete protection.

For peak performance and safety, you'll need to take into account these essential installation steps:

- Choose two-layer rubber mats with conductive backing for superior grounding and heat resistance, making sure they're IEC certified for reliability.

- Install the mats in areas with static-sensitive equipment, confirming there's a clear path to ground through proper connection of all ESD safety components.

- Select the appropriate size and thickness based on your workplace needs, and maintain regular cleaning schedules to preserve effectiveness.

The right installation matters for both safety and functionality. Don't forget to check the surface resistance regularly and verify it stays within recommended ranges.

If you're setting up entrance mats, position them strategically to reduce static buildup while maintaining clean work areas.

Maintenance For Maximum Effectiveness

You'll need to regularly clean your conductive floor mats with appropriate cleaning solutions and methods to maintain their static-dissipative properties and prevent performance degradation.

It's essential to check your mats' grounding connections daily, ensuring they maintain proper electrical contact and meet safety requirements.

Watch for signs of wear and tear, such as cracks, peeling, or discoloration, as these issues can compromise the mats' effectiveness and require immediate attention.

Regular Cleaning Methods Required

Proper maintenance of conductive floor mats requires a systematic cleaning routine to guarantee their continued effectiveness. You'll need to perform daily sweeping or vacuuming to remove debris, followed by weekly mopping using mild detergent and distilled water.

It's vital to avoid harsh chemicals and abrasive materials that can damage the mat's conductive properties.

For peak performance and longevity, you should incorporate these essential cleaning practices:

- Use static-reducing cleaning products specifically designed for ESD mats, and always rinse thoroughly to prevent residue buildup.

- Clean with lint-free cloths or brushes while wearing proper grounding equipment to prevent static generation during maintenance.

- Follow manufacturer guidelines strictly and document all cleaning activities for compliance purposes.

You'll need to pay special attention to high-risk environments where mats require cleaning after each use.

When cleaning, work in an area away from sensitive equipment and make sure the mat dries completely before returning it to service.

Remember to regularly inspect for wear and replace mats showing signs of degradation, as damaged mats won't provide adequate protection against static electricity.

Grounding Connection Checks Essential

To maintain ideal performance of conductive floor mats, regular grounding connection checks are essential for guaranteeing consistent static dissipation. You'll need to verify that your mat's grounding system remains effective by testing the resistance between the mat and its grounding point, making sure it falls within manufacturer-specified limits.

You should inspect your grounding wires and straps frequently, as they provide the vital path for static electricity to discharge safely to earth. When you're using ESD mats, pair them with appropriate ESD footwear or heel straps to create a complete grounding system.

Remember that without proper grounding, your mat can't provide maximum protection against static discharges.

Make certain you're following industry standards and certifications, such as IEC requirements, when testing your grounding connections. You'll want to conduct regular audits to maintain compliance and guarantee your mat meets safety criteria.

Keep your grounding points easily accessible for routine testing, and document your checks to track the mat's performance over time. If you discover any resistance measurements outside the specified range, take immediate action to restore proper grounding and maintain your mat's effectiveness.

Monitor Wear And Tear

Regular maintenance inspections serve as the foundation for maximizing your conductive floor mat's effectiveness and longevity. You'll need to check for cuts, tears, and signs of degradation while maintaining a consistent cleaning schedule that aligns with your facility's usage patterns.

It's essential to monitor the mat's antistatic properties, as these can diminish over time.

When cleaning your conductive floor mats, stick to methods that won't compromise their protective qualities. You should vacuum or sweep daily, and use damp mopping with mild detergent for deeper cleaning.

Remember, harsh chemical cleaners can damage the mat's antistatic properties, so avoid them entirely.

- Check your mat's grounding connections weekly to verify proper electrical continuity

- Inspect the mat's surface monthly for physical damage, discoloration, or wear patterns

- Test antistatic properties quarterly using appropriate measurement equipment

Don't wait until your mats show obvious damage before replacing them. When you notice significant wear, reduced antistatic properties, or inadequate grounding, it's time for replacement.

Keep your mats properly positioned at workstations and entrances, making sure they're secured firmly to prevent tripping hazards and maintain consistent protection against static discharge.

Industry Applications And Uses

You'll find conductive floor mats are essential in critical manufacturing environments where static electricity can damage sensitive electronic components during production.

In healthcare facilities and operating rooms, these mats protect crucial medical equipment from static-related malfunctions while ensuring patient safety.

Chemical laboratories also rely on conductive floor mats to prevent static sparks that could ignite flammable materials and compromise research operations.

Critical Manufacturing Environments

Three major industrial sectors rely heavily on conductive floor mats to maintain safe and efficient manufacturing environments.

You'll find these protective surfaces in electronics manufacturing facilities, automotive plants, and chemical laboratories where static electricity poses significant risks. These environments demand thorough ESD protection to prevent equipment damage, guarantee worker safety, and maintain continuous production flows.

When you're operating in these critical settings, you'll need specific types of conductive floor mats based on your risk level and application. Static dissipative mats work well for moderate-risk areas, while high-risk zones require fully conductive mats with proper grounding systems.

- Electronics manufacturing requires complete workstation protection, including floor mats that prevent static buildup during component handling and assembly.

- Automotive manufacturing facilities need extensive floor coverage to protect sensitive electronic systems during vehicle assembly and testing.

- Chemical laboratories depend on conductive flooring to prevent static sparks that could ignite flammable materials.

Healthcare And Lab Settings

Building on the specialized needs of manufacturing environments, healthcare facilities and laboratories present their own unique demands for conductive floor mats. You'll find these mats essential for protecting sensitive medical equipment and guaranteeing accurate test results by preventing static electricity damage.

In healthcare settings, you're dealing with life-critical equipment that can't afford static-related failures. These mats help you maintain regulatory compliance while providing a safer workspace for your staff. They're designed to be chemical-resistant and easy to clean, meeting strict hygiene requirements.

| Feature | Healthcare Benefit | Lab Benefit |

|---|---|---|

| ESD Protection | Protects essential medical devices | Preserves sensitive test equipment |

| Chemical Resistance | Withstands cleaning agents | Handles lab chemical spills |

| Slip Prevention | Reduces fall risks | Guarantees worker safety |

| Cleanroom Compatible | Meets sterile environment needs | Maintains controlled conditions |

For laboratory applications, you're getting thorough static control that's significant when working with precision instruments. The mats integrate seamlessly with other ESD equipment like wrist straps and heel grounders, creating a complete static-free workstation. They're particularly valuable in areas where you're handling flammable materials or conducting sensitive tests that static interference could compromise.

Worker Health And Comfort

While standing on hard surfaces for extended periods can take a toll on workers' bodies, conductive floor mats offer significant health and comfort benefits.

These specialized mats reduce fatigue and discomfort by improving circulation and decreasing pressure on joints, muscles, and the spine. You'll notice immediate improvements in worker comfort and a substantial reduction in musculoskeletal disorders.

The ergonomic benefits of conductive floor mats translate directly into measurable productivity gains. You can expect to see up to a 22% increase in productivity, which adds approximately 45 extra workdays per employee annually.

They'll also help you reduce workplace injuries and absenteeism, with studies showing a 23% drop in missed workdays over two years.

- The mat's domed surface manipulates pressure points in your feet, breaking up stress patterns throughout your body.

- The sponge base promotes subtle leg and calf muscle movement, enhancing blood flow back to your heart.

- Diamond-Plate designs reduce joint impact by over 50%, boosting both energy levels and worker morale.

Compliance And Safety Standards

When selecting conductive floor mats, you'll need to guarantee compliance with key industry standards like ASTM D178 for electrical insulation and ANSI/ESD S7.1 for electrostatic discharge protection.

You must verify that your mats undergo proper testing and certification, including ESD performance testing, flammability assessments, and slip resistance evaluations.

Your mats should carry certification labels indicating compliance with relevant standards, and you'll want to maintain documentation of these certifications for workplace safety audits.

Key Industry Regulations

Industry regulations lay down strict guidelines for conductive floor mats to guarantee workplace safety and equipment protection.

You'll need to comply with key standards like ISO 6356 and EN 1815, which specify requirements for controlling electrostatic discharge in workspaces. The EOS/ESD-S4 standard outlines specific criteria for selecting protective flooring, while NFPA 99 provides essential guidelines for healthcare facilities.

When implementing conductive floor mats, you must ascertain they meet the following vital requirements:

- Maintain electrical resistance within 10^5 to 10^9 ohms range for effective static dissipation

- Pass certification and third-party testing to validate compliance with safety standards

- Adhere to OSHA 29 CFR 1926.405 requirements for proper grounding and protection

Your facility's compliance with these regulations isn't just about meeting legal requirements – it directly impacts your bottom line.

Proper implementation protects sensitive electronic equipment from damage, prevents costly downtime, and ascertains employee safety.

In specialized environments like cleanrooms, server rooms, and chemical plants, you'll find these standards particularly vital as they help prevent equipment failures and potential workplace hazards.

Testing And Certification Requirements

To maintain the highest safety standards, conductive floor mats must undergo rigorous testing and certification processes. You'll need to guarantee your mats meet specific requirements for surface resistance and grounding capabilities, as established by organizations like the IEC and ESDA. These tests measure the mat's ability to safely dissipate static electricity and protect against electrostatic discharge.

When selecting conductive floor mats, you should verify they're constructed from approved materials such as vinyl, rubber, or nitrile that meet resistance standards. The mats must include proper grounding mechanisms and undergo testing for durability and chemical resistance.

In medical settings, you'll need to comply with AAMI standards.

You'll want to implement regular testing and maintenance protocols to maintain certification. This includes conducting internal audits and guaranteeing your mats continue to meet ISO 9001 quality management standards.

Don't forget to train your employees on proper mat usage and integrate them with other ESD protection measures. Regular inspections will help you identify wear and tear, guaranteeing your mats remain effective at preventing static buildup and protecting sensitive equipment.

Cost Benefits And ROI

Why do businesses hesitate to invest in conductive floor mats when the cost benefits are so compelling? The return on investment (ROI) becomes evident when you consider that ESD damage costs the electronics industry billions annually.

You'll find that implementing anti-static mats offers immediate and long-term financial advantages through reduced equipment damage, prevention of accidents, and improved productivity.

- You can greatly cut repair and replacement costs by protecting sensitive electronics from static discharge, while simultaneously reducing costly downtime and data loss incidents that impact your bottom line.

- You'll save on insurance premiums and avoid regulatory fines by creating a safer workplace, as these mats effectively prevent static-related fires and accidents in flammable environments.

- You're investing in improved operational efficiency when you factor in increased worker comfort, reduced maintenance time, and extended equipment lifespan.

The durability of high-quality ESD mats means you won't need frequent replacements, making them a cost-effective long-term solution.

When you consider the all-encompassing benefits, from preventing equipment damage to enhancing workplace safety, the initial investment in conductive floor mats quickly pays for itself through multiple cost-saving channels.

Choosing The Right Mat Material

Making smart material choices directly impacts the ROI benefits we just explored. When selecting an ESD mat, you'll need to take into account two primary options: two-layer rubber mats or three-layer vinyl mats. While both provide similar electrical performance, rubber mats offer superior thermal stability and chemical resistance.

You'll want to focus on mats made from durable compounds like static dissipative natural rubber or 100% nitrile fire-resistant rubber. These materials guarantee proper grounding capability and appropriate surface resistance, whether you need conductive (less than 1 x 10^4 ohms) or dissipative properties for slower discharge rates.

Don't overlook essential safety features when choosing your mat material. Look for anti-slip designs and beveled edges to prevent workplace accidents. If you're working in areas with open flames or sparking equipment, you'll need mats with fire-retardant properties. For standing workstations, select materials that incorporate anti-fatigue cushioning.

Remember to verify that your chosen mat meets IEC certification and complies with EOS/ESD-S4, ISO6356, and EN1815 standards.

You'll need to maintain these mats regularly to preserve their effectiveness and guarantee continued protection for your sensitive equipment and personnel.

Frequently Asked Questions

Can Conductive Floor Mats Be Used Outdoors in Wet Conditions?

Yes, you can use conductive floor mats outdoors in wet conditions. They're designed to resist water and chemicals, but you'll need to secure them properly and maintain them regularly to guarantee effective static dissipation.

How Often Should Grounding Connections Be Tested for Optimal Performance?

You should test grounding connections daily in high-risk areas and monthly in moderate-use settings. Don't forget to document your results and adjust testing frequency based on environmental conditions and usage patterns.

Do Conductive Floor Mats Interfere With Wireless Signals or Electronic Devices?

No, you won't experience wireless signal interference from properly installed ESD mats. They're designed to dissipate static electricity through controlled paths to ground, without affecting your electronic devices or wireless communications.

What Footwear Works Best With Conductive Floor Mats for Maximum Effectiveness?

You'll get the best results by wearing ESD-certified footwear or heel straps with conductive soles. They're specifically designed to work with conductive floor mats, ensuring proper grounding and maximum static electricity dissipation.

Can Multiple Conductive Floor Mats Be Connected to Share a Grounding Point?

Yes, you can connect multiple conductive floor mats to share a grounding point. This setup enhances your ESD protection across larger areas while simplifying the grounding arrangement. It's both efficient and recommended for extensive coverage.

In Summary

You'll find conductive floor mats are crucial investments in any workplace dealing with sensitive electronics or hazardous materials. They protect your equipment, guarantee worker safety, and help meet compliance requirements while preventing costly accidents. By choosing the right mat for your needs, you're creating a safer work environment that pays for itself through reduced risks and equipment protection. Don't overlook this essential safety measure.

Leave a Reply