Conductive boot soles with carbon black offer the highest conductivity and fastest static dissipation for hazardous work environments. You'll want to look for soles certified to ISO 20345:2014 or ASTM F2413-18 standards, ensuring proper safety compliance. For top performance, choose polyurethane (PU) or thermoplastic polyurethane (TPU) soles with conductive additives – they're lightweight, chemical-resistant, and provide excellent static discharge properties. Don't forget to take into account your specific workplace needs: explosive environments require 100% conductivity, while electrical work might need composite materials. There's much more to learn about the technical specifications and industry-specific requirements that'll keep you safe on the job.

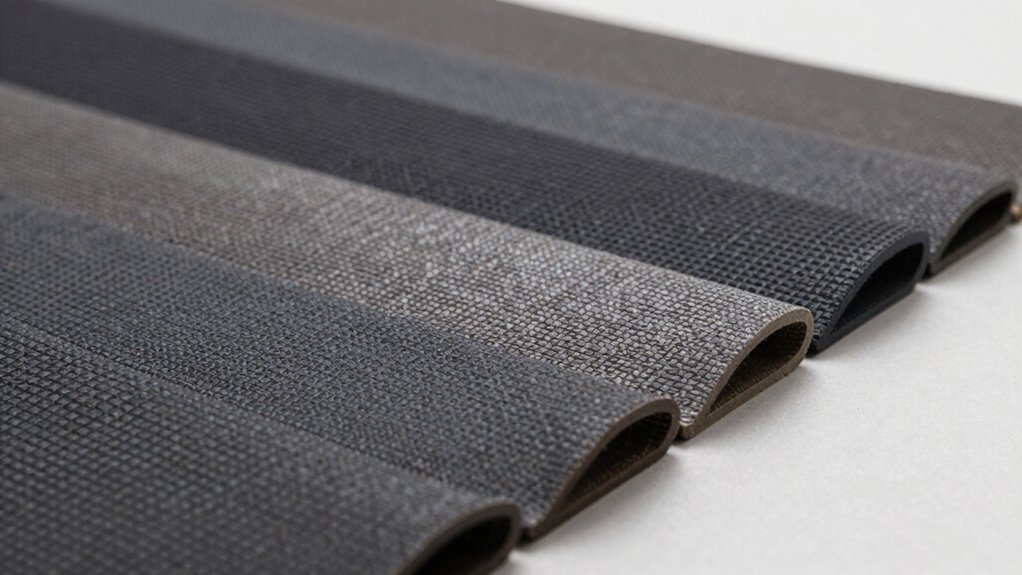

Understanding Conductive Boot Sole Materials

For workers in hazardous environments, understanding conductive boot sole materials is essential to workplace safety. These specialized soles create a pathway that dissipates static electricity into the ground, protecting you in areas where electrical hazards are present.

You'll find several key materials used in conductive boot soles. Carbon black offers 100% conductivity and rapid static dissipation, making it ideal for high-risk environments. Floor resistance plays a crucial role in the effectiveness of conductive footwear.

Polyurethane (PU) provides anti-static properties and works well in settings requiring electrostatic discharge protection. PVC combined with conductive elements like carbon fiber delivers both durability and electrical conductivity.

When you're selecting boot soles, you'll need to evaluate the material's specific properties. Natural leather becomes conductive when hydrated, while rubber requires conductive additives like copper or carbon to achieve conductivity.

The manufacturing process also impacts performance – direct injection creates more durable soles compared to glued alternatives.

These materials must meet strict standards like ASTM F2413 for Static Dissipative Electrical Protective Footwear. You'll want to verify that your chosen boots comply with relevant safety standards for your specific work environment, ensuring proper protection against static electricity hazards.

Safety Features and Protection Standards

When you're selecting conductive work boots, you'll need to verify they meet key safety certifications like ISO 20345:2014 and look for the "C" marking on the ASTM label.

Your boots' electrical resistance should fall between 0 and 500,000 ohms to effectively dissipate static electricity through the sole into grounded floors.

These boots must provide reliable static discharge protection while maintaining other essential safety features like slip resistance and chemical protection to guarantee thorough workplace safety. Regular voltage probe testing at 500 volts helps ensure the boots maintain their conductive properties over time.

Key Protection Certifications Required

Safety certifications serve as your roadmap to selecting properly protected conductive work boots. When choosing conductive footwear, you'll need to verify it meets several critical standards, particularly ASTM F2413-18 and ASTM F2412-18a, which establish the baseline requirements for protective toe caps and testing methods.

For European markets, you'll want to look for the EN ISO 20345 certification, which covers extensive safety features including toe protection and material quality.

If you're working in U.S. environments, make sure your boots comply with ANSI Z41 CLASS 75 and OSHA 29 CFR 1910.136 requirements, as these are mandatory for workplaces with foot injury risks. Meeting these standards ensures your boots have proper impact resistance ratings to protect against heavy falling objects.

When it comes to conductive properties, you'll need boots with carbon black soles that meet static dissipation requirements. These soles must effectively conduct electricity while still maintaining other safety features.

Pay special attention to AS/NZS 2210.3 and 2210.5 standards if you're in Australia or New Zealand, as they provide specific guidelines for conductive footwear.

Remember that conductive boots aren't designed for high-voltage environments – they're specifically meant for areas where static electricity buildup poses a hazard.

Static Discharge Safety Measures

The thorough protection offered by static discharge safety features requires multiple integrated components working together. Your conductive work boots use specialized materials like carbon black soles and anti-static PU/TPU components to eliminate electrical resistance. These materials work in tandem with grounded floors to safely discharge static electricity from your body, preventing dangerous sparks or electrical accumulation that could ignite flammable materials.

When selecting conductive work boots, you'll need to consider several critical safety measures:

- Your boots must maintain consistent ground contact while walking, as effectiveness depends on your movement patterns and contact with surfaces.

- Keep your boots clean and regularly tested, as contamination and wear can compromise their static-dissipative properties.

- Don't rely solely on conductive footwear – use it as part of an extensive safety system that includes other insulating equipment.

- Think about using dielectric overshoes in wet conditions, as moisture can reduce EH protection.

- Monitor your work environment's humidity levels and floor resistance, as these factors affect static buildup.

Remember that proper maintenance is vital – regular testing and inspection guarantee your boots maintain their protective properties against static discharge hazards. Following ASTM F2413 and F2892 standards ensures your footwear meets industry-recognized safety requirements for static dissipative protection.

Electrical Resistance Testing Requirements

When selecting conductive work boot soles, you'll need boots that meet strict testing protocols under ASTM F2412-05, which requires thorough electrical resistance testing using metal sphere-filled boots and specialized electrode setups.

Your boots must fall within specific resistance ranges – below 100 KΩ for conductive footwear, between 100 KΩ and 1 GΩ for antistatic, and above 1 GΩ for insulating properties.

Regular inspection before use is critical to ensure boots maintain their electrical resistance properties. The certification process involves voltage testing at 14,000V for one minute and leakage current testing that guarantees no more than 3.0 mA passes through in dry conditions.

Standard Test Method Protocols

Understanding electrical resistance testing protocols begins with two primary standards: ASTM F2413-18 and ASTM F2892-18. These standards require boots to withstand 18,000 volts at 60 Hz for one minute, with current flow not exceeding 1.0 mA under dry conditions.

Safety boots and labels must meet rigorous international certifications before being approved for use. Conductive boots must effectively dissipate electrical charges, while dielectrically insulated footwear needs to meet even more stringent requirements for high-risk environments.

When you're selecting work boots with electrical protection, look for these testing certifications:

- CSA White rectangle with orange Ω symbol, indicating 18,000V shock resistance

- OSHA-compliant certification for impact and compression resistance

- ASTM F2413-18 certification for conductive protection with toe caps

- Test results showing 600V resistance in dry conditions

- Dielectric insulation test results for high-risk electrical environments

You'll need to verify that your boots comply with OSHA standards, which mandate specific safety features like non-skid soles and built-in toe caps. Manufacturers must prove their boots meet these standards through rigorous testing before they can legally claim specific electrical protections. This confirms you're getting reliable protection for your specific work environment.

Resistance Range Requirements

Safety standards establish clear resistance range requirements that vary based on your work environment and protection needs. When selecting conductive work boots, you'll need to match the resistance levels to your specific workplace hazards. EH-rated boots provide isolation up to 600V AC in dry conditions, with non-conductive materials exceeding 1 GΩ resistance. Understanding your job site risks helps determine the appropriate electrical resistance requirements for maximum safety.

| Boot Type | Resistance Range | Primary Use |

|---|---|---|

| EH-Rated | >1 GΩ | High voltage protection |

| Anti-static | 0.1 – 1000 MΩ | Static discharge prevention |

| ESD | 0.1 – 100 MΩ | Electronic component handling |

For static dissipative requirements, you'll find three distinct classifications: SD 100, SD 35, and SD 10, offering protection up to 100, 35, and 10 megaohms respectively. It's essential to understand that EH boots aren't suitable for live electrical work and won't protect you if sharp objects penetrate the sole. You'll need to verify that your chosen boots meet relevant standards like ASTM F2413-18 for EH protection, EN ISO 20344:2011 for anti-static properties, or BS EN IEC 61340-4-3:2018 for ESD compliance. Remember, these resistance ranges are tested under specific conditions and serve as secondary protection measures.

Certification Testing Procedures

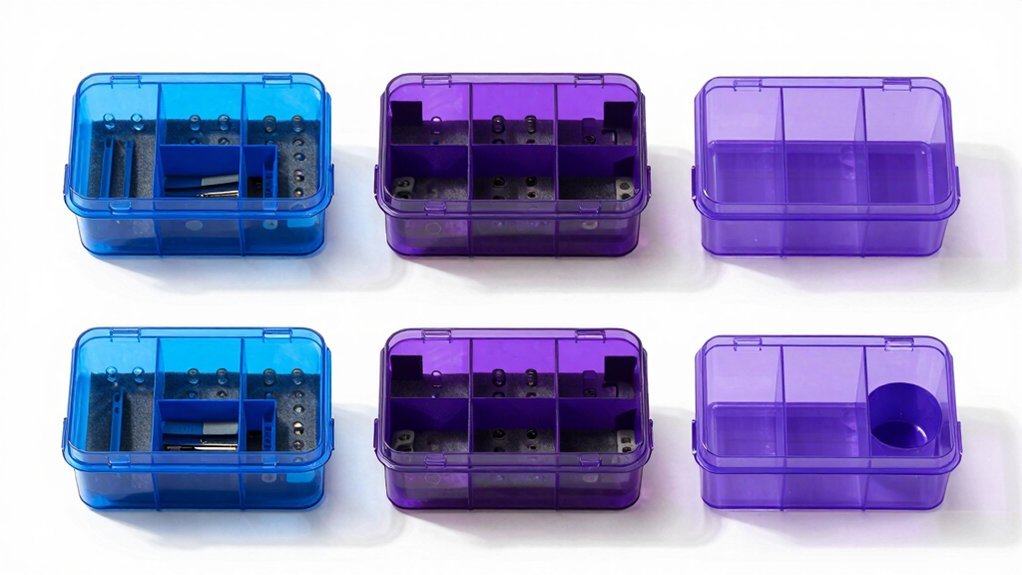

Rigorous certification testing procedures guarantee your conductive work boots meet stringent electrical safety standards. Major certifications like EN 20345:2011, ASTM F2413, and EN 50321-1:2018 require specific testing protocols to verify electrical properties.

You'll find that testing involves placing steel balls inside the boot while it rests on a copper plate, allowing precise measurement of electrical resistance under controlled conditions. Testing is performed using stainless steel balls with a carefully calibrated mass of 4 kilograms.

During certification, your boots must undergo multiple tests to confirm consistent performance:

- Electrical resistance measurements between 100V to 30kV, depending on the specific standard you're working with

- Water resistance testing where boots are filled with water to simulate real-world moisture conditions

- Puncture resistance verification to confirm electrical properties remain intact even after sole penetration

- High voltage testing up to 14,000 volts with strict leakage current monitoring

- Extended duration testing under various humidity levels to confirm sustained protection

Testing parameters are carefully controlled, with specific requirements for test duration, voltage levels, and environmental conditions. These procedures aren't just formalities – they're critical safeguards confirming your conductive boots will perform reliably in hazardous electrical environments.

Workplace Applications and Industries

In workplaces where static electricity poses serious risks, conductive work boot soles play a vital role in safety protocols. These specialized boots are primarily found in explosive environments and facilities handling highly flammable materials, where they are essential for preventing static electricity buildup that could trigger dangerous ignitions.

If you're working in explosives manufacturing, fireworks production, or chemical plants, you'll need conductive safety shoes to dissipate static charges safely to the ground. These boots help maintain minimal electrostatic charges on your body, preventing potentially catastrophic sparks in these sensitive environments.

However, you shouldn't use conductive work boots if you're in electrical work, general construction, or standard industrial settings. For electrical work and utilities, you'll want Electrical Hazard (EH) shoes instead, which feature non-conductive soles to protect against electrical shocks.

Similarly, if you're in construction or general manufacturing, you're better off with steel-toe or composite-toe boots with slip-resistant and puncture-resistant features. Remember, your choice of safety footwear should always match your specific workplace hazards and safety requirements.

Static Discharge Technology Explained

Understanding how conductive work boot soles protect you requires knowledge of static discharge technology. When you walk or move, your body builds up static electricity through friction between different materials. This process creates an electrostatic charge, where one material becomes positively charged while the other becomes negatively charged.

Without proper protection, this charge can suddenly release when you touch sensitive equipment or surfaces, potentially causing damage or safety hazards.

Conductive work boot soles use specially designed materials and construction techniques to safely disperse static electricity. They're made with compounds like treated rubber, TPU, or polyurethane that create low electrical resistance paths to the ground, preventing charge buildup.

- Your boots constantly work to discharge static electricity through their specialized outsoles

- The electrical resistance in conductive soles ranges from 0 to 500,000 ohms

- The soles create a continuous path to ground, similar to how ESD protection devices work

- Materials like leather and conductive rubber compounds work together to eliminate resistance

- Special construction techniques guarantee consistent conductivity throughout the sole

These technological features make conductive work boots essential in environments where static discharge could pose risks to equipment or safety.

Slip Resistant Design Elements

Through careful engineering, slip-resistant design elements combine specialized tread patterns and material composition to maximize grip and prevent workplace accidents.

You'll find that effective slip-resistant soles feature interlocked treads and strategic channels that allow fluids to flow freely, similar to how car tires prevent hydroplaning.

When you're selecting conductive work boots, look for designs that incorporate both larger and smaller tread patterns. The larger patterns handle contaminants effectively, while smaller patterns provide better grip on slick surfaces.

You'll want soles with a wide surface contact area and deep treads, especially if you're working in wet or oily conditions.

The material composition is equally vital for slip resistance. High-grade rubber compounds offer superior adhesion, while PU and TPU provide varying levels of slip resistance. If you're working in particularly slippery environments, soft rubber soles will give you enhanced grip.

Modern designs often integrate Kevlar or carbon components for improved durability without compromising slip resistance.

To guarantee you're getting reliable protection, check for SRC ratings, which indicate the boots have passed both ceramic tile and steel floor slip resistance tests.

Chemical Protection Properties

Chemical protection stands as a crucial feature in conductive work boot design, where specialized materials work together to shield your feet from hazardous substances. You'll find chemical-resistant polyurethane, rubber, nitrile, and specialized materials like TECtuff working to protect against various chemical threats.

When you're working in environments with fats and oils, you'll want to choose PVC or TPU soles over rubber, as they offer superior resistance to degradation.

For maximum protection in chemical-intensive environments, look for these essential features:

- Chemical-resistant materials that won't deteriorate upon exposure to adhesives, sealants, or cleaning agents

- Steel toe caps that provide additional protection against impacts while maintaining conductivity

- Enhanced grip patterns designed specifically for wet, contaminated surfaces

- Penetration-resistant midsoles to guard against sharp objects

- Acid-proof properties to protect against corrosive substances

Your conductive work boots must meet strict safety standards, including Grade 1 impact resistance and proper electrical resistance ranges (0 to 500,000 ohms). This combination of chemical protection and conductivity guarantees you'll stay safe while maintaining the necessary electrical properties for your work environment.

Comfort and Durability Factors

Anyone who spends long hours on their feet knows that comfort and durability can't be compromised in work boots. When selecting conductive work boots, you'll want to focus on features that provide lasting comfort and resilience in demanding environments.

| Comfort Features | Durability Elements |

|---|---|

| Ergonomic footbeds with superior arch support | Full-grain leather construction with reinforced stitching |

| Breathable materials for moisture control | Robust sole construction for extended wear |

| Lightweight design with ample cushioning | Abrasion and puncture-resistant materials |

You'll find that the best conductive work boots combine lightweight materials with ergonomic design to reduce foot fatigue during long shifts. Look for boots that offer adjustable fastenings to guarantee a proper fit, as this directly impacts both comfort and longevity. The durability of your boots largely depends on the quality of materials used – full-grain leather uppers and strong stitching are vital for withstanding tough conditions. You'll want to pay particular attention to the sole construction, as it needs to maintain its conductive properties while providing consistent performance over time. Remember that superior cushioning and proper arch support aren't just comfort features – they're vital for preventing long-term foot strain and extending the life of your boots.

Manufacturing Quality Control

Manufacturing quality control stands at the heart of producing reliable conductive work boots, with stringent testing protocols guaranteeing each pair meets essential safety standards.

You'll find that high-quality manufacturers rely on direct injection molding rather than glued soles, as this creates an unbreakable bond between the sole and upper. This process involves injecting molten materials like TPU or Nitrile directly onto pre-formed uppers in controlled factory settings.

Quality control labs test each boot design against ASTM 2412-05 and EN ISO 20345 standards, verifying electrical resistance, compression strength, and impact protection. They'll measure leakage current to guarantee it maintains at least 3.0 mA in dry conditions, while also testing the boots' ability to withstand 14,000 Volts at 60Hz for a full minute.

- Direct injection molding creates stronger bonds than traditional glued soles

- Each boot undergoes electrical resistance testing in controlled laboratories

- Quality control checks verify non-skid and oil-resistant properties

- Impact and compression testing guarantee toe protection meets safety standards

- Manufacturers test slip resistance according to EN ISO 13287:2019 requirements

When selecting your work boots, always check for certification labels indicating compliance with these rigorous quality control standards.

Proper Boot Maintenance Tips

Regular deep cleaning of your conductive work boots should include removing all dirt from sole grooves and applying appropriate cleaners based on the boot's material composition.

You'll need to store your boots in a cool, dry place with shoe trees inserted to maintain their shape and prevent moisture-related damage to the conductive properties.

Check your boot soles weekly for signs of wear, paying special attention to the conductive components and tread pattern to guarantee top safety performance.

Regular Deep Cleaning Methods

Maintaining conductive work boots through proper deep cleaning guarantees top performance and longevity. Start by laying out a protective towel and gathering all necessary cleaning supplies before tackling one boot at a time.

When cleaning conductive boots, it's essential to use neutral detergents and avoid harsh chemicals that could damage the conductive fibers.

For effective deep cleaning, create a mild solution using OxiClean and warm water for the midsoles and soles. Remove embedded debris from treads using tweezers, and use a stiff-bristled synthetic brush to clean between sole ridges.

You'll want to be especially careful not to brush too vigorously, as this can compromise the boot's conductive properties.

- Use a moderately damp cloth for leather uppers, but keep moisture minimal.

- Clean heel and groove areas thoroughly with a small brush.

- Remove stones from treads using tweezers before applying cleaning solution.

- Apply leather conditioner every 1-6 months, depending on wear.

- Store boots indoors and use waterproofing agents when necessary.

Always make certain boots are completely dry after cleaning to prevent moisture damage, and avoid machine washing to maintain the integrity of conductive elements.

Safe Storage Guidelines

At the end of each workday, proper storage of conductive work boots plays a critical role in maintaining their performance and extending their lifespan. You'll want to store your boots in a well-ventilated area away from direct sunlight, as UV rays can damage the leather and compromise the conductive properties. Don't use plastic bags or airtight containers, as these can trap moisture and promote mold growth.

| Storage Do's | Storage Don'ts |

|---|---|

| Use shoe trees or stuffing paper | Store in plastic bags |

| Keep in cool, dry places | Place in direct sunlight |

| Allow proper ventilation | Stack boots on top of each other |

To maintain your boot's shape and absorb internal moisture, insert shoe trees or stuff them with paper when not in use. If you're using multiple pairs of conductive boots, implement a rotation system to allow each pair sufficient drying time between uses. This practice helps preserve the integrity of both the conductive soles and the boot's structure. Remember to check your stored boots regularly for signs of wear or damage, particularly around the conductive components and fastening systems, to guarantee they remain safe for work use.

Sole Inspection Techniques

Thorough inspection of your conductive work boot soles requires four key techniques to guarantee maximum safety and performance. You'll need to examine the sole's physical condition, check for wear patterns, assess structural integrity, and verify proper adhesion to the upper boot material.

When inspecting your boots, use a flashlight to spot hidden damage in hard-to-reach areas, and pay special attention to the heel and toe regions where wear typically occurs first.

Before conducting any detailed inspection, you'll want to clean the soles thoroughly with mild soap and water, using a stiff-bristled brush to remove all dirt and debris. Once cleaned and dried, you can properly assess the sole's condition and prepare it for conductivity testing if needed.

- Look for cracks or cuts that might compromise the sole's structural integrity

- Check for uneven wear patterns, especially in high-impact areas

- Examine the bond between the sole and upper boot material

- Inspect the tread depth and pattern for signs of excessive wear

- Test the electrical conductivity using a resistance meter if required for safety compliance

Clean boots regularly and maintain proper documentation of your inspections to guarantee ongoing safety and compliance with workplace requirements.

Cost Versus Performance Analysis

When evaluating conductive work boot soles, you'll find that prices range from under $50 to over $200, reflecting significant variations in quality, safety features, and durability. While budget options might seem attractive initially, investing in higher-priced boots often proves more cost-effective due to their superior longevity and enhanced safety features.

You'll need to think about your specific workplace requirements when weighing cost against performance. High-quality vulcanized rubber soles provide better slip resistance and wear resistance compared to cheaper PVC alternatives.

For electrical hazard protection, make certain your boots meet ASTM F2413-18 standards, even if it means paying more. Features like cushioned insoles and ergonomic designs might increase the initial cost but will boost your productivity through improved comfort during long shifts.

To maximize your investment, think about composite toe options as a cost-effective alternative to steel toes, offering similar protection with added benefits like non-conductivity. Compare different brands carefully, as you'll often find similar features at varying price points.

Remember that boots meeting essential safety certifications while offering durability can reduce your long-term costs by extending the replacement cycle.

Environmental Impact Considerations

Modern conductive work boot manufacturers are increasingly prioritizing environmental sustainability alongside safety features. When you're choosing conductive work boots, consider their environmental impact through their entire lifecycle.

Many manufacturers now use renewable PU soles instead of traditional rubber, substantially reducing environmental harm while maintaining durability and conductivity.

You'll find these eco-conscious features in today's conductive work boots:

- Biodegradable upper materials made from organic cotton and hemp

- Recycled rubber components that reduce natural resource consumption

- Chemical-free membranes that provide breathability without environmental harm

- Waste-free manufacturing processes that minimize production scraps

- Energy-efficient production methods that reduce carbon footprint

The industry's shift toward sustainable practices doesn't compromise safety or performance. Instead, it offers you the opportunity to make environmentally responsible choices while meeting your workplace safety requirements.

Look for boots with closed-loop recycling programs, where manufacturers collect and recycle worn-out boots into new products. When evaluating options, check for LCA (Life Cycle Assessment) certifications that demonstrate the manufacturer's commitment to measuring and reducing environmental impact throughout the product's lifecycle.

Frequently Asked Questions

Can Conductive Boot Soles Be Replaced When Worn Out?

Yes, you can replace conductive boot soles, but it depends on the construction. While welted boots can be resoled easily, cement-constructed boots are harder to repair. Consider the boot's construction when purchasing.

How Often Should Conductive Boots Be Tested for Electrical Resistance?

You'll need to inspect your conductive boots visually before each use. While there's no set testing frequency requirement, you should replace them when you notice significant wear or damage to maintain safety standards.

Do Conductive Boots Work Effectively in Wet Conditions?

Yes, your conductive boots will work effectively in wet conditions, but they'll only properly dissipate static electricity when used on grounded floors. Remember they're not meant for protection against live electrical circuits.

Are Conductive Boot Soles Compatible With Orthopedic Inserts?

Yes, you can use orthopedic inserts with conductive boot soles if your boots have removable footbeds. You'll need to guarantee proper fitting and may require some adjustments to maintain both comfort and conductivity.

What's the Average Lifespan of Conductive Boot Soles Under Normal Use?

Under normal use, you'll typically get 6-12 months from your conductive boot soles. However, with proper maintenance and high-quality materials, you can extend their lifespan to 3-5 years of reliable performance.

In Summary

When you're investing in conductive work boots, don't compromise on quality or safety standards. Remember to check electrical resistance ratings, verify ESD compliance, and guarantee proper fit for your specific workplace needs. You'll maximize your investment by following maintenance guidelines and regularly testing conductivity levels. While price matters, prioritize protection and durability – your safety's worth the investment in high-quality conductive boot soles.

Leave a Reply