To properly ground dissipative containers, you'll need to connect them directly to an earth ground using 12-gauge stranded wire or braided cables. Make certain all metal-to-metal connections remain clean and secure, with total resistance staying under one mega-ohm. For non-metal containers, install grounding rods that extend below the frost line. You should bond dispensing and receiving containers together to maintain equal static potential, and verify connections meet ESD standards using a multimeter. Regular testing and maintenance of your grounding system helps prevent costly damage to sensitive electronics and reduces fire risks from static discharge. Understanding environmental factors can further enhance your static control measures.

Understanding Static Dissipative Materials

Static dissipative materials' unique properties make them essential for protecting sensitive electronic components from electrostatic discharge. These materials allow electric charges to flow in a controlled manner, with surface resistivity ranging between 10^6 and 10^12 ohms per square, preventing sudden discharges that could damage electronics.

You'll find static dissipative materials in various forms, including polypropylene, polyethylene terephthalate, and thermoplastic polyurethane. Each type serves specific applications, from packaging and handling trays to protective covers and wire insulation. These materials are particularly effective in clean room environments due to their compatibility with stringent cleanliness requirements.

Unlike conductive materials that allow rapid electron flow, static dissipative materials offer controlled discharge rates that you'll need for safe handling of sensitive components.

When you're working with electronic components, you'll notice that static dissipative containers are manufactured specifically to safely dissipate static electricity while protecting your valuable items. While they're often more expensive than basic anti-static options, they provide vital protection that can prevent costly repairs and product failures.

You can identify these materials by their medium surface resistivity, which makes them ideal for applications requiring frequent human contact while maintaining controlled static discharge properties.

Essential Container Grounding Equipment

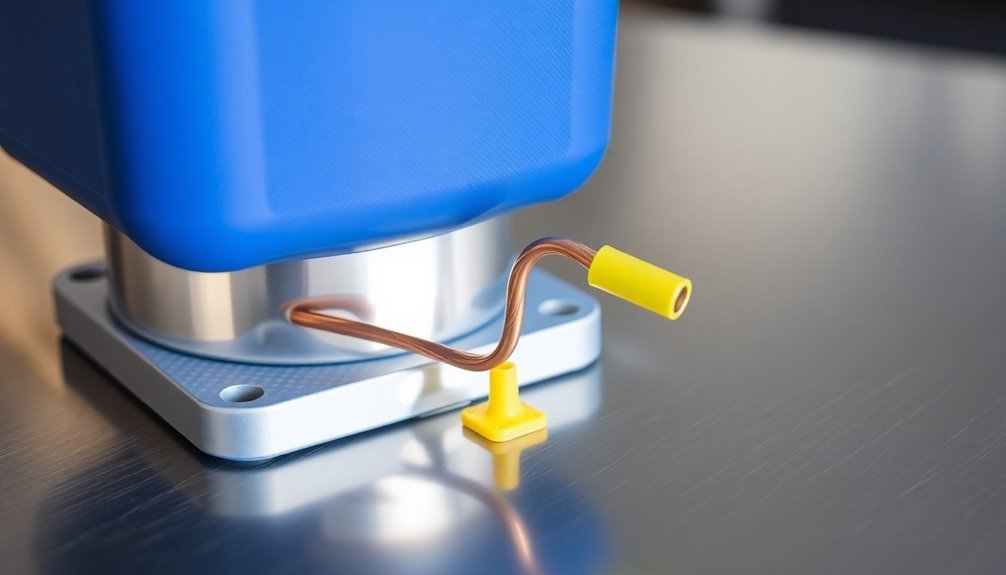

Three critical pieces of equipment form the foundation of proper container grounding: grounding cables, bonding wires, and grounding rods. You'll need grounding cables to connect your dispensing container to an earth ground or building static grounding system, ensuring a resistance of less than 5 ohms. Flow rates under 15 fps help minimize dangerous static buildup during transfers.

For non-metal containers, you must insert a properly supported grounding rod to provide a secure bonding point, while metal containers can connect directly to metallic floorplates.

Key equipment requirements you can't ignore:

- Metallic floorplates that serve both as bonding points and secondary containment

- Clean, debris-free conductive materials for effective grounding connections

- Metal-to-metal connections throughout the entire grounding system

- Annual electrical inspections to verify ground resistance levels

When you're setting up your grounding system, remember that all receiving containers need secondary containment during transfers. Metal containers can be bonded directly with cables, while non-metal containers require grounding rods.

Your grounding system must provide a continuous path to ground and comply with NFPA 77 standards, which recommend resistance levels below 10 ohms – though you should aim for 5 ohms for added safety.

Proper Bonding Connection Methods

Building on your grounding system knowledge, you'll need to master specific bonding methods to safely connect containers during material transfers. Use 12-gauge stranded wire for permanent setups, while braided wire works best for temporary connections. You'll want to guarantee both attachment points have clean, bare metal surfaces for ideal contact. The total resistance level should remain under one mega-ohm for proper static discharge.

| Connection Type | Wire Choice | Attachment Method |

|---|---|---|

| Permanent | Stranded 12-gauge | Screw clamps/welding |

| Temporary | Braided wire | Spring/magnetic clamps |

| Metal containers | Either type | Direct container-to-container |

| Non-metal containers | Either type | Via grounding rod |

When connecting metal containers, you can bond them directly or through a metallic floorplate. For non-metal containers, you'll need to insert a metal grounding rod into the receiving container. Don't forget to provide proper support to prevent tipping. Always make your connections before starting any transfer, especially with liquids having flashpoints below 100°F.

Safety Standards for Container Storage

Every storage facility requires strict adherence to safety standards when housing dissipative containers. You'll need to implement thorough safety measures that address engineering controls, material handling, and maintenance procedures to safeguard safe storage operations. Keeping your facility well ventilated and cool helps prevent hazardous vapor buildup and temperature-related risks.

- Store flammable materials in approved storage cabinets with proper ventilation

- Use secondary containment systems to prevent spills from spreading

- Install proper grounding and bonding equipment to prevent static buildup

- Maintain clear identification with UN placards and emergency contact details

When storing dissipative containers, you must separate incompatible materials and safeguard proper ventilation throughout your facility.

It's crucial to use chemically-resistant materials in your storage areas and maintain proper electrical grounding to prevent static discharge.

You'll need to conduct regular inspections of your storage areas, checking for signs of container damage, leaks, or corrosion.

Don't forget to restrict access to authorized personnel only and keep detailed maintenance records.

Your storage facility should comply with local building codes and fire safety regulations, including properly installed smoke detectors and fire alarms.

Remember to establish clear emergency exit paths and regularly practice emergency procedures with your team.

Container Resistance Testing Procedures

Testing container resistance in accordance with established standards helps guarantee the safety and reliability of your dissipative storage solutions.

You'll need to follow ASTM D257 guidelines when measuring surface resistivity, which requires applying electrodes under load to your container's surface and taking measurements with an ohm meter. It's vital to verify good contact between the electrodes and the container surface, often requiring significant pressure for accurate readings. The ability to resist loads during storage and distribution is a critical factor in container testing.

For thorough testing, you'll want to evaluate your container's compressive resistance using ASTM D642 methods. This involves applying external loads to different areas of your container – faces, edges, and corners – using either fixed-platen or swivel-platen machines depending on your testing needs.

When measuring static dissipative properties, follow ANSI/ESD STM 11.11-2015 procedures, which provide reliable surface resistance measurements within one half-order of magnitude accuracy. Remember that environmental conditions can affect your results, so you'll need to maintain specified testing conditions.

After confirming resistance properties, you should verify proper grounding connections using strong clamps with sharp teeth to verify effective metal-to-metal contact, particularly when dealing with containers storing materials with flashpoints of 100°F or less.

Grounding Path Verification Steps

After confirming your container's resistance properties, you'll need to establish and verify proper grounding paths to maintain safe static dissipation.

Using a multimeter or surface resistance megohmmeter, check all grounding connections to confirm they meet ESD Association standards. Make sure all metal-to-metal connections are secure and use properly braided grounding cables with reliable clips. Compliance with ANSI/ESD S20.20 helps prevent costly ESD damage in your facility.

Key verification points you must follow:

- Test your personal grounding equipment daily while wearing it – ground snaps and cords should measure less than 1 ohm resistance

- Connect containers directly to an earth ground source using appropriate bonding wires

- Verify electrical outlets quarterly with an AC outlet analyzer

- Check resistance-to-ground (RTG) measurements using a three-wire extension cord

When establishing container grounding paths, you'll need to bond dispensing and receiving containers together. Keep resistance measurements within 1 x 10E6 to less than 1 x 10E9 ohms range for worksurfaces and confirm all surrounding equipment, including carts, seating, and shelving, maintains less than 1 x 10E9 ohms resistance.

Don't forget to regularly inspect and maintain all grounding equipment and connections as part of your verification routine.

Environmental Factors Affecting Grounding

Environmental conditions play a vital role in your container's grounding effectiveness, with humidity levels directly impacting the conductivity of surfaces and materials you're working with.

You'll need to account for temperature variations, as freezing conditions can markedly increase soil resistivity and compromise your grounding system's performance. Ground enhancement materials can help maintain consistent grounding performance across temperature fluctuations.

Surface contamination from dust, oils, or chemical residues can either enhance or interfere with your container's static dissipation properties, making regular cleaning and maintenance essential for reliable grounding.

Humidity's Role In Conductivity

Through extensive research and testing, humidity has emerged as a critical factor in the conductivity of dissipative containers and their grounding systems. You'll find that higher humidity levels substantially increase air conductivity by introducing more water molecules that act as conductors. The presence of polar water molecules in humid environments creates conductive bridges between gas particles, enhancing electrical flow.

This enhanced conductivity directly affects how well your dissipative containers maintain their grounding properties and manage static electricity.

- Humidity levels above 60% can dramatically improve static dissipation by increasing surface conductivity

- Water vapor increases free ions in the air, enhancing overall conductivity and grounding effectiveness

- Higher moisture content typically reduces grounding resistance in soil-based systems

- Temperature changes can affect relative humidity, impacting the speed of static electricity dispersal

When you're setting up grounding systems for dissipative containers, you'll need to take into account both relative and absolute humidity levels. These factors affect not only the containers' surface conductivity but also the performance of your entire grounding system.

You'll want to monitor humidity levels regularly, as they can fluctuate throughout the day and seasons. Remember that excessive moisture can sometimes be counterproductive, potentially increasing grounding resistance in certain soil conditions or causing corrosion in electrical components.

Temperature Effects On Grounding

Temperature stands alongside humidity as a major influence on grounding system performance. When you're dealing with dissipative containers, you'll need to account for how temperature affects both your soil conditions and the flammable materials you're storing.

In freezing conditions, soil resistivity increases markedly as moisture turns to ice, which can compromise your grounding effectiveness.

You'll need to make certain your ground rods extend below the frost line to maintain reliable grounding year-round. This is particularly vital because seasonal temperature changes can drastically alter soil conductivity.

For your flammable materials, be aware that higher temperatures increase liquid volatility, raising the risk of static-related fires.

When you're designing your grounding system, consider your local climate conditions carefully. If you're operating in an area with extreme temperatures, you'll need specific design adaptations. At higher altitudes, you'll face additional challenges as lower air pressure affects flash points and ideal vapor-air ratios.

Don't forget to inspect and maintain your grounding systems regularly, as temperature fluctuations can accelerate corrosion of grounding elements and connections, potentially increasing resistance over time.

Surface Contamination Impact

Surface contamination poses substantial challenges when you're establishing reliable grounding for dissipative containers. Various environmental factors and surface conditions can markedly impact your grounding effectiveness, particularly when dealing with protective coatings, rust build-up, and material deposits that may accumulate on your containers over time.

- Moisture content and soil composition directly affect your grounding system's performance

- Protective coatings and rust can inhibit safe static dissipation

- Material deposits and adhesives may prevent proper electrical contact

- Regular cleaning and maintenance are essential for reliable grounding

You'll need to pay close attention to surface conditions and implement proper maintenance protocols to guarantee effective grounding.

If you're dealing with contaminated surfaces, use specialized grounding clamps designed to penetrate protective layers and maintain consistent contact. Consider using ground enhancement materials in areas where soil conductivity is poor or contamination is present.

When installing your grounding system, factor in environmental conditions like soil type and moisture content. Remember that high-quality cables and connectors are vital for maintaining reliable grounding connections, especially in environments where contamination is a concern.

Maintenance of Grounding Systems

You'll need to test your grounding systems annually with an electrician to verify resistance levels remain below 5 ohms and guarantee proper continuity.

Check your ground attachments frequently to confirm they're clean, metal-to-metal connections free from paint, dirt, or debris that could interfere with conductivity.

Your inspection should include a thorough examination of all grounding system components for signs of wear, damage, or deterioration that might compromise performance.

Regular Testing Requirements

A robust testing schedule stands at the core of maintaining effective grounding systems for dissipative containers. You'll need to conduct thorough testing during pre-installation, periodic maintenance, post-modification, and troubleshooting phases to validate your grounding systems remain reliable and compliant with safety standards.

- Use clamp-on ground resistance testers for inductive measurements

- Perform regular resistance tests to verify electrical continuity

- Check for clean, corrosion-free grounding connections

- Implement systematic inspection programs for early problem detection

During initial installation, you must verify proper grounding through earth ground testing and resistance measurements. Don't skip testing after any modifications or additions to your electrical system, as these changes can impact grounding effectiveness.

You'll want to use approved ohmmeters for periodic testing and maintain detailed records of all inspections.

When troubleshooting, focus on identifying potential issues with ground rods and connections. You should regularly inspect for signs of deterioration or poor connections that could compromise your grounding system's performance.

Remember to test grounding systems thoroughly after repairs to validate they meet safety regulations and protect your valuable equipment from electrical hazards.

Ground Path Inspection Methods

Building upon proper testing protocols, maintaining effective ground paths requires specific inspection methods to guarantee long-term system reliability. You'll need to conduct both visual and electrical inspections to confirm your grounding system remains functional and compliant with safety standards.

Start with visual inspections by checking grounding electrodes and wires for signs of damage or corrosion. You must verify that all connections are secure and that grounding rods are driven to the proper depth. Don't forget to examine grounding straps and clamps for wear or degradation.

For electrical testing, you'll need to use the 3-point (Fall-of-Potential) method to measure earth resistance. This requires isolating the grounding system from the utility neutral and taking measurements at various points.

You should use a four-terminal tester for detailed resistance readings and plot the results to determine accurate earth resistance values.

Throughout your inspection process, confirm that all metallic parts of equipment enclosures maintain proper grounding connections. You must verify continuous bonding of metallic conduits and confirm that your grounding paths are free of operational current.

Remember to prioritize safety compliance over performance requirements when evaluating your grounding system.

Frequently Asked Questions

How Often Should Grounding Clamps and Wires Be Replaced?

You'll need to replace grounding clamps and wires based on regular inspections rather than fixed intervals. Replace them immediately if you spot any signs of damage, corrosion, wear, or connection issues during checks.

Can Multiple Dissipative Containers Share the Same Grounding Point?

You can connect multiple dissipative containers to the same grounding point, but it's safer to use parallel grounding connections. Make sure each container has a direct, reliable path to the common ground source.

What Happens if a Container's Dissipative Coating Wears Off?

If your container's dissipative coating wears off, you'll lose static electricity protection, increasing fire and explosion risks. You'll need to reapply the coating or replace the container to maintain safety compliance.

Do Temperature Extremes Affect the Grounding Requirements for Dissipative Containers?

Yes, temperature extremes substantially affect your grounding needs. You'll need stricter grounding in high temperatures due to increased vapor volatility, while cold temperatures reduce risks but still require standard grounding practices.

Are Special Grounding Procedures Needed When Using Dissipative Containers Outdoors?

Yes, you'll need special outdoor grounding procedures. Connect containers to earth sources like buried metal plates, use weather-resistant cables, and regularly check connections for environmental damage. Always maintain bare metal-to-metal contact points.

In Summary

You'll need to maintain proper grounding of dissipative containers to prevent static discharge and protect sensitive materials. Always verify your grounding connections daily, guarantee resistance readings fall within specified ranges, and keep your grounding paths clear of corrosion or damage. Don't forget to account for environmental conditions and follow regular maintenance schedules. When in doubt, consult your facility's safety guidelines and ESD standards.

Leave a Reply