Seven smart foam storage solutions will protect your electronic components while keeping them organized. You'll find custom anti-static foam trays that prevent ESD damage, ESD-safe drawer systems with adjustable dividers, and heat-sensitive protection solutions for temperature-sensitive parts. Consider modular stack-on storage cabinets for expandability, precision-cut foam workbench inserts for easy access, conductive polyurethane options for static dissipation, and small parts foam management systems for tiny components. Whether you're storing ICs, resistors, or specialized tools, these foam solutions offer both protection and efficiency. Discover how each solution can transform your electronic component storage approach.

Custom Anti-Static Foam Trays

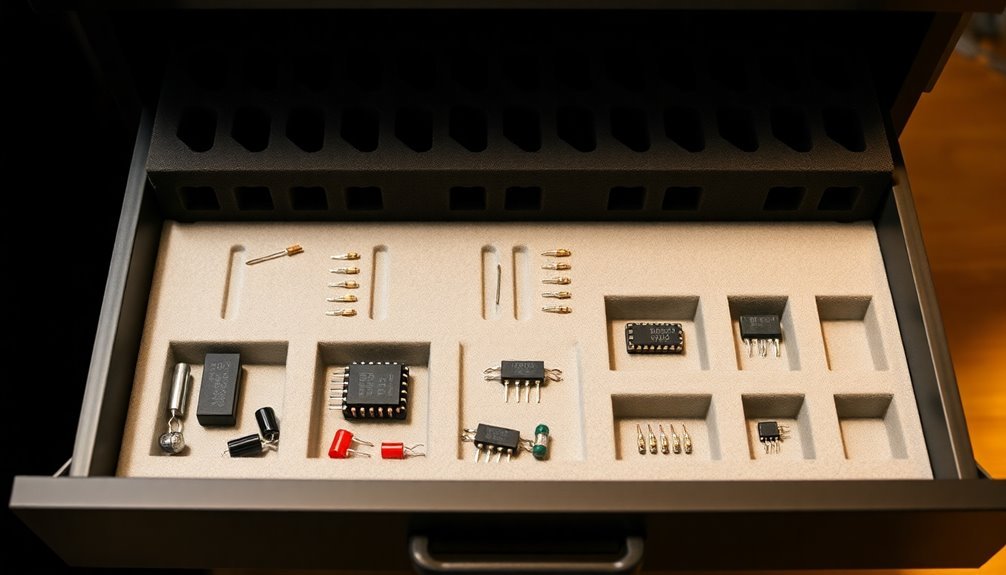

Every electronic component needs proper protection from static electricity and physical damage. Custom anti-static foam trays provide a tailored solution that combines both safety and organization for your sensitive electronics.

You'll find two main foam options for your custom trays: anti-static polyurethane (PU) and polyethylene (PE) foam. PU foam, typically pink in color, features an open-cell structure that's excellent for shock absorption and quick recovery.

PE foam, available in black, offers durability and reliable cushioning with its closed-cell structure. Vibration dampening properties make these materials ideal for protecting components during transit.

When you're designing custom foam trays, you can choose die-cutting or injection molding to create precise compartments for your components. The foam can be fabricated into various shapes, densities, and thicknesses to match your specific needs.

This customization guarantees each component sits securely in its designated space, preventing movement during transport or storage.

These trays aren't just about organization – they're actively working to protect your components by dissipating electrostatic charges that could damage sensitive electronics. By selecting high-quality materials and guaranteeing proper compliance with industry standards, you'll create a storage solution that maintains its protective properties over time.

ESD-Safe Drawer Organization Systems

Managing electronic components effectively requires more than just basic storage – you'll need an ESD-safe drawer organization system that meets strict industry standards. These systems comply with IEC 61340-5-1 and ANSI ESD-S20.20 standards, ensuring your sensitive components stay protected from electrostatic discharge.

You'll find various options to suit your specific needs, from modular drawer units in different heights to high-density storage cabinets. Many units are available with over 100 combinations of drawer configurations. The systems use conductive plastics and galvanized steel materials, with earth lead connectors for proper grounding.

You can choose between conductive plastic cabinets, ESD bin systems with semiconductive bins, or units with perforated panels for additional organization.

Whether you're working in electronics manufacturing, engineering labs, or industrial environments, these drawer systems offer efficient space utilization while maintaining ESD protection. You'll benefit from easy access to components, extended tool life, and compliance with regulatory standards.

The customizable nature of these systems lets you adapt the storage space to your specific component sizes and handling requirements. For storing PCBs, reels, or SMD components, you'll find configurations that maximize both protection and accessibility.

Heat-Sensitive Component Protection Solutions

Thermal management foam systems provide essential protection for your heat-sensitive electronic components through specialized materials, but not necessarily polyurethane materials as mentioned.

Thermal management in electronic components often involves advanced materials such as metal foams. For instance, Duocel® metal foam is a high-performance material used in heat exchangers. It consists of solid ligament, open-celled metal foam that can be integrated with electronic devices and modules. This material improves thermal performance by transferring higher heat fluxes to ambient, reducing or eliminating soft thermal interfaces. Elastomeric silicone materials provide additional thermal protection while maintaining flexibility in storage solutions.

Temperature-regulated storage designs can incorporate various materials to ensure proper heat dissipation while maintaining electrical isolation. However, thermally conductive silicone materials and Kapton tapes are not the primary focus in these advanced systems. Instead, materials like Duocel® metal foam are used because they can be brazed or soldered to a substrate material, eliminating highly resistive thermal interfaces and improving thermal performance.

Your heat-sensitive components can stay protected with custom solutions featuring integrated thermal management properties. For example, metal foam based compact heat exchangers can be integrated directly to the sources of heat generation via solder bonding, which eliminates the need for soft thermal interfaces like thermal pads or pastes. This approach prevents overheating during storage and handling by ensuring efficient heat dissipation.

Thermal Management Foam Systems

Electronics manufacturers face unique challenges when protecting heat-sensitive components, making thermal management foam systems a critical consideration in storage and handling.

You'll find that metal foams like Duocel offer superior thermal performance compared to traditional heatsinks, while keeping your components lighter and more cost-effective. These foam systems can be directly soldered to eliminate thermal interfaces, improving reliability and heat transfer efficiency. The high surface density of these foams enables exceptional convective cooling performance.

When you're working with printed wiring boards, you can braze these compact foam heat exchangers to low expansion skin layers for peak performance.

For enhanced thermal insulation, you'll want to evaluate Solimide foams. They're exceptionally fire-resistant, meeting FAR 25.856 specifications, and they maintain stability in both cryogenic and high-temperature conditions up to 300°C. You can rely on their long-term performance even in humid environments.

When you're designing your storage solution, incorporate anti-static foam layers to protect against ESD damage while maintaining proper thermal management. You can customize these foam systems with multiple layers, combining thermal insulation with vibration protection.

This approach guarantees your heat-sensitive components remain safe and stable during storage, transportation, and handling.

Temperature-Regulated Storage Designs

Beyond thermal foam systems, implementing temperature-regulated storage designs represents a fundamental aspect of safeguarding electronic components. You'll need to maintain specific temperature ranges to prevent damage from both heat and cold extremes, as these can substantially impact your components' functionality and longevity.

When you're designing your storage solution, consider implementing climate-controlled systems like Vertical Lift Modules (VLMs) that manage both temperature and humidity. You'll want to guarantee your ICs are stored between -40°C and 125°C with 10% to 60% humidity, while passive components require temperatures from -55°C to 125°C with humidity levels between 10% and 90%.

Direct sunlight exposure can accelerate component degradation, so storage areas should be carefully positioned away from windows and other light sources. To achieve superior protection, you should incorporate advanced thermal barriers and heat-spreading materials. Solutions like ProCell EV Firewall series can help you manage thermal propagation while providing additional benefits such as vibration dampening and gap filling.

You'll need to combine these materials with proper thermal insulation and refrigeration systems to maintain consistent environmental conditions. Remember to follow manufacturer guidelines for specific components, as requirements can vary substantially.

Modular Stack-On Storage Cabinets

You'll find that Modular Stack-On Storage Cabinets offer endless possibilities for organizing electronic components through their customizable drawer configurations.

For additional organization options, popular brands like Husky and Sandusky offer compatible storage solutions that integrate seamlessly with these systems.

By using the cabinet's built-in dividers and adding foam inserts, you can create tailored compartments that keep your components secure and easily accessible.

Your storage setup can grow with your needs since these cabinets allow you to stack additional units and reconfigure drawer arrangements as your component collection expands.

Drawer Organization Techniques

When setting up modular Stack-On storage cabinets, proper drawer organization becomes essential for efficient component management.

You'll need to establish a systematic approach by dividing your drawers into distinct sections for different component types, using adjustable dividers to create customized compartments that fit your specific needs.

Start by grouping similar components together, such as keeping all resistors in one section and capacitors in another. Using anti-static containers will protect sensitive electronic components from electrostatic discharge damage.

You'll want to use transparent containers or compartmentalized trays within the drawers, making it easier to spot the components you're looking for without having to dig through multiple containers.

Don't forget to incorporate drawer inserts to maximize space efficiency and prevent components from mixing.

Implement a clear labeling system for each drawer and compartment. You'll find it helpful to include detailed information such as component values, types, and quantities on your labels.

Consider maintaining a digital inventory system, like a spreadsheet, to track your components' locations and quantities.

Regular maintenance of your drawer organization system will guarantee you can quickly locate and access the components you need while preventing clutter and disorganization over time.

Cabinet Configuration Methods

Modern modular Stack-On storage cabinets offer versatile configuration options to maximize your workspace efficiency. You'll find these systems particularly adaptable, with the ability to stack units vertically, connect them side-by-side, or arrange them back-to-back depending on your space requirements. Utilizing transparent container options helps quickly identify stored components at a glance.

The MBS-series bins guarantee cross-compatibility throughout your storage system, while built-in safety features like secure bin tracks and lockable casters keep your components protected and mobile.

When configuring your cabinet system, consider these key layout options:

- Vertical stacking with heights customized to your ceiling clearance, utilizing secure connection hardware between modules.

- Side-by-side arrangements with optional pegboard panels for additional tool storage and organization.

- Back-to-back configurations that maximize floor space while maintaining easy access to components.

- Combination setups incorporating tabletop surfaces and dry-erase boards for workstation integration.

You can further enhance your cabinet configuration with removable storage bins in various sizes, supporting up to 20 pounds each. The standard 18.2" width and depth dimensions guarantee consistent alignment across different modules, while features like hanger boards and layout kits help maintain organized, efficient component storage.

Precision-Cut Foam Workbench Inserts

Precision-cut foam workbench inserts have revolutionized the way professionals organize and protect their electronic components and tools.

You'll find these custom-designed inserts are compatible with various CAD formats, including .dwg, .dxf, .svg, and .ai, making it easy to create perfectly tailored storage solutions for your specific needs.

When you're working with sensitive electronic components, you'll appreciate how aerospace-grade polyethylene closed-cell foam provides superior protection. This material's water and chemical resistance guarantees your tools stay safe in any environment.

You can choose from different densities and thicknesses to match your protection requirements, while contrasting colors help you quickly identify missing tools.

You've got multiple options for customization, from professional CNC cutting services to DIY methods using utility knives. The precision cuts guarantee each tool has its designated spot, supporting 5S methodology and improving your workspace efficiency.

Whether you're storing delicate testing equipment or frequently used hand tools, you'll notice immediate benefits in time savings and reduced risk of damage. The foam's adaptability means you can reconfigure your storage setup as your tool collection grows or changes.

Conductive Polyurethane Storage Options

Protecting sensitive electronic components demands specialized storage solutions, and conductive polyurethane foam stands out as an essential material for this purpose.

You'll find this versatile material offers thorough protection against electrostatic discharge while providing superior shock absorption for delicate parts. When you're handling expensive electronic components, you can't afford to risk damage from static electricity or physical impact.

The customizable nature of conductive polyurethane foam lets you create storage solutions that perfectly match your specific needs. You're able to design compartments that securely house different components while maintaining their integrity through proper ESD protection.

Whether you're storing microprocessors, circuit boards, or sensitive sensors, the foam's insulating properties guarantee optimal protection.

- Select foam containers with anti-static properties rated for your components' sensitivity levels

- Implement custom-cut foam inserts to prevent movement during transportation

- Use foam sheets to create layered storage systems for different component types

- Install foam-lined drawers in your workstation for easy access to frequently used parts

Small Parts Foam Management

Anyone working with electronic components knows that managing small parts effectively can make or break a project's success. When you're dealing with numerous tiny components, custom foam trays offer an organized, secure solution that'll streamline your workflow and protect your valuable parts.

Custom foam trays can be precisely tailored to fit your specific components, whether they're resistors, capacitors, or specialized tools. These trays, typically made from polyurethane or polyethylene foam, don't just organize your parts – they also provide essential protection against heat and physical damage.

If you're working with static-sensitive components, you can opt for conductive polyurethane foam that creates an ESD-safe environment.

The efficiency gains you'll experience with custom foam solutions are significant. You'll spend less time searching for parts and more time focusing on your actual work. The foam shadow boards create clear visual organization, making it easy to spot missing components instantly.

Whether you're in manufacturing, development, or maintenance, you'll find these storage solutions essential for maintaining component integrity during both storage and transport. They're particularly valuable when you need to guarantee consistent performance and reliability in your electronic projects.

Frequently Asked Questions

How Long Does Anti-Static Foam Maintain Its Protective Properties?

You'll find anti-static foam typically maintains its protective properties for 1-2 years, but it's variable based on humidity, handling, and storage conditions. You should test it regularly to guarantee effectiveness.

Can Custom Foam Inserts Be Designed for Components of Varying Sizes?

Yes, you'll find that custom foam inserts can accommodate components of different sizes within a single case. Through precision cutting and layered designs, you can create compartments that fit your varied equipment perfectly.

What Cleaning Methods Are Safe for Electronic Component Foam Storage?

You'll want to use lint-free microfiber cloths and foam swabs with 70% isopropyl alcohol solution. Don't spray directly on foam; instead, gently wipe surfaces while ensuring proper ventilation and wearing protective gloves.

Are Foam Storage Solutions Recyclable After Their Useful Life?

You'll find most storage foams are recyclable, but they require specific handling. EPS isn't curbside recyclable, while PE and PU foams can be recycled through specialized facilities. Check your local recycling guidelines for options.

How Do Temperature Fluctuations Affect Foam Storage Material Performance?

Temperature fluctuations can seriously impact your foam's performance by altering its chemical properties. You'll notice reduced expansion, compromised structural integrity, and inconsistent curing when temperatures aren't stable during storage and application.

In Summary

You'll find that investing in proper foam storage solutions protects your valuable electronic components while keeping them organized and easily accessible. Whether you've chosen anti-static trays, ESD-safe systems, or custom-cut inserts, these seven storage options help prevent damage and extend component life. Don't overlook the importance of proper storage – it's vital for maintaining your electronics inventory and ensuring project success.

Leave a Reply