When selecting an anti-static workbench for manufacturing, you'll want to focus on models featuring high-quality ESD laminate surfaces with embedded carbon layers and resistance values between 1.0 x 10^6 and 1.0 x 10^11 ohms/square. Look for durable steel frames with proper grounding bolts and avoid plastic components that can accumulate static. You'll need essential accessories like ESD wrist straps, floor mats, and heel grounders for complete protection. Top solutions include workbenches with modular storage, adjustable heights, and integrated power management systems. Understanding the full scope of ESD protection features will help you make the best choice for your facility's needs.

Understanding ESD Workbench Requirements

Today's electronics manufacturing demands robust anti-static protection, making proper ESD workbench setup essential for component safety.

You'll need to guarantee your workbench meets specific resistance requirements, maintaining levels between 1 x 10E6 and 1 x 10E9 ohms for maximum protection against static discharge.

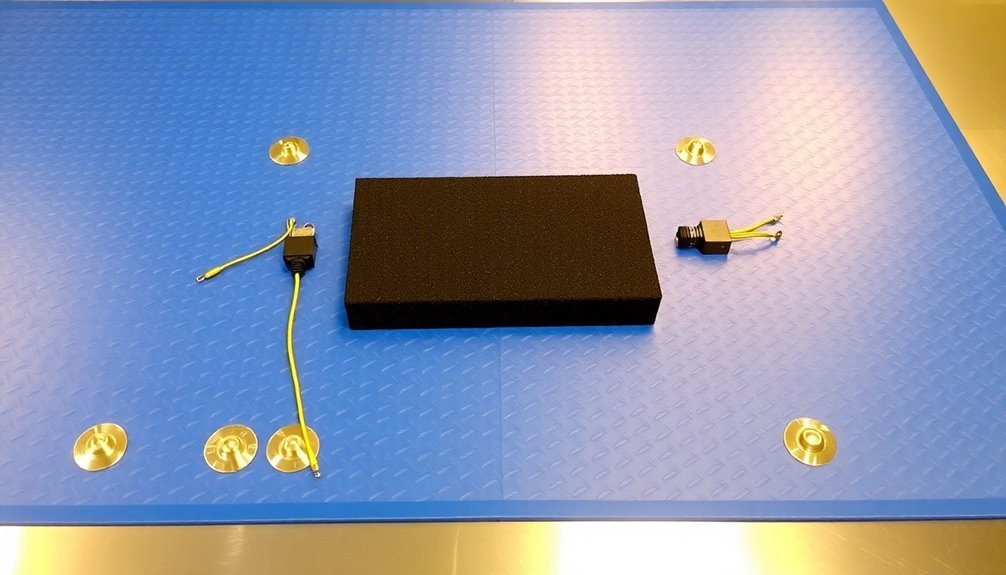

Your workbench's construction should prioritize metal and wood materials over plastic components that can accumulate charges. You'll want to cover the entire work surface with properly grounded ESD matting, connecting it to a common ground point using metal snaps and grounding cords.

This setup must comply with IEC61340-5 and ANSI/ESD S20.20 standards to guarantee proper safety protocols. Ionizer placement at the workstation helps neutralize static charges on insulative materials.

The workstation's design should incorporate static dissipative elements throughout, including shelves and storage areas.

You'll need to equip your workspace with essential accessories like wrist straps for operators and anti-static floor mats. When selecting chairs, opt for ESD-rated models that prevent static buildup.

Remember to connect your workbench to the laboratory's grounding point using copper wire, and guarantee all components feature either conductive or dissipative properties to maintain a consistently protected environment.

Top Anti-Static Workbench Models

Leading manufacturers offer several standout ESD workbench models that meet the stringent requirements we've discussed. You'll find premium options featuring height adjustments between 650-950mm, making them adaptable to various working positions and operator heights.

These models come with impressive load capacities ranging from 200kg to 300kg, ensuring stability for your heavy equipment and materials. The modular design options allow for easy expansion and reconfiguration as your workspace needs evolve.

For specialized manufacturing needs, you'll want to evaluate models that offer temperature resistance up to 300°C, particularly useful in electronics manufacturing and industrial settings.

Top models include built-in power panels with six grounding sockets and integrated LED lighting systems for both overhead and localized illumination. You can customize your workbench using online configurators to add essential accessories like PO/1 additional shelves or RK bin rails for storage.

Look for models that comply with IEC 61340-5-1 standards, featuring conductive surfaces with ESD dissipation rates between 10^6 and 10^9. The best options include thorough grounding systems with wrist strap jacks and grounding lugs.

For semiconductor and PCB manufacturing, choose models with perforated panels for tool organization and durable steel frames with proper grounding bolts.

Key ESD Protection Features

While protecting sensitive electronic components requires multiple safety measures, proper ESD protection features serve as your first line of defense against static electricity damage.

You'll find that effective grounding mechanisms are essential, including wrist straps and copper wire connections that establish a zero-potential ground between the floor, worksurface, and user. Product reliability significantly improves when proper grounding is maintained throughout the assembly process.

Your workbench's surface materials play a vital role in static dissipation. Look for surfaces with resistivity between 10^6 to 10^9 ohms, made from conductive laminates or static-dissipative materials. Anti-static laminated tables with conductive substrates offer both wear resistance and high-temperature protection.

You'll need to guarantee compliance with industry standards like ANSI/ESD S20.20, which requires regular testing of static control features. This attention to safety doesn't just protect your electronic components – it also saves you money by preventing costly repairs and downtime.

Don't overlook ergonomic features when selecting an ESD workbench. You'll want adjustable height options, integrated power outlets, and cable management systems.

Include essential accessories like ESD-safe storage bins and grounding cords to complete your static protection setup.

Workbench Customization and Accessories

You'll find that modular storage solutions for your anti-static workbench include ESD-safe bins, shelves, and drawer units that can be easily rearranged to match your workflow needs.

The work surface is adjustable from 30-36 inches to accommodate different worker heights and tasks.

Essential grounding equipment, such as wrist straps, grounding cords, and common point grounds, must be properly installed to maintain an effective static-free workspace.

These accessories work together with your workbench's built-in ESD protection features to create a complete static control system that safeguards sensitive electronic components.

Modular Storage Solutions

When designing an anti-static workbench, modular storage solutions offer unparalleled flexibility and organization for your workspace.

You'll find multiple storage options that can be strategically placed to maximize efficiency and protect sensitive electronic components. Under-bench storage modules provide convenient access to drawers, files, and lockers, while overhead storage with sliding or flipper door cabinets helps keep your workspace clear. Gravity-fed conveyors can be integrated into the system for enhanced material handling workflows.

The ESD-safe storage solutions include static dissipative surfaces, cupboards, and shelves specifically designed for storing electronic parts, tools, and equipment. You can customize these storage solutions to match your specific requirements, guaranteeing that every item has its designated space.

Whether you need small compartments for components or larger storage areas for equipment, the modular design allows you to configure your storage exactly as needed.

You're not limited to standard configurations – you can mix and match different storage modules to create the perfect setup. The beauty of modular storage lies in its adaptability; as your needs change, you can easily reconfigure or expand your storage system.

This flexibility guarantees that your anti-static workbench remains organized and efficient, regardless of how your manufacturing processes evolve.

Essential Grounding Equipment

To maintain a safe environment for handling sensitive electronic components, proper grounding equipment serves as the cornerstone of any anti-static workbench setup. You'll need a thorough collection of grounding tools, including work surface mats with proper resistance values (between 1.0 x 10^6 and 1.0 x 10^9 Ω), grounding cords, and secure connecting devices like metallic crimps and banana plugs. Static-free storage bags should be readily available to protect components when not in use.

When setting up your grounding system, prioritize these essential elements for maximum protection:

- Personal grounding equipment: Wear properly fitted wrist straps and foot grounders to maintain a continuous path to ground while you're working with sensitive components.

- Surface protection: Install an anti-static mat on your work surface, ensuring it's connected to ground through a reliable grounding cord.

- Testing and verification: Use a ground/polarity tester to regularly check your outlet's grounding integrity and maintain safe operating conditions.

Don't forget to complement your grounding setup with ESD-safe accessories like conductive chairs, shelving units, and protective clothing. Each component should be electrostatically dissipative to create a thorough ESD-protected workspace that safeguards your sensitive electronic components from static damage.

Each component should be electrostatically dissipative to create a thorough ESD-protected workspace that safeguards your sensitive electronic components from static damage.

Proper Grounding System Setup

A proper grounding system forms the foundation of any effective anti-static workbench setup. You'll need to start by installing an earth electrode, followed by connecting your grounding wires and rods. Make sure to space your ground rods at twice their length to prevent zone overlap and maintain maximum effectiveness. Using copper ground rods will ensure optimal conductivity and longevity in your grounding system.

Your workbench setup must include several critical components working together to guarantee proper static discharge. Connect your anti-static mat to a verified ground using appropriate grounding cords with secure connectors like metallic crimps or banana plugs.

| Component | Required Action |

|---|---|

| Earth Electrode | Install in suitable ground location |

| Ground Rods | Space at 2x rod length |

| Static Control Devices | Connect to verified ground point |

Don't forget to verify your system's functionality through regular resistance and voltage checks. You'll need to maintain readings below 25 ohms – if you can't achieve this with a single electrode, you'll need to install additional ones. Keep your system maintained by regularly cleaning your anti-static mats with specialized cleaners and checking all connections. Remember to use full-size grounding conductors for top power quality and include proper static control devices like wrist straps and foot grounders.

Material Quality and Durability Standards

Material durability serves as a cornerstone of effective anti-static workbench design. You'll find that high-quality ESD laminated countertops offer superior performance compared to anti-static rubber mats, providing better wear resistance and temperature tolerance. Static electricity charges can severely impact product quality and safety across multiple industries.

For lasting protection, all metal components should feature static dissipative paint or ESD powder coating to prevent unexpected discharges while maintaining structural integrity.

When selecting materials for your anti-static workbench, focus on these critical standards:

- Surface resistance must fall between 1.0 x 10^6 and 1.0 x 10^9 ohms to guarantee proper static dissipation without risking rapid discharge

- Materials should maintain permanent ESD properties that won't degrade over time, particularly in high-traffic manufacturing environments

- All components, including storage bins and shelving, must be static dissipative to maintain a complete ESD-protected workspace

You'll want to prioritize materials that offer easy maintenance while maintaining their ESD-safe properties. Cold steel frames combined with ESD laminating worktops provide the durability you need for long-term performance.

The modular design approach allows you to replace damaged parts easily, making your investment more cost-effective over time while guaranteeing consistent static protection.

Frequently Asked Questions

How Often Should ESD Workbench Mats Be Cleaned and With What Products?

You should clean your ESD workbench mats daily in high-use areas, using specialized ESD mat cleaners. Don't use household cleaners or alcohol. Wipe with a lint-free cloth and guarantee it's completely dry before use.

Can Regular Office Chairs Be Used With Anti-Static Workbenches?

No, you shouldn't use regular office chairs with anti-static workbenches. They can generate static electricity and compromise your ESD protection. You'll need ESD-safe chairs that are properly grounded to maintain workplace safety.

What Is the Average Lifespan of an ESD Workbench Under Normal Use?

You can expect your ESD workbench to last 5-10 years with normal use. If you maintain it properly with regular cleaning and inspections, and avoid damaging the surface, it'll likely reach the upper range.

Do Temperature and Humidity Affect ESD Workbench Performance?

Yes, temperature and humidity substantially affect your ESD workbench's performance. You'll get the best protection at 40% relative humidity, while extreme temperatures can reduce your workbench's ESD protection effectiveness and reliability.

Are ESD Workbenches Effective Against Water-Based Static Buildup?

Yes, your ESD workbench will effectively handle water-based static buildup. It's designed to safely dissipate static charges through its conductive surface, regardless of whether they're caused by water, humidity, or other environmental factors.

In Summary

Your success in electronics manufacturing depends heavily on proper ESD protection. By selecting the right anti-static workbench solution, you'll safeguard sensitive components and maintain product quality. Remember to prioritize proper grounding, choose high-quality materials, and regularly maintain your ESD protection system. Don't forget to train your team on correct usage and safety protocols for maximum effectiveness of your anti-static workstation investment.

Leave a Reply