An electronics protection certification program will cover essential elements to safeguard your sensitive electronic components and equipment. You'll learn proper ESD (electrostatic discharge) control through grounding techniques, protected area setup, and safe packaging standards. The program includes compliance training for key industry standards like ANSI/ESD S20.20 and IEC 61340-5-1, along with safety protocols and emergency procedures. You'll master equipment testing methods, maintenance requirements, and proper documentation practices. From basic handling procedures to advanced circuit protection schemes, this extensive certification equips you with vital skills for effective electronics protection management.

Core Program Components

The Electronics Protection Certification Program combines essential training modules with rigorous compliance standards to safeguard electronic devices against electrostatic discharge (ESD). When you participate in the program, you'll learn fundamental concepts based on ANSI/ESD S20.20 guidelines, which form the backbone of effective ESD protection strategies.

The core components you'll master include proper grounding techniques for both facilities and personnel, the establishment of ESD-protected areas, and implementation of appropriate packaging standards.

You'll gain hands-on experience with ESD protection equipment and learn how to assess your control program's effectiveness through systematic audits and evaluations. The program ensures compliance with telecommunications industry standards, as referenced in TL9000 best practices.

The program emphasizes practical understanding of ESD models, including Human Body Model (HBM), Charged Device Model (CDM), and Machine Model (MM). You'll study protection schemes and device design principles that are vital for preventing ESD damage.

Through demonstrations and applied learning, you'll develop the skills to identify key characteristics of ideal ESD protection and implement them in your facility.

The certification guarantees you're equipped to develop, maintain, and assess a thorough ESD control program that meets industry standards and protects sensitive electronic components.

ESD Protection Standards

Four major standards govern ESD protection in electronics manufacturing and handling: ANSI/ESD S20.20, IEC 61340-5-1, JEDEC JESD625B, and MIL-STD-1686. You'll need to understand these standards thoroughly when implementing your electronics protection certification program, as they form the foundation of ESD control practices.

To achieve certification, you'll need to comply with specific requirements outlined in these standards, including proper grounding procedures, use of ESD-safe materials, and regular auditing of your control measures. You must also establish an electrostatic protective area (EPA) that meets environmental control specifications for humidity and ionization. Regular compliance audits are essential to verify ongoing adherence to established ESD regulations and standards.

| Standard Type | Primary Focus | Key Requirements |

|---|---|---|

| ANSI/ESD S20.20 | General Manufacturing | ESD Control Program Development |

| IEC 61340-5-1 | European Electronics | Component Protection Protocols |

| JEDEC JESD625B | Semiconductor Industry | Manufacturing Environment Control |

Your certification process will require third-party verification through EOS/ESD Association, Inc. You'll need to maintain documentation of your compliance efforts, regularly train personnel, and keep up with standards revisions to guarantee your certification remains valid.

Safety Protocol Training

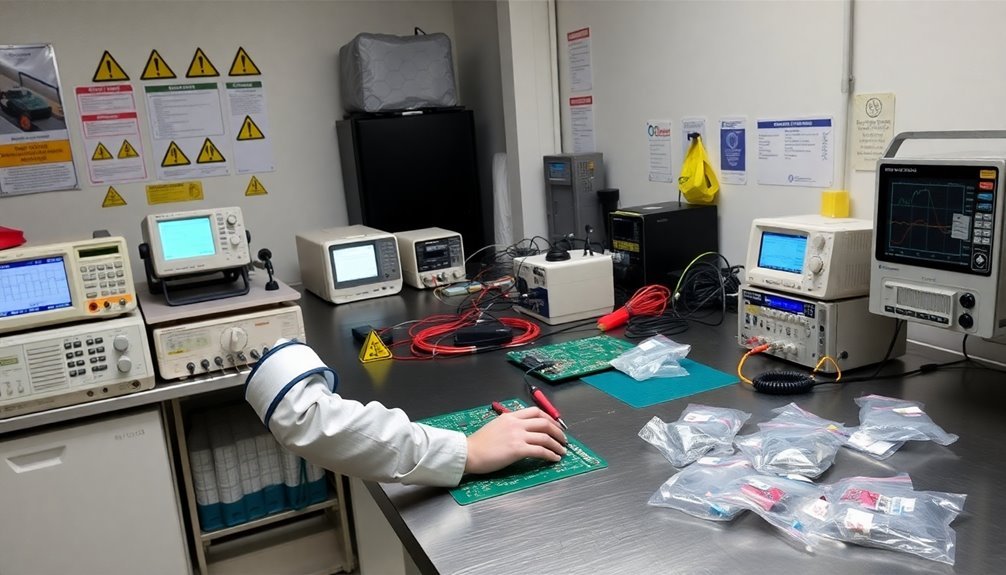

Safety protocol training's fundamental role in electronics protection requires a thorough approach covering workplace safety, electrical fundamentals, process-specific protocols, and emergency response procedures.

You'll learn to identify and mitigate workplace risks associated with electronic assembly processes through proper signage recognition and PPE implementation. The training emphasizes understanding safety concerns related to handling procedures and reinforces the importance of ongoing safety education. With 24/7 access to training, you can review safety protocols whenever needed to ensure complete understanding.

When it comes to electrical fundamentals, you'll master the factors that lead to electrical shocks and arc flashes. You'll also learn how to create electrically safe conditions during high-voltage work and select appropriate protective equipment based on arc ratings.

Process-specific protocols focus on recognizing potential hazards in soldering operations, radiation-based equipment, and various manufacturing environments. You'll gain expertise in tool safety and specialized electronic assembly procedures.

Emergency preparedness training equips you with essential skills to identify electrical emergencies and respond effectively. You'll learn proper procedures for handling electrical fires and shock incidents, including CPR administration and AED usage.

Additionally, you'll develop competency in burn care and emergency response planning specific to electrical incidents.

Equipment and Testing Methods

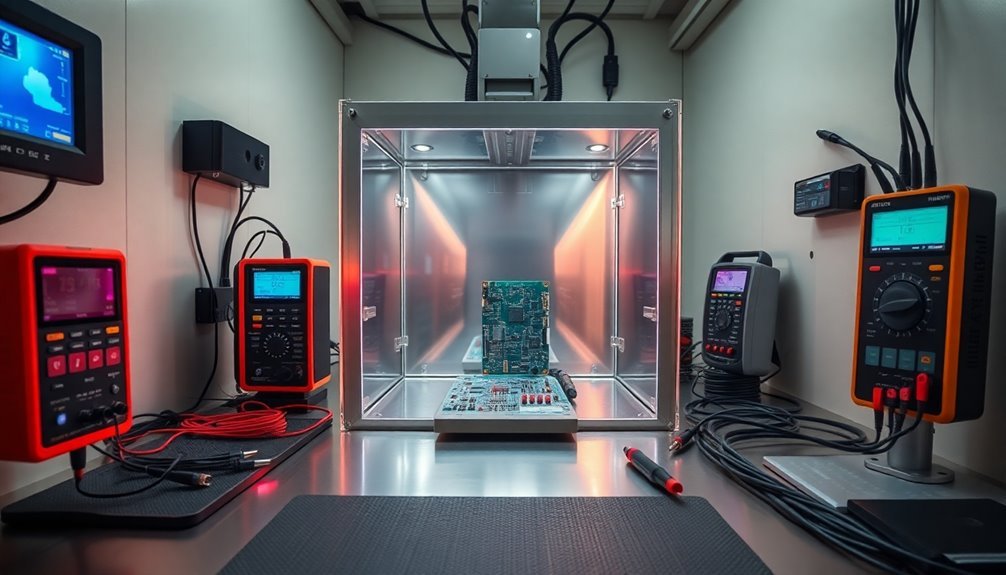

You'll need to understand the essential laboratory test equipment standards, including the ESA609 Electrical Safety Analyzer and environmental testing chambers that meet IEC 61010-1 requirements.

The most common testing protocols involve a combination of visual inspections, electrical safety tests, and environmental stress simulations using specialized equipment like leak detection instruments and high-voltage testers. Mean time between failures analysis helps predict long-term reliability through statistical evaluation of component performance.

To achieve quality control certification, you must document your testing procedures, maintain calibrated equipment, and demonstrate compliance with relevant standards such as IP67 and NFPA-99 throughout the certification process.

Laboratory Test Equipment Standards

Testing and certifying laboratory equipment requires adherence to the thorough IEC 61010 series of standards, which covers everything from basic measurement devices to specialized atomic spectrometers.

You'll find this extensive standard addresses essential test equipment like signal generators and power supplies, while also encompassing laboratory apparatus such as stirring equipment, scales, and environmental chambers.

The standard ensures protection against effects of fluids and fluid-related hazards in laboratory settings.

When you're looking at safety testing requirements, you'll need to evaluate multiple hazard types:

- Electric shock and burn protection, including insulation resistance and electric strength testing

- Mechanical safety factors such as stability, moving parts, and loading capacities

- Environmental considerations like fire spread prevention, temperature limits, and fluid pressure safety

The standard's specific equipment sections provide detailed requirements for different device categories. You'll need to comply with IEC 61010-2-034 for insulation testing equipment, while sterilization equipment falls under IEC 61010-2-040. For specialized laboratory equipment like atomic spectrometers, you'll reference IEC 61010-2-061.

Additionally, you must guarantee your equipment meets regional certification requirements, including EMC/EMI compliance standards specific to your market area.

Common Testing Protocols

Implementing common testing protocols requires strict adherence to standardized equipment and methods for non-portable electronics certification. You'll need to follow specific safety verification procedures that protect both equipment and operators during the testing phase.

| Test Type | Equipment Required | Safety Focus |

|---|---|---|

| Electrical | Multimeter, Power Supply | Circuit Protection |

| Thermal | Heat Chamber, Sensors | Overheating Prevention |

| Environmental | Climate Chamber, Monitors | Operational Stability |

When you're conducting certification tests, you must verify safety mechanisms in non-portable equipment through multiple stages. Start with baseline electrical measurements to confirm proper grounding and insulation. Then, move on to thermal testing, where you'll monitor heat dissipation and component temperature thresholds. Finally, run environmental tests to confirm the equipment's stability under various conditions. Working with third-party laboratories ensures comprehensive testing expertise and accelerates the certification timeline.

You'll need to document each test result meticulously, including any deviations from expected values. Make sure to calibrate all testing equipment regularly and maintain detailed records of certification processes. Remember that different equipment categories may require specific additional protocols, but these core testing procedures form the foundation of your certification program's safety verification process.

Quality Control Certification Methods

After establishing baseline testing protocols, quality control certification requires specialized equipment and methodical testing procedures to guarantee electronics meet industry standards.

You'll need to employ various testing instruments, including multimeters for basic electrical measurements, LCR meters for component analysis, and oscilloscopes to visualize circuit responses over time. Automated Test Equipment (ATE) streamlines the process by conducting and recording tests efficiently in high-volume manufacturing environments. Pre-production inspections of components and circuits help prevent defects from entering the manufacturing process.

The certification process incorporates several critical testing methods:

- In-Circuit Testing using bed-of-nails testers identifies component-level issues on PCBs, detecting problems like shorts or incorrect values before they affect final products

- Functional Testing simulates real-world operational conditions to verify that hardware performs according to specified requirements

- Environmental Stress Testing exposes electronics to extreme conditions, verifying durability and reliability under various usage scenarios

You'll need to combine these methods with thorough visual inspections following IPC standards. This thorough approach guarantees your electronic products meet quality benchmarks and certification requirements.

Regular calibration of testing equipment and detailed documentation of results maintain testing accuracy and provide traceability throughout the certification process.

Documentation and Record Keeping

Proper documentation and record keeping serve as the backbone of any electronics protection certification program. You'll need to maintain thorough documentation covering technical specifications, user guides, installation manuals, and block diagrams.

Your records should include detailed Bills of Materials (BOM), component datasheets, and electrical schematics that provide complete product information. For certification through organizations like the FCC, you must include a complete Form 731 application with your documentation.

For regulatory compliance, you must keep PCB layouts, firmware documentation, and traceability information readily available. You'll also need to maintain internal and external product photographs and proper label designs showing certification marks.

It's essential to establish secure electronic management systems for storing these documents while ensuring they're accessible for audits.

Your record keeping obligations extend to maintaining compliance evidence, certification records, and technical specifications shared under NDAs. You'll need to regularly update these documents to reflect product changes and implement version control systems.

Remember to comply with legal retention requirements and maintain confidentiality of sensitive information. Your documentation system should provide clear audit trails and enable quick verification of compliance status, making it easier to demonstrate your product's conformity with certification standards.

Certification Requirements and Procedures

To earn your electronics protection certification, you'll need to complete thorough documentation and pass rigorous testing procedures, including electrical safety reviews, EMC testing, and regulatory compliance checks.

Your certification process must follow a structured five-step approach that covers design review, product safety testing, project assessment, factory inspection, and final report issuance.

You'll also need to maintain your certification through periodic reviews and updates, ensuring your documentation stays current with evolving safety standards and regulatory requirements.

Documentation and Testing Steps

Organizations seeking electronics protection certification must follow a structured path of documentation and testing procedures. You'll need to prepare detailed documentation including compliance statements, detailed test reports, and technical specifications for your electronic products.

Understanding the importance of working with accredited laboratories that can perform the required testing protocols and provide official documentation of results is crucial.

The testing phase involves multiple specialized procedures that your products must successfully complete:

- EMC and RF testing to verify electromagnetic compatibility and radio frequency emissions meet regulatory standards

- ESD and safety testing to guarantee product durability and protection against electrical hazards

- Environmental testing to confirm compliance with regulations like RoHS and assess environmental impact

You'll need to properly label your products with relevant certification marks and include appropriate safety information in user manuals. Your technical documentation must be thorough and accurate, detailing all specifications and test results.

After completing these steps, you'll submit your application package to certification bodies, including all test reports and supporting documents. Remember that certification isn't a one-time process – you'll need to maintain ongoing compliance and may require periodic retesting to keep your certification valid.

Ongoing Maintenance Requirements

Maintaining electronics protection certification requires ongoing commitment and adherence to specific requirements based on your certification type.

For CCITP-F certification, you'll need to complete 100 PDUs over two years, while CCITP-A certification requires the same number of PDUs but spread across three years.

If you hold an ETA certification, you must complete 10 hours of continuing education annually.

You'll track your certification maintenance through dedicated platforms. CCITP offers an online system where you can document your PDUs, while ETA allows you to upload your continuing education records at any time. You're able to submit recertification plans 30 days before your credential expires with CCITP.

Your PDU activities should align with specific requirements. For CCITP-F, you'll need to divide your PDUs between C-InT specific activities and professional growth. ETA certifications may require hands-on training components depending on your specific program.

You'll find support materials, including user guides and reference tables, to help you track and maintain your certification properly. Remember to keep your contact information current and maintain accurate documentation of all educational activities.

Practical Application Techniques

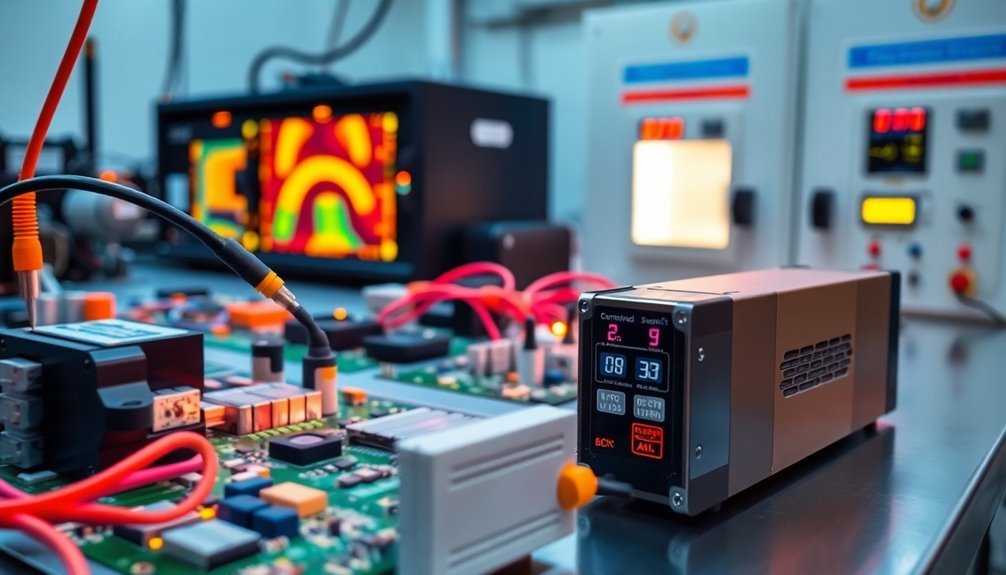

Successful electronics protection requires mastering a diverse set of practical techniques ranging from basic EMP shielding to advanced circuit protection.

You'll learn to implement various shielding methods, from professional Faraday cages to DIY solutions like properly grounded steel containers and foil wrapping. Understanding radar systems, waveforms, and electronic attack techniques will help you develop effective countermeasures against both traditional and emerging threats.

The program's hands-on components teach you to:

- Design hybrid network protection schemes that incorporate both primary and secondary protection devices

- Apply electromagnetic shielding barriers and proper grounding techniques for EMP protection

- Implement specialized countermeasures using Digital Radio Frequency Memories (DRFMs), chaff, flares, and modern radar decoys

You'll gain practical experience in circuit protection design, focusing on PCB layout optimization and matching protection components to specific circuit architectures. The training covers dynamic performance considerations between protection devices and I/O stages, ensuring your protected systems maintain top-tier functionality.

These skills extend to both communication and infrared countermeasures, preparing you to handle diverse protection scenarios in real-world applications.

Frequently Asked Questions

How Long Does an Electronics Protection Certification Typically Remain Valid?

You'll typically find that electronics protection certificates are valid for 13 months (397 days), following TLS/SSL standards. However, you can purchase multi-year subscriptions while still needing annual certificate renewals for security.

Can Certification Programs Be Completed Entirely Online?

You'll find certification availability varies online. While ESD Control and Human Subjects Protection programs offer fully online options, other electronics protection certifications may require blended learning with some in-person components.

What Job Roles Specifically Require Electronics Protection Certification?

You'll need electronics protection certification as an electronics technician, electrical engineer, electronic warfare technician, or technical support specialist. These roles require formal validation of your skills in protecting and maintaining electronic systems.

Are There Different Certification Levels for Beginners Versus Experienced Professionals?

Yes, you'll find distinct certification levels – starting with the Associate CETa for beginners with under 2 years' experience, and advancing to Journeyman level certifications for professionals with 2+ years in electronics.

How Much Does a Complete Electronics Protection Certification Program Cost?

You'll spend $1,760 for the complete program, which includes all 24 modules and learning resources. If you prefer, you can start with $380 for initial enrollment and pay $60 per additional module.

In Summary

You've learned that an electronics protection certification program equips you with thorough knowledge of ESD safeguards, testing procedures, and safety protocols. By mastering proper documentation methods and hands-on protection techniques, you're now prepared to implement these standards in real-world settings. Whether you're handling sensitive components or overseeing protection protocols, your certification guarantees you'll maintain the highest level of electronics safety and reliability.

Leave a Reply