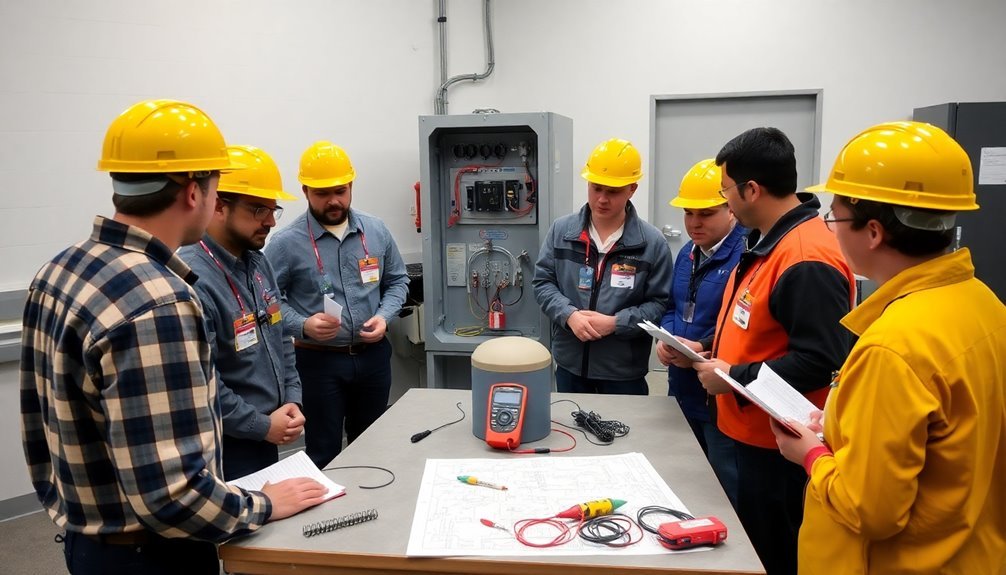

You'll need thorough electrical safety training as a production worker to protect yourself from workplace hazards. This includes learning to recognize common electrical dangers, using proper PPE like insulated gloves and arc-rated face shields, and mastering emergency response protocols. You must understand lockout/tagout procedures, safe equipment operation, and proper grounding practices. Regular training should cover how to inspect tools, maintain clear work areas, and document safety incidents. Your facility's specific requirements may vary, but these fundamental safety elements will form the foundation of your electrical safety knowledge.

Basic Electrical Hazard Recognition

Recognition of electrical hazards starts with understanding their fundamental nature and potential consequences. As a production worker, you'll need to identify common hazards like exposed wiring, damaged equipment, and overloaded circuits that could lead to shock, burns, or electrocution.

You must treat all electrical wires as if they're energized and maintain proper clearance from power lines. Regular inspection and maintenance of electrical systems helps prevent potential equipment failures and accidents.

Your safety depends on conducting thorough inspections of electrical tools and equipment before each use. You'll need to check for signs of wear, damage, or improper grounding that could create dangerous conditions.

Understanding basic electrical principles will help you recognize potential risks in your work environment.

Pay special attention to common hazard sources like faulty outlets, improper extension cord use, and contact with energized equipment. You should be able to spot warning signs such as frayed cords, missing ground pins, or damaged insulation.

Remember that electrical hazards aren't always visible, so you must remain vigilant about maintaining safe distances from power sources and following proper grounding procedures. By developing these recognition skills, you'll be better equipped to protect yourself and others from electrical accidents in the workplace.

Personal Protective Equipment Requirements

Protecting yourself from electrical hazards requires specific personal protective equipment (PPE) that acts as your first line of defense against shock, burns, and arc flash injuries. You'll need safety glasses and face shields to guard against sparks and debris, while insulated gloves and sleeves protect your hands and arms from electrical shock. Don't forget flame-resistant clothing, which shields your body from arc flashes and potential burns.

You must know how to properly use and maintain your PPE through regular inspections and hands-on training. Check your equipment frequently for wear and tear, and replace damaged items immediately. Regular refresher courses are essential to stay current with safety protocols and equipment updates.

Your PPE should include appropriate head protection, ear canal inserts, safety boots, and insulating mats when necessary.

Make sure you can easily access your PPE whenever you need it, and store it properly to maintain its protective qualities.

Remember that your PPE selection should be based on workplace hazard assessments and must comply with OSHA standards and NFPA guidelines. Your employer should provide thorough training on when to use specific PPE types, how to inspect them, and proper wearing techniques.

Always participate in training sessions to safeguard that you're using your protective equipment correctly and effectively.

Emergency Response Protocols

When electrical emergencies strike, you must know exactly how to respond to protect yourself and others. Your facility needs a thorough emergency response plan that clearly outlines procedures for incident assessment, safety protocols, and damage control.

You'll need to know who's on your emergency response team and how to contact them immediately when incidents occur.

Make sure you're trained in essential emergency response skills, including first aid for electrical shock, CPR, and proper fire extinguisher use. You should also master contact release techniques to safely help colleagues who may be in contact with energized equipment. Regular inspections and maintenance of electrical systems help identify potential hazards before they become serious malfunctions.

Know where to find emergency response kits containing voltage testers and insulated tools, and familiarize yourself with the locations of emergency shut-off valves.

You'll need to participate in annual refresher training to stay current with emergency protocols and maintain compliance with OSHA and NFPA standards. Your supervisor will guarantee you're properly trained in lockout/tagout procedures and hazard identification.

Remember that quick access to emergency equipment and clear communication protocols can mean the difference between life and death during an electrical emergency.

Lockout Tagout Proper Procedures

To keep yourself and others safe during equipment maintenance, you'll need to follow specific energy control program steps, starting with preparation and moving through shutdown, isolation, lockout/tagout application, and verification.

When working with electrical equipment, you must identify all potential energy sources and guarantee they're properly isolated using the appropriate lockout devices. The OSHA standard 1910.147 requires strict compliance with these safety protocols.

You'll verify equipment-specific isolation through testing controls, checking voltage meters, and confirming zero-energy state before beginning any maintenance work.

Energy Control Program Steps

An effective energy control program requires four essential steps to guarantee worker safety during equipment maintenance and repair: preparation, shutdown, isolation with lockout/tagout, and verification.

During preparation, you'll need to identify all hazardous energy sources and determine specific control methods. When shutting down equipment, you must follow manufacturer procedures and inform affected employees about the duration and reason for the shutdown. For isolation, you'll apply lockout/tagout devices to each energy-isolating point and confirm they're secured in the "safe" position. Annual reviews of the energy control program are required by employers to ensure procedures remain effective and compliant.

| Step | Key Actions | Critical Points |

|---|---|---|

| Preparation | Identify hazards | All energy types |

| Shutdown | Turn off equipment | Inform workers |

| Isolation | Apply devices | Secure position |

| Lockout/Tagout | Label devices | Include name |

| Verification | Check stored energy | Test controls |

Finally, you'll need to verify the equipment's complete de-energization before starting any maintenance work. This includes checking for stored energy and confirming all controls are in the "off" position. Remember to review your lockout/tagout procedures at least annually to maintain safety standards and compliance.

Equipment-Specific Verification Methods

Proper verification methods for specific equipment serve as the cornerstone of an effective lockout/tagout program. You'll need to guarantee each piece of equipment has its own documented procedure that details the exact steps for shutdown, isolation, and verification. Following proper procedures helps reduce workplace accidents and protect workers from hazardous energy exposure.

When you're performing lockout/tagout procedures, you must first notify all affected employees about the shutdown. Next, shut down the equipment using standard procedures and verify all moving parts have stopped completely.

You'll then need to isolate the equipment from its energy sources by turning off breakers or closing valves.

After isolation, you must apply your lockout or tagout devices to each energy-isolating point. Each authorized employee working on the equipment needs to attach their personal lock to prevent accidental re-energization. If you can't use a lock, you'll need to apply a tag with specific information including the date, time, and your name.

Your final step is verification. You'll need to check for any stored energy and release it safely. Test the equipment to confirm it's fully de-energized and conduct periodic inspections to guarantee your lockout/tagout procedures remain effective.

Safe Equipment Operation Guidelines

Safe equipment operation depends on up to and beyond the basic understanding of electrical hazards. You'll need to master both pre-operational checks and proper operating procedures to maintain a safe working environment.

Before starting any equipment, inspect all tools, cords, and electrical fittings for signs of wear or damage, and verify that machine guards are securely in place. A voltage tester verification must be performed before any exposed contact work begins.

During operation, you must wear appropriate PPE, including safety glasses, gloves, and hearing protection when required. Always follow lockout/tagout procedures before performing maintenance, and confirm you're working with properly grounded equipment.

Don't lift or pull equipment using extension cords, as this can damage the wiring and create shock hazards.

You should maintain clear access to all electrical equipment and pay attention to warning signs and labels. If you notice exposed wires, faulty insulation, or overloaded circuits, report them immediately to your supervisor.

Remember that only qualified personnel should work on live electrical systems. Stay alert to your surroundings and know your facility's emergency response procedures.

If you're unsure about any aspect of equipment operation, ask for clarification before proceeding.

Arc Flash Protection Measures

To protect yourself from arc flash hazards, you'll need to select PPE that matches the specific hazard category and arc thermal performance value of your work environment.

You must establish and respect flash protection boundaries based on voltage levels and available short-circuit currents, maintaining safe working distances from energized equipment.

Before starting any electrical work, you'll need to complete an arc flash risk assessment that considers factors like equipment condition, voltage levels, and the specific maintenance tasks you'll perform. All employees who may be exposed to electrical hazards must undergo proper safety training according to OSHA and NFPA standards.

PPE Selection Guidelines

Personal protection against arc flash incidents demands careful selection of appropriate PPE based on hazard levels and work tasks. You'll need to wear arc-rated clothing made from fire-resistant materials like Nomex and Kevlar when working in high-risk areas. This includes properly fitted coveralls, shirts, pants, and jackets that meet NFPA 70E standards.

Your basic PPE setup must include arc-rated face shields mounted on protective helmets, safety glasses with arc-rated lenses, and hearing protection. Don't forget safety footwear with non-conductive soles to protect against electric shock.

When performing live electrical work, you'll need insulating gloves and sleeves rated for the voltage level you're working with.

Verify that you inspect your PPE regularly and replace any damaged items immediately. You'll also need to participate in thorough electrical safety training to learn proper PPE selection and use.

Remember that your PPE must match the specific hazard category of your work task. Always follow lockout/tagout procedures before accessing electrical equipment, and verify you're familiar with emergency response procedures.

Your compliance with these PPE guidelines isn't optional – it's essential for your safety.

Flash Boundary Safety Rules

Within electrical work environments, arc flash boundaries establish essential safe distances between workers and energized equipment. You'll need to understand that these boundaries mark the distance where an arc flash could cause second-degree burns, requiring at least 1.2 calories/cm² of incident energy.

As a production worker, you must never cross the arc flash boundary without proper PPE and supervision. If you're not qualified, you'll need to maintain the minimum safe distance marked by warning labels on the equipment.

These labels will show you the specific arc flash boundary distance, risk severity, and required PPE for that area.

Your facility should have remote control systems that let you operate switchboards from a safe distance. You'll also find protective measures like ARCBLOC systems that contain and isolate arc flash energy.

Remember that these boundaries aren't arbitrary – they're determined through detailed arc flash studies that calculate incident energy levels at specific working distances.

Always follow your site's safety protocols, which are based on NFPA 70E standards. These rules protect you from severe injuries and guarantee regulatory compliance while working near energized equipment.

Arc Flash Risk Assessment

Effective arc flash risk assessment begins with understanding the key factors that create electrical hazards in your work environment. You'll need to identify potential issues like faulty equipment, improper installations, and unauthorized modifications that could increase arc flash risks. Pay special attention to equipment that's operating beyond its rated capacity, as this can lead to dangerous overheating situations.

Your risk assessment should follow structured techniques aligned with NFPA 70E standards. You'll need to conduct hazard mapping to determine both the likelihood and severity of potential incidents, while performing incident energy calculations to account for any system changes.

Regular inspections and existing documentation will help you spot developing hazards before they become critical.

Once you've identified the risks, you'll need to implement appropriate controls. While de-energization is always your best option, you'll sometimes need to rely on administrative controls and PPE. Make sure you're using proper warning systems, including clear labels and signage, to alert workers to potential dangers.

Don't forget that your assessment process should include regular reviews of safety programs, pre-job briefings, and worker involvement in safety inspections to maintain effective hazard control.

Grounding and Bonding Fundamentals

Essential to workplace electrical safety, grounding and bonding work together as two critical systems that protect both workers and equipment from electrical hazards. You'll need to understand that grounding provides a safe path for electrical currents to flow into the earth during faults or overloads, while bonding connects all metal components to maintain equal electrical potential throughout the system.

When you're working around electrical equipment, you'll rely on proper grounding to prevent shock hazards and protect sensitive equipment from damage. The system uses grounding electrodes, such as ground rods and metal water pipes, along with conductors that safely channel fault currents to the ground.

Meanwhile, bonding guarantees that all metal parts in your work area – from water pipes to gas lines and electrical panels – maintain the same electrical potential, eliminating dangerous voltage differences that could cause shocks.

You must recognize that both systems require regular inspection and maintenance to function correctly. If you notice any issues with grounding or bonding systems, such as loose connections or damaged conductors, you should report them immediately.

Electrical Tool Safety Practices

While grounding and bonding provide foundational safety measures, proper electrical tool practices represent your next line of defense against workplace accidents. You'll need to focus on inspection, safe operation, and proper maintenance of your electrical tools to prevent injuries and equipment damage.

| Safety Phase | Key Actions | Why It Matters |

|---|---|---|

| Pre-Use | Check cords and inspect guards | Prevents shock and injury risks |

| Connection | Use GFCI and 3-prong plugs | Confirms proper grounding |

| Operation | Keep tools away from wet conditions | Reduces electrocution hazards |

| Maintenance | Disconnect before adjusting | Prevents accidental startup |

| Storage | Keep in dry, secure location | Extends tool life and safety |

Before using any electrical tool, you'll need to verify it's been tested and approved. Don't use tools with frayed cords or missing guards – tag them as "Out of service" immediately. When you're working, you must use tools with proper grounding or double insulation, and always connect to a GFCI in wet conditions. Keep power cords clear of hazards and maintain body positioning that avoids contact with grounded surfaces. You'll also need to wear appropriate PPE, including safety glasses and boots, while maintaining a clean work area to prevent accidents.

Documentation and Reporting Standards

Proper documentation and reporting serve as critical pillars of your electrical safety program. You'll need to maintain detailed records of all training sessions, including specific content covered, dates completed, and the equipment you're qualified to work on.

These records must be kept throughout your employment and verified annually by your supervisor to confirm you're up-to-date with current safety practices.

When it comes to electrical incidents, you're required to report them immediately to your supervisor. Include detailed information about what happened, the equipment involved, and any injuries sustained.

Your supervisor will investigate the incident and implement necessary corrective actions to prevent future occurrences.

For work involving energized equipment, you'll need an Energized Electrical Work Permit (EWP) before starting. Here's what you must include:

- Justification for why the equipment can't be de-energized

- Specific safety precautions and PPE requirements for the task

- Written approval from management before proceeding

Your documentation needs to demonstrate that you understand and can apply your training effectively. Remember, proper documentation isn't just about compliance—it's about guaranteeing your safety and the safety of those around you.

Frequently Asked Questions

How Often Should Electrical Safety Training Certifications Be Renewed?

You'll need to renew your electrical safety training certifications every one to three years, depending on OSHA requirements. This guarantees you're up-to-date with current safety standards and maintains workplace compliance.

What Are the Specific Voltage Limits for Non-Qualified Workers?

You don't have a specific voltage limit. Instead, you must follow approach boundaries and can't cross the Limited Approach Boundary without being briefed and escorted by a qualified person with proper safety measures.

Can Temporary Workers Perform Electrical Maintenance Tasks With Limited Training?

You can't perform electrical maintenance tasks with limited training as a temporary worker. You'll need proper supervision from a licensed professional and thorough training that matches your specific job responsibilities and hazard exposure.

How Does Weather Affect Outdoor Electrical Equipment Operation Safety Protocols?

You'll need to protect outdoor equipment with weatherproof covers, GFCI protection, and regular inspections. Monitor for moisture, ice damage, and corrosion. Don't skip maintenance during harsh conditions to prevent safety hazards.

Are Contractors Required to Follow the Same Electrical Safety Training Requirements?

Yes, you'll need to follow standard electrical safety training requirements as a contractor. You must comply with OSHA 29 CFR 1910.332, complete hazard awareness training, and maintain proper documentation of your training certification.

In Summary

You'll need to stay proactive with your electrical safety training program to protect production workers. Keep documentation current, regularly refresh workers' knowledge, and guarantee they understand all safety protocols. Don't skip periodic assessments of their competency with LOTO procedures, PPE usage, and emergency responses. Remember, electrical safety isn't just about compliance – it's about sending your workers home safely every day.

Leave a Reply