You'll find the most versatile ESD storage box dimensions perfectly match different electronic components and workspace needs. For small parts like ICs and resistors, start with 40x37x15mm boxes. For medium projects, consider the standard 400x300mm or 600x400mm sizes that offer excellent modularity. Larger PCB assemblies work well with 800x600mm containers, while the 1200x400mm size handles multiple boards efficiently. Don't forget specialized options like hinged boxes (150x150x20mm) and divided storage solutions (11"x8"x3"). Each dimension serves specific purposes, and understanding their applications can transform your electronics storage strategy.

Standard Small Box 400x300mm

A correction is necessary regarding the standard small ESD storage box dimensions. While some sources might reference 400x300mm boxes, the standard small ESD storage boxes actually measure 40 x 37 x 15 mm. These compact dimensions are specifically designed for storing and protecting sensitive electronic components. The box features one single compartment for organized storage of parts.

These boxes are made from ESD-safe materials like conductive plastic or polystyrene, meeting ANSI ESD-S20.20 and EN 61340-5-1 standards. They feature surface resistivity between 10² to 10⁵ ohms/sq. cm., ensuring proper protection against static discharge.

The boxes can withstand temperatures from -10°C to +70°C, making them suitable for various storage conditions.

These boxes come with spring-loaded lids and an interlocking modular design, allowing you to create customized storage solutions. You can fit 36 boxes in a standard 6-tray drawer cabinet, making them compatible with storage systems like the SM0810 model.

When purchasing, you'll find prices starting at $4.11 per unit, with bulk discounts available – 3% off for 50 units, 6% for 75 units, and 12% for 100 units. They're readily available from suppliers like Transforming Technologies with a 30-day return policy.

Medium Box Series 600x400mm

Standard medium ESD storage boxes in the 600x400mm series offer expanded capacity for larger electronic components and assemblies. You'll find these boxes particularly useful when you're working with sizeable electronic parts or need to store multiple components in a single container. The boxes feature a volume loaded construction similar to their smaller counterparts for consistent static protection.

With dimensions of 600mm length, 400mm width, and 278mm height, these boxes provide ample storage space while maintaining essential ESD protection.

These medium-sized containers are manufactured from conductive polypropylene materials, giving you reliable static protection with surface resistivity ranging from 10^3 to 10^5 ohms for conductive types.

You'll benefit from their modular design, which allows you to stack them efficiently in your workspace or storage area. The boxes come with optional dividers, helping you organize different components while preventing contact damage.

When you're setting up an ESD Protected Area (EPA), these boxes will integrate seamlessly into your protection strategy. They comply with both ANSI ESD-S20.20 and IEC 61340-5-1 standards, ensuring your components stay safe from static discharge.

You can count on their durability features, including shockproof and waterproof construction, making them suitable for both storage and transportation needs.

Large Container 800x600mm

You'll find exceptional storage capacity with the 800x600mm container's spacious dimensions, allowing for efficient organization of larger electronic components and PCB boards.

These containers offer versatile stacking options that let you maximize vertical warehouse space while maintaining easy access to stored items.

The sturdy polypropylene construction guarantees reliable stacking stability, and you can add dividers or foam inserts to customize the internal space for your specific storage needs. The containers feature ESD static dissipative properties with surface resistivity between 1 x 10^8 to 9.9 x 10^9 ohms/square for optimal protection of sensitive electronics.

Maximum Storage Capacity Benefits

Large containers measuring 800x600mm deliver exceptional value through their maximum storage capacity, offering several key advantages for electronics storage management. You'll find that these containers substantially reduce your need for multiple smaller storage units, streamlining your inventory management process and making it easier to track your electronic components.

When you utilize these larger containers, you'll maximize your warehouse space efficiency while decreasing your overall storage solution costs. The 800x600mm dimension aligns perfectly with standard pallet sizes, enhancing your logistical operations and making transportation more efficient.

The safe work environment these containers provide helps protect employees from static discharge risks. You can optimize your storage further by incorporating dividers and customized compartments to organize different electronic components within the same container.

The containers' robust construction guarantees they can handle heavy-duty use while protecting your valuable electronics. You'll appreciate how these larger units simplify your operations by consolidating storage needs into fewer containers.

For enhanced protection, you can add foam inserts or conductive materials to maintain proper ESD safety standards. With surface resistance between 10^6 and 10^9 ohms/square, these containers provide the necessary ESD protection while maximizing your storage capacity.

Stacking Features For Warehouses

These 800x600mm ESD storage boxes feature robust stacking capabilities that maximize vertical warehouse space while maintaining essential ESD protection.

You'll find modular designs that enable secure interlocking between containers, making it easy to organize and stack your electronic components efficiently. The ANSI/ESD S20.20 compliant boxes meet rigorous industry standards for electrostatic discharge protection. The boxes include specialized stacking ridges and ribbed walls that not only provide structural strength but also accommodate optional dividers for customized storage solutions.

For your warehouse operations, you'll appreciate the nesting and stacking designs that come with secure lids, enhancing both convenience and protection. The containers are built from high-strength, glass-reinforced composites specifically formulated to dissipate electrostatic discharge while withstanding extreme temperatures from -60° to 250° Fahrenheit.

They're also resistant to cutting oils, greases, and mild chemical solutions, guaranteeing long-term durability in industrial environments.

You can optimize your factory logistics with these stackable containers, as they're ideal for transportation, distribution, storage, and processing of sensitive electronic components. The smooth surfaces and radial edges guarantee safe handling, while the nesting capability allows for space-efficient storage when the containers aren't in use.

Extra Large Storage 1200x400mm

You'll find the 1200x400mm ESD storage box ideal for maximizing assembly line efficiency with its extended length that accommodates multiple PCB boards in a single container.

The unique dimensions let you store longer electronic components while maintaining a manageable width that won't obstruct workspace traffic. Made from polypropylene material, these boxes offer excellent resistance to oils and acids during extended storage periods.

The extra-large format offers a practical solution for transporting numerous PCBs simultaneously, reducing the number of trips needed between workstations.

Maximizing Assembly Line Space

Maximizing space within and around assembly lines requires strategic planning when dealing with extra-large 1200x400mm storage containers. You'll need to think about both vertical and horizontal space optimization, particularly when working with ESD KLT 12415 boxes that measure 1200 x 400 x 147mm externally.

Start by implementing vertical storage solutions to make the most of your available height. You can install mezzanines and overhead storage systems while using lift trucks for easy access. These storage configurations can safely accommodate containers with loads up to 20kg, ensuring efficient use of vertical space.

Reduce aisle widths to their practical minimum, ensuring you've got just enough space for safe material handling equipment operation. This approach lets you fit more pallet racking systems into your facility.

When organizing your assembly line storage, you'll want to incorporate modular racking systems that can accommodate varying box sizes. The ESD KLT 12415's internal dimensions of 1142 x 360 x 144.50mm make it ideal for large electronics, and you can stack 32 units per pallet.

Think about implementing automated storage systems to enhance efficiency and reduce retrieval times. Automated systems, such as vertical lift modules (VLMs) or vertical carousel modules (VCMs), can significantly reduce the risk of injury, enhance inventory control, and lower the costs associated with inventory storage and handling.

Remember to maintain proper ESD protection throughout your storage setup, as static control remains essential for protecting sensitive electronics during storage and handling.

Efficient Long Component Storage

Long component storage for 1200x400mm ESD boxes requires precise environmental control and strategic organization. While this size isn't standard, you can achieve equivalent storage capacity by combining smaller units like 600x400mm boxes.

These containers are crafted from durable polypropylene material for lasting performance and reliable static protection.

You'll need to maintain ultra-dry conditions with relative humidity below 2% to protect your components from oxidation and diffusion damage.

For your large storage needs, you'll want to implement a combination of dry storage cabinets and moisture barrier bags. Using nitrogen-filled bags and maintaining vapor pressure below 2.82 will substantially extend your components' storage life.

You can customize your storage space with dividers and compartments to maximize organization within these larger configurations.

When you're working with extra-large storage requirements, consider implementing automated solutions like Modula VLMs. These systems help you efficiently manage and monitor your inventory in real-time while maintaining strict ESD safety protocols.

Remember to use ESD-safe materials that meet industry standards, and guarantee your storage system includes proper humidity control features. You'll find that combining smaller ESD-safe units offers more flexibility while achieving your needed 1200x400mm storage capacity.

Multiple PCB Transport Solution

Effectively transporting multiple PCBs in 1200x400mm configurations requires a tailored storage approach since standard ESD boxes don't accommodate these dimensions. You'll need to pursue custom manufacturing solutions that maintain essential ESD protection while ensuring structural integrity for your large-format PCBs.

When designing your custom storage solution, focus on incorporating conductive polystyrene or polypropylene materials that comply with ANSI ESD S20.20 standards.

You'll want to specify features like reinforced corners and sturdy bases to support the weight of multiple PCBs while preventing flexing or warping during transport.

Consider implementing a modular design that allows for efficient stacking and secure interlocking between units. You should also request lid options that provide both easy access and complete protection during storage and movement.

While standard sizes typically max out at 600x400x340mm, your custom 1200x400mm solution can incorporate similar successful design elements from these proven configurations.

To maximize your storage efficiency, you'll benefit from including internal compartments or adjustable dividers that prevent PCB contact during transport. Remember to verify that all customized features maintain proper ESD protection throughout the entire storage system.

Variable Depth Storage Solutions

Designed for flexible organization, variable depth storage solutions provide customizable compartments through adjustable partitions and indexing ribs. You'll find these storage options available in conductive corrugated cardboard and fluted plastic, both offering durable, waterproof protection with full Faraday Cage capabilities when equipped with removable lids.

| Material Type | Protection Level | Key Benefits |

|---|---|---|

| Corrugated Cardboard | ESD + Faraday Cage | Cost-effective, lightweight |

| Fluted Plastic | ESD + Waterproof | Durable, moisture resistant |

| High Impact Polypropylene | ESD Safe | Heavy-duty, long-lasting |

When selecting your storage solution, you'll need to think about the size requirements for your components. The bins accommodate various reel sizes from 7" to 15", and you can adjust partition configurations to match your specific needs. You'll also find FIFO vertical SMD reel holders that maximize space efficiency at workstations.

For enhanced functionality, you can add ESD foam inserts, handles for easy transport, and mobile cart options with adjustable heights. The storage solutions integrate seamlessly with interlocking SMD component boxes, allowing you to create an organized, scalable storage system that grows with your needs.

Stackable RL-KLT Box Dimensions

You'll find RL-KLT boxes in two primary sizes: the standard 297 x 198 x 147.5 mm and the larger 396 x 297 x 174 mm variants, both designed for efficient electronic component storage.

These boxes feature precise inner dimensions (243 x 162 x 129.5 mm for standard size) that maximize storage capacity while maintaining compatibility with automated handling systems.

Their uniform construction guarantees you can stack them securely, with reinforced walls supporting substantial loads in warehouse and production environments.

Popular Sizes and Capacities

Stackable RL-KLT boxes come in an extensive range of dimensions to meet diverse electronics storage needs. You'll find standard sizes ranging from compact 400x300x120mm units to larger 600x500x400mm containers, giving you flexibility in storing various electronic components.

Whether you're handling small parts or larger assemblies, there's likely a size that fits your requirements.

For small electronic components, you can opt for bins as compact as 40x37x15mm, while medium-sized electronics fit perfectly in 350x265x125mm or 400x300x148mm containers. If you're working with larger components, you'll want to evaluate the 600x500x360mm or 600x500x400mm options.

These boxes come with ESD protection features, including conductive materials and specialized foam options like pink ESD foam or black conductive foam.

You can also request custom dimensions if standard sizes don't meet your specific needs. For organizing smaller parts, insert trays measuring 14.5″ x 9″ are readily available.

Many sizes offer optional lids for additional protection, and all boxes feature smooth, easy-to-clean surfaces that resist compression and cracking while maintaining their anti-static properties.

Modular Stacking Compatibility

Most RL-KLT boxes feature precise modular dimensions that enable seamless vertical and cross-stacking compatibility.

You'll find two main base designs: smooth bases with drainage holes in VDA RL-KLT boxes and ribbed composite bases in VDA R-KLT containers.

The smooth-based 600x400x147 offers internal dimensions of 544x359x129.50mm, while its ribbed counterpart provides 544x364x109.50mm of space.

For larger storage needs, you can opt for the 600x400x280 model, which comes in both base varieties. The smooth-based version gives you 544x359x262mm of internal space, while the ribbed version provides 544x364x242mm.

If you're handling oversized components, the 800x600x210 model offers expansive internal dimensions of 739x556x200mm.

You'll achieve maximum stacking stability by matching compatible bases. The ribbed R-KLT bases excel at cross-stacking and maintaining stability in tall configurations, while smooth RL-KLT bases integrate well with ESD trolleys and plastic pallets.

Both types feature conductive properties (10^5-10^9 Ohm surface resistance) and comply with NEN-EN-IEC 61340-5-1 standards for safe electronic component storage.

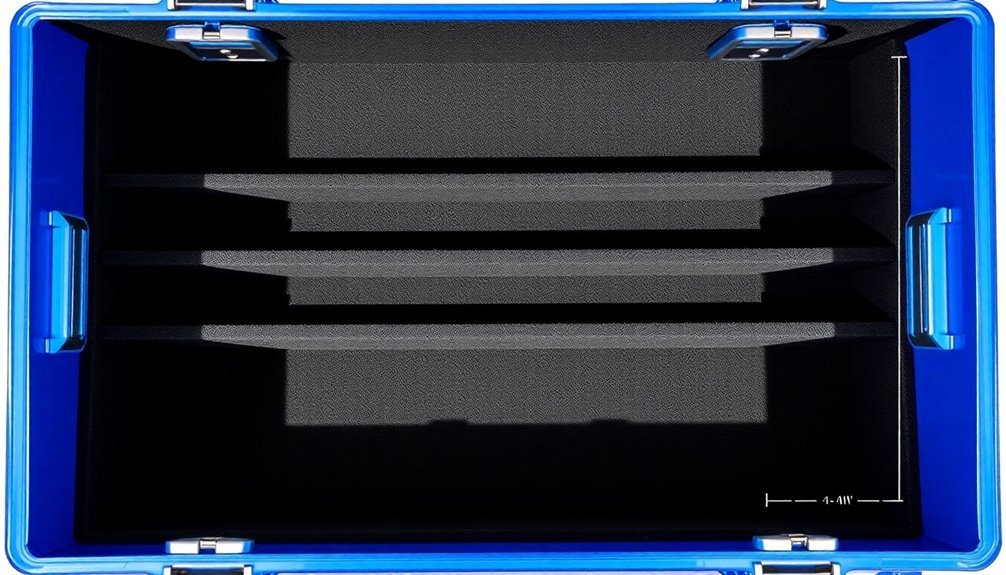

Hinged Box Measurements

Understanding the standard measurements for ESD hinged boxes helps you select the right storage solution for your electronic components.

You'll find standard ESD hinged boxes available in several key dimensions, including 150x150x20mm, 92x120x16mm, 90x110x20mm, 80x80x18mm, and 70x100x18mm.

For smaller components, you can choose from compact sizes like 75x50x15mm, 65x65x15mm, or even 35x35x15mm.

If you need precise internal measurements, consider boxes with dimensions of 60.2mm W. x 38.1mm L. x 22.86mm H. These boxes feature spring-loaded lids with stay-open features and film hinges with snap fasteners.

You'll also find larger storage options measuring up to 600x400mm for bulk storage needs. All these boxes are manufactured using black conductive polypropylene or volume carbon-loaded polystyrene, ensuring permanent anti-static protection.

The boxes meet ANSI ESD S20.20 requirements and offer surface resistivity between 1×10^10 to 9.9×10^12 ohms per square.

You can customize these boxes with foam inserts, and they're designed with interlocking modular features for efficient stacking and organization.

Divided Storage Box Sizes

ESD divided storage boxes come in five standard sizes, ranging from compact 11" x 8" x 3" units to larger 16" x 11" x 5" containers.

You'll find two main box families: the S-25310/11 series for smaller components and the S-24187/88/89 series for larger storage needs. Each box accommodates both short and long divider configurations to help you customize your storage layout.

For flexible organization, you can choose from these divider options:

- Compact boxes (11" x 8") feature 7 short dividers or 5 long dividers

- Standard boxes (16" x 11") accommodate 11 short dividers or 7 long dividers

- Multiple manufacturer options like Grainger and Hisco offer additional size variations

- Custom configurations available with divider counts ranging from 7 to 26 slots

When selecting your divided storage solution, consider both the box dimensions and divider configurations. The S-25310 and S-25311 work well for smaller components, while the S-24187, S-24188, and S-24189 series provide more space for larger items.

Each size offers specific divider arrangements to maximize your storage efficiency while maintaining proper ESD protection for your sensitive electronic components.

Tote Box Specifications

Tote boxes form the backbone of safe electronic component storage, with standard models offering robust dimensions of 400x300x100mm and internal measurements of 354x254x96mm. You'll find these containers provide 8.7 liters of storage capacity while supporting impressive maximum loads of up to 500 kg.

The boxes are crafted from conductive polypropylene, ensuring reliable ESD protection with surface resistance of ≤10^4 Ω. You can stack them securely thanks to their reinforced ridges, and their ribbed walls accommodate optional dividers for organized storage. The injection molding process guarantees uniform wall thickness and maximum strength throughout the container.

You'll discover various size options from leading manufacturers like LewisBins and Olympic, with specific models such as the Benstat Blue ESD tote measuring 9"x7"x3".

When you need custom solutions, you can opt for specialized configurations with partitions and ESD foam inserts. For added functionality, you can equip your totes with snap-on covers, drop-in lids, mobile dollies, and ESD-safe cardholders.

The boxes come in bulk quantities of 48 units per carton, making them ideal for large-scale storage solutions.

Cleanroom Storage Dimensions

When setting up cleanroom storage, you'll find standard boxes ranging from compact 68x57x15mm SMD containers to larger 190x152x129mm wafer storage units.

You'll need to think about both ESD protection and cleanroom compatibility when selecting storage dimensions, as these units must meet ISO 5 cleanliness standards and maintain surface resistivity between 10² to 10⁵ ohms/sq. cm.

Storage options include wall-mounted, benchtop, and freestanding configurations to maximize your cleanroom space. You can choose from antistatic polypropylene, stainless steel, or powder-coated steel materials that offer broad chemical and microbial resistance while meeting ANSI ESD-S20.20 standards.

- Freestanding cabinets come in various heights and widths, with customizable shelf configurations

- Under-cabinet storage units fit efficiently beneath workstations to save floor space

- Mobile carts feature lightweight frames with adjustable shelving for flexibility

- Wall-mounted systems offer vertical storage solutions without consuming valuable floor area

For specialized requirements, you can opt for custom configurations that include features like mirrored exteriors, reinforced doors, or UV sterilization modules.

Temperature-controlled units with nitrogen purge systems are available for sensitive components requiring precise environmental conditions.

Frequently Asked Questions

Can ESD Boxes Be Custom-Made for Specific Product Dimensions?

Yes, you can get ESD boxes custom-made to fit your specific product dimensions. You'll have flexibility in choosing sizes, materials, and features like dividers to perfectly accommodate your electronic components and requirements.

How Long Does the Anti-Static Protection Last in ESD Storage Boxes?

Your ESD storage box's anti-static protection can last 2-5 years with proper care. You'll need to monitor its surface resistance, maintain ideal storage conditions, and regularly inspect for physical damage to guarantee effectiveness.

Are ESD Boxes Recyclable After Their Service Life Ends?

Yes, you can recycle your ESD boxes after their service life. They're usually made from recyclable plastics like polystyrene. Just clean them first and check your local recycling guidelines to guarantee proper disposal.

What Cleaning Solutions Are Safe to Use on ESD Storage Boxes?

You'll want to use ESD-safe cleaners like Staticide Mat and Table Top Cleaner. Avoid harsh chemicals and tap water. You can also dry clean with soft cloths or brushes. Always test after cleaning.

Do ESD Boxes Require Special Handling During International Shipping?

Yes, you'll need to follow IPC standards and clearly identify ESD packaging during international shipping. You must use ESD-protected materials throughout transit and guarantee continuous protection against static discharge during handling and transportation.

In Summary

You'll find these standardized ESD storage box dimensions essential for protecting your sensitive electronic components. Whether you're working with the compact 400x300mm boxes or need the expansive 1200x400mm containers, there's a size that fits your needs. Remember to take into account depth options, divided compartments, and cleanroom specifications when selecting your storage solution. Choose the right dimensions to maintain proper ESD protection and organization.

Leave a Reply