When choosing between wide and narrow ESD runners, you'll want to prioritize comfort and safety for your work environment. Wide ESD runners offer better pressure distribution, reducing foot fatigue during long shifts and lowering your risk of developing bunions or plantar fasciitis. While narrow runners may provide slightly better energy efficiency for movement, wide options give you more toe space and improved stability without compromising static discharge protection. Both styles meet essential safety standards like ANSI ESD-S20.20, but your foot shape and comfort needs should guide your decision. Understanding the full impact of runner width can transform your workplace experience.

Understanding ESD Runner Width Basics

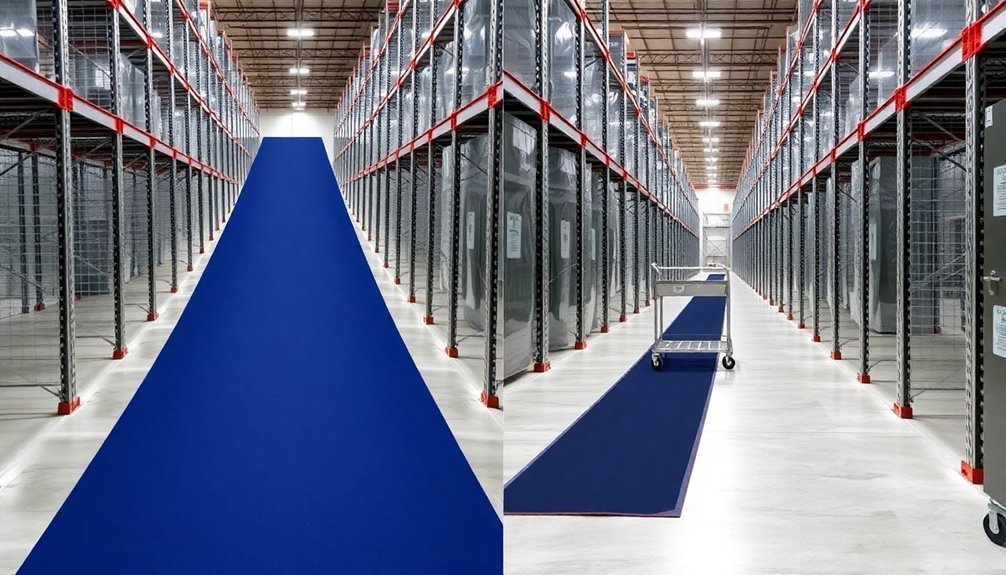

The assembly line's ESD protection starts with choosing the right runner width. You'll find standard ESD matting available in 24″, 30″, 36″, and 48″ widths, though custom sizes can be ordered for your specific needs.

These standard measurements are designed to accommodate typical workstation layouts and assembly line configurations. Full rolls can provide cost-effective coverage when outfitting multiple workstations or planning for future expansion. Offers include free shipping over $100 for immediate delivery of stocked sizes.

When you're selecting an ESD runner width, you'll be glad to know that the width itself doesn't affect the mat's static control performance. What matters most are the electrical properties and material composition.

You'll need to guarantee the surface resistance falls within the dissipative or conductive range (less than 10^9 ohms/square) to meet ANSI ESD-S20.20 standards.

You can choose from vinyl or rubber materials in various thicknesses, including 5/8", 7/8", and 1/2". Your selection should be based on your workspace layout and specific applications.

The mats are designed for easy cutting, allowing you to customize the fit to your work area. If you're using pre-cut mats, they often come with grounding hardware included, making installation straightforward and guaranteeing proper static protection.

Benefits of Wide ESD Runners

Wide ESD runners can dramatically improve your comfort during long work shifts by distributing pressure more evenly across your feet.

You'll experience less fatigue and strain since the broader base allows your feet to spread naturally as you walk or stand. The 3D mesh lining helps maintain optimal temperature and moisture control for enhanced comfort. The enhanced width allows for proper static charge dissipation by maximizing contact with ESD flooring surfaces.

The enhanced width promotes proper foot alignment and movement, helping you maintain better posture and reducing the risk of foot-related discomfort throughout your workday.

Enhanced Comfort During Work

Comfort takes center stage when choosing ESD runners for long workdays. You'll find that wide ESD runners offer superior comfort through their use of soft, breathable materials like mesh and synthetic leather, keeping your feet cool and dry throughout your shift.

The proper fit and support features of wide ESD runners greatly enhance your work experience. These shoes provide ample toe space and balanced arch support, reducing fatigue and boosting your productivity. The impact-absorbing materials, such as EVA and impact foam, protect your feet and spine from constant shock during movement. Meeting EN 61340-5-1 standards, these runners maintain electrical resistance levels that effectively protect against static discharge. With prices ranging from 37.99 to 294.00, there are options to suit every budget.

| Feature | Benefit |

|---|---|

| Breathable Materials | Prevents foot sweating and discomfort |

| Wide Toe Box | Allows natural toe spreading and movement |

| EVA Cushioning | Absorbs impact and reduces foot fatigue |

| Arch Support | Maintains proper foot alignment |

| Lightweight Design | Minimizes overall leg fatigue |

You'll appreciate that wide ESD runners come in various styles suitable for different work environments. Whether you're in a casual or business setting, you can find options that blend comfort with professional appearance while maintaining essential safety features.

Natural Foot Movement Benefits

Building on the comfort advantages, natural foot movement emerges as a major benefit of wide ESD runners. When you wear wide shoes, your toes can splay naturally, reducing pressure points and allowing proper foot function. This natural movement strengthens your intrinsic foot muscles and helps maintain overall foot health. Studies show that barefoot-style shoes lead to increased muscle strength in feet and lower legs. Recent research indicates a 34% reduction in bunion pain when switching to shoes with wider toe boxes.

Wide ESD runners promote better posture and alignment throughout your body. Without heel elevation, you'll maintain a more neutral spine position, which can reduce your risk of back and hip pain. The natural foot strike encouraged by these shoes also decreases impact forces on your body, lowering your chance of injury.

You'll find that wide ESD runners can help prevent or alleviate common foot conditions. The spacious toe box reduces compression that often leads to bunions, Morton's neuroma, and ingrown toenails. Additionally, the neutral design helps prevent overuse injuries like plantar fasciitis and stress fractures by promoting proper foot alignment.

For long-term benefits, consistently wearing wide ESD runners can prevent chronic foot problems and deformities. Your feet will maintain their natural strength and flexibility, contributing to better balance and improved biomechanics during work activities.

Workplace Safety and Foot Health

Safety in the workplace consistently demands attention to both protective features and long-term foot health when selecting ESD runners.

You'll need to guarantee your footwear meets essential standards like EN ISO 20345:2011 for Europe or CSA Z195 for Canada while protecting against workplace hazards.

When you're choosing between wide and narrow ESD runners, consider that narrow designs can contribute to chronic foot issues like bunions and plantar fasciitis.

Wide toe boxes offer a healthier alternative by providing adequate space for natural toe movement while maintaining vital safety features.

Your ESD runners should include robust toecap protection that withstands impacts up to 200 J, along with penetration-resistant midsoles capable of handling up to 1100 Newton of force.

You can't overlook the importance of breathability and slip resistance.

Look for features like Poromax lining to keep your feet dry and SRC-rated outsoles to prevent slips.

The footwear must also maintain proper static dissipation properties, indicated by certifications like the CSA Yellow Rectangle.

Comfort Vs Performance Factors

The critical balance between comfort and performance defines your choice of ESD runners, as both factors greatly impact workplace productivity and safety.

While comfort features like breathability and proper arch support keep you focused during long shifts, performance aspects guarantee consistent static protection in sensitive environments.

When weighing comfort against performance, you'll need to take into account these essential factors:

- Breathable materials enhance your comfort by reducing sweat buildup, but they must still maintain proper conductivity for static control.

- Arch support and cushioning improve your daily comfort, yet they shouldn't compromise the shoe's electrical resistance requirements.

- The fit must accommodate your foot width while guaranteeing full contact with ESD floors for peak static discharge.

- Material quality affects both comfort and performance – high-grade conductive materials provide reliable static protection while remaining comfortable.

Your ESD footwear must meet specific resistance standards and comply with ANSI/ESD protocols while providing adequate support for extended wear.

Don't sacrifice one aspect for the other – modern ESD runners can deliver both superior comfort through ergonomic design and consistent performance through quality conductive materials.

Selecting the Right Size

While balancing comfort and performance sets the foundation for ESD footwear selection, accurate sizing ultimately determines your daily work experience. When choosing between wide and narrow ESD runners, you'll need to take into account both length and width measurements to guarantee the best fit and safety.

Start by consulting the brand's specific sizing chart, as measurements can vary greatly between manufacturers. You'll often find that wide-fit options come in various ranges, from standard to extra wide, letting you match your foot's unique shape.

Don't hesitate to order multiple sizes if you're shopping online, as it's better to compare fits than settle for an uncomfortable choice. Pay attention to customer reviews about sizing patterns – they'll often suggest whether to size up or down for specific brands.

If you're trying on ESD runners, remember that proper length should leave enough room to prevent toe pressure, while width should accommodate your foot without pinching. You'll want to think about how different materials might affect the fit, as some may stretch or remain rigid over time.

If you're between sizes, it's typically better to opt for the slightly larger option, especially if you'll be wearing your ESD runners for extended periods.

Material and Design Considerations

Material choices and design features play interconnected roles in ESD runner performance. When selecting between wide and narrow ESD runners, you'll need to take into account how materials and design affect both comfort and static dissipation capabilities.

Wide runners typically offer better material distribution, allowing for more effective integration of conductive elements while maintaining comfort.

The key differences in material and design considerations include:

- Wide runners provide more surface area for conductive materials, ensuring better ground contact and static dissipation, while narrow designs may limit the effectiveness of ESD properties.

- The broader toe box in wide designs allows for better material flexibility and ventilation, which helps maintain ideal humidity levels for static control.

- Material layering in wide runners can accommodate both protective features and comfort elements without compromising fit.

- Design elements like composite toes integrate more seamlessly into wide runners without creating pressure points.

You'll find that wide ESD runners often incorporate more sophisticated ventilation systems and can better accommodate specialized insoles. The additional space allows manufacturers to include enhanced conductive materials without sacrificing comfort or protection.

When maintaining your ESD runners, you'll notice that wider designs are typically easier to clean and maintain due to their more accessible surfaces.

Cost Impact and Value

Understanding cost implications can greatly impact your choice between wide and narrow ESD runners. While the initial material costs don't differ markedly between wide and narrow options, you'll find the true value lies in long-term benefits and application-specific advantages.

You'll need to evaluate your workspace's requirements carefully, as choosing the wrong type can lead to expensive corrections. Wide runners often provide better value in high-risk environments where extensive protection is vital, particularly in electronics manufacturing or explosive environments. Their broader surface area typically offers enhanced durability and wear resistance.

When assessing costs, you'll want to factor in integration with your existing ESD protection system. Both wide and narrow runners contribute to an effective ESD control strategy, but wide runners may offer superior protection in essential areas.

While you'll pay slightly more upfront for ESD runners compared to traditional flooring, you'll benefit from reduced maintenance costs and extended lifespan.

Don't forget that compliance with standards like ANSI/ESD S20.20 is essential – incorrect installation or inappropriate selection can result in costly rework and potential regulatory fines.

Your investment in properly selected ESD runners will pay off through protected equipment and reduced maintenance needs.

Workplace Compliance Requirements

When selecting ESD runners for your facility, you'll need to meet strict safety standards for both wide and narrow options, including resistance requirements below 1.0 x 10^9 ohms and proper grounding connections.

Your choice must align with your industry's specific ESD requirements, particularly in electronics manufacturing where extensive EPA protocols are mandatory.

You're required to maintain detailed documentation of regular testing, maintenance records, and compliance verification for whichever runner width you choose.

Safety Standards Compliance

Throughout the modern workplace, compliance with ESD safety standards requires strict adherence to established guidelines like ANSI/ESD S20.20 and IEC 61340-5-1. When you're selecting between wide and narrow ESD runners, you'll need to verify they meet essential safety requirements, including system resistance not exceeding 1.0 x 10^9 ohms and peak voltage staying below 100 volts.

To maintain proper safety standards compliance, you must follow these critical testing protocols:

- Perform regular body voltage generation tests to verify voltage remains under 100 volts.

- Document resistance testing for both footwear and flooring according to ANSI/ESD STM97.1 and STM97.2.

- Implement continuous monitoring systems in line with ESD TR53 requirements.

- Conduct point-to-ground and point-to-point resistance testing.

Whether you choose wide or narrow ESD runners, you'll need to wear them exclusively within controlled environments. They must meet applicable EU standards (SBP, SB, S3, S2, S1, S1P) and provide adequate electrical contact with ESD flooring materials.

Remember that proper documentation and regular testing aren't optional – they're essential components of maintaining compliance with workplace safety standards.

Industry-Specific ESD Requirements

Different industries face unique ESD control challenges that require specific compliance measures for wide and narrow ESD runners.

In aerospace and military settings, you'll need to guarantee your ESD runners comply with MIL-PRF-38535 standards, while adhering to strict supply chain auditing requirements that NASA and military facilities enforce.

For telecommunications and IT environments, you must select runners that work effectively with your facility's flooring system, meeting resistance requirements between 1 x 10E6 and 1 x 10E9 ohms.

Your choice should align with ATIS-0600321 and FAA 019f standards, particularly when working in data centers.

In manufacturing settings, your ESD runners need to meet ISO 20345 and ESD STM97.2-2006 standards while working in conjunction with ESD floor mats.

For healthcare and cleanroom environments, you'll want to prioritize runners that meet ESDA standards while maintaining cleanliness requirements.

When selecting between wide and narrow options, consider your specific workplace requirements, including the need for additional stability in aerospace assembly versus enhanced maneuverability in cleanroom settings.

Regulatory Documentation Guidelines

In accordance with workplace safety regulations, you must maintain thorough documentation for your ESD runner program.

Whether you're choosing wide or narrow runners, your documentation needs to comply with ANSI/ESD S20.20 and IEC 61340-5-1 standards.

You'll need to establish a detailed ESD Control Program Plan that outlines your facility's procedures for managing ESD-sensitive items and maintaining compliant flooring systems.

To guarantee your ESD runner documentation meets regulatory requirements, implement these essential steps:

- Document detailed material specifications for your chosen runners, including electrical resistance requirements and testing parameters that align with both ANSI and IEC standards.

- Maintain regular testing records that verify your flooring-footwear system's compliance with resistance measurements and body voltage limits.

- Keep certification records from recognized testing programs that validate your facility's adherence to ESD standards.

- Create clear marking procedures for all ESD-protected areas and guarantee they're properly documented in accordance with customer requirements and purchase orders.

Long Term Health Effects

Recent studies have revealed four major health concerns associated with long-term ultra-endurance running, affecting the cardiovascular, musculoskeletal, renal, and respiratory systems.

Your cardiovascular system faces serious risks, including right ventricular dysfunction, heart calcification, and increased chances of atrial fibrillation.

You'll likely develop cardiac hypertrophy and coronary artery calcium buildup if you're consistently running ultra-distances.

Your musculoskeletal system won't fare much better. You're at higher risk for osteopenia, stress fractures, and osteoarthritis in your hips and knees.

You'll also face increased chances of back pain, muscle tears, and bursae injuries that can affect your joints, cartilage, and tendons.

Your kidneys may suffer from acute kidney injury, particularly during extreme conditions or dehydration.

There's potential for developing chronic kidney disease through repeated stress, and your kidney function typically decreases during intense exercise.

Your respiratory system can experience significant damage.

You'll likely face impaired lung function after ultra-endurance events, along with inflammation and bronchial constriction.

The repeated exposure to unconditioned air can lead to airway narrowing and permanent respiratory damage.

Common Width Measurement Standards

You'll find that measuring your foot width correctly starts with using a Brannock Device, the industry standard tool that provides precise length and width measurements.

The letter width classification system (N, M, W, XW) helps you identify the appropriate width category across many shoe brands, though you should note that these can vary between manufacturers.

International size charts offer standardized measurements that let you convert between different sizing systems, making it easier to find the right ESD runner width regardless of where they're made.

Brannock Device Sizing Guide

Getting your ESD shoe size right starts with a proper Brannock Device measurement – the industry standard tool for accurate foot sizing.

You'll need to stand with your feet firmly on the device, ensuring your heel sits snugly against the heel cup and your longest toe aligns with the slider for precise measurement.

When measuring for ESD shoes, you should consider both width and length measurements carefully, as proper fit affects static dissipation effectiveness.

Your width measurement is particularly important, as you'll need to slide the width bar firmly against the widest part of your foot while checking the corresponding measurement on the movable width bar.

- Always measure both feet while wearing your intended work socks – choose the larger size if there's a difference.

- Position your foot's arch to align with the device's arch slider for best flex point matching.

- Check both arch length and heel-to-toe measurements – use the larger of the two for sizing.

- Consider going up a size if you're between measurements to accommodate foot swelling during long shifts.

Remember to take these measurements for each type of ESD footwear you're considering, as different shoe styles may require different sizing approaches.

Letter Width Classification System

After measuring your foot with the Brannock Device, you'll need to understand the letter width classification system used for ESD runners. While standard width classifications aren't specifically detailed for ESD runners, it's vital to select the right width to guarantee proper conductivity and safety in your work environment.

When choosing your ESD runner width, you'll need to take into account how it interfaces with your ESD-compliant footwear. The proper width guarantees consistent contact between your ESD footwear and the runner's conductive or dissipative materials, maintaining resistance levels between 1×10^6 and 1×10^9 ohms as required by ANSI/ESD S20.20 standards.

This contact is essential for creating an effective static discharge path to ground. Your runner width selection directly impacts safety and performance. A runner that's too narrow may not provide adequate contact area for proper static dissipation, while one that's too wide might affect mobility in your workspace.

You'll want to guarantee your chosen width maintains consistent electrical contact while meeting both EN 61340-5-1 guidelines and ASTM D257 testing requirements for surface and volume resistivity measurements.

International Size Charts Standards

International size standards for ESD runners follow distinct measurement systems across different regions, making it essential to understand these variations for proper width selection.

Just as clothing sizes differ between countries, footwear width measurements also vary considerably across global markets. You'll find that brands often use their own sizing systems, which can complicate your search for the perfect fit.

Understanding international width standards helps you make informed decisions when purchasing ESD runners across different regions.

Here's what you need to know about global width measurements:

- US and UK systems typically use letter classifications (A, B, D, E, EE) for width measurements, with each letter representing a specific width increment.

- European manufacturers often use numerical millimeter measurements for width specifications, providing more precise sizing options.

- Asian markets frequently employ their own regional standards, which may differ from Western measurements and require careful conversion.

- International brands usually provide thorough size charts that include width conversions between different regional standards.

Remember to always check brand-specific size charts, as standardization varies even within the same region or manufacturer.

User Experience and Reviews

User feedback on ESD runners reveals distinct preferences between wide and narrow options.

You'll find that those requiring wide sizes report considerable relief when they secure properly fitting shoes, with brands like Asics Gel-Kayanos and New Balance offering 2E widths. However, your options might be limited, as few manufacturers produce wide ESD runners.

If you're considering narrow runners, research suggests they could be more efficient for your running style. Marathon runners often prefer narrower step widths because they reduce side-to-side kinetic energy fluctuations, making your runs more energy-efficient.

You'll experience better stability and energy return, particularly during longer distances.

For workplace requirements, you'll notice that comfort plays a vital role in user satisfaction. Workers consistently report that proper width appreciably improves their daily experience while maintaining essential ESD protection.

Whether you choose wide or narrow options, you'll want to verify your shoes meet workplace safety standards. Companies like Reebok Work offer various ESD options that combine safety features with comfort.

Remember that your choice should align with both your foot width and specific workplace requirements for static dissipation.

Frequently Asked Questions

Can Wide ESD Runners Affect Balance and Stability During Precision Tasks?

Wide ESD runners can improve your stability during precision tasks by providing a broader base of support. You'll find they offer enhanced balance control, though you'll need to adjust to their wider platform initially.

How Often Should ESD Runners Be Replaced to Maintain Their Static-Dissipative Properties?

You'll need to replace your ESD runners every 6-12 months, depending on usage. Don't wait longer if you notice visible wear, failed static tests, or deteriorating comfort, as these indicate compromised static-dissipative properties.

Do Wide ESD Runners Require Different Cleaning Methods Than Narrow Ones?

You'll use similar cleaning methods for both wide and narrow ESD runners. However, you might need larger cleaning tools and more solution for wide runners to guarantee thorough, even coverage across the surface.

Are There Specific Sock Materials Recommended for Optimal ESD Runner Performance?

You'll get the best ESD performance using moisture-wicking socks made from bamboo or conductive materials. Avoid pure cotton, wool, and synthetic materials that can interfere with static dissipation. Choose ESD-certified socks when possible.

Can Temperature Changes Affect the Fit and Performance of ESD Runners?

Yes, temperature changes can affect your ESD runners. You'll notice they may expand in heat and contract in cold, potentially altering their fit and impacting their electrostatic dissipative properties and overall performance.

In Summary

Choosing between wide and narrow ESD runners impacts both your comfort and safety at work. You'll find wide runners offer better stability and weight distribution, while narrow options provide greater mobility. Consider your foot shape, daily activities, and workplace requirements when deciding. Don't compromise on fit – the right width guarantees proper ESD protection and reduces foot fatigue during long shifts.

Leave a Reply