You'll need specialized ESD (Electrostatic Discharge) foam to safely ship your sensitive electronics. Choose between conductive foam for maximum protection, anti-static foam for moderate needs, or static dissipative foam for controlled discharge – all designed to prevent static damage during transit. These foams, made from materials like polyethylene and EVA, offer density ranges from 45-67kg/m³ and excellent shock absorption. Wrap individual components, use double-layer packaging, and select sturdy containers that fit your devices properly. The world of protective shipping materials has much more to offer for your specific electronic shipping needs.

Understanding ESD Foam Basics

Have you ever wondered how delicate electronic components make it safely from manufacturer to consumer? The answer lies in ESD foam, a specialized protective material designed to safeguard electronics during storage and transport.

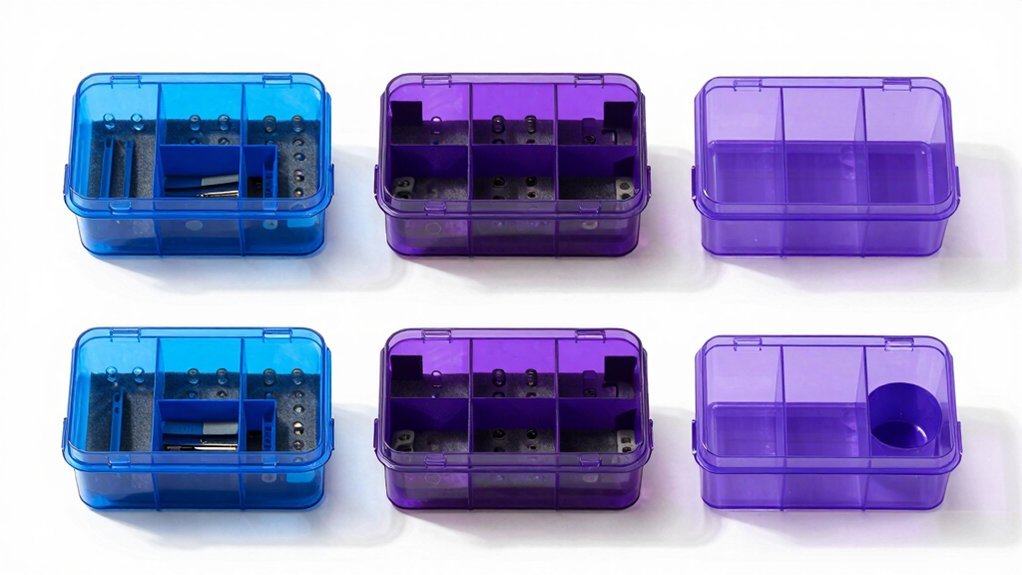

ESD (Electrostatic Discharge) foam comes in three distinct types: conductive, anti-static, and static dissipative. Each type serves specific protection needs, with conductive foam offering the lowest surface resistance at under 10^4 ohms/sq., while anti-static foam ranges between 10^6-10^9 ohms/sq.

You'll find these foams crafted from materials like Expanded Polyethylene, Ethylene Vinyl Acetate, and polyurethane, all incorporating special conductive fillers. Density ranges from 45kg/m³ to 67kg/m³ for PE foam varieties.

When you're handling sensitive electronic components, you'll want to understand how ESD foam works. It actively dissipates electrostatic charges that could otherwise damage your electronic devices.

Think of it as a protective shield that prevents harmful static electricity from building up and transferring between components.

The foam's effectiveness is guaranteed through EIA-541 Packaging Material Standards, ensuring your electronics receive top-notch protection.

Whether you're shipping microchips or storing circuit boards, ESD foam provides the essential safeguarding your sensitive components need.

Choosing the Right Protection

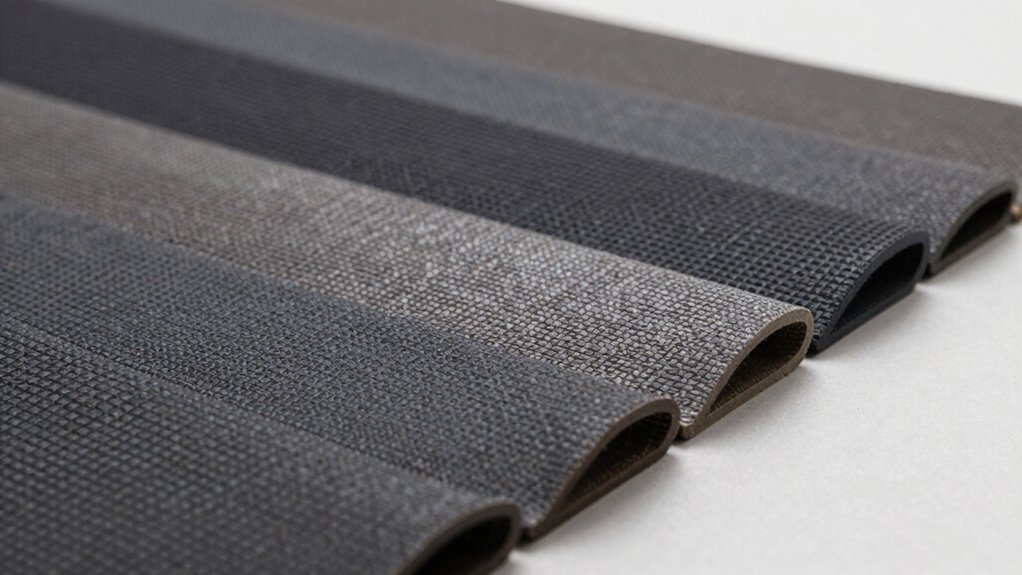

Now that you understand ESD foam basics, selecting the right protective material for your specific needs becomes your next important step. You'll need to assess your device's sensitivity to static, shock, and moisture while considering your typical shipping conditions and environmental requirements.

For static-sensitive electronics, you'll want to choose between three main options: anti-static foam to prevent static build-up, static dissipative foam for safe discharge, or conductive foam for complete electromagnetic shielding.

If you're shipping heavier items, opt for PE foam's durability and superior shock absorption. For more delicate electronics, PU foam's gentle cushioning properties make it an ideal choice. Just as surge protectors with higher joule ratings provide better protection for sensitive electronics, choosing the right foam density is crucial for safeguarding your devices.

Don't forget to factor in your shipping environment. If you're planning long-distance or international shipments, you'll need more durable foam options. Consider moisture resistance for humid conditions, and evaluate whether you need eco-friendly alternatives to align with sustainability goals.

Your foam's density and thickness should match your device's weight and fragility level. By carefully matching these properties to your specific needs, you'll guarantee your electronics arrive safely while maintaining cost efficiency.

Custom Foam Solutions

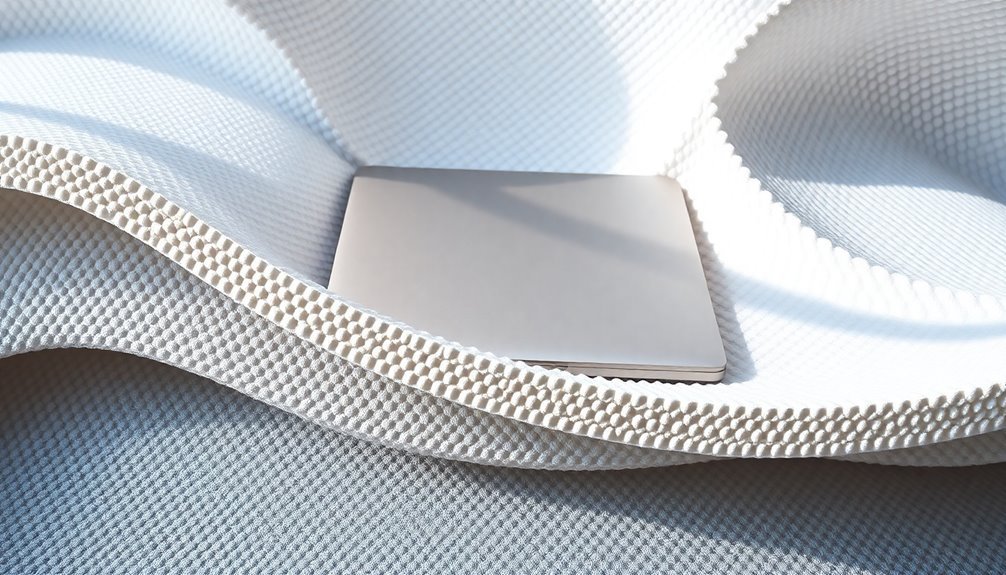

Custom foam solutions represent the gold standard in electronics protection, offering precision-engineered safeguards tailored to your specific devices. When you're shipping valuable electronics, you'll find that custom foam packaging substantially reduces damage risks and guarantees your products arrive safely at their destination. The specialized packaging process begins with understanding your device's unique dimensions and fragility requirements.

You'll have access to various foam materials, each serving distinct purposes. Polyurethane foam provides excellent shock absorption, while EVA foam creates a snug fit for your devices. For moisture-sensitive electronics, PE foam offers reliable protection, and if you're concerned about static discharge, anti-static foam variants will safeguard your components.

The design process guarantees your electronics receive top-notch protection. Engineers create precise digital models of your devices, selecting the most appropriate foam material based on weight, fragility, and sensitivity.

Using advanced cutting techniques, they'll craft form-fitting inserts that cradle your electronics perfectly.

Whether you're shipping smartphones, medical equipment, or industrial components, custom foam solutions adapt to your needs. You'll benefit from enhanced brand reputation through safer deliveries, while organized storage solutions keep your components secure during transit and warehouse storage.

Safe Shipping Best Practices

While shipping electronics requires careful attention to detail, following proven best practices substantially reduces the risk of damage during transit.

You'll need to implement double-layer packaging by placing your electronics in their original box before inserting them into a larger outer container.

Don't forget to wrap each device and its removable parts individually using bubble wrap or tissue paper.

Protect screens with clear protective film and use anti-static materials to prevent static electricity damage.

You'll want to double up on cushioning materials and select the right type of foam – anti-static foam for sensitive components and PE foam for heavier items.

Always choose sturdy containers that fit your electronics properly to prevent movement during shipping.

Remember to label your packages correctly, indicating fragile contents and any lithium-ion batteries included.

Position labels away from container seams and flaps, and remove old labels from reused boxes.

When shipping in humid environments, use vapor-barrier bags with desiccants and humidity indicators.

For maximum protection, consider custom-designed wood crates, and always require a signature upon delivery to safeguard secure reception of your valuable electronics.

The optimal humidity range of 40-80% during shipping helps prevent both static electricity buildup and moisture damage to your electronics.

Handling Environmental Shipping Challenges

Shipping electronics sustainably presents unique environmental challenges that extend beyond basic packaging considerations. You'll need to balance protecting sensitive components while minimizing your environmental footprint throughout the shipping process.

When you're preparing electronics for shipment, consider using anti-static foam and vapor-barrier bags that protect against temperature fluctuations and humidity while being less harmful to the environment. These materials help prevent damage that could result in electronic waste, which is currently the fastest-growing waste stream globally. The reliance on complex logistics networks increases the overall carbon footprint of electronics distribution.

You'll need to comply with strict regulations, especially when handling batteries or shipping internationally. Verify you're following proper protocols for hazardous materials and implementing protective measures that meet safety standards while maintaining environmental responsibility.

To reduce your shipping's environmental impact, you can opt for packaging materials that are easier to recycle and choose shipping routes that minimize fossil fuel consumption. Remember that proper handling during transportation isn't just about protecting your products—it's about preventing damage that could contribute to the growing e-waste problem.

Consider incorporating renewable energy solutions in your shipping operations and exploring alternative packaging materials with lower ecological footprints.

Frequently Asked Questions

How Long Can Protective Shipping Foam Be Reused Before It Needs Replacement?

You can reuse protective shipping foam for 3-6 months with regular use, but you'll need to inspect it before each use. If you notice wear, compression, or loss of anti-static properties, replace it immediately.

Can Shipping Foam Be Recycled or Disposed of in an Environmentally-Friendly Way?

Yes, you can recycle most shipping foam types like EPS, PE, and PU through specialized facilities. You'll need to find local drop-off locations or recycling services, as standard curbside programs don't usually accept foam materials.

Does Colored Shipping Foam Offer Different Protection Levels Than Standard White Foam?

No, the color of your shipping foam doesn't affect its protective capabilities. You'll get the same level of protection from colored foam as white foam – it's the foam type and density that matter most.

What Cleaning Methods Are Safe to Use on Anti-Static Shipping Foam?

You'll want to use specialized ESD cleaners and anti-static cloths. Don't use household cleaners – they'll damage the foam. Spray cleaners lightly and wipe gently with ESD-safe swabs, letting it dry completely.

Can Shipping Foam Lose Its Protective Properties if Stored for Extended Periods?

Yes, your shipping foam can lose its protective qualities during extended storage. If you don't store it properly, heat, moisture, and compression will degrade its cushioning properties. It's best to rotate stock regularly.

In Summary

Don't take chances when shipping your valuable electronics. You'll protect your investment by selecting the right ESD foam packaging and following proper handling procedures. Whether you're using custom-cut solutions or standard foam options, make sure you've addressed static protection, cushioning, and environmental factors. Take time to properly pack and secure your items – it's worth the extra effort to guarantee safe delivery.

Leave a Reply