When shipping electronics, you'll need specialized ESD (electrostatic discharge) foam to prevent static damage and physical shock. Three main types can protect your devices: anti-static foam (pink), static dissipative foam, and conductive foam (black). Each offers different levels of protection based on their surface resistance properties. For maximum safety, choose foam that matches your device's sensitivity level and combine it with proper cushioning techniques. Don't forget sturdy outer packaging and clear handling instructions. Your expensive electronics deserve premium protection, and understanding the right foam selection will guarantee they arrive safely at their destination.

Understanding ESD Foam Basics

ESD foam stands out among packing materials for its unique ability to protect sensitive electronic components from static electricity damage. This specialized foam performs two critical functions: it dissipates static charges that could harm your electronics while providing essential cushioning during transportation and storage.

When you're handling electronic components, you'll appreciate how ESD foam creates a safe pathway for static discharge, effectively preventing the buildup of potentially damaging electrostatic charges. This foam doesn't just block static electricity; it actively manages it through controlled dissipation, safeguarding your sensitive equipment remains protected at all times. Anti-static foam maintains a surface resistance rating between 10^6 and 10^9 ohms, ensuring reliable protection for general electronic components.

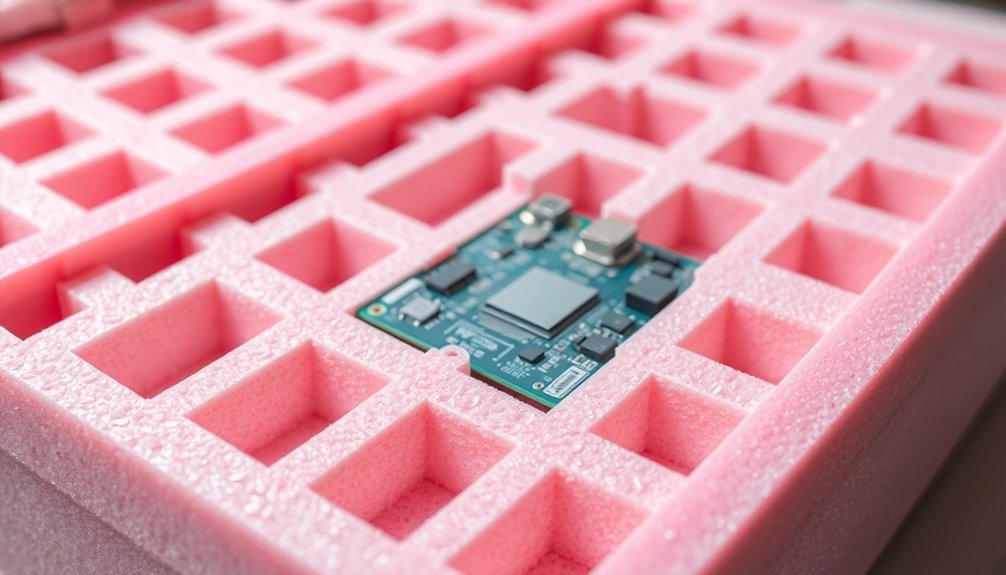

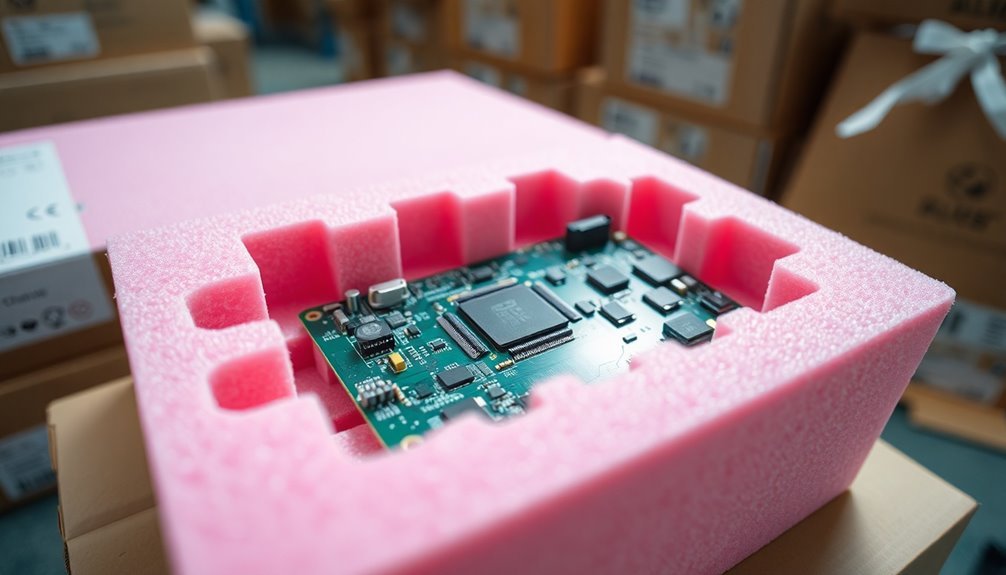

You can rely on ESD foam's versatility, as it's available in various forms to match your specific needs. Whether you're working with delicate circuit boards or complete electronic devices, you'll find options ranging from sheets and rolls to custom-cut trays.

The foam's surface resistance can be tailored to your requirements, offering conductive, anti-static, or static dissipative properties. To guarantee maximum protection, you should always select ESD foam that meets industry standards like EN 61340-5-2 and comes from reputable suppliers with proven track records.

Types of Anti-Static Foam Materials

Several distinct types of anti-static foam materials serve different protective needs in electronics packaging. Anti-static PE foam offers lightweight protection while remaining odorless, making it perfect for basic shipping needs. With a regular density of 45kg/m3, PE foam provides reliable cushioning for standard electronics transport.

EVA foam combines flexibility with high impact resistance, while PU foam delivers superior cushioning for heavy-duty applications. For maximum protection, conductive foam creates a Faraday cage effect, blocking electromagnetic fields completely.

When you're handling sensitive electronics, choosing the right foam type becomes essential. Static dissipative foam allows charges to dissipate slowly, preventing sudden discharges that could damage your components. It's available in both carbon-impregnated and surface-treated varieties, with surface resistance ranging from 10^5 to 10^9 ohms.

Your valuable circuit boards deserve protection from unexpected static shocks.

Your company's reputation depends on delivering undamaged electronics.

Your customers trust you to ship their sensitive components safely.

Consider your specific needs when selecting foam type. If you're shipping highly sensitive devices, opt for conductive foam with its full static shielding capabilities. For work-in-progress situations, static dissipative foam offers the perfect balance of protection while allowing safe handling. Remember to check compliance with EIA-541 Packaging Material Standards for ESD-sensitive items.

Selecting the Right Foam Grade

When you're choosing protective foam for shipping electronics, you'll need to weigh three critical factors: density for impact absorption, proven durability through testing, and appropriate anti-static properties.

Your foam's density directly affects its ability to protect against drops and shocks, while material durability testing confirms consistent performance across various shipping conditions. Pink anti-static foam is ideal for single-trip shipping applications.

The foam's anti-static properties, measured in surface and volume resistivity, must match your electronic components' sensitivity levels to prevent static discharge damage during transit.

Density and Impact Protection

Selecting the right foam density stands out as a critical factor in protecting shipped items from damage. When you're shipping sensitive electronics, understanding how density affects impact protection can make the difference between safe arrival and costly damage.

Dense foams offer superior energy absorption and maintain their shape under pressure, making them ideal for heavier items that might face significant impacts during transit. The foam's thermal insulation properties also help protect temperature-sensitive components during shipping.

Consider these emotional stakes when selecting foam density:

- Imagine the sinking feeling of opening a package to find your expensive equipment damaged due to inadequate protection.

- Picture the confidence of knowing your shipment is cushioned by precisely-engineered foam that's matched to your product's needs.

- Think about the peace of mind that comes from choosing foam that will maintain its protective properties throughout the entire shipping journey.

However, don't automatically opt for the densest foam available. While higher density provides better load-bearing capacity and compression resistance, it can actually harm delicate items if it's too rigid.

You'll want to strike a balance between protection and practicality, ensuring your foam choice aligns with both your product's weight and its fragility level.

Material Durability Testing

Beyond foam density alone, rigorous material durability testing provides the scientific backbone for choosing the right foam grade. You'll want to evaluate key metrics like tear strength (ASTM D3574-17) and compression setting to guarantee your foam can withstand shipping stresses. Water absorption and flame resistance ratings are equally vital for protecting your electronics. Closed-cell foam structures provide superior shock absorption and durability compared to open-cell options for shipping protection.

| Test Type | Why It Matters |

|---|---|

| Tear Strength | Measures your foam's resistance to tearing forces (lbs/lin inch), vital for packages that may snag during transit |

| Compression Setting | Tests how well your foam maintains shape under weight, guaranteeing consistent protection at 25% compression |

| Water Absorption | Determines moisture resistance using ASTM D 3575-93, protecting electronics from humidity damage |

| Flame Resistance | Verifies safety compliance through UL94 HF-1 and FMVSS302 standards |

When selecting shipping foam, you'll need to confirm that the material passes these essential durability tests. Check for tear strength ratings that match your shipping requirements, and guarantee the compression setting aligns with your product's weight. Don't overlook water absorption ratings if your packages might encounter moisture, and always verify flame resistance certification for safety compliance.

Anti-Static Properties Explained

A critical aspect of shipping foam selection lies in understanding its anti-static properties, especially when protecting sensitive electronic components. When you're shipping electronics, you'll need foam that prevents electrostatic discharge through proper surface resistance of 10^9 – 10^12 ohms.

Both polyurethane (PU) and polyethylene (PE) foams can be treated with anti-static agents to achieve this protection. The shipping environment conditions must be carefully evaluated when selecting foam type and grade.

You'll find two main varieties: pink anti-static foam made from polyurethane, and black conductive foam made from carbon-filled polyethylene. The low-density versions offer more flexibility for cushioning, while high-density options provide rigid structural support.

When selecting your foam, verify it meets EIA-541 Packaging Material Standards for ESD sensitive items.

- Protect your valuable circuit boards from invisible static damage that could cost thousands in repairs

- Secure your electronic investments with foam that acts as a Faraday cage against electromagnetic fields

- Preserve your components' integrity with customizable foam solutions that fit your exact specifications

Consider the item's size and weight when choosing between open-cell polyurethane for smaller components and closed-cell polyethylene for bulkier items.

Remember that most anti-static foam is designed for single-trip use and isn't reusable.

Custom Foam Solutions

Custom foam solutions with precision cuts give you exceptional protection for your valuable electronics while eliminating excess material waste.

Available in various foam densities, from lightweight to heavy-duty options, these protective solutions can be precisely matched to your specific shipping needs.

You'll benefit from exact-fit designs that cradle your products perfectly, preventing movement and reducing the risk of shipping damage.

These tailored solutions often prove more cost-effective than standard packaging options, as they minimize product returns and optimize material usage through smart design principles.

Precision Cut Material Benefits

Through precision cutting technologies, modern foam solutions deliver unmatched accuracy and versatility for protecting sensitive equipment. Whether you're using water jet cutting, CNC routing, or die cutting processes, you'll get precisely engineered foam components that fit your electronics perfectly. Multiple cavity depths can be achieved without expensive custom tooling costs.

These cutting-edge techniques guarantee your delicate devices receive maximum protection without compromising on fit or function.

Your electronic components deserve protection that's tailored to their unique specifications. Custom-cut foam solutions offer you:

- Peace of mind knowing your valuable equipment is suspended in precisely engineered cavities that absorb shock and vibration

- Confidence in shipping delicate components with foam that's cut to exact dimensions, eliminating movement and potential damage

- Satisfaction from professional-looking packaging that reflects the quality of your products

With densities ranging from 2 to 6 lbs. pcf in anti-static materials, you'll find the right foam solution for your needs. The precision-cut materials, enhanced with carbon black compounds, provide consistent anti-static protection without degradation.

You can choose from various materials like ECH, EPDM, EVA, or Polyurethane, each cut to exact specifications for the best protection of your sensitive electronic equipment.

Cost-Effective Design Solutions

Modern packaging demands call for both precision and affordability. You'll find that custom foam solutions offer cost-effective design options that don't compromise on protection. With materials like polyurethane, polyethylene, and EVA foams, you can select the perfect combination for your specific needs.

| Solution Type | Benefits | Cost Impact |

|---|---|---|

| Manual Systems | Custom-molded shapes | Lower initial investment |

| Semi-automated | Increased production speed | Moderate setup costs |

| Fully Automated | High-volume efficiency | Higher upfront cost |

| Foam-in-Place | Lowest cost per cubic foot | Maximum adaptability |

You'll discover that ETHAFOAM™ products provide exceptional value through their built-in anti-static properties and superior impact protection. These solutions can be tailored to your exact specifications, ensuring your electronics remain secure during transit and storage. By implementing custom foam designs, you're not just protecting your products – you're optimizing your packaging costs. The ability to choose between manual, semi-automated, and fully automated systems lets you match your production scale while maintaining cost-effectiveness. With foam-in-place packaging systems offering the lowest cost per cubic foot, you'll find the perfect balance between protection and budget constraints.

Cost Benefits of Protective Packaging

Protective packaging represents a strategic investment that delivers substantial cost benefits across multiple business operations. When you choose the right foam packaging solutions, you'll markedly reduce material waste while maximizing protection for your sensitive electronics.

Custom-sized foam inserts and standardized packaging dimensions work together to enhance your storage and transportation costs.

The long-term financial advantages of proper protective packaging extend beyond immediate savings. You'll notice reduced returns and replacements, lower shipping costs, and improved customer satisfaction. By investing in high-quality foam packaging, you're effectively preventing damage and minimizing the expenses associated with customer complaints and product replacements.

Your brand's reputation strengthens as customers receive their electronics in perfect condition, leading to increased loyalty and repeat business.

You'll slash operational costs by preventing damage-related returns and eliminating the need for replacement shipments.

Your sustainability efforts improve when you choose eco-friendly foam options, appealing to environmentally conscious consumers.

Through strategic packaging choices and material optimization, you'll achieve considerable cost savings across your supply chain. Bulk purchasing of foam materials and standardized sizing further enhance your cost-efficiency while maintaining superior protection for your sensitive electronics.

Safety Standards and Compliance

When you're shipping sensitive electronic components, your foam packaging must meet EIA-541 standards and ANSI/ESD S20.20 compliance requirements for electrostatic protection.

Your shipping materials need verified surface resistance ratings between 10^4 and 10^9 ohms, along with proper anti-static treatments that prevent triboelectric charging.

You'll also need to guarantee your foam packaging undergoes regular testing for both conductive properties and humidity resistance to maintain industry certifications.

Industry Safety Requirements

Safe shipping of electronics demands strict adherence to complex industry regulations and safety standards. When shipping sensitive electronic equipment, you'll need to comply with carrier-specific guidelines, particularly for items containing lithium batteries. FedEx and USPS maintain strict requirements for battery handling, and you must properly label all hazardous materials.

Your shipping process must incorporate proper protective measures, including anti-static materials and vapor-resistant packaging. Climate-controlled containers are essential when temperature sensitivity is a concern, and you'll need to use wire rope systems to minimize vibration damage during transit.

Your business reputation depends on every package arriving safely – don't risk costly damage claims. Each damaged shipment represents lost revenue and frustrated customers. One regulatory violation could result in significant fines and shipping restrictions.

Remember to disassemble products when possible to protect fragile components, and always use appropriate cushioning materials. You must back up data and remove sensitive information before shipping any electronic devices.

For international shipments, guarantee you're aware of customs regulations and maintain proper documentation. Consider insurance coverage for valuable shipments, and always use tracking services to monitor your package's progress through the shipping network.

Material Testing Standards

A rigorous testing framework governs every aspect of shipping foam production and certification. You'll find that ASTM D3574 serves as the cornerstone standard, measuring critical properties like density, compression force, and tensile strength to guarantee your products arrive safely.

For your electronic shipments, you'll need foam that meets EIA-541 standards, specifically designed to protect against electrostatic discharge. Your foam must maintain a surface resistance between 10^4 and 10^9 to effectively prevent static buildup.

| Property Type | Testing Requirement |

|---|---|

| Density | ASTM D3574 compliant measurement |

| Static Protection | EIA-541 surface resistance verification |

| Flame Resistance | ASTM E84 flame spread rating |

| Compression | Force deflection testing |

| Durability | Tear and tensile strength analysis |

When selecting foam for your sensitive electronics, you'll want to evaluate whether open-cell polyurethane or closed-cell polyethylene better suits your needs. Open-cell foam works best for lightweight components like circuit boards, while closed-cell options provide superior protection for heavier equipment. The foam's compliance with military specifications (MIL-SPECs) also guarantees it meets the highest standards for environmental resistance and compressive strength.

Regulatory Compliance Certifications

Regularly complying with safety standards becomes essential when shipping electronic components with protective foam packaging.

You'll need to verify that your foam materials meet CertiPUR-US standards, which verify they're manufactured without harmful substances like formaldehyde, ozone depleters, and heavy metals. Additionally, ESD foam must comply with EIA-541 standards to protect sensitive electronics from static damage.

Your shipping foam needs multiple certifications to demonstrate full compliance. ISTA certification proves your packaging can withstand various transportation conditions, while NRTL certification confirms overall safety standards. For international shipping, you'll need to research specific requirements for your target markets.

- Protect your business from costly returns and damage claims by using CertiPUR-US certified foam with verified low VOC emissions

- Safeguard your reputation by choosing foam that meets rigorous ISO 17025 testing standards

- Avoid regulatory penalties by verifying that your packaging includes proper FCC labeling and ESD protection

Remember that child-resistant packaging requirements apply when shipping electronics with hazardous components or batteries. Your foam packaging must work in conjunction with these safety measures while maintaining its protective properties through the entire shipping cycle.

Key Features of Shipping Foam

Designed to protect valuable cargo during transit, shipping foam offers several essential features that make it indispensable for safe transportation. High-quality shipping foam provides exceptional insulation properties, creating a barrier that shields your products from temperature fluctuations that could compromise their integrity during shipping.

When it comes to protecting your electronics, the foam's shock absorption capabilities are critical. It effectively dissipates impact energy, reducing the risk of damage from drops, bumps, or vibrations.

If you're shipping sensitive electronic components, you'll want to pay special attention to static protection features. Anti-static foams prevent electrostatic discharge that could otherwise destroy your valuable equipment.

You'll also benefit from moisture-resistant properties in many shipping foam varieties, keeping your products safe from humidity and condensation. The foam's abrasion resistance is another essential feature, particularly when you're shipping items with delicate surfaces that could be scratched or scuffed during transport.

These protective qualities work together to create a thorough shield for your products, ensuring they arrive at their destination in perfect condition. Each feature plays a specific role in maintaining the safety and integrity of your shipped items.

Storage and Handling Guidelines

Proper storage and handling of shipping foam guarantees its long-term effectiveness and protective qualities. When storing foam concentrates, keep them in a cool, dry indoor location away from direct sunlight and heat sources.

You'll want to verify your storage area isn't susceptible to flooding and that all containers remain sealed when not in use.

For safe handling, always use clean equipment when transferring foam materials to prevent contamination. It's vital to check the compatibility of your storage containers and connected equipment to avoid electrolytic corrosion.

If you're working with fixed tanks, consider applying a thin layer of mineral oil to prevent evaporation, but avoid this practice with moveable containers.

- Don't risk your valuable shipments with improperly stored foam that's lost its protective properties

- Protect your investment by following proper rotation and inventory tracking

- Save money and time by preventing contamination through careful handling

Regular inspections are essential for maintaining foam quality. You should conduct annual evaluations and send samples to qualified laboratories for analysis.

When in doubt about storage or handling procedures, don't hesitate to consult the manufacturer's guidelines for your specific foam products.

Environmental Impact of Foam Materials

With environmental concerns on the rise, shipping foam's impact on our planet demands careful examination. Traditional foam materials, particularly those using hydrofluorocarbons (HFCs), contribute substantially to greenhouse gas emissions, with a warming potential thousands of times greater than carbon dioxide.

You'll find that most conventional shipping foam poses substantial waste management challenges. Since it's not easily recyclable, it often ends up in landfills where it can release harmful chemicals over time.

The average foam product's lifecycle of about twenty years means you're contributing to long-term environmental issues when using traditional materials.

However, you've got environmentally friendly alternatives to think about. These sustainable options use natural or recycled materials instead of petroleum-based chemicals, substantially reducing greenhouse gas emissions and your reliance on non-renewable resources.

You'll find options like soy-based polyols and plant-based substitutes that promote better indoor air quality by containing fewer volatile organic compounds.

When choosing shipping foam, you can opt for non-CFC alternatives like expanded polystyrene (EPS) produced with pentane. By selecting recyclable or eco-friendly foam options, you're supporting responsible waste reduction efforts while still protecting your sensitive electronics.

Common Shipping Mistakes to Avoid

Shipping mistakes can devastate your business, leading to damaged products, unhappy customers, and unnecessary expenses. When you're shipping sensitive electronics, proper documentation and packaging aren't just good practices – they're essential safeguards for your products and reputation.

Don't risk your shipment's safety with incorrect labeling or inadequate documentation. You'll need accurate BOL information, precise handling instructions, and proper hazardous materials labels when applicable.

Your packaging strategy must include sufficient cushioning, appropriate box sizes, and proper securing methods to prevent movement during transit.

For electronics specifically, you'll want to:

- Protect against electrostatic discharge using static shielding bags

- Control moisture damage with desiccant bags

- Isolate and secure batteries to prevent short-circuiting

Remember to use shock absorbers and vibration dampeners for sensitive components. If you're shipping in bulk, guarantee proper pallet stacking and securing to prevent crushing.

Consider implementing IoT monitoring solutions to track shipping conditions in real-time. These precautions might seem extensive, but they're far less costly than replacing damaged products or losing customers due to shipping mishaps.

Best Practices for Electronics Packaging

Effective electronics packaging requires a thorough understanding of both product vulnerabilities and protection methods. You'll need to identify your product's specific sensitivities to static electricity, moisture, and physical impact before selecting appropriate protective materials.

When packaging electronics, you'll want to use antistatic materials to prevent ESD damage, especially for sensitive components. Custom-cut foam inserts provide precise cushioning and protect against impacts during transit.

Don't forget to incorporate moisture-resistant materials if your electronics are vulnerable to humidity.

For maximum protection, consider implementing a double-boxing strategy for particularly delicate items. You'll also want to guarantee your packaging materials comply with industry standards like EIA-541 for ESD protection.

Use non-abrasive materials to prevent scratching and incorporate tamper-evident features to maintain security.

Remember to include clear handling instructions and special requirement labels on your packaging. While protection is paramount, you shouldn't overlook the importance of user-friendly design – your packaging should be secure yet accessible.

Choose recyclable materials whenever possible and include recycling guidelines to promote environmental responsibility. This balanced approach guarantees both product safety and customer satisfaction.

Frequently Asked Questions

Can Shipping Foam Be Reused for Multiple Shipments?

Yes, you can reuse shipping foam for multiple shipments as long as it's in good condition. You'll need to inspect it regularly for wear and damage to guarantee it maintains proper protection levels.

How Long Does Anti-Static Foam Maintain Its Protective Properties?

You'll find anti-static foam typically maintains its protective properties for 1-3 years, but it's best to test it regularly. Environmental conditions and handling can affect its lifespan, so you should monitor its effectiveness.

What Temperature Ranges Can Shipping Foam Withstand During Transit?

You can rely on shipping foam to perform effectively between -40°C to 40°C. For refrigerated items, you'll need 1-inch thick liners, while frozen goods require 1.5-2 inches for ideal temperature protection during transit.

Does Colored Shipping Foam Provide the Same Protection as Standard White Foam?

Yes, your colored shipping foam provides identical protection as white foam when made from the same materials. You'll get the same shock absorption, vibration dampening, and protective qualities regardless of the foam's color.

How Do You Properly Dispose of Used Electronic Shipping Foam?

You can recycle your shipping foam through local recycling facilities, community programs, or big box stores. If it's marked with "X6" or "NP6," drop it at specialized centers that handle foam packaging materials.

In Summary

You'll save significant money and protect your valuable electronics by choosing the right shipping foam for your needs. Don't risk damage when proper packaging solutions are readily available. Whether you're shipping delicate components or storing sensitive equipment, invest in quality anti-static foam that meets your specific requirements. Remember to follow proper handling guidelines and consider environmental impact when making your selection.

Leave a Reply