Three critical ESD mat resistance standards you must know for effective static protection: First, conductive materials should measure between 10^1 to 10^5 ohms to guarantee proper static dissipation. Second, surface resistance should fall within 1 x 10^5 to 1 x 10^11 ohms/square for ideal static charge control. Third, your mat's resistance-to-ground (RTG) measurement must be less than 1.0 x 10^9 ohms to meet ANSI/ESD S4.1-2006 standards. You'll need regular testing with an RTG meter to maintain these specifications and guarantee your ESD protection stays effective. Discover how proper grounding and material selection can enhance these standards even further.

Conductive Range Specifications

Within the domain of ESD protection, conductive range specifications serve as critical benchmarks for mat performance. You'll find that conductive materials fall within a specific resistance range of 10^1 to 10^5 ohms, designed to efficiently dissipate static electricity to ground. These specifications guarantee your ESD mats provide reliable protection for sensitive electronic components.

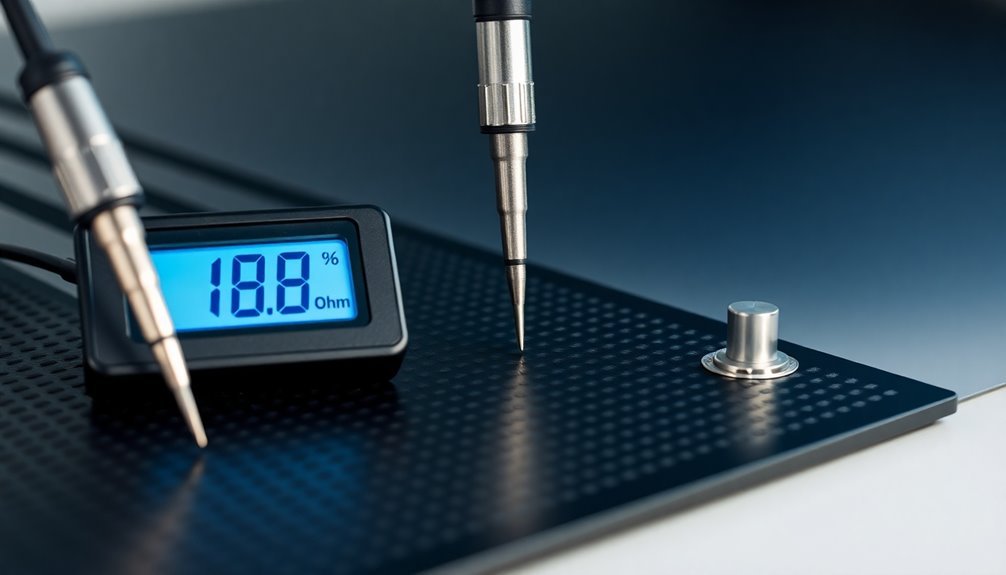

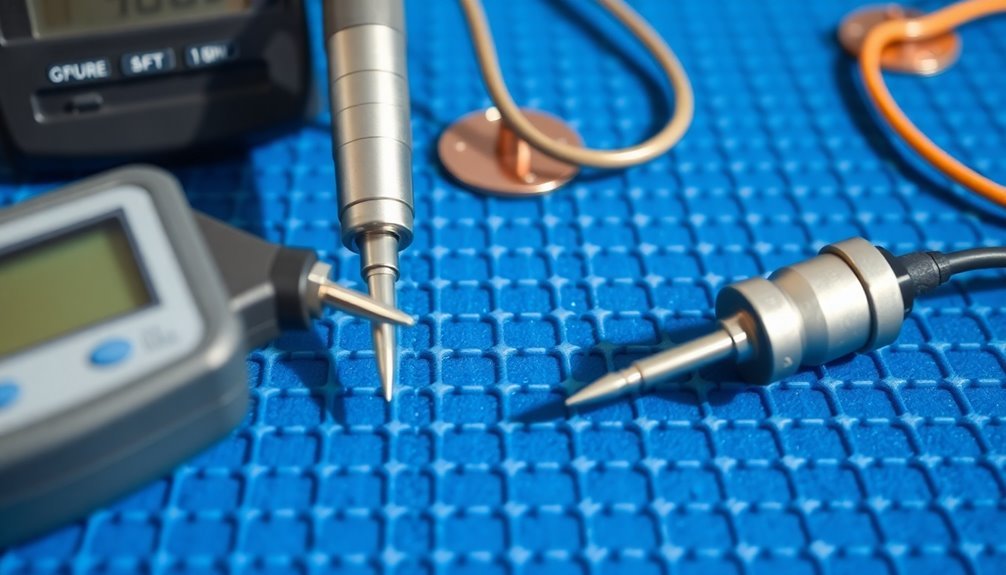

When you're working with ESD mats, you'll need to verify they meet the minimum resistance requirement of less than 1 x 10^5 ohms for conductive materials. The maximum resistance shouldn't exceed 1 x 10^9 ohms to maintain overall ESD control effectiveness. You'll start testing at 10 volts, but if the resistance reads higher than 1.0 x 10^6 ohms, you'll need to switch to 100 volts. Grounding cables with eyelets are essential for securing proper connections to electrical outlets. Regular testing is crucial as long-term electrical properties directly impact the mat's protective capabilities.

Your ESD mats might incorporate multiple layers, combining conductive and dissipative materials to achieve peak performance. You'll commonly encounter both rubber and vinyl options, each offering distinct properties.

To guarantee compliance with ANSI/ESD S20.20 standards, you must regularly test your mats using resistance-to-ground (RTG) and resistance top-to-top (RTT) measurements, documenting all results for verification purposes.

Static Dissipative Properties

A key characteristic of static dissipative materials is their surface resistance range of 1 x 10^5 to 1 x 10^11 ohms/square. This specific range allows these materials to effectively slow down the flow of static charge, safely neutralizing static electricity as it moves into the grounded mat. Static dissipative mats come in both tabletop and floor varieties to suit different workplace needs. Controlled charge transfer through these mats helps protect sensitive electronic components from ESD damage.

You'll find static dissipative mats available in different configurations, including single-layer, two-layer, and three-layer designs. While homogenous single-layer mats offer good mechanical performance, multi-layer options provide enhanced electrical properties through their conductive and dissipative layers.

If you're looking for added comfort, some multi-layer mats include foam layers for ergonomic benefits.

When selecting a static dissipative mat, you'll need to ascertain it meets ANSI ESD-S20.20 standards and maintains a resistance of less than 10^9 ohms for proper ESD protection. You can choose between vinyl and rubber materials, with rubber offering superior heat and chemical resistance, while vinyl provides a more cost-effective solution.

Remember that proper grounding is essential for effective static dissipation, regardless of the material you select. The mat's gradual charge bleed-off capability helps minimize the risk of rapid discharge that could damage sensitive components.

Essential Grounding Requirements

Before installing an ESD mat, you'll need to establish proper grounding requirements to confirm effective static discharge control. Your mat's resistance-to-ground (RTG) must measure less than 1.0 x 10^9 ohms when placed on an ESD floor, following ANSI/ESD S4.1-2006 standards.

Connect your mat directly to an electrical outlet using grounding cables, especially when dealing with insulative surfaces like carpets or painted floors. You'll want to guarantee all equipment and materials share the same electrical potential through a common point ground. Using a Metriso 3000 kit for testing ensures accurate resistance measurements. Regular cleaning is essential to maintain optimal conductive properties of the mat surface.

| Grounding Element | Requirement | Testing Method |

|---|---|---|

| RTG Value | < 1.0 x 10^9 ohms | RTG meter test |

| Ground Connection | Direct to outlet | Continuity check |

| Common Point | Single ground point | Visual inspection |

| Equipment Bond | All items connected | Resistance meter |

| Regular Testing | Monthly checks | RTG verification |

Don't forget to install conductive snaps on your mat to create a dedicated path for static dissipation. You'll need to regularly test your grounding system's effectiveness and address any issues promptly. If you experience static events, check your grounding cord's integrity and connection points immediately. Consider using ESD control flooring systems with ESD footwear for a thorough grounding solution.

Frequently Asked Questions

How Often Should ESD Mats Be Cleaned to Maintain Proper Resistance Levels?

You should clean your ESD mats daily in high-traffic areas and weekly in less-used spaces. Don't forget to use ESD-safe cleaners and test resistance levels afterward to maintain proper performance.

Can Environmental Factors Like Humidity Affect ESD Mat Resistance Measurements?

Yes, humidity greatly affects your ESD mat's resistance measurements. You'll notice higher resistance in low humidity and lower resistance in high humidity. It's important you test mats in controlled environmental conditions.

What Causes ESD Mats to Lose Their Protective Properties Over Time?

Your ESD mat's protective properties deteriorate due to contaminants like oils and flux residues, UV exposure, improper cleaning methods, physical wear, and environmental factors that affect the mat's conductive materials over time.

Are There Specific Cleaning Solutions That Won't Damage ESD Mat Surfaces?

You'll want to use specialized ESD mat cleaners that are non-alcohol based and biodegradable. These solutions are designed to maintain anti-static properties while safely cleaning your mat without leaving harmful residues.

How Do Temperature Changes Impact the Resistance Readings of ESD Mats?

You'll notice minimal resistance changes in your ESD mats under normal temperatures. However, extreme heat can affect rubber mats less than vinyl ones, which might show inconsistent readings when exposed to high temperatures.

In Summary

You'll need to understand these three key ESD mat resistance standards to properly protect your sensitive electronics. Remember to check your mat's conductive range, verify its static dissipative properties, and maintain proper grounding connections. Don't skip these essential requirements – they're vital for preventing costly damage from electrostatic discharge. By following these standards, you're ensuring best ESD protection in your workspace.

Leave a Reply