To choose the right ESD garments for cleanroom work, you'll need to match your protective clothing to your facility's ISO class requirements and specific tasks. Your garments must provide complete body coverage with static-dissipative properties and meet standards like ANSI/ESD S20.20 and IEC 61340. Look for non-linting materials with sealed zip fasteners and elasticated openings at cuffs and ankles. Don't forget proper grounding capabilities and a comfortable fit that won't restrict movement. Regular testing and maintenance of your garments will guarantee continued protection. Understanding the full scope of ESD protection can help you make even better choices for your cleanroom needs.

Understanding ESD Garment Standards

Cleanroom safety standards form the backbone of effective ESD garment protocols in controlled environments. When you're selecting ESD garments for your cleanroom operations, you'll need to verify they comply with key standards like ANSI/ESD S20.20 and IEST-RP-CC052. These standards define the essential properties your garments must possess to maintain a controlled environment.

Your ESD garments must demonstrate specific static-dissipative properties to prevent the buildup of static electricity. The risk of contamination increases significantly when static-generating clothing is worn in cleanroom environments. They'll need proper grounding of conductive components, which is vital for maintaining their protective performance.

The garments you choose should also minimize electrostatic attraction of particles, preventing contamination that could compromise your cleanroom's integrity.

To verify compliance, you'll need to conduct various tests on your ESD garments. These evaluations verify the fabric meets requirements for high density, tear resistance, and electrical continuity.

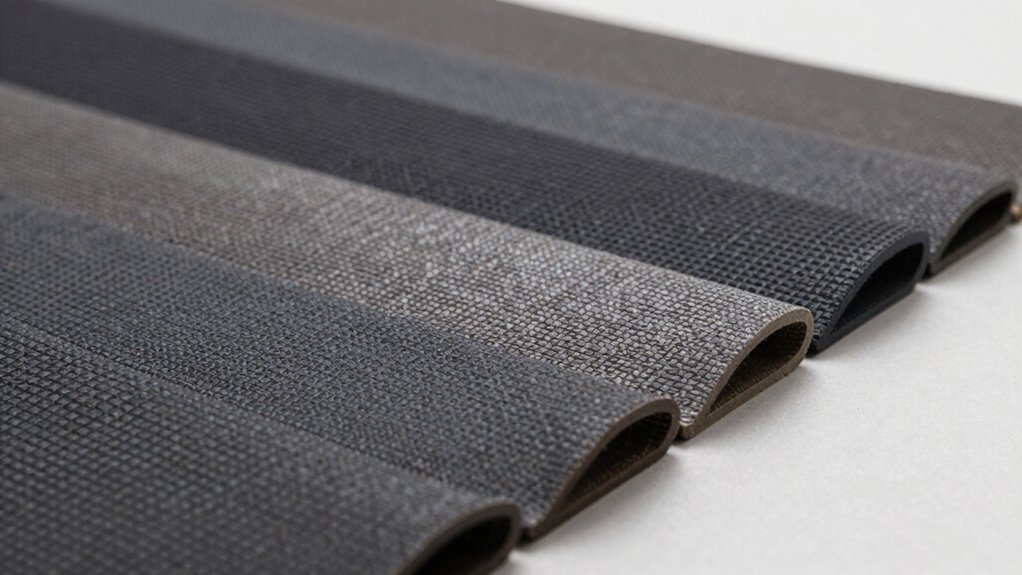

Look for garments with a dense grid of conductive threads, as they provide superior electrostatic shielding. The fabric should also be non-linting to prevent particle shedding that could contaminate your workspace.

Essential Features of Protective Clothing

The essential features of protective ESD garments combine both static dissipative properties and cleanroom-appropriate design elements.

When selecting your cleanroom ESD clothing, look for garments that offer complete body coverage with sealed zip fastening fronts and elasticated openings at the cuffs and ankles.

You'll want to avoid designs with pockets, pleats, or hook-and-pile fasteners, as these can trap contaminants. Instead, choose garments made with spun-bonded non-woven polypropylene laminated with polyethylene film for maximum protection against fine particles and sprays. Regular maintenance and proper washing guidelines must be followed to maintain the garments' effectiveness.

You should verify that your ESD garments work in conjunction with other grounding devices, such as ESD mats and wrist straps. The clothing must restrict any charges generated by your regular clothes to the inside of the garment.

For the best protection, select garments that meet IEST-RP-CC003.4 standards and match the specific requirements of your cleanroom class and task duration.

These garments are made from specialized materials like texturized polyester and carbon nylon fibers that create a Faraday cage effect, effectively dissipating static charges while protecting sensitive electronics.

Selecting Proper Cleanroom Attire

Properly selecting cleanroom attire requires careful consideration of multiple factors, from the ISO class requirements to specific industry standards. You'll need to match your garment choices to your cleanroom's classification level, with higher classes demanding more thorough coverage and frequent changes.

For ISO 8 environments, you'll require basic protection including a bouffant cap, frock or lab coat, shoe covers, face mask, and gloves.

As you move to stricter environments like ISO 5, you'll need to add items like hoods, full coveralls, and boot covers, with daily garment changes becoming mandatory. Proper gowning protocols must be strictly followed during both donning and doffing to maintain cleanliness standards.

If you're working in electronics assembly, make certain your garments provide ESD protection through conductive or static dissipative materials.

Consider the material's properties carefully – it must be non-shedding and low-linting to minimize particle generation. Your garments should fit well without restricting movement, as poor fit can compromise effectiveness and comfort during extended wear.

Don't forget to factor in your industry's specific requirements; pharmaceutical manufacturing typically demands ISO 5 conditions with complete body coverage, while industrial manufacturing often operates at ISO 6-8 levels.

Testing and Certification Requirements

Once you've selected appropriate cleanroom garments, testing and certification protocols must be followed to verify their ESD protection capabilities. You'll need to confirm your garments meet standards like IEC 61340-4-9:2016 and ANSI/ESD STM2.1:2018, which require specific resistance levels below 1.0 x 10^11 ohms.

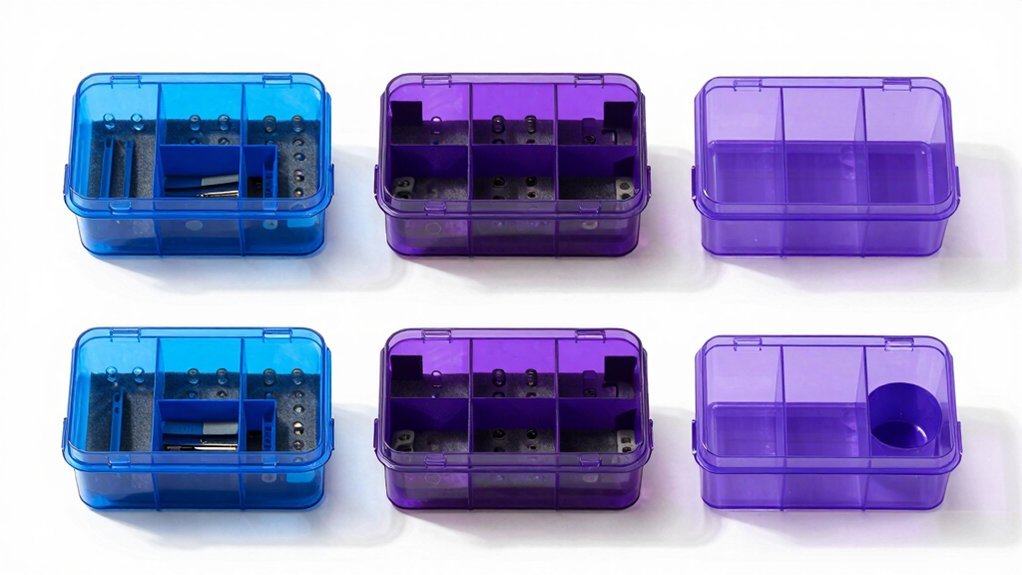

Regular point-to-point testing and surface resistivity measurements are essential to maintain compliance. You should use calibrated test kits to perform sleeve-to-sleeve and panel-to-panel resistance checks. Testing should be conducted with garments laid on an insulative surface with electrodes.

Don't forget to document all test results to track garment performance over time.

If you're using reusable ESD garments, you'll need to audit your laundry service providers to verify they're maintaining proper washing parameters. Wash temperatures shouldn't exceed 40°C to preserve the garments' ESD properties.

Your suppliers must provide certificates of conformity that detail test procedures and results.

Additional testing requirements include particle containment tests and microbial penetration evaluations for cleanroom compatibility.

You'll want to establish a regular testing schedule based on manufacturer recommendations and usage patterns to confirm your ESD garments remain effective throughout their expected lifecycle.

Common ESD Garment Types

When selecting ESD protection for cleanroom work, you'll need to choose between full-coverage coveralls and more flexible lab coats based on your facility's requirements.

Lab coats offer greater mobility and comfort for less stringent environments, while coveralls provide thorough protection against particle contamination and static discharge in critical areas. These garments must be made with conductive fabric blends to ensure proper static dissipation throughout the material.

Your ESD garment choice must also include appropriate footwear, such as ESD shoes or boot covers that maintain a continuous path to ground while meeting cleanliness standards.

Lab Coats vs. Coveralls

The choice between lab coats and coveralls in ESD-protected environments comes down to the level of protection needed and specific cleanroom requirements.

Lab coats provide adequate protection for ISO 5-6 cleanrooms while offering comfort and breathability with features like snap fastening and breast pockets. The carbon fiber content in these garments ranges from 1-2% to ensure proper static dissipation. Coveralls, on the other hand, deliver full-body protection and are essential for ISO 1-4 cleanrooms where stringent contamination control is critical.

When deciding between these garments, consider these key differences:

- Coverage Area: Lab coats protect primarily the upper body and arms, while coveralls provide thorough protection from head to ankle.

- Application: Lab coats suit less restrictive environments like standard laboratories, while coveralls are necessary for high-risk areas requiring superior contamination control.

- Material Options: Lab coats often use polyester-cotton blends with conductive fibers, whereas coveralls typically utilize specialized materials like Tyvek for liquid resistance.

- Standards Compliance: Lab coats meet IEC 61340-5-1 standards for basic ESD protection, while coveralls often comply with additional standards like EN 14126 for infectious agents and EN 1073-2 for radioactive particles.

Both options incorporate ESD protection, but your choice should align with your facility's specific requirements and contamination control needs.

Specialized ESD Footwear Options

From workstations to testing areas, specialized ESD footwear serves as a critical line of defense against static discharge in cleanroom environments.

When selecting ESD footwear, you'll find various options designed to meet specific workplace requirements while guaranteeing both protection and comfort. Available in half and full sizes, these shoes accommodate a wide range of fits for both men and women.

You can choose between shoes and clogs, with many models featuring 2 MegOhm resistors for enhanced static protection. Look for footwear that complies with ASTM F2413-11 and ANSI/ESD S20.20-2014 standards to guarantee reliable static dissipation. Brands like Nautilus and Estashoe offer options that combine safety features with ergonomic design.

Your ESD footwear should include conductive materials, often paired with rubber or EVA components for durability and comfort.

You'll want to evaluate features like slip-resistance, oil-resistance, and built-in ventilation systems to maintain comfort during long shifts.

The best options will offer water-repellent and odor-resistant properties for easy maintenance.

When assessing cost-effectiveness, factor in the footwear's durability and maintenance requirements.

While initial costs may vary, investing in quality ESD footwear can reduce long-term expenses through decreased replacement needs and better protection for sensitive electronics.

Maintenance and Care Guidelines

You'll need to follow strict washing procedures for your ESD garments, including using appropriate detergents and water temperatures as specified by the manufacturer's guidelines.

Store your cleanroom garments in dedicated, controlled environments away from potential contaminants and dust to maintain their protective properties.

Regular inspection of garments before and after washing helps guarantee they maintain their ESD effectiveness and structural integrity throughout their service life.

Cleanliness testing should be conducted periodically to verify your garments meet microbial and particulate cleanliness standards.

Proper Washing Procedures

Maintaining ESD garments requires strict adherence to proper washing procedures to preserve their protective qualities. You'll need to wash these specialized garments in cool or cold water, never exceeding 90°F, and use only non-ionic liquid detergents with a neutral pH level.

Don't use bleach or fabric softeners, as they'll damage the conductive components and interfere with the garment's performance.

When it comes to drying your ESD garments, hanging them to dry is your best option. If you must use a dryer, select the lowest heat setting and remove items promptly to prevent wrinkles. You should avoid ironing whenever possible, but if necessary, use the lowest temperature setting.

Follow these essential steps for superior results:

- Select a non-ionic liquid detergent free from enzymes, bleaches, or builders

- Wash in cold water (max 90°F) using a gentle cycle

- Avoid all fabric softeners and any type of bleach

- Hang dry or use low heat tumble dry, removing items immediately

If you're using a professional laundry service, verify they're familiar with cleanroom garment procedures and can follow manufacturer-specific guidelines for ESD clothing care.

Storage Best Practices

Proper storage of ESD garments plays a crucial role in extending their lifespan and maintaining their protective qualities. You'll need to keep your garments in a controlled environment, away from direct sunlight and extreme temperatures. Store them in ESD-safe containers or cabinets, and consider using desiccants to control moisture levels.

| Storage Factor | Impact | Prevention Measure |

|---|---|---|

| Humidity | Reduces effectiveness | Use climate control |

| Sunlight | Degrades material | Store in dark areas |

| Contamination | Compromises safety | Use sealed containers |

| Physical damage | Shortens lifespan | Handle with care |

When storing your ESD garments, make certain they're clean and completely dry to prevent contamination. You'll want to use breathable packaging materials to avoid moisture buildup while maintaining protection from environmental factors. Label all storage containers clearly with handling instructions and safety precautions for easy identification and proper use.

Remember to implement a tracking system for your stored garments. Keep detailed records of inspection dates, usage patterns, and replacement schedules. This documentation helps maintain accountability and confirms you're following industry standards for ESD garment maintenance and storage.

Risk Assessment and Safety Measures

The assessment of ESD risks in cleanrooms demands a thorough approach to safety and compliance. You'll need to evaluate multiple factors, from human-generated static to environmental conditions, as ESD can damage sensitive components with voltages as low as 30V.

Your facility must maintain proper humidity levels between 30-50% while maintaining strict particle count standards are met.

When conducting your risk assessment, focus on these critical areas:

- Monitor airborne particle levels in your cleanroom, making sure they don't exceed specified limits (e.g., 100 particles per cubic foot in Class 100 environments)

- Evaluate your ESD protection systems, including flooring, workstations, and ionization equipment

- Inspect staff compliance with gowning protocols and proper use of ESD protective gear

- Verify the effectiveness of your grounding equipment, including wrist straps and footwear

You'll need to implement regular maintenance schedules for all ESD control equipment and conduct frequent inspections of protective clothing to maintain compliance with standards like EN 1149-3.

Remember that contamination can come from various sources, so you must maintain vigilant monitoring of both human activities and environmental factors within your cleanroom.

Frequently Asked Questions

How Long Can ESD Garments Be Worn Before Requiring Replacement?

You'll need to replace your ESD garments based on manufacturer guidelines, wash cycles, and performance tests. Most should be switched after 50-100 washes or when they show wear, damage, or fail conductivity testing.

Can ESD Garments Be Worn Over Regular Clothing?

Yes, you can wear ESD garments over your regular clothing. They're specifically designed to suppress static charges from your everyday clothes while providing protection. Just make certain they're properly grounded for maximum effectiveness.

Are Different Sizes of ESD Garments Equally Effective in Static Control?

No, different sizes aren't equally effective. You'll need properly fitted ESD garments to guarantee consistent contact with your skin. Loose or oversized garments won't provide reliable static discharge due to inconsistent skin contact.

Do ESD Garments Lose Effectiveness in High Humidity Environments?

No, your ESD garments won't lose effectiveness in high humidity. In fact, they'll work better because moisture improves their dissipative properties. You'll get enhanced static control when humidity levels are higher.

Can ESD Garments Trigger Metal Detectors During Security Screening?

Yes, your ESD garments can trigger metal detectors since they're made with conductive materials like carbon fibers and metal components. It's best to inform security personnel beforehand that you're wearing ESD protective clothing.

In Summary

Choosing the right ESD garments isn't just about compliance – it's essential for product quality and workplace safety. You'll need to carefully evaluate your cleanroom requirements, understand certification standards, and select garments that meet both ESD and cleanliness specifications. Remember to maintain your protective clothing properly and regularly test its effectiveness. By following these guidelines, you're protecting both your products and your operations.

Leave a Reply