Seven essential workstation safety certification standards you'll need to master include ISO 45001 for occupational health management, COR certification for thorough safety systems, and SSIP for construction industry compliance. You'll also need to understand ESD protection standards (ANSI/ESD S20.20), proper grounding requirements, static control equipment specifications, and material handling certifications. These standards maintain your workspace meets international safety protocols, protects sensitive electronics, and upholds employee well-being. Each certification plays a vital role in creating a secure work environment, and there's much more to explore about implementing these standards effectively.

ESD Safety Basics

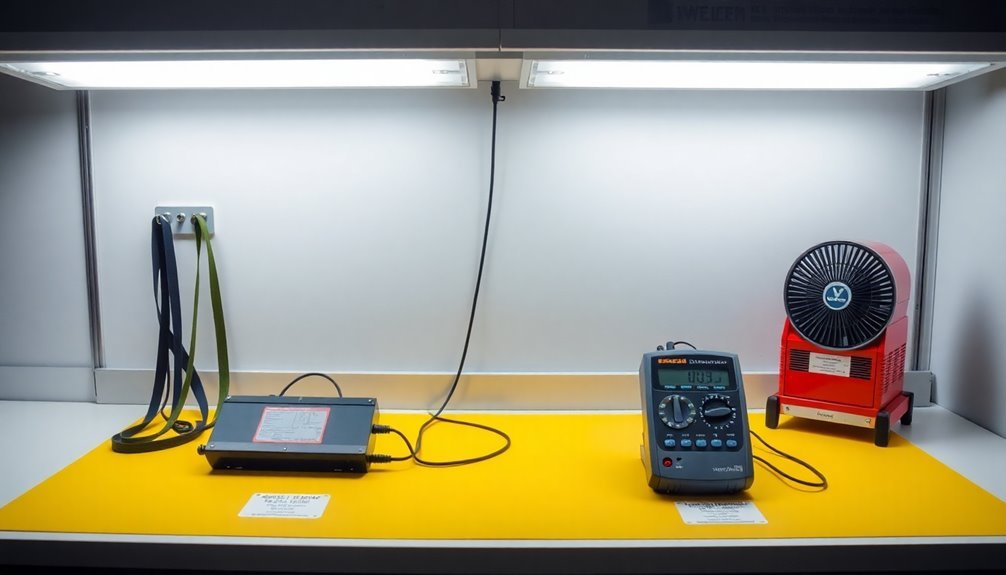

Three critical components form the foundation of ESD safety: protected areas, proper attire, and controlled handling procedures. You'll need to understand how these elements work together to maintain a safe workstation environment.

ESD Protected Areas (EPAs) serve as designated zones where you can safely handle sensitive electronic components, featuring conductive floors, workbenches, and specialized tools designed to control static electricity. Simple activities like walking on carpet can generate thousands of volts of static electricity.

Your attire plays a vital role in preventing ESD damage. You must wear antistatic garments and use proper grounding straps while working in EPAs. ESD-safe footwear completes your protective ensemble by helping dissipate static charges through the floor.

When handling components, you'll need to follow strict protocols, including using conductive packaging with protective foam layers and opening packages only at ESD-protected workstations.

To guarantee ongoing safety, you'll need to participate in regular compliance checks and testing procedures. This includes verifying ground connections and maintaining proper ESD control measures.

Keep an eye out for ESD symbols and signage that identify protected areas and remind you of essential safety protocols. Remember, every piece of equipment, from your chair to your tools, must meet ESD safety standards.

Grounding Requirements

Proper grounding forms the cornerstone of electrical safety and ESD protection in your workstation. You'll need to guarantee your grounding system connects to the main electrical system's ground through approved grounding electrode conductors.

Don't rely on a single ground electrode unless it tests below 25 ohms resistance to earth – it's safer to install at least two electrodes or use a grounding ring system. Installing drag chain connections for ESD chairs ensures consistent grounding when staff move around the workspace.

For your workstation setup, you must connect both worksurface and wrist-strap grounds to the nearby electrical power system ground. If you're operating equipment without AC power, you can ground it to a common bus rod mounted near your workstation.

Adding grounding mats provides an extra layer of ESD protection, offering both conductive and dissipative options for your specific needs.

You'll need to implement constant monitoring systems to detect any breaks or degradation in your grounding circuits immediately. Make sure you're testing these circuits regularly and maintaining proper documentation.

Static Control Equipment Standards

Industry-wide static control standards fall under the administration of EOS/ESD Association, Inc., which oversees ANSI/ESD S20.20 certification through ISO9000 accredited bodies. These standards protect sensitive electronic devices rated at 100v or less, while reducing costly downtime and component failures. Over 1,900 certified facilities worldwide demonstrate the growing commitment to proper ESD control implementation.

Your static control equipment must meet specific resistance requirements. Wrist strap systems can't exceed 3.5 x 10^7 ohms, and your groundable static control garment systems must maintain the same resistance level.

For footwear and flooring systems, you'll need to guarantee resistance stays below 1.0 x 10^9 ohms with peak voltage under 100 volts.

You must regularly test and verify your equipment using electrostatic field meters, ground testers, and high-range resistance meters. Your worksurfaces should maintain point-to-point and point-to-ground resistance below 1.0 x 10^9 ohms.

When it comes to packaging, you'll need conductive materials below 1.0 x 10^4 ohms and dissipative materials between 1.0 x 10^4 and 1.0 x 10^11 ohms. Document all resistance values to maintain compliance and qualification standards.

Personnel Safety Certification

Beyond equipment standards, personnel safety certification represents a cornerstone of workplace safety compliance. You'll need to meet specific requirements to become certified, including a bachelor's degree in a relevant field and four years of safety experience where safety duties make up at least 50% of your work responsibilities. Professional safety specialists who achieve certification typically earn a median base salary of $104,000 annually.

To maintain your certification, you'll need to complete annual renewals and meet recertification requirements while holding a BCSP Qualified Credential. The certification process culminates in passing the CSP examination, which validates your expertise in workplace safety management.

| Certification Level | Experience Required | Key Focus Areas |

|---|---|---|

| Safety Associate | Entry Level | OSHA Standards |

| Specialist | Mid-Level | Proactive Programs |

| Certified Official | Advanced | Regulation Implementation |

| Fundamentals | Basic | Hazard Identification |

Your certification journey should align with industry-specific requirements, whether you're in construction, general industry, or maritime safety. You'll need to stay current with ISO 45001 standards and SSIP requirements while developing expertise in hazard identification and control procedures. This thorough approach guarantees you're equipped to implement and maintain effective workplace safety programs.

Workstation Layout Specifications

Establishing precise workstation dimensions stands as a fundamental requirement for workplace safety compliance. You'll need to guarantee your workstations meet standard size requirements, typically ranging from 6' x 7' for standard layouts to smaller configurations of less than 6' x 6' for compact spaces.

Work surfaces must provide adequate leg room with a minimum depth of 600mm and clear leg space of 550mm deep by 600mm wide. Cable management trays keep power and data cables neatly concealed while maintaining a safe, organized workspace.

When setting up your workstation layout, focus on these critical measurements:

- Monitor positioning must maintain the screen top at or slightly below eye level, never exceeding a 15-degree downward angle.

- Keyboard placement should align with elbow height, creating a 90-degree angle between upper and lower arms.

- Transaction interaction spaces shouldn't exceed 610mm in depth between workers and clients.

You'll need to incorporate ergonomic accessories effectively within these dimensions. Mount monitor arms and task lighting on performance rails to maximize work surface space. Keep the workspace organized with document holders at monitor height and utilize Ubi work tools for storage.

Remember to maintain proper temperature (68-72°F) and humidity (30-50%) levels while guaranteeing adequate air circulation throughout the workstation area.

Testing and Monitoring Procedures

Professional workstation certification requires a thorough series of testing and monitoring procedures to maintain safety standards. You'll need to start by creating an online account and submitting your application, which BCSP's Certification Services Department will review.

Once approved, you'll purchase your exam and schedule it at a Pearson VUE testing center. You have one year of eligibility to take the exam after your application is approved.

On exam day, you must bring a valid government-issued ID with both your photo and signature. You'll find an on-screen calculator that mimics the TI-30XS scientific calculator for your use during the test. Remember, you can't bring personal belongings into the secure testing room, and the exam clock continues running during your self-scheduled breaks.

After completing your exam, you'll receive your results immediately. If you pass, BCSP will award your certification, but maintaining it requires ongoing commitment.

You'll need to pay an annual fee and earn recertification points every five years. This guarantees you're staying current with professional practice changes. The recertification process demonstrates your dedication to continuous learning and professional development in workstation safety standards.

Material Handling Guidelines

Safe material handling starts with a thorough risk assessment that identifies potential hazards in your workstation. You'll need to evaluate tasks carefully, considering both manual and mechanical handling risks while confirming all equipment receives proper maintenance. Every task should include emergency response protocols in case accidents occur during material handling operations.

Don't overlook the importance of clear pathways and secure storage to prevent accidents.

To maintain certification standards, you must implement these critical guidelines:

- Use appropriate mechanical aids like carts, hand trucks, and forklifts whenever possible, and confirm operators are thoroughly trained in their use and maintenance.

- Provide workers with proper PPE including gloves, safety glasses, and steel-toed boots, while enforcing their consistent use.

- Design tasks with ergonomics in mind, following NIOSH guidelines for maximum lifting weights and incorporating proper lifting techniques.

Remember to address ergonomic considerations by analyzing past injuries and implementing preventive measures. You'll need to regularly train your workers on proper lifting techniques, including bending at the knees and keeping loads close to the body.

Make sure you're consistently evaluating and updating your material handling procedures to maintain compliance with safety standards and prevent workplace injuries.

Environmental Control Standards

You'll need to meet strict air quality control requirements by monitoring and managing particulate matter, VOCs, and other airborne contaminants in your workstation area.

Connected gas detectors enable real-time monitoring of air quality conditions to ensure compliance with safety standards.

Your facility's temperature and humidity levels must stay within prescribed ranges to guarantee both worker comfort and proper equipment operation.

Proper lighting management calls for adequate illumination levels, minimizing glare, and incorporating both natural and artificial light sources to reduce eye strain and maintain worker alertness.

Air Quality Control Requirements

Maintaining proper air quality control stands as a vital component of workstation safety certification standards. You'll need to address various contaminants, including chemicals, gases, vapors, and biological agents that can impact workplace health.

By implementing thorough control measures like ventilation, filtration, and microbe management, you're protecting your employees from respiratory issues, headaches, and other health concerns.

To meet certification requirements, you must focus on these essential elements:

- Guarantee effective ventilation systems that promote adequate air exchange and prevent stagnation, following WELL Standard and ASHRAE guidelines.

- Install and maintain proper filtration systems to remove airborne pollutants, particularly focusing on particulate matter and VOCs.

- Implement regular monitoring and maintenance procedures to track air quality metrics and address issues promptly.

You'll need to conduct systematic inspections, respond to complaints quickly, and maintain thorough documentation of your air quality control measures. Training your staff on best practices and keeping up with evolving regulations is essential.

Remember to regularly update your air quality management strategies based on new standards from organizations like EPA and ASHRAE to maintain compliance and guarantee workplace safety.

Temperature and Humidity Standards

Proper temperature and humidity control forms the backbone of workplace environmental safety standards. You'll need to maintain temperatures between 68-76°F for general workspaces, while data centers require a broader range of 64-81°F. For humidity, you must keep levels between 20-60% in most workplace settings, though specialized environments may need stricter controls.

| Environment Type | Temperature Range | Humidity Range |

|---|---|---|

| General Workplace | 68-76°F | 20-60% RH |

| Data Centers | 64-81°F | 20-80% RH |

| Low Corrosion Areas | 64-69.8°F | Below 50% RH |

| Cleanrooms | Environment-specific | Environment-specific |

You're responsible for implementing regular monitoring systems and maintaining proper HVAC functionality to meet these standards. If you're managing specialized environments like cleanrooms or laboratories, you'll need to follow more stringent controls and guarantee continuous monitoring. Don't forget to document all environmental readings and corrective actions – it's vital for compliance. Remember that these standards aren't just guidelines; they're essential for protecting your workforce and maintaining product quality in specialized environments like data centers and manufacturing facilities.

Proper Lighting Management

Effective lighting management stands at the forefront of workplace safety and productivity standards. Your workspace must meet OSHA's minimum lighting requirements, which specify foot-candle measurements for different areas. For general construction, you'll need at least 5 foot-candles, while first aid stations require 30 foot-candles of illumination.

To guarantee your workstation meets certification standards, you'll need to implement these essential lighting controls:

- Install fully shielded fixtures for lamps exceeding 2,000 lumens and direct light only where it's needed to prevent unnecessary glare and light trespass.

- Use warm-colored lighting when possible, and don't exceed brightness requirements – remember that brighter isn't always better.

- Incorporate automatic controls like timers and motion sensors to manage light usage efficiently and reduce energy waste.

You'll need to regularly inspect your lighting systems and maintain proper documentation through a Lighting Management Plan.

If you're working in temporary or mobile conditions, consider using vehicle-mounted lights or portable light towers instead of permanent fixtures.

Remember that proper lighting isn't just about brightness – it's about creating a safe, efficient workspace that protects both workers and the environment.

Documentation and Record Keeping

Thorough documentation forms the backbone of any workstation safety certification program. You'll need to maintain clear, accessible records of all safety procedures, policies, and training sessions to meet certification requirements.

Guarantee your documentation includes detailed protocols for emergency situations, specific roles and responsibilities, and step-by-step procedures using clear, concise language.

You must establish robust record-keeping protocols for tracking incidents, near-misses, and training certifications. Store these records securely while maintaining confidentiality, and implement a regular schedule for reviewing and updating them.

Don't forget to include visual aids like diagrams and charts when they'll help clarify procedures.

Your documentation system should incorporate version control with clear dates and updates. You're required to conduct regular audits to verify that all safety documentation remains consistent with current standards and regulations.

When you perform these audits, involve key stakeholders and maintain records of the review process and any subsequent changes. Remember to keep all documentation easily accessible to employees while guaranteeing it complies with legal and industry requirements.

Update your records promptly when safety protocols change or new procedures are implemented.

Frequently Asked Questions

How Often Should Ergonomic Training Be Renewed for Workstation Safety Certification?

You should renew your ergonomic training annually, but also whenever there are workplace changes or new equipment. For high-risk industries, you'll need more frequent updates. Don't forget to retrain after significant workspace modifications.

Are Remote Workstations Subject to the Same Certification Requirements?

Yes, your remote workstations must meet identical certification requirements, with additional security protocols for digital certificates, trusted CA validation, and SSL/TLS encryption to guarantee secure remote connections and protect confidential data.

What Penalties Exist for Non-Compliance With Workstation Safety Certification Standards?

You'll face serious consequences for non-compliance, including fines up to $1.5 million for corporations, personal fines up to $100,000, and possible jail time. Repeat violations bring higher penalties and stop-work orders.

Can Temporary Workstations Receive Safety Certification?

Yes, you can get safety certification for temporary workstations. You'll need to complete risk assessments, provide proper training, maintain documentation, and guarantee compliance with OSHA regulations and relevant ISO standards.

Do International Workstation Safety Certifications Transfer Between Different Countries?

Yes, you'll find that major certifications like ISO 45001 transfer between countries. However, you'll need to check local regulations, as some nations may require additional compliance or adaptations to their specific standards.

In Summary

You're now equipped with the essential knowledge of workstation safety certification standards. By implementing proper ESD controls, grounding protocols, and safety measures while maintaining thorough documentation, you'll create a safer workplace that meets industry requirements. Don't forget to regularly test your equipment, train your personnel, and monitor environmental conditions. Stay compliant and keep your workstation running smoothly and safely.

Leave a Reply