To effectively protect your workbench, you'll need five essential monitoring tools. Start with a real-time ESD monitoring system that provides instant alerts for static discharge events. Add surface testing equipment like optical microscopes or tape tests to check for contamination. Install personnel grounding verification tools, including wrist strap and footwear testers, at workstation entry points. Incorporate environmental sensors to track temperature, humidity, and dew points that could affect your work. Finally, implement a secure data logging system to maintain compliance records and track historical trends. Understanding these tools' complete capabilities will maximize your workbench protection strategy.

Real-Time ESD Monitoring Systems

Real-time ESD monitoring systems serve as essential safeguards in protecting workbench environments from electrostatic discharge threats.

You'll find these systems equipped with both visual and audible alarms that instantly alert you to any fault detection or threshold breaches. The continuous monitoring eliminates your need for time-consuming periodic testing and manual logging.

You can choose between dual-wire and single-wire monitors based on your specific needs. Dual-wire monitors are your best choice for critical applications, as they observe resistance throughout the entire loop between wires, personnel, and wristbands.

Single-wire monitors work effectively with standard wrist straps and coil cords, focusing on impedance measurements. Models like the HS-CWSM-01 series provide comprehensive monitoring solutions for various industry requirements.

You'll find these systems are easy to install on or under your workbench using simple components like C-clamps or L-brackets. They're built tough for industrial environments and seamlessly integrate with existing ESD control systems.

The monitors can detect even split-second failures, such as over-flexed coil cords, and provide you with thorough historic data logging. This data helps you analyze performance and make informed decisions about your static control strategies.

Workbench Surface Testing Equipment

While ESD monitoring systems protect against electrical threats, maintaining clean workbench surfaces requires specialized testing equipment. You'll need various tools to guarantee your workbench meets cleanliness standards and remains contamination-free. Calibration in a controlled environment prevents potential safety risks and contamination issues.

Contact angle measurement devices and gravimetric analysis tools will help you assess surface wettability and contaminant mass. For visible inspection, you can use optical microscopes to examine surfaces closely, while tape tests offer a quick way to check for dust and particles.

If you're concerned about hydrophobic contamination, atomizer tests are essential additions to your testing arsenal.

You'll want to choose your testing equipment based on your specific industry requirements. If you're working in cleanrooms or pharmaceutical facilities, you'll need high-sensitivity tools that comply with strict regulatory standards. For production facilities, simpler methods like tape tests might suffice.

Consider the type of surface you're testing and the level of precision you need.

The right testing equipment will improve your quality control, reduce contamination risks, and help you maintain compliance with industry standards. Make certain your chosen tools are easy to operate and provide clear, interpretable results while staying within your budget constraints.

Personnel Grounding Verification Tools

Personnel grounding verification tools serve as your first line of defense against ESD damage in the workplace. You'll need to test your wrist straps and footwear daily before handling sensitive devices, as these grounding devices have limited lifespans and require regular verification. Visual inspections alone cannot detect potential failures, making daily testing essential for workplace safety.

Whether you choose standalone wrist strap testers or combined units that check both wrist straps and footwear, confirming proper functionality is essential for ESD protection.

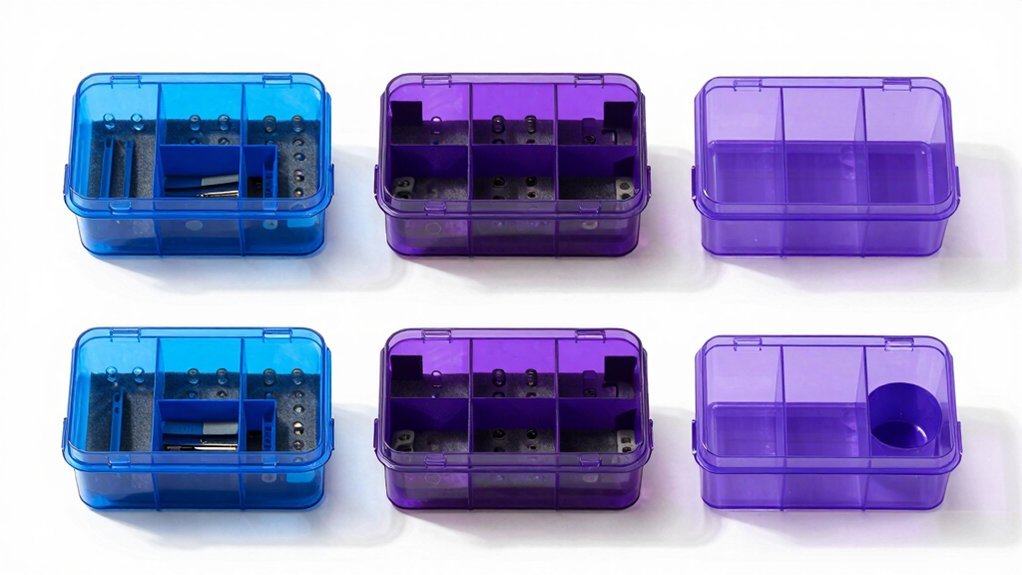

Modern testers come in various formats to suit your specific needs:

- Portable testers for supervisors conducting spot-checks or small lab environments

- Wall-mountable units providing convenient access at workstation entry points

- Split footplate systems allowing simultaneous testing of both feet

- Data acquisition testers that automatically log results and operator information

When using these tools, you'll need to follow proper testing procedures. If you're wearing foot grounders, test each one independently while worn. Should you receive a fail result, stop work immediately and check both the foot grounder and contact strip separately.

Remember to maintain detailed test records for quality control purposes, and confirm your testing equipment undergoes regular calibration to guarantee accurate readings.

Environmental Condition Measurement Devices

Beyond personal grounding measures, maintaining proper environmental conditions plays a key role in protecting sensitive electronic components. You'll need several measurement devices to monitor and control your workspace environment effectively. Key tools include dew point meters to prevent moisture-related issues, humidity sensors to track relative humidity levels, and temperature sensors to maintain optimal working conditions.

Modern environmental monitoring devices offer multi-parameter measurement capabilities and real-time data logging, allowing you to track conditions over time. These devices can store up to 10,000 datasets of environmental readings for comprehensive analysis. Many units can send alerts when environmental parameters exceed preset thresholds, helping you prevent damage to sensitive components before it occurs.

| Monitor Type | Critical Function | Protection Benefit |

|---|---|---|

| Dew Point Meter | Moisture Formation Prevention | Prevents Corrosion |

| Temperature Sensor | Heat Level Control | Prevents Thermal Damage |

| Humidity Monitor | Moisture Level Control | Prevents Static Build-up |

These tools comply with international standards like ISO 8502-4 and ASTM D3276, guaranteeing reliable measurements. By implementing thorough environmental monitoring, you'll extend equipment lifespan, reduce energy consumption, and maintain favorable working conditions for sensitive electronic components. The investment in these devices ultimately safeguards your infrastructure and prevents costly downtime.

Data Logging Security Solutions

Modern data logging security demands robust solutions that safeguard sensitive workbench information. These solutions provide thorough protection through integrated platforms that combine advanced query capabilities with secure data management. The systems support multi-stage analytics for comprehensive security assessments.

These systems let you analyze logs using natural language prompts while maintaining strict security protocols and compliance standards.

Your workbench security can be enhanced through collaborative features that enable team-wide visibility while restricting access to sensitive data. The platforms support two-factor authentication and guarantee compliance with data use agreements, protecting your valuable information from unauthorized access.

- Cross-domain analysis tools allow you to investigate patterns and vulnerabilities across multiple data sources without compromising security.

- Forensic analysis capabilities help you proactively identify potential threats through historical log examination.

- Secure API integrations connect your workbench with essential security tools while maintaining data integrity.

- Collaborative workspaces enable team sharing while enforcing access controls and preventing unauthorized data linkage.

When implementing these solutions, you'll benefit from advanced visualization tools that help track security metrics in real-time. The platforms support external data integration while maintaining strict controls on personally identifiable information, guaranteeing your workbench remains both functional and secure.

Frequently Asked Questions

How Often Should Security Monitoring Tools Be Updated for Optimal Performance?

You'll need to update security monitoring tools weekly for basic maintenance, monthly for extensive updates, and immediately for critical patches. Don't forget to run vulnerability scans monthly and review policies quarterly.

Can Multiple Workbench Monitoring Systems Be Integrated Into One Dashboard?

Yes, you can integrate multiple workbench monitoring systems into one dashboard using platforms like Automated Logic's MSI or through standard protocols. You'll get centralized control and improved efficiency for your monitoring needs.

What Backup Protocols Are Recommended if Monitoring Systems Fail?

If your monitoring systems fail, you'll need to implement manual checks, activate redundant monitoring tools, and follow your 3-2-1 backup strategy. Don't forget to enable automated alerts and immutable backups.

How Do Different Monitoring Tools Communicate With Each Other During Alerts?

You'll find monitoring tools communicate through notification channels, webhooks, and APIs. They'll share alerts via HTTP endpoints, integrate directly with other systems, and use unified dashboards to aggregate information effectively.

What Training Requirements Exist for Staff Using Advanced Monitoring Systems?

You'll need thorough technical training, including online modules, hands-on labs, and instructor-led courses. You must maintain certification through ongoing education and comply with industry standards for advanced monitoring systems.

In Summary

You'll gain peace of mind knowing your workbench protection system has these five essential monitoring tools in place. By integrating real-time ESD tracking, surface testing, personnel grounding checks, environmental measurements, and secure data logging, you're creating a thorough safety net for sensitive components. Don't wait for equipment failure – implement these tools now to protect your valuable work and maintain quality standards.

Leave a Reply