You'll find four main types of tools to measure surface discharge values accurately in the field. Radar-based devices like the Geolux RSS-2-300WL can take contactless measurements up to 30 meters away, while electromagnetic meters such as the OTT MF Pro excel in low-flow conditions. Mechanical flow meters, including the OTT C31, provide reliable velocity readings from 0.025 to 10 m/s. For thorough monitoring, sensor-based systems like the OTT CTD combine multiple measurements including water level, temperature, and conductivity. The right choice depends on your specific environmental conditions and measurement needs.

Surface Contact Discharge Tools

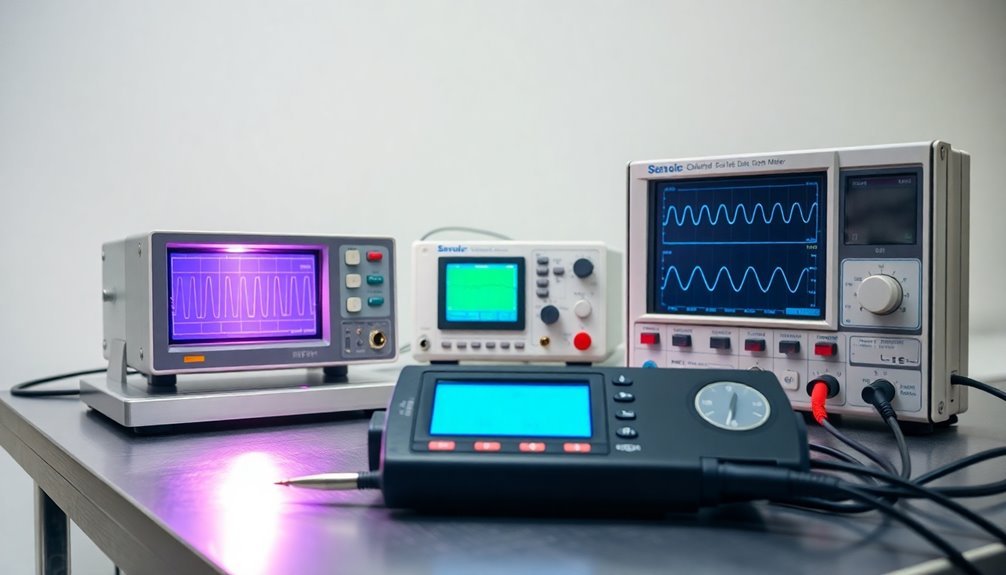

Precision in surface discharge measurement relies on four main categories of contact tools: radar-based, electromagnetic, mechanical, and sensor-based instruments.

You'll find the Geolux RSS-2-300WL among the most advanced radar-based options, offering contactless measurements up to 30 meters with a speed range of 0.02 to 15 m/s. The system operates efficiently in extreme conditions with an operating temperature range from -40°C to +85°C.

For electromagnetic measurements, you can use the OTT MF Pro, which excels in low flow and turbulent conditions, delivering accuracy within ±2% for velocities up to 3 m/s.

When you need mechanical measurements, the OTT C31 universal current meter provides reliable flow velocity readings from 0.025 to 10 m/s, making it ideal for rivers and open waterways.

You'll appreciate its versatility with wading rods, bridges, and cable-way installations.

For sensor-based measurements, you've got options like the OTT CTD, which combines water level, temperature, and conductivity monitoring in one unit.

These tools often include integrated dataloggers and various interface options like RS-232 and RS-485 Modbus.

When selecting your tool, you'll need to take into account critical specifications like detection distance, speed range, and level resolution to guarantee accurate discharge measurements for your specific application.

Field Strength Measurement Equipment

Along with surface discharge tools, field strength measurement equipment forms an essential component of extensive testing systems. You'll need two primary tools: field strength meters and RF field probes. These devices work together to measure electric field strength emanating from transmitters and guarantee accurate radiation immunity testing.

When you're working with field strength meters, you'll find they combine a receiver with a calibrated antenna, measuring frequencies from 10 Hz to 60 GHz and field strengths from 0.1 V/m to 1000 V/m. The RF field probes you'll use feature dipole antennas and can measure fields in multiple dimensions (X, Y, Z). Modern probes like the HI-6153 laser-powered probe enhance measurement precision significantly.

| Equipment Type | Key Features | Testing Applications |

|---|---|---|

| Field Meters | 10 Hz – 60 GHz range | GTEM testing |

| RF Probes | Multi-dimensional | Anechoic chambers |

| Calibration Tools | Precision control | Standard compliance |

| Data Indicators | Quality assurance | EMC verification |

| Commercial Models | Brand-specific specs | Industry-specific use |

You'll need to guarantee proper calibration before each use and consider environmental conditions when selecting your equipment. For compliance with standards like IEC 61000-4-3, choose instruments that match your specific testing requirements and site parameters.

Digital Resistance Testing Methods

You'll need to understand two main types of conductivity probes for accurate surface discharge testing: contact-style probes for direct measurements and non-contact probes for sensitive surfaces.

For optimal resistance readings, 4-wire configuration methods should be implemented when measuring values below 100 kΩ.

When calibrating your digital resistance meter, it's crucial to use certified reference standards that match your expected measurement range and follow the manufacturer's specified temperature compensation procedures.

Proper meter calibration directly impacts your testing accuracy, so you should verify calibration before each testing session and maintain detailed calibration records.

Modern Conductivity Probe Types

Digital resistance testing has evolved to include four primary types of conductivity probes, each designed for specific measurement needs.

You'll find conductive probes as the most straightforward option, using two electrodes to measure current flow through solutions. They're ideal when you need real-time monitoring of water, acid, or salt solutions without damaging the sample. The measurement process uses constant current flow between electrodes to determine conductivity levels.

If you're working in a laboratory setting requiring high precision, you'll want to take into account resonant conductivity probes. These utilize capacitance and inductance principles to form resonant circuits, delivering the sensitivity needed for research-grade measurements.

For continuous monitoring in industrial settings, you'll benefit from inductive or contactless probes. They don't require direct contact with the solution, making them perfect for food processing, water treatment, and chemical applications. The toroidal design guarantees reliable measurements without probe contamination.

When you're conducting field measurements, submersible conductivity probes are your best choice. These rugged instruments are designed for direct immersion in outdoor environments, offering corrosion resistance and durability for environmental monitoring and water quality analysis. You can rely on them for extended periods of underwater testing.

Meter Calibration Best Practices

Calibration accuracy forms the backbone of reliable digital resistance testing. You'll need to choose between 2-wire and 4-wire configurations based on your resistance range. For measurements above 100 kΩ, use 2-wire setups, while 4-wire configurations deliver better precision for values below 100 kΩ. Regular calibration intervals are essential to maintain measurement integrity throughout the year.

| Method | Best Use Case | Key Consideration |

|---|---|---|

| 2-Wire | High resistance >100 kΩ | Simple setup, minimal cabling |

| 4-Wire | Low resistance <100 kO | Higher precision, more complex |

| Offset Compensated | All ranges | Eliminates thermal EMFs |

| Shielded Setup | High resistance testing | Prevents noise interference |

You'll need to account for cable resistance and electrostatic interference in your measurements. For high-resistance testing above 10 MΩ, consider Johnson noise's impact on your readings. Remember to implement proper shielding, especially when measuring resistances exceeding 100 kΩ. When you're setting up your measurement system, pay attention to bandwidth settings – narrower bandwidths reduce noise but slow down measurement speed. Use offset nulling techniques to eliminate zero drift and improve measurement accuracy by subtracting baseline readings from your samples.

Static Decay Analysis Instruments

Testing static decay requires specialized instruments designed to measure how quickly electrostatic charges dissipate from materials and products.

You'll find these instruments equipped with three main components: a control unit, test fixture, and environmental chamber. The analyzers can measure charge voltages up to ±5KV with decay time resolution of 0.01 seconds. The device runs on a 220V power supply that enables continuous testing operations.

You can choose between two primary models: the Model 4406, which complies with standards like MIL STD 3010 and ANSI/ESD S541, or the T402 Model featuring a separation structure for enhanced stability.

Both offer automatic and manual testing modes, letting you adapt to different testing requirements.

When you're using these instruments, you'll benefit from real-time display and analysis software that stores your test data.

The environmental chamber allows you to test materials under controlled temperature and humidity conditions, guaranteeing accurate results.

You can test various shapes and sizes of materials non-destructively, making these tools versatile for multiple applications including electronics packaging, clean rooms, and hospital environments.

The instruments' patented sensor technology and Faraday cage isolation assure you'll get precise measurements every time.

Ground Path Verification Systems

When you're installing ground path verification systems, you'll need to strategically position sensors at critical contact points while maintaining proper spacing between calibration reference markers.

You can enhance your monitoring accuracy by establishing multiple fixed calibration points that serve as baselines for resistance measurements and system validation. Bond-Rite systems use high intensity LEDs to provide visual confirmation of proper grounding connections.

Your mobile tracking methods should incorporate both portable verification units and fixed monitoring stations to guarantee extensive coverage across different operational zones.

Sensor Placement and Layout

Ground path verification starts with strategic sensor placement to maintain safety in hazardous environments. You'll need to guarantee your sensors monitor both the clamp and ground cable paths continuously, verifying resistance stays below critical thresholds like 10Ω. These systems won't just measure – they'll actively protect your operation by shutting down equipment if ground connections fail. The Civacon 8030 system provides reliable ground verification monitoring for modern transport vehicles.

For ideal sensor placement and layout, follow these essential steps:

- Position monitoring sensors at key connection points where they can verify the integrity of your ground path and detect any resistance fluctuations.

- Install visual indicators (like LED displays) in easily visible locations so operators can quickly confirm ground status.

- Connect interlock circuits to your filling equipment, guaranteeing automatic shutdown if ground verification fails.

- Place sensors in environmentally sealed enclosures to protect against harsh conditions.

You'll find systems like the STS300 and Dixon A240 Series offer user-friendly terminal blocks for straightforward installation.

When you're working with hazardous materials, these intrinsically safe monitoring circuits provide essential protection through continuous resistance monitoring and immediate response to ground connection issues.

Calibration Reference Points

After establishing proper sensor placement, your ground path verification system needs accurate calibration reference points to function reliably.

You'll need to understand that calibration determines the relationship between measured and true values, guaranteeing your instruments provide consistent, dependable data for water quality and quantity assessments.

You'll want to use multiparameter instruments and radar flow meters as your primary tools, making sure they're regularly calibrated to maintain accuracy. Your goal should be to achieve measurements within 10% of true discharge values, following USGS standards.

You can develop stage-discharge rating curves, but you'll need to validate them against direct measurements.

When you're setting up calibration protocols, consider factors that can affect your measurements. You'll need to account for temporal mismatches, vegetation growth, and channel changes that impact discharge readings.

Don't forget to implement continuous monitoring and regular validation checks to track your system's performance.

Using the S3CAR framework, which combines RCA and solar calibration techniques, you can improve your calibration accuracy and guarantee your ground path verification system maintains its reliability over time.

Mobile Tracking Methods

Through careful analysis of the facts, it's clear we need to shift our focus from ground path verification systems to mobile discharge measurement tools.

While ground verification systems serve an important role in static electricity monitoring, they're not applicable for measuring surface water discharge. Instead, you'll want to use specialized mobile tools designed specifically for water flow measurements.

Modern mobile tracking devices like the OTT ADC and OTT Qliner 2 offer precise discharge measurements using Doppler technology. These advanced tools provide real-time data collection and automatic calculations based on velocity and depth readings.

You can expect accurate results through:

- Acoustic Doppler current meters that measure point velocities and depth using integrated pressure cells

- Wireless data transmission capabilities for immediate analysis

- Automated discharge calculations based on collected measurements

- Vertical velocity distribution monitoring across water bodies

When you're selecting mobile tracking methods, consider using handheld instruments like the SonTek FlowTracker2, which offers GPS integration and Bluetooth connectivity.

These devices guide you through the measurement process with smart QC alerts and visual prompts, ensuring you collect defensible data while minimizing handling errors.

Continuous Monitoring Device Applications

Modern continuous monitoring devices provide powerful solutions for measuring surface discharge in various water bodies.

These devices use non-intrusive optical flow measurements that can track water level, surface velocity, and discharge without contacting the water. You'll find they're equipped with remote transmission capabilities that send both measurement data and HD proof images to a web-based dashboard.

You can easily install these devices in various mounting positions, and they'll operate autonomously using 12V batteries charged by solar power or fuel cells.

The systems employ patented cross-correlation techniques for surface velocity measurement and sophisticated image processing for water level detection. When you're monitoring wider rivers, you can use the multi-view mode with pan-tilt-zoom cameras.

What makes these devices particularly effective is their ability to operate without flow tracers, relying instead on visible moving surface structures.

You'll receive alerts when critical states are reached, and you won't need frequent service missions thanks to remote access capabilities.

These systems comply with EN ISO 748:2007 standards for vertical velocity profile measurement, ensuring you get accurate, representative measurements of volumetric flow rates in rivers, irrigation channels, and wastewater systems.

Walking Test Measurement Tools

Professional walking test measurement tools help you assess floor and footwear static discharge performance by measuring body voltage generation during standardized walking patterns.

Two leading devices, the WT5000 and EFM51.WT, offer thorough measurement capabilities for your ESD control needs.

The WT5000 provides measurements up to ±5000 volts with 5% accuracy and fast 10ms response time, while the EFM51.WT extends capabilities to ±160kV in distance mode.

You'll need to follow the six-step walking pattern three times to guarantee accurate results, keeping in mind that effective floor/footwear systems shouldn't generate more than 100 volts on the body.

- Use the WT5000 when you need high impedance testing (>10^14 Ohm) and computer connectivity for real-time analysis

- Choose the EFM51.WT for broader measurement ranges and its peak value hold feature

- Monitor results on the device's display or through included software for immediate feedback

- Confirm proper testing by using the included hand probe and following ANSI/ESD STM 97.2 standards

Both kits come with essential components like electrometers, connecting cables, and conductive carrying cases, making them ready for immediate deployment in your ESD control program.

Charge Generation Assessment Equipment

Advanced charge generation evaluation equipment empowers you to evaluate and monitor the complex electrical systems in electric vehicles (EVs).

You'll find specialized charging interface testers that work with multiple standards like CCS, CHAdeMO, and GB/T, helping you verify charging protocols and communication between EVs and charging stations.

When you're testing battery performance, you'll want to use regenerative battery test systems that offer bidirectional AC/DC conversion.

These systems let you analyze battery pack quality while achieving up to 94% energy regeneration back to the grid. You can customize voltage and current ranges to match your specific testing needs.

For thorough battery assessment, you'll need battery performance testers that measure capacity, charge/discharge characteristics, and cycle life.

These testers use DSP&IGBT power control schemes to guarantee precise measurements across various battery specifications.

You can also access complete EV test solutions that comply with standards like SAE J1772 and GB/T 18487.1.

These solutions combine AC/DC power supplies, electronic loads, and power analyzers to support testing across R&D, quality assurance, production, and field service applications.

Environmental Monitoring Parameters

While charge generation equipment focuses on electrical systems, environmental monitoring requires precise surface discharge measurements for water flow analysis.

You'll need to take into account various parameters that affect measurement accuracy, including turbidity levels, flow angles, and stage fluctuations. Modern tools like the Geolux RSS-2-300WL and LaserFlow sensors offer contactless measurements, reducing maintenance needs while providing reliable data.

When selecting measurement tools for environmental monitoring, you'll want to focus on these critical parameters:

- Flow conditions: Choose instruments that match your water environment – use acoustic Doppler meters for turbulent flows, or electromagnetic meters like OTT MF Pro for low-flow situations.

- Channel characteristics: Reflect on depth, width, and accessibility to determine whether surface or subsurface measurements are more appropriate.

- Turbidity and aeration levels: Account for these factors as they can affect acoustic and mechanical meter accuracy.

- Stage fluctuations: Monitor water level changes that require adjustments in measurement techniques.

Understanding these parameters helps you select the right equipment and method, whether it's conventional current-meter techniques, tracer dilution, or the moving boat method.

Remember to apply angle corrections when flow directions deviate more than 15 degrees from perpendicular.

Frequently Asked Questions

How Often Should Surface Discharge Measurement Tools Be Calibrated?

You'll need to calibrate your surface discharge tools annually, but you should adjust frequency based on usage and environment. If you're in high-risk settings, calibrate every 3 months for ideal accuracy.

Can Multiple Measurement Methods Be Used Simultaneously for Better Accuracy?

You can definitely use multiple methods simultaneously to improve accuracy. It's recommended to combine direct measurements like velocity-area with indirect methods like rating curves for cross-validation and more reliable discharge data.

What Safety Precautions Are Needed When Using Tracer Dilution Methods?

You'll need protective gear like gloves and eyewear, proper ventilation, and spill response equipment. Make certain you've got emergency protocols ready and follow proper disposal guidelines when using tracer dilution methods.

How Do Seasonal Changes Affect the Accuracy of Different Measurement Tools?

You'll find seasonal changes impact your measurement tools considerably – higher temperatures affect radar sensors' accuracy, winter ice disrupts acoustic meters, and varying water levels can compromise mechanical current meters' reliability throughout the year.

Which Method Is Most Cost-Effective for Long-Term Continuous Monitoring?

You'll find image-based systems most cost-effective for long-term monitoring since they use affordable cameras, require minimal maintenance, and provide continuous data through automated deep learning algorithms without needing constant human intervention.

In Summary

You'll find multiple tools essential for measuring surface discharge: electrostatic fieldmeters, surface resistance meters, charged plate monitors, and static decay testers. For precise measurements, you'll want to use walking test systems and continuous monitoring devices. Don't forget to include environmental sensors to track humidity and temperature, as they directly affect discharge readings. Regular calibration of these tools guarantees accurate results.

Leave a Reply