Protect your factory floor with three key grounding practices for maximum safety and equipment protection. First, install copper grounding straps strategically – you'll need one strap per 1000 square feet of ESD flooring, with at least one strap per room. Second, guarantee proper connections by removing center screws from electrical outlets and securing copper straps tightly, verifying connections with a volt ohm meter. Third, maintain your grounding system through regular testing, including annual resistance measurements and quarterly joint inspections. These fundamentals will dramatically reduce static discharge risks, but there's much more to creating a complete grounding solution.

Essential Floor Grounding Equipment

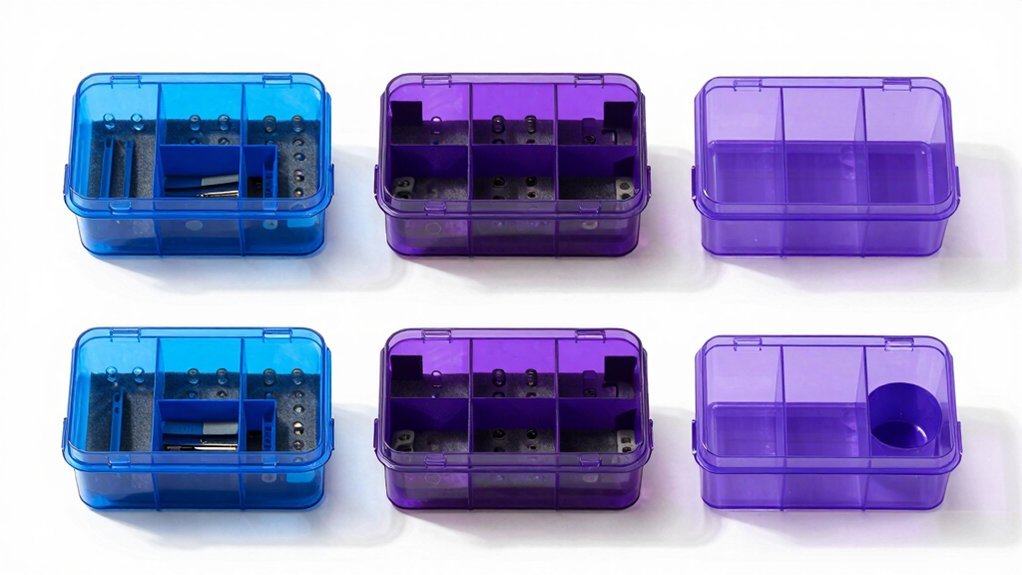

Inside of your factory floor installation, proper grounding equipment plays a vital role in maintaining ESD protection. You'll need a copper grounding strap for every 1,000 square feet of ESD flooring to establish reliable connections. One strap per room is required at minimum for proper static dissipation.

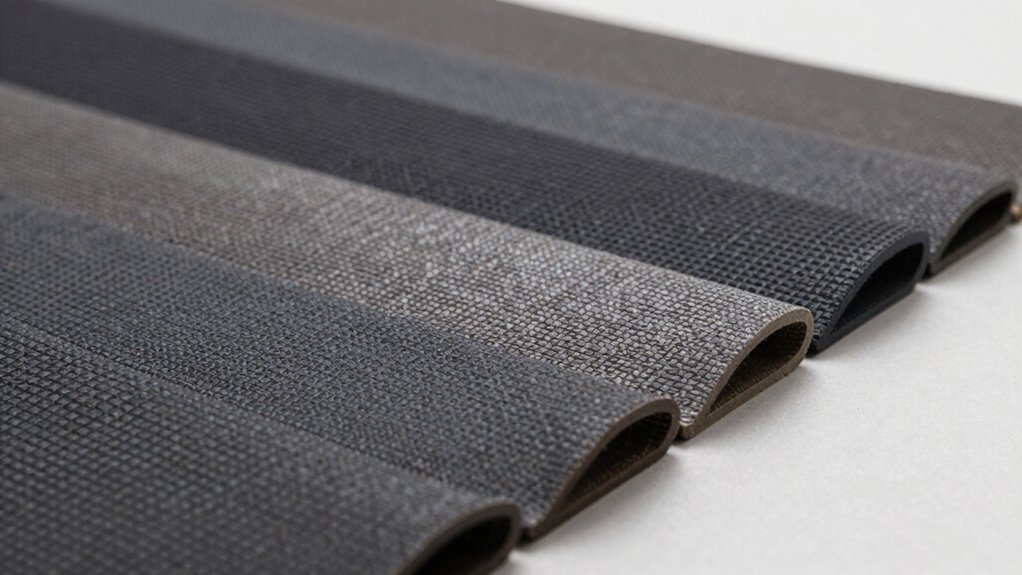

When installing the flooring, use conductive adhesive to secure it while maintaining conductivity throughout the surface.

For on-grade or below-grade installations, you'll want to incorporate copper grounding rods driven into the earth. Connect these rods using grounding clamps and wire nuts to create a solid path to ground.

If you're working with aluminum studs, secure copper grounding straps using sheet metal screws for proper bonding.

Don't forget to include ESD electrical outlets as grounding points for your conductive and static-dissipative flooring. These outlets provide convenient connection points throughout your facility.

When attaching grounding straps to exposed steel support columns, use appropriate grounding clamps to guarantee low-resistance connections.

Remember to follow ANSI/ESD S6.1 standards for impedance requirements and conduct routine testing of your grounding system. This guarantees your floor grounding equipment maintains its effectiveness and complies with safety regulations.

Proper Installation Best Practices

How can you guarantee your ESD flooring installation provides reliable protection? The key lies in following precise grounding methods that create a secure path for static discharge.

You'll need one copper grounding strap per 1000 square feet of flooring, with at least one strap per room. When connecting to electrical outlets, remove the center screw from the cover plate and the grounding screw inside.

Create a small hole in your copper strap and secure it firmly to the outlet using the grounding screw.

For natural earth grounding, drive a copper rod 4-6 feet into the ground and attach your strap using a grounding clamp. If you're connecting to structural elements, secure the strap to support columns or I-beams after drilling appropriate holes. Periodic testing and maintenance of grounding equipment is essential according to company policy and industry standards.

Don't forget to verify connections with a volt ohm meter.

Your facility's safety depends on these connections – take pride in getting them right.

Each properly installed strap protects valuable equipment and personnel.

A well-grounded floor is your first line of defense against costly ESD damage.

Remember to use conductive adhesives to cover exposed straps and confirm all connections are tight and secure. Regular testing will confirm your installation maintains its protective properties over time.

Testing and Maintenance Requirements

A well-installed grounding system requires regular testing and maintenance to maintain its effectiveness.

You'll need to conduct soil resistivity tests using four stakes before installation and follow up with fall of potential tests to verify proper grounding resistance. Your system should measure 5.0 ohms or less to meet NFPA and IEEE recommendations, though NEC allows up to 25.0 ohms.

Schedule your inspections before thunderstorm season and guarantee you're checking all joints for tightness, good contacts, and signs of rust.

You'll want to measure your grounding grid's resistance annually and get verification from a qualified electrical contractor every three years or after major changes. Pay special attention to sensitive equipment areas, which must maintain 5.0 ohms or less resistance.

Don't forget to monitor potential degradation factors like electrical system modifications, water table changes, and corrosion. Your grounding lead-in wire shouldn't exceed 30m and needs proper anti-corrosion treatment.

If you've installed ESD flooring, you'll need to conduct surface tests per FAA 019f standards, including seam testing and low humidity conditioning for 72 hours to guarantee consistent performance. Regular point-to-point resistance tests are essential to evaluate surface conductivity and identify potential grounding issues.

Frequently Asked Questions

How Do Seasonal Temperature Changes Affect Factory Floor Grounding Performance?

You'll notice your grounding performance fluctuates as seasons change. When soil freezes, resistance increases, and when it thaws, resistance decreases. Temperature changes also affect metal conductivity and soil moisture levels.

Can Multiple Types of ESD Flooring Materials Be Safely Mixed?

You can mix different ESD flooring materials if you select them for specific area needs, but don't combine ESD and non-ESD tiles in the same space as it'll disrupt electrical conductivity between surfaces.

What Are the Risks of Over-Grounding in High-Humidity Manufacturing Environments?

You'll face increased corrosion risks, equipment damage, and potential safety hazards when over-grounding in humid conditions. It can accelerate metal deterioration and create harmful surface discharges that produce damaging nitric acid.

How Does Wireless Equipment Interference Relate to Floor Grounding Systems?

Your wireless equipment can create high-frequency noise that'll disrupt factory systems. You'll need proper floor grounding with meshed systems to control interference and protect equipment through effective high-frequency noise suppression.

When Should Existing Floor Grounding Systems Be Completely Replaced Versus Upgraded?

You should completely replace your grounding system when resistance exceeds 4Ω, there's widespread corrosion, or safety risks emerge. Consider upgrades for equipment changes or minor issues that don't compromise system integrity.

In Summary

Following these three essential tips guarantees your factory floor grounding system operates at peak performance. You'll minimize static discharge risks and protect sensitive equipment by selecting quality grounding equipment, following precise installation protocols, and maintaining a regular testing schedule. Don't skip these vital steps – they're your frontline defense against costly equipment damage and workplace safety hazards. Stay proactive with your grounding system maintenance.

Leave a Reply