A workstation grounding cord replacement involves installing a new grounding system to protect electronic components from electrostatic discharge (ESD). You'll need a common point ground cord, coil cord, and proper connectors like metallic crimps, snaps, or banana plugs. The replacement cord must connect to a verified grounding point, typically the center screw of a standard 110VAC outlet, with resistance measuring less than 1 Ohm AC impedance. When installing, you'll secure connections between your table mat, wrist strap, and the equipment ground at your utility point. Understanding the complete requirements and best practices will guarantee your workspace stays properly protected against costly ESD damage.

Understanding Workstation Grounding Cord Basics

Properly grounded workstations are essential for protecting sensitive electronic components from electrostatic discharge (ESD) damage.

You'll need to guarantee all workstation components connect to a common point ground, which links to the equipment grounding conductor (green wire) to maintain equal electrical potential throughout your setup.

When you're installing grounding cords, you must connect them to verified grounding points, such as the center screw of a standard 110VAC outlet.

Don't rely on "floating" ground points, and always use secure connecting devices like metallic crimps, snaps, and banana plugs instead of alligator clips.

You'll encounter different types of grounding methods in your workstation.

Wrist straps protect seated personnel, while foot grounders work for standing or mobile workers when used with ESD flooring.

You'll also need floor mat and worksurface mat grounding cords connected to your common point ground.

To maintain your grounding system's effectiveness, you'll need to conduct regular inspections and immediately replace damaged cords or connections.

Remember to keep non-conductive materials away from your workstation and consider using ionizers to neutralize charges on insulators.

Your system's resistance should measure less than 1 Ohm AC impedance for proper functioning.

1 to 10 megohms is the ideal resistance range for effective charge dissipation within the protected area.

A current limiting resistor of 1 megohm is built into the ground cord as a safety feature.

Essential Components and Materials

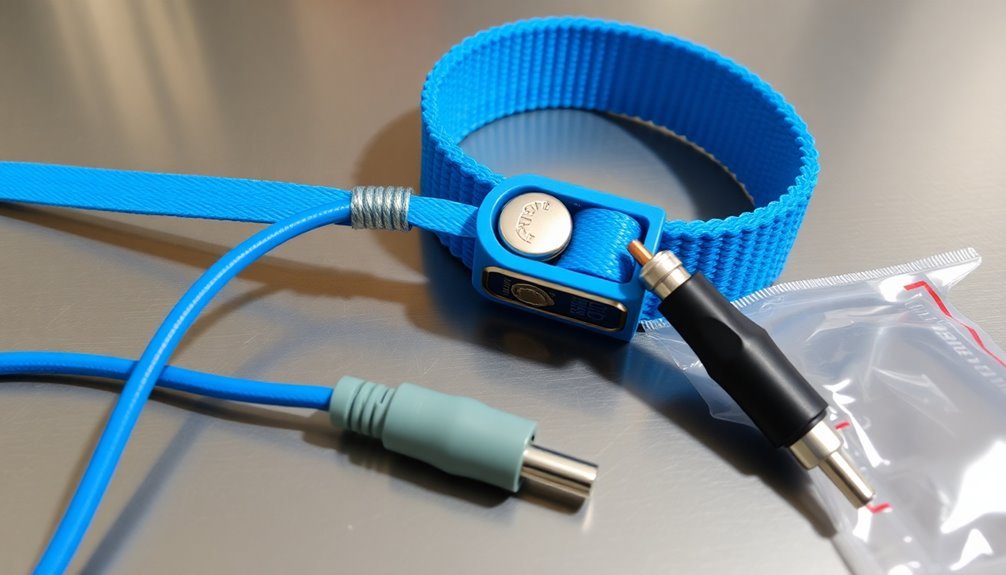

A complete workstation grounding system requires specific components designed to guarantee reliable ESD protection. When replacing your workstation grounding cord, you'll need to take into account both the cord materials and connection types that best suit your setup. The core component consists of high-strength tensile wire with protective coating, available in various lengths including 10' and 15' options.

You'll find several essential grounding components commonly used in workstation setups:

- High-strength tensile wire with protective coating for durability

- Round prong connectors for standard grounded outlets

- Banana plug receptacles for wrist strap connections

- Special snap attachments for grounding mats and sheets

- Dome-style ground cords for low-profile installations

Your grounding system must maintain compatibility with your existing ESD protection equipment, including table mats, floor mats, and wrist straps. The components you choose should meet safety standards and feature durable construction to prevent accidental disconnection. Proper grounding equipment helps restore natural electrical balance in the body while maintaining workplace safety standards.

For under-table installations, you'll want to take into consideration bench mount options, while mobile setups might require drag chains for wire carts and shelving units. Look for components with proper ESD symbols and high-quality materials to guarantee reliable performance. Common point ground cords are essential as they effectively ground multiple items simultaneously through a single connection point.

Installation Steps and Methods

Installing a workstation grounding cord requires careful attention to both sequence and technique.

You'll need to start by connecting the common point ground cord to your table mat using either the left or right snap. Next, attach the coil cord to the common point ground cord using a banana plug, followed by securing the wrist band to the coil cord. Make sure you wear the wrist band directly on bare skin and tighten it properly to prevent gaps. The wrist band serves as static electricity protection for sensitive electronic components.

To complete the installation, you'll need to connect the common point ground cord to the equipment ground, typically found at the nearest utility ground point. The center screw of a standard 110VAC outlet often serves as an ideal connection point. You should secure the ground wire neatly to avoid creating obstacles in your workspace. Using mild heat exposure can help remove any shipping creases from your table mat before installation.

Don't forget to test your installation using either a surface resistivity meter or an ohmmeter. You'll want to verify continuity from the ground point to all workstation elements, ensuring resistance from the banana jacks to the common ground point is less than 1 Ohm AC impedance.

Remember to include a current limiting resistor in the wrist strap ground cord for safety.

Testing Your Grounding System

You'll need to check your grounding system's resistance using an approved surface resistivity meter to verify readings are less than 1 x 10^9 ohms.

Regular inspections of ground cord snaps and connections should be performed for optimal performance.

Test the complete ground path by measuring continuity from the common ground point to each workstation component, including floor mats and wrist straps.

Resistance Testing Methods

Testing your workstation's grounding system requires precise measurement techniques and appropriate equipment to confirm compliance with IEC 61340-2-3 standards.

You'll need to verify your resistance meter is properly calibrated and suitable for measuring the resistance to ground (Rg), which should be less than 1 x 10^9 ohms.

Regular testing is essential to maintain effective ESD protection. When testing your grounding system, check the entire setup, including ground cords and wrist straps.

Don't forget to verify that your grounding points connect properly to a verified electrical system ground or grounding bus.

Key testing requirements you should follow:

- Measure working surface resistance to ground regularly

- Test ground cords for continuity and proper connection

- Verify wrist straps are grounded through a separate path

- Check for wear or damage on all grounding components

- Document all test results for compliance verification

When testing ground cords, confirm they include a current limiting resistor (typically 1 megohm) as specified by ANSI/ESD S1.1.

You'll need to verify the continuity from the working surface to the grounding source and inspect for any physical damage that could compromise effectiveness.

Ground Path Verification

A properly functioning ground path verification system forms the foundation of effective ESD protection. To guarantee your workstation's grounding system is working correctly, you'll need to perform regular continuity testing from the ground point to all workstation components using a surface resistivity meter with a "resistance to ground" function.

You should verify that all components are connected to the same electrical ground point, known as the common point ground. This includes testing the dissipative working surface to confirm its Rg is less than 1 x 10^9 ohms, in accordance with IEC 61340-2-3.

You can install constant monitor units into your workbench frame to receive visual and audible alerts if the ground connection fails.

Make sure your wrist straps have a one megohm current-limiting resistor and are properly tested using a wrist strap tester. When installing your grounding system, connect the Earth Bonding Point cords to the equipment grounding conductor in the electrical receptacle.

Don't forget to check that your ESD-safe chairs have functional drag chains and ESD-safe casters, and that your ESD control flooring system works effectively with your ESD control footwear.

Compliance Check Tools

Professional compliance verification requires specific tools to confirm your ESD grounding system functions correctly. You'll need to use various testing equipment to measure surface resistivity, verify ground connections, and ascertain all components maintain proper electrical potential.

These tools help you comply with industry standards like ANSI/ESD S1.1 and IEC 61340-2-3.

Essential compliance check tools include:

- Surface Resistivity Meters for measuring resistance values across surfaces and to ground

- Grounding Checkers to confirm proper ground connections

- Resistance-to-Ground Testers for verifying specific point measurements

- Wrist Strap Testers to validate operator safety equipment

- Constant Monitors for continuous system oversight

You'll need to conduct regular testing of your workstation components, including work surfaces, floor mats, and heel grounders.

Keep detailed records of all tests and inspections, and ensure your testing equipment stays properly calibrated.

Remember to train your personnel on correct testing procedures to maintain consistent results.

Common Grounding Problems

When checking your workstation's grounding system, you'll often find problems with loose connections where cords meet snap points or ground attachments.

You might notice damaged components like frayed wires, worn insulation, or broken snap fasteners that compromise your ESD protection.

If your ground point wasn't properly installed to begin with, you'll need to address issues like incorrect mounting hardware or improperly secured connections to guarantee effective static discharge.

Loose Connection Issues

Loose connections in workstation grounding cords pose significant risks to your equipment and personnel safety. When you're experiencing grounding issues, it's essential to check all connection points, including the outlet insertion, ESD mat snap contacts, and Earth ground connections.

Movement, vibration, and regular wear can compromise these critical connection points over time. You'll need to implement a systematic approach to diagnose and prevent loose connections in your workstation grounding setup. Regular maintenance and proper installation techniques are necessary for maintaining reliable grounding protection.

- Check for proper cord insertion at all connection points daily

- Clean conductive surfaces regularly to guarantee optimal contact

- Inspect grounding cords for signs of wear or damage

- Verify that all mounting hardware is securely fastened

- Test connections using appropriate diagnostic tools

Don't overlook the impact of environmental factors on your grounding connections. Temperature changes and humidity can affect connection stability, so you'll want to monitor these conditions.

If you notice intermittent grounding issues, isolate each component systematically to identify the source. Remember to document any problems and solutions you encounter, as this information will prove valuable for future troubleshooting efforts.

Damaged Cord Components

Beyond loose connections, damaged cord components represent a major threat to proper workstation grounding. If you've noticed physical damage to your grounding cord, such as cuts, frays, or breaks, you'll need to replace it immediately to maintain proper static dissipation.

Common sources of damage include pets chewing on cords, accidental breaks caused by children, and general wear and tear from frequent use.

You'll know your cord is damaged if it fails to establish a consistent grounding connection, shows visible physical deterioration, or causes electrical shock during use.

Over-tightening snap connections or incorrectly using the grounding cord can also lead to mechanical damage that disrupts the grounding path.

When replacing your damaged cord, make certain you select one with the correct length and compatible snap connections for your workstation.

You'll need to maintain your new cord properly to prevent future damage. This includes regular inspections, proper storage, and careful handling.

Don't forget to keep the grounding point clean and debris-free to guarantee effective static dissipation.

If you notice any signs of damage, don't wait – replace your grounding cord right away to maintain workplace safety.

Improper Ground Installation

Four critical grounding problems can undermine your workstation's ESD protection. When you don't properly install your ground point or follow standardized procedures, you risk compromising your entire ESD protection system.

Installing ground points to unverified electrical grounds or failing to bond all components to the same ground point can create dangerous potential differences.

To avoid improper ground installation issues, watch for these common problems:

- Using non-conductive materials or insulators that prevent adequate grounding of your workstation

- Failing to test workstation continuity after installation, leaving potential grounding issues undetected

- Not following ANSI/ESD S6.1 standards for proper grounding procedures

- Installing ground cords incorrectly or without proper securing mechanisms

- Missing current-limiting resistors in wrist strap ground cords, creating safety risks

You'll need to verify your ground point installation meets all compliance standards and regularly test your grounding system's effectiveness.

Don't forget to use appropriate testing equipment, like surface resistivity meters, to confirm proper grounding.

Remember that inconsistent grounding practices across different workstations can lead to confusion and errors, so maintain standardized procedures throughout your facility.

Safety Measures and Requirements

Safety protocols form the foundation of proper workstation grounding cord maintenance and installation.

You'll need to inspect your grounding cords regularly for wear, damage, or corrosion, and test them every six months using specialized testing equipment to guarantee they're functioning correctly.

When installing replacement grounding cords, you must verify the electrical system ground first and connect cords to a reliable earth ground or common point ground block.

Don't daisy chain workstations; instead, confirm each station has its individual grounding connection. You'll want to install an Earth Bonding Point at each workstation and use banana jacks for wrist strap connections.

Your safety measures should include using current limiting resistors in grounding cords to prevent electrical shock, and you'll need to measure resistance from ground snaps to common ground points.

Keep your work area clear and organized to prevent tripping hazards, and make sure ground wires are properly managed and secured.

Always follow local regulations and verify you've received proper training before working with grounding systems.

Remember to isolate electrical circuits before performing any work on grounding systems, and combine your grounding measures with other static control practices to prevent ESD damage.

Maintenance Best Practices

Through consistent upkeep and monitoring, you'll ascertain your workstation grounding system maintains its reliability and effectiveness. Regular maintenance should include daily cleaning with ESD-safe products and thorough dust removal to prevent static buildup.

You'll need to inspect your grounding points frequently, ascertaining connections remain secure and conductors aren't compromised.

When maintaining your workstation grounding system, focus on these critical tasks:

- Test resistance levels regularly to confirm they're below 1 x 10^9 ohms

- Inspect grounding cords daily for wear, damage, or loose connections

- Replace worn-out wrist straps and damaged ESD matting immediately

- Keep spare ESD control products on hand for quick replacements

- Verify all components meet current industry standards

Implementation of continuous monitoring systems will help you detect potential failures before they become serious issues.

You should utilize real-time monitors for wrist straps and work surfaces, while maintaining an effective alarm system to alert you of any grounding failures.

Don't forget to document all maintenance activities and conduct regular compliance verification tests to ascertain your workstation remains properly grounded and safe for use.

Regulatory Compliance Guidelines

Maintaining regulatory compliance for workstation grounding cords requires adherence to multiple industry standards and safety protocols. You'll need to follow OSHA guidelines, NFPA standards, and NEC requirements to guarantee your grounding cord replacements meet all necessary regulations.

You must conduct daily visual inspections of your cords before use, checking for defects like damaged insulation or deformed pins. All cords operating above 50 volts require testing and labeling by an OSHA-recognized laboratory, and you'll need to confirm they're UL-approved for your specific application.

Keep detailed records of all inspections and replacements for compliance verification.

When installing replacement cords, remember they're for temporary use only and shouldn't exceed 100 feet in length. Match the amperage rating to your equipment and verify proper grounding conductors are present.

Don't run cords through walls, ceilings, or other structural elements, and keep them away from wet locations. You must also provide adequate ventilation to prevent heat buildup.

Failure to comply with these regulations can result in fines and legal liability, so it's essential to maintain proper documentation and follow all testing and certification requirements.

Frequently Asked Questions

How Often Should Workstation Grounding Cords Be Replaced?

You should test your workstation grounding cords every six months and replace them immediately if they fail testing, show visible wear, exceed 35 megohm resistance, or don't comply with safety standards.

Can Multiple Workstations Share a Single Ground Point Connection?

Yes, you can safely connect multiple workstations to a single ground point using common point ground cords. It's an efficient solution that reduces clutter while maintaining proper ESD protection across all connected workstations.

What's the Maximum Length Allowed for a Workstation Grounding Cord?

You'll want to keep your workstation grounding cord under 10 feet in length. While it's technically possible to use longer cords, they're not recommended as they can reduce effectiveness and create safety hazards.

Are There Color-Coding Requirements for Different Types of Grounding Cords?

No, you won't find specific color-coding requirements for different types of grounding cords. Industry standards focus on functionality and proper grounding rather than color distinctions. What matters most is the cord's effectiveness and compatibility.

Do Grounding Cords Require Special Certification From Regulatory Agencies?

You don't need specific certification from regulatory agencies for grounding cords, but they must meet established ESD standards like ANSI/ESD S6.1 and undergo proper testing for resistance and continuity requirements.

In Summary

You'll find that replacing your workstation grounding cord is essential for maintaining a safe ESD-protected workspace. By following proper installation steps, regular testing, and maintenance protocols, you're ensuring the safety of sensitive electronic components and personnel. Remember to keep up with regulatory compliance standards and address any grounding issues promptly to maintain an effective static-free environment at your workstation.

Leave a Reply