When selecting lab grounding mats, you'll want to focus on three key factors. First, choose between rubber mats for superior chemical resistance or vinyl mats for better cushioning, guaranteeing they meet ANSI ESD-S20.20 compliance with resistance under 10^9 ohms. Second, measure your workspace carefully and select a mat size that allows for future expansion, considering standard widths of 24" to 48". Third, verify the mat includes proper grounding components and maintain regular testing protocols using RTT and RTG measurements. Understanding these fundamentals will help protect your sensitive equipment and guarantee workplace safety.

Material Selection and Safety Standards

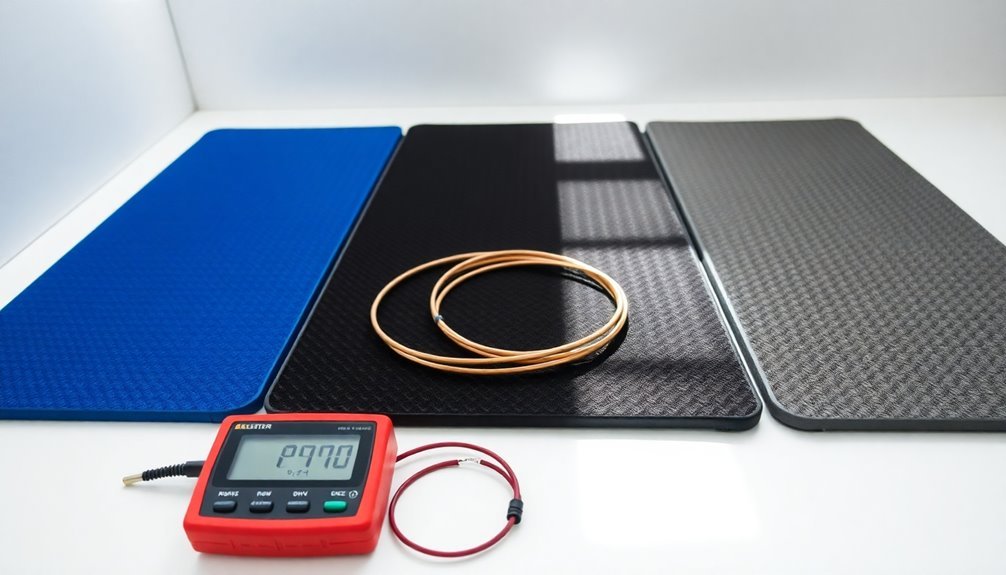

Laboratory safety begins with proper ESD mat selection, which requires understanding both material types and compliance standards. Most suppliers offer pre-cut sizes to simplify installation.

You'll find two primary materials available: rubber and vinyl. Rubber mats offer superior heat and chemical resistance, while vinyl mats excel in tabletop applications and provide better cushioning. These mats can come in single, double, or triple-layer configurations, each offering different thickness and ESD performance characteristics. Regular surface resistance testing ensures these mats maintain their protective qualities over time.

When selecting your mat, you'll need to guarantee it meets ANSI ESD-S20.20 requirements and ANSI/ESD S6.1-2019 grounding standards. The mat should demonstrate dissipative properties with resistance less than 10^9 ohms.

For proper classification, conductive materials must show less than 1 x 10^5 ohms/square resistance, while dissipative materials range from 1 x 10^5 to 1 x 10^11 ohms/square. Don't consider materials with resistance greater than 1 x 10^12 ohms/square, as they're classified as insulative and aren't ESD safe.

You'll also need to verify that your complete grounding system, including personnel, footwear, and flooring, maintains resistance below 1.0 x 10^9 ohms and generates less than 100 volts during standard walking voltage tests.

Proper Size and Installation Requirements

When determining the ideal size for your lab's grounding mat, you'll need to take into account both standard dimensions and installation requirements.

You'll find that most mats come in rolls of 50' or 60' with standard widths of 24", 30", 36", and 48". If these sizes don't perfectly match your workspace, don't worry – you can easily cut the material to fit your specific needs, or opt for pre-cut mats with pre-installed grounding hardware. Regular testing of grounding systems ensures your mat continues functioning effectively. Made from durable conductive materials, these mats provide reliable static control in industrial settings.

Before installation, verify your grounding system meets the required resistance of less than 5 ohms to earth, as specified by IEEE 81 and NEC standards.

You'll need to measure this using the fall-of-potential method before connecting to existing grounds. Connect your mat to a common ground point using a grounding cord equipped with a resistor for controlled discharge.

If you're setting up an ESD protected area (EPA), you'll need to establish clearly marked boundaries and verify all equipment connects to a common ground point.

Don't forget to factor in potential workspace expansions when selecting your mat size.

For specialized environments like clean rooms, you'll need additional considerations for both equipment and maintenance requirements.

Testing and Maintenance Protocols

Regular testing of your grounding mat guarantees consistent performance and protection against static discharge.

The ground plane areas should be thoroughly cleaned and prepared to ensure optimal conductivity between surfaces.

You'll need to perform two essential resistance tests: the Resistance Top-to-Top (RTT) and Resistance Top-to-Ground (RTG) tests.

For RTT testing, place two five-pound electrodes 10-12 inches apart on your mat's surface to measure static dissipativity.

When conducting RTG tests, position one electrode at least 2 inches from the ground snap and 3 inches from any edge to verify proper grounding conductivity. Your mat should show less than 1 x 10^9 ohms of resistance for peak performance.

You can also employ stake-less earth testing using a clamp-on tester to measure the complete ground loop resistance. This method doesn't require auxiliary test electrodes but demands understanding of parallel resistances in the ground system.

For critical lab operations, consider installing continuous monitoring systems.

These devices constantly check your mat's ground connection and alert you through visual and audible signals if grounding fails. This approach is particularly valuable when you're handling sensitive components or conducting high-value production processes that require reliable static protection. Following NEC guidelines, ensure your grounding system maintains resistance under 25 ohms for general lab applications.

Frequently Asked Questions

How Long Do Grounding Mats Typically Last Before Requiring Replacement?

Your grounding mat should last 2-3 years with proper care, but you'll need to replace it sooner if you notice fraying, cracking, conductivity loss, or diminishing health benefits during regular inspections.

Can Grounding Mats Be Used in Wet Laboratory Conditions?

Yes, you can use grounding mats in wet lab conditions. They're actually more effective when moist since water increases conductivity. Just guarantee your mat has waterproof coating and is properly connected to a grounded outlet.

Do Temperature Extremes Affect the Conductivity of Grounding Mats?

Yes, you'll find that temperature extremes affect your grounding mat's conductivity. Extreme heat above 100°C or cold below -20°C can greatly change how well it conducts, impacting its effectiveness for grounding.

Are Grounding Mats Effective When Placed on Carpeted Surfaces?

Your grounding mat won't work effectively on carpet since it acts as an insulator. You'll need to connect it directly to a grounding source, like an electrical outlet, to achieve proper grounding results.

Can Multiple Pieces of Equipment Share the Same Grounding Mat?

Yes, you can safely share a grounding mat among multiple equipment pieces if you connect each device to a common grounding point using separate cables. Don't daisy chain connections, and guarantee proper equipotential bonding.

In Summary

You'll get the best protection from your lab grounding mats by selecting ESD-certified materials, ensuring proper size and installation for your workspace, and following regular testing protocols. Don't skip routine maintenance checks or forget to verify connections. When you implement these three key considerations, you're creating a safer lab environment and protecting sensitive equipment from costly electrostatic discharge damage.

Leave a Reply