You'll want to maintain humidity levels between 40-60% at your electronics workbench to protect sensitive components from ESD damage and corrosion. Essential solutions include portable ultrasonic humidifiers, dehumidifiers with digital controls, real-time RH monitoring systems, and smart HVAC controls with automated adjustments. Consider using localized moisture control systems like compressed air atomizers, desiccant materials, and humidity chambers for specific tasks. Don't forget proper maintenance routines, including using distilled water and regular sanitization. Combine these solutions with seasonal strategies and ESD protection measures to create your ideal workbench environment. Let's explore each option in detail to maximize your component protection.

Understanding Humidity Control Basics

Managing humidity in your electronics workbench starts with grasping the fundamental concepts of humidity control. You'll need to understand that humidity control involves regulating moisture content in the air to protect your electronic components and maintain ideal working conditions.

If you're working with sensitive electronics, uncontrolled humidity can be particularly damaging, leading to static discharge or component failure. Automated systems help maintain precise humidity control with minimal manual intervention.

Effective humidity control relies on maintaining relative humidity within specific ranges through various methods and technologies. For your electronics workbench, you'll need to monitor and adjust humidity levels using components like humidity sensors, control units, and appropriate actuators.

The relationship between temperature and relative humidity is vital – as temperature changes, so does the air's capacity to hold moisture.

When you're setting up your workbench, remember that proper humidity control isn't just about comfort; it's essential for preventing damage to your electronic components and ensuring consistent performance.

You'll want to aim for humidity levels that prevent both static electricity (which occurs in low humidity) and condensation (which occurs in high humidity), typically maintaining levels between 30-50% relative humidity for most electronics applications.

Portable Humidification Units

Your portable humidification unit's compact design lets you position it conveniently on your electronics workbench without compromising valuable workspace.

You'll notice quick humidity adjustments through the unit's responsive misting system, which can output up to 100ml/h for rapid environmental control. The whisper-quiet operation ensures your work environment remains peaceful and distraction-free.

You should regularly check and refill the 1-qt water tank while following the maintenance guidelines to maintain consistent performance and prevent mineral buildup.

Desktop Size and Placement

The strategic placement of portable humidification units on electronics workbenches requires careful consideration of both size and space efficiency. You'll want to guarantee your humidifier doesn't interfere with your workspace while maintaining ideal humidity levels for ESD protection.

Choose units with compact footprints that won't compromise your valuable bench space or obstruct access to tools and components. Modern units that run at 0.2 kW per hour offer excellent energy efficiency for continuous workspace operation.

When selecting and positioning your humidification unit, consider these essential factors:

- Look for models with a minimal footprint (under 12 inches square) to maximize available workspace

- Position the unit at least 12 inches away from electronic components to prevent direct moisture contact

- Choose units with built-in handles or castors for easy relocation during bench reorganization

- Select models with vertical designs rather than horizontal layouts to conserve precious surface area

- Guarantee power cords can reach outlets without creating tripping hazards

Remember to factor in maintenance accessibility when placing your unit. You'll need clear access to water tanks and filters for regular cleaning and refilling.

If you're using multiple units, space them strategically to create overlapping coverage zones while maintaining an uncluttered work environment. Consider mounting options or elevated platforms to free up additional bench space.

Quick Humidity Response Time

Rapid humidity control stands as a critical feature when selecting portable humidification units for your electronics workbench. The SmartFog ES100's ability to deliver over 12 pounds of moisture per hour guarantees you'll achieve your desired humidity levels quickly and maintain them with precision.

You'll benefit from its fast-evaporating fog technology that maintains fluctuations within ±2% of your target. An integrated LCD display screen provides real-time monitoring of the current humidity conditions.

The system's plug-and-play design means you won't waste time with complex setups when you need immediate humidity adjustment. Its advanced S Series sensors work alongside the CPLC controller to provide 'set and forget' accuracy, automatically adjusting water spray temperature to maintain your specified relative humidity levels.

You'll appreciate how the unit's decorrelation method generates droplets with 100% water use efficiency, making it both responsive and economical.

For your electronics work environment, the non-wetting humidity control is particularly valuable. You can safely adjust humidity levels from 1% to 99% without risking moisture damage to your sensitive components.

The system's rapid diffusion guarantees uniform humidity distribution throughout your workspace, helping prevent electrostatic discharge while maintaining ideal conditions for electronics handling.

Water Tank Maintenance

While maintaining precise humidity levels is essential for electronics protection, proper water tank maintenance guarantees your humidifier operates at peak performance.

You'll need to empty and refill your portable humidifier daily with distilled or demineralized water to prevent microbial growth and mineral buildup. For units under five gallons, implement a sanitization routine using a weak bleach solution every third day, followed by thorough rinsing. Using regular white vinegar solution is a cost-effective and safe cleaning method recommended by manufacturers.

To effectively clean the water tank, use a vinegar solution (1:1 ratio with water) and let it sit for 30 minutes before scrubbing with a soft-bristled brush. Always unplug the unit before performing any maintenance and make certain all surfaces are completely dry after cleaning.

- Empty and refill with fresh distilled water daily

- Clean all surfaces with a soft towel to prevent moisture accumulation

- Use vinegar solution to remove mineral deposits every week

- Sanitize with diluted bleach solution every third day

- Store in a dry place when not in use

When choosing water for your humidifier, opt for distilled or demineralized options to minimize scale buildup and reduce cleaning frequency. If you're using tap water, you'll need to increase your maintenance schedule due to higher mineral content.

Automated Climate Control Systems

Modern automated climate control systems offer sophisticated solutions for maintaining ideal humidity levels. You'll find both analog and digital options available, each providing distinct advantages for your workspace.

Analog systems excel in reliability and precision, allowing you to make quick adjustments based on real-time monitoring of your workbench environment. Compressed air operation makes these systems particularly easy to maintain and install.

Digital electronic controls (DDC) take automation a step further by enabling remote monitoring and control through internet connectivity. You can track humidity levels from your smartphone and adjust settings without being physically present at your workbench. These systems use advanced algorithms to maintain precise humidity levels, which is vital for protecting sensitive electronic components.

For the most advanced solution, you'll want to evaluate smart HVAC controls. They incorporate machine learning to optimize humidity levels automatically, adapting to your workspace's changing conditions. You won't need to worry about constant adjustments, as these systems can maintain ideal humidity levels based on your predetermined schedules or room occupancy.

When choosing a control system, evaluate your workbench's specific needs, including system complexity, energy efficiency requirements, and potential future expansion plans.

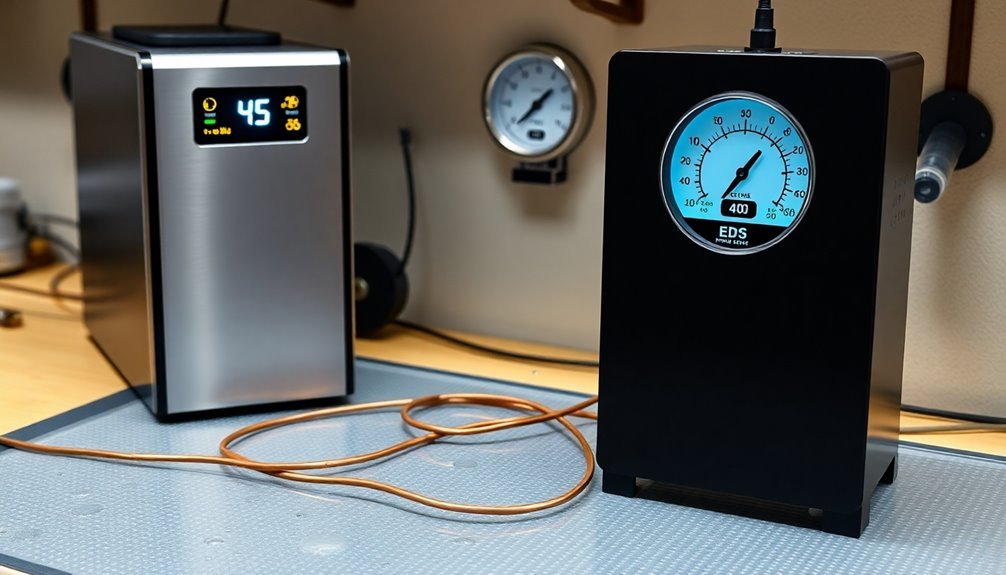

RH Monitoring Equipment

Three essential components make up effective RH monitoring equipment for electronics workbenches: sensors, transmitters, and data management systems. You'll need precise monitoring equipment that measures both temperature and humidity ranges from -30°C to 80°C and 0 to 100% RH.

Modern RH monitoring systems include configurable alerts, LED indicators, and automatic reporting features to help you maintain ideal conditions for your electronic components. The systems can be integrated with ESD protective surfaces to provide comprehensive protection for sensitive electronics.

- Prevents costly ESD damage by maintaining proper humidity levels

- Features high/low temperature alerts with instant notifications

- Includes external sensors for enhanced measurement accuracy

- Delivers automated email reports with min/max/average readings

- Offers wireless monitoring options for flexible workspace setup

Your electronics workbench requires reliable monitoring equipment like the HygroFlex1 transmitter or HC2A-S probe to measure relative humidity and calculate dew points. These devices work together to protect sensitive components from electrostatic discharge and corrosion.

When selecting monitoring equipment, consider calibration requirements, water quality needs, and proper installation procedures. Regular maintenance and compliance with industry standards will guarantee your monitoring system continues to provide accurate, dependable readings that safeguard your electronic components.

ESD Protection Through Humidity

Effective ESD protection starts with maintaining proper humidity levels in your electronics workspace. You'll want to keep your relative humidity (RH) between 30% and 70%, with 40% being the ideal target. At this level, moisture in the air forms a protective film that helps dissipate electric charges across surfaces.

Understanding why humidity matters is essential. When you're working in low humidity conditions, static electricity builds up much more easily. For instance, simply walking across a carpeted floor can generate up to 35,000V in dry conditions, compared to just 1,500V in humid environments. That's why you'll notice more static shocks during dry winter months.

While humidity control is helpful, don't rely on it as your only ESD protection measure. You'll still need proper grounding solutions, as humidity alone won't prevent all ESD events.

Keep in mind that excessive humidity can cause other problems like corrosion and soldering defects. For best protection, maintain humidity levels closer to 60% while implementing thorough ESD control measures.

If you're in a drier climate, you'll need to pay extra attention to humidity control during autumn and winter months when indoor air typically becomes drier.

Workbench Humidification Solutions

You'll find that localized moisture control systems provide targeted humidity management directly at your electronics workbench, ensuring ideal conditions exactly where you need them.

Modern automated humidity maintenance equipment uses advanced technologies like centrifugal humidifiers and compressed air atomizers to maintain precise moisture levels while protecting sensitive components.

These smart systems can integrate seamlessly with your existing workbench setup, offering both energy efficiency and reliable ESD protection through consistent humidity control.

Localized Moisture Control Systems

Maintaining precise humidity levels at electronics workbenches doesn't require controlling an entire facility's environment. Localized moisture control systems offer targeted solutions that protect sensitive components while maximizing energy efficiency.

You'll find these systems particularly effective at preventing condensation and electrostatic discharge, which can damage your electronic components.

Modern localized moisture control technologies give you multiple options to match your specific needs:

- Ultrasonic humidifiers create fine water droplets using high-frequency sound waves, offering quiet and efficient operation

- Adsorption materials actively control moisture levels by absorbing excess humidity

- Compressed air atomizers deliver precise humidity control without temperature increase

- Immersed electrode systems generate steam based on electrical current modulation

- Adiabatic humidifiers cool and humidify simultaneously without external energy input

You'll benefit from reduced energy costs since you're only controlling humidity in specific work areas. These systems are typically easier to maintain than centralized solutions and can be customized to fit your workbench setup.

When implementing a localized system, guarantee you've got accurate sensors and easy maintenance access. The system should integrate smoothly with your existing HVAC while meeting regulatory requirements for electronics manufacturing.

Automated Humidity Maintenance Equipment

Building on the concept of localized moisture control, automated humidity maintenance equipment represents the latest advancement in workbench humidification technology. You'll find these systems equipped with precise controls that maintain exact humidity levels using technologies like Smart Fog's adiabatic humidification and compressed air atomizers.

| Feature | Benefit | Application |

|---|---|---|

| Smart Sensors | Automatic adjustments | Temperature-based control |

| Adiabatic Systems | Energy efficiency | HVAC integration |

| Digital Controls | Precise maintenance | 40% RH compliance |

When you're setting up an automated system, you can choose between flexible installation options that integrate with your existing air conditioning or standalone units positioned above work areas. These systems help you maintain the vital 40% relative humidity level needed to prevent ESD damage to electronic components. You'll appreciate the easy maintenance features, including large access openings for cleaning and adaptable designs that fit various workspace configurations. The systems also comply with EPA standards and industry regulations while protecting both your electronic equipment and employees. With dedicated water systems and digital control panels, you can easily monitor and adjust humidity levels to maintain ideal manufacturing conditions.

Seasonal Humidity Management Strategies

Successful electronics workbench operations require different humidity management approaches throughout the year. You'll need to adapt your control strategies based on seasonal changes to maintain ideal conditions for your electronic components and prevent damage from moisture or static electricity.

- Monitor and maintain 45-55% relative humidity year-round to protect against static and condensation.

- Use dehumidifiers in spring and summer to combat excess moisture.

- Install humidifiers during autumn and winter to prevent static buildup.

- Implement real-time monitoring systems for quick adjustments to changing conditions.

- Consider your specific climate zone when selecting humidity control equipment.

During warmer months, focus on removing excess moisture using dehumidification systems and proper air circulation. You'll want to prevent condensation that can damage sensitive components.

In contrast, colder months require active humidification to maintain adequate moisture levels and prevent static electricity buildup.

If you're working in extreme climates, you'll need specialized solutions – desert regions demand consistent humidification, while tropical areas require robust dehumidification systems.

Don't forget to calibrate your equipment seasonally and perform regular maintenance to safeguard ideal performance. Integration with real-time monitoring systems will help you maintain precise control over your workbench environment throughout the year.

Essential Humidity Safety Protocols

How can you protect your electronics from humidity-related damage while maintaining a safe work environment? You'll need to maintain humidity levels between 40% and 60% RH to prevent electrostatic discharge while avoiding moisture-related issues. This range enhances surface conductivity and helps dissipate electric charges effectively.

Don't rely solely on humidity control for ESD protection. You must combine it with standard ESD safety measures to guarantee thorough protection.

Install both humidifiers and dehumidifiers to maintain ideal conditions, and use your air conditioning system to help regulate moisture levels. When humidity rises too high, you'll risk condensation and corrosion; when it drops too low, you'll face increased ESD risks.

To implement effective humidity control, you should regularly maintain your equipment and consider using desiccants in areas prone to moisture buildup.

Follow industry standards like MIL-STD-1695 and monitor both temperature and humidity levels, as they work together to affect surface resistivity.

Remember that while humidity control is vital, it's just one part of a thorough safety strategy that requires consistent operator discipline and adherence to established protocols.

Frequently Asked Questions

How Often Should Humidity Sensors Be Recalibrated for Optimal Performance?

You'll need to recalibrate your humidity sensors annually at minimum, but check them more frequently if you're working in harsh environments or need high precision. Follow your manufacturer's specific guidelines for best results.

Can Multiple Humidification Systems Interfere With Each Other's Effectiveness?

Yes, your multiple humidification systems can interfere with each other, causing over-humidification and reduced efficiency. You'll need proper calibration and strategic placement to prevent overlap and maintain ideal performance in your space.

What Emergency Procedures Should Be Followed During Sudden Humidity Control Failures?

You should immediately notify relevant teams, isolate affected areas, activate backup systems, and deploy temporary humidity controls. Don't forget to document the incident and assess any potential damage to your equipment.

How Do Different Flooring Materials Affect Workbench Humidity Control Requirements?

Your floor choice impacts humidity control needs: hardwood requires 40-60% RH, engineered materials need 30-50% RH, and vinyl's flexible 35-65% RH range offers easier maintenance for your workbench environment.

Are There Specific Humidity Requirements for Storing Unused Electronic Components?

You'll need to store unused electronic components at 30-60% relative humidity. Use silica gel packs and dehumidifiers to maintain these levels, and monitor regularly with humidity indicator cards to prevent moisture damage.

In Summary

You'll find that proper humidity control is essential for protecting your electronic components and maintaining an ideal work environment. Whether you've chosen portable units or automated systems, remember to monitor RH levels regularly and adjust your strategy seasonally. By implementing these solutions and following safety protocols, you're ensuring the longevity of your equipment while creating ideal conditions for electronics work.

Leave a Reply