Start your ISO electronics protection training by defining SMART objectives and tracking competency through pre and post-assessments. You'll want to incorporate interactive learning modules with virtual labs and hands-on demonstrations of proper ESD protection techniques. Don't forget to document all training progress in a digital system while maintaining strict compliance standards. Create clearly marked ESD protection zones and conduct regular equipment performance audits. Schedule certification updates and keep your training records current. Monitor completion rates and regularly evaluate your program's effectiveness. These essential tips are just the beginning of developing an exhaustive electronics protection program.

Establish Clear Training Objectives

When setting up ISO electronics protection training, establishing clear objectives serves as the foundation for success. You'll need to guarantee these objectives align perfectly with your organization's goals and ISO standards while maintaining specificity about expected outcomes.

To create effective training objectives, you'll want to implement the SMART criteria – making each goal Specific, Measurable, Achievable, Relevant, and Time-bound. Start by conducting a thorough job analysis to identify essential skills and knowledge gaps. Implementing risk-based training helps ensure more extensive preparation for tasks with higher potential impact.

Focus your objectives on tasks that directly impact product quality and consider the risk level to determine how in-depth your training should be.

You should establish clear evaluation methods from the start. Use assessment tools like practical tests and performance metrics to measure training effectiveness.

Don't forget to document all objectives and outcomes thoroughly – this isn't just good practice, it's essential for ISO compliance.

Remember to regularly review and update your training objectives through feedback mechanisms. Conduct periodic training needs analyses to identify new gaps and adjust your programs accordingly.

Design Interactive Learning Modules

Having established clear training objectives, your next focus should be creating dynamic interactive learning modules that engage and educate your workforce. You'll want to incorporate various interactive elements that specifically address ISO electronics protection protocols while maintaining engagement throughout the learning process. Your training program should emphasize real-time feedback to help participants immediately understand and correct their handling mistakes.

Design your modules using a mix of simulation-based scenarios where employees can practice proper handling procedures, interactive checklists for step-by-step ESD protocols, and hotspot activities that highlight critical components of electronic devices. Consider implementing VR simulations for high-risk procedures and drag-and-drop exercises for component identification.

| Activity Type | Purpose | Implementation |

|---|---|---|

| Virtual Labs | Hands-on Practice | ESD workstation setup simulation |

| Quizzes | Knowledge Check | Multiple-choice assessments on protective measures |

| Branching Scenarios | Decision Making | Troubleshooting common ESD issues |

| Interactive Videos | Visual Learning | Proper handling demonstrations |

| Checklists | Protocol Compliance | Daily ESD safety procedures |

Remember to gather feedback through built-in assessments and tracking mechanisms to measure the effectiveness of your interactive elements. Use analytics to identify areas where employees might need additional support or where the content could be optimized for better understanding of electronics protection standards.

Implement Hands-On Protection Demonstrations

You'll gain essential hands-on experience through real-world grounding exercises that teach proper techniques for protecting sensitive electronic equipment.

Laboratory sessions feature noise and DRFM waveforms to demonstrate electronic attack scenarios in controlled environments.

The visual equipment practice stations provide opportunities to work directly with various protection systems and components, allowing you to master vital safety protocols.

These interactive demonstrations strengthen your practical skills and guarantee you're ready to implement protective measures in actual workplace scenarios.

Real-World Grounding Exercises

The implementation of real-world grounding exercises requires a thorough hands-on approach to teach proper protection techniques. You'll need to focus on thick ground traces and the best placement of ground points to minimize interference while ensuring EMC compliance in your electronic designs. Analog and digital grounds should be carefully separated to prevent noise interference in sensitive measurement circuits.

When conducting grounding exercises, you'll want to incorporate these critical elements:

- Practical simulations of ground loop scenarios to demonstrate how unwanted currents can affect system performance

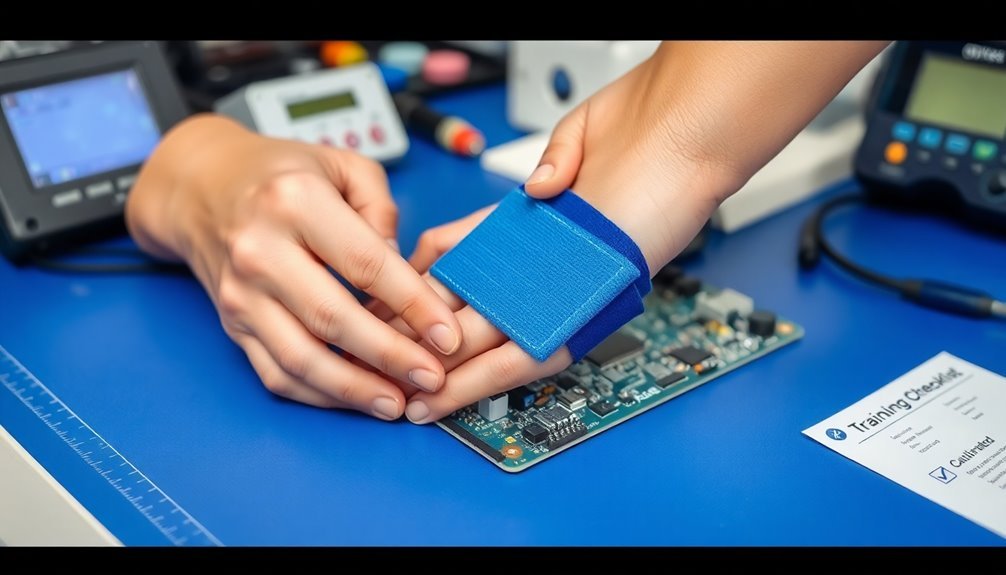

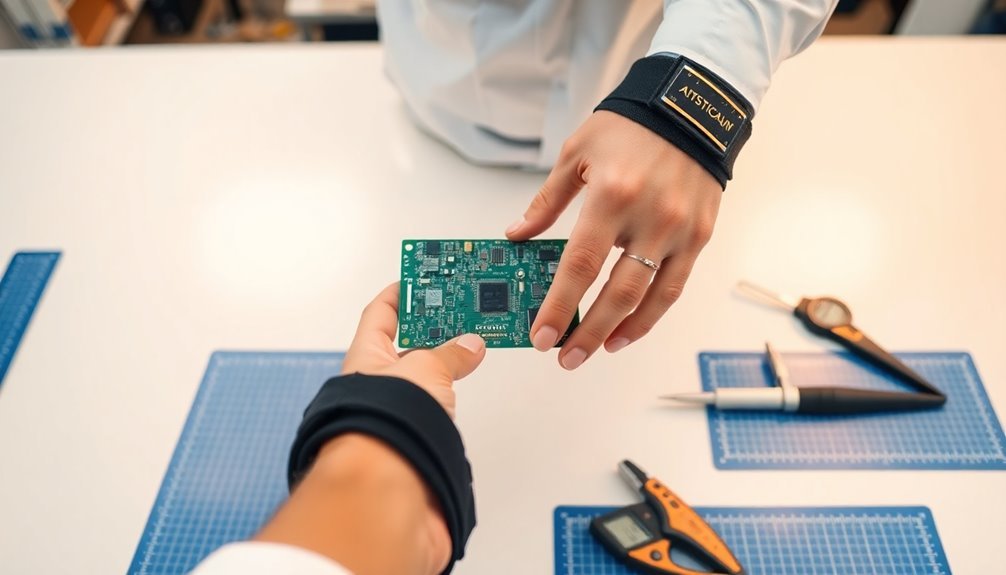

- Hands-on training with ESD protection equipment, including proper use of grounded mats and wrist straps

- Real-time fault current demonstrations to show how proper grounding triggers circuit breakers during hazardous conditions

During your training sessions, you should wear appropriate PPE and ESD-safe clothing while working with electrical components. Don't forget to maintain static control measures throughout your exercises.

You'll need to emphasize the importance of keeping ground traces thick and ground points close to components for top performance. Make sure you're following NFPA 70E standards while conducting these exercises, and always verify that your circuit analysis includes proper consideration of return paths and resistance values for safety compliance.

Visual Equipment Practice Stations

Professional practice stations enable hands-on experience with essential electrical protective equipment and safety demonstrations. You'll learn to inspect equipment for critical defects like holes, tears, punctures, and textural changes before each use. Equipment must be certified and marked with test dates and results when put back into service.

These stations let you perform air tests on insulating gloves and verify clear visual markings that identify class, type, and manufacturer.

You'll practice safe operation of switches, disconnects, and breakers while wearing proper PPE including electrical gloves and arc flash gear. The stations provide opportunities to rack out breakers and use personal grounds and hot sticks under controlled conditions.

You'll understand how to properly store protective equipment away from damaging elements like light, extreme temperatures, and excessive humidity.

Through interactive displays, you'll see firsthand the potential hazards of unsafe actions around power lines and learn proper use of ground fault interrupters.

The practice stations allow you to conduct AC/proof tests within design voltage parameters and verify equipment can withstand applied voltage continuously.

You'll master the critical skill of identifying when equipment must be removed from service due to unclear markings or visible damage.

Document Training Progress Effectively

You'll want to establish a digital training records system that captures each employee's progress in ISO electronics protection protocols and certification status.

Track individual competency over time through regular assessments, performance evaluations, and completion of hands-on demonstrations. Leveraging tracking software tools helps reduce administrative time spent managing training documentation and compliance efforts.

Keep certification status updates current by monitoring expiration dates and scheduling recertification training well in advance of deadlines.

Track Competency Over Time

Effective competency tracking forms the backbone of successful ISO electronics protection training programs. You'll need robust systems and processes to monitor how well your team retains and applies critical electronics protection protocols over time.

The extensive 89.1 continuing education units offered ensure comprehensive skill development across all required competencies. A Learning Management System (LMS) serves as your central hub for tracking progress, automating assessments, and maintaining detailed training records.

- Pre and post-training assessments reveal knowledge gaps and measure improvement

- Supervisor feedback provides real-world validation of applied skills

- Continuous evaluation confirms lasting competency and identifies retraining needs

To maximize your tracking efforts, implement a combination of automated and human-centered approaches. Your LMS should handle the data-heavy aspects like test scores and completion rates, while supervisor reports offer insights into how well employees apply their training on the floor.

Make sure you're regularly comparing pre and post-assessment results to gauge program effectiveness and identify areas needing reinforcement. Set up a structured process for ongoing evaluation that includes both formal assessments and informal feedback loops.

This thorough approach helps maintain high standards in electronics protection while confirming your team's skills remain sharp and up-to-date with ISO requirements.

Digital Training Records System

Building on your competency tracking foundation, a robust digital training records system enhances your ISO electronics protection program's accountability and compliance. You'll need to implement validated electronic systems that create, maintain, and store accurate training records while meeting 21 CFR 11.10(a) requirements.

Set up your system to generate detailed copies of training records that include timestamps, responsible personnel, and electronic signatures. Guarantee each signature is unique and permanently linked to its corresponding record to prevent falsification. The system must maintain secure audit trails for all changes made to training records.

You'll want to establish secure user authentication and role-based access controls to protect sensitive training data.

Implement time-stamped audit trails to record all training activities transparently, making it easy to track who completed what training and when. Your system should integrate with your Learning Management System (LMS) to streamline training material distribution and activity tracking.

Don't forget to develop written policies that hold individuals accountable for their training actions and conduct regular risk assessments to identify areas needing additional training focus.

Remember to choose ISO standard-based software that can automate training tasks, evaluate employee competence, and generate compliance reports aligned with ISO 9001:2015 requirements.

Certification Status Updates

Maintaining accurate certification status updates requires a thorough tracking system that integrates both automated tools and human oversight. You'll want to leverage learning management systems (LMS) to automate data collection while implementing supervisor feedback channels to guarantee extensive progress tracking.

Key elements of effective certification tracking include:

- Pre and post-training assessments to measure learning outcomes and identify gaps

- Regular performance evaluations to verify practical application of knowledge

- Documentation reviews to guarantee compliance with ISO 27001 requirements

To maintain your ISO 27001 certification status, you'll need to focus on both quantitative and qualitative data collection. Track metrics like completion rates and attendance while gathering supervisor reports on real-world application.

This dual approach helps you identify areas where additional training might be needed and guarantees your security awareness programs remain effective.

Keep your certification current by continuously monitoring control implementation and maintenance. You'll need to document all training activities, verify that security measures follow global best practices, and guarantee employees understand their role in maintaining organizational security standards.

Regular updates to your tracking system help demonstrate ongoing compliance and readiness for external audits.

Create ESD Protection Zones

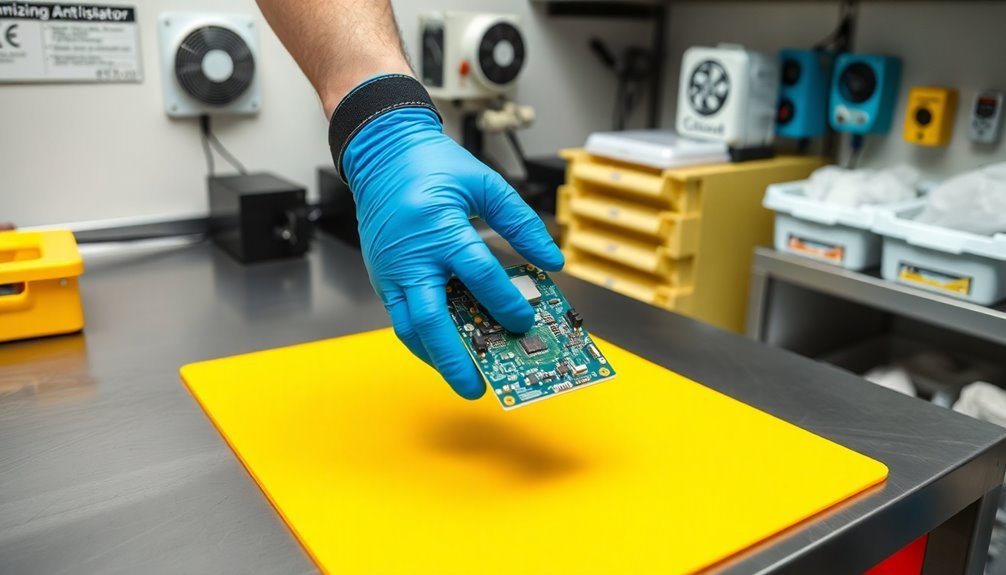

To safeguard sensitive electronic components, organizations must establish dedicated ESD protection zones that prevent static discharge incidents. You'll need to start by conducting a thorough risk assessment to identify areas requiring protection and implement proper grounding systems that connect all conductive elements to a common point.

Set up your workstations with essential ESD control equipment, including static-dissipative mats, wrist straps, and grounding cords. Don't forget to mark your protected zones clearly with visual indicators and restrict access to authorized personnel only.

| Zone Type | Required Equipment | Daily Checks |

|---|---|---|

| Basic | ESD Mat, Wrist Strap | Ground Resistance |

| Intermediate | Air Ionizers, ESD Shoes | Static Levels |

| Advanced | Complete ESD Flooring | Equipment Status |

| Storage | ESD-Safe Containers | Container Integrity |

| Testing | Specialized Tools | Calibration Check |

You'll need to maintain these zones through regular audits and equipment inspections. Train your staff thoroughly on proper ESD procedures and guarantee they understand the invisible nature of static electricity. Keep your ESD control measures current by collecting employee feedback and updating procedures as needed. Remember to regularly test all ESD-safe equipment and replace worn components promptly.

Measure Equipment Performance Standards

Once you've established your ESD protection zones, proper equipment performance measurement becomes your next priority. You'll need to track four essential metrics to guarantee your electronics protection equipment operates at peak levels: availability, performance, quality, and utilization.

These measurements help you identify potential issues before they impact your ESD protection system's effectiveness.

- Monitor your equipment's availability by calculating the percentage of time it's operational during scheduled production hours – if your ESD ionizer runs for 90 hours out of 100 scheduled hours, you've got 90% availability.

- Track performance ratios by comparing ideal production times against actual production times – this helps you spot efficiency gaps in your ESD protection processes.

- Measure quality rates by calculating the percentage of properly protected components versus those with ESD damage.

When implementing these measurements, you'll want to focus on utilization metrics to maximize your facility's ESD protection capabilities. Calculate your utilization rate by dividing actual operational time by total available time. For instance, if your ESD monitoring equipment operates for 80 hours out of 100 available hours, you're achieving 80% utilization.

This data helps you optimize your equipment's effectiveness and justify necessary upgrades or maintenance schedules.

Schedule Regular Certification Updates

Regular certification updates serve as the backbone of your ISO electronics protection program. You'll need to stay current with evolving standards to maintain compliance and guarantee your organization's security controls remain effective. With conversion periods lasting up to three years, like ISO 27001:2022's deadline of October 2025, you've got time to implement changes systematically.

You should focus on updating key areas including organizational structures, physical security controls, and technological safeguards. Don't forget to enhance your people-oriented controls through regular training and awareness programs.

You'll also need to integrate modern practices like threat intelligence and cloud service security into your framework.

If you don't keep your certifications current, you're risking non-compliance penalties and potentially compromising your organization's security posture. Make sure you're documenting all updates and maintaining clear records of certification renewals.

You'll benefit from improved operational efficiency, enhanced data protection, and increased credibility with stakeholders. Remember to align your update schedule with industry standards and regulatory requirements, and you'll maintain a competitive edge while guaranteeing your electronics protection measures remain robust and effective.

Frequently Asked Questions

How Often Should ESD Wrist Straps Be Tested for Proper Grounding?

You should test your ESD wrist strap daily when used regularly. If you're handling highly sensitive components, consider using continuous monitoring. Always test the strap while wearing it for accurate results.

Can Mobile Phones Cause ESD Damage in Protected Work Areas?

Yes, your mobile phone can cause ESD damage in protected areas. They're capable of storing static charges and discharging through external connections. It's best to leave phones outside or use approved ESD-safe containers.

What Humidity Level Is Optimal for Preventing Static Buildup?

You'll want to maintain humidity levels above 60% for ideal static prevention. However, you can still achieve good protection between 40-60%, though you should monitor areas near heat-generating equipment for dry spots.

Do Different Electronics Require Different Levels of ESD Protection?

Yes, you'll need varying ESD protection based on your device's sensitivity class. Check your component's HBM, MM, and CDM classifications to determine the required protection level, from Class 0 (most sensitive) to higher classes.

Are There Specific Cleaning Products That Should Be Avoided Near Esd-Sensitive Components?

You'll need to avoid traditional cleaners with bleach, ammonia, or abrasive chemicals near ESD-sensitive components. Instead, use only ESD-safe cleaning products that won't damage protective properties or create static discharge risks.

In Summary

You've now got the essential tools to protect sensitive electronics through proper ISO training protocols. Remember to consistently update your certification, maintain ESD zones, and document all progress. By following these seven tips, you'll create a robust training program that safeguards equipment and guarantees compliance. Don't forget to measure performance regularly and adjust your protocols as technology evolves.

Leave a Reply